A device and method for treating high-salt wastewater containing phenol and aniline

A high-salt wastewater treatment method technology, applied in biological treatment devices, chemical instruments and methods, multi-stage water treatment, etc., can solve the problems of device leakage and blockage, high investment, strong corrosion of equipment, etc., and achieve oil-water separation interface Clear, low one-time investment and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

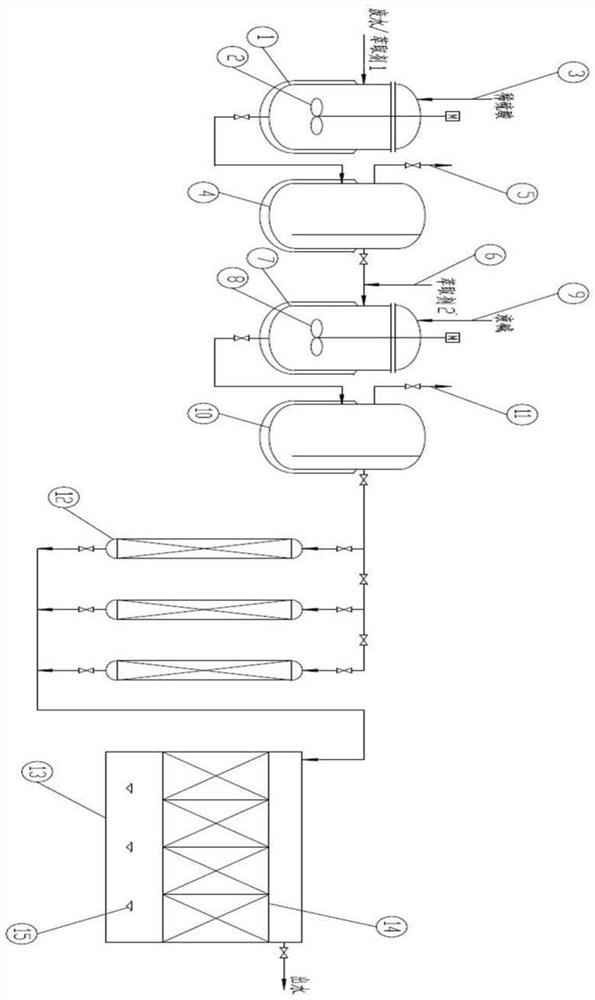

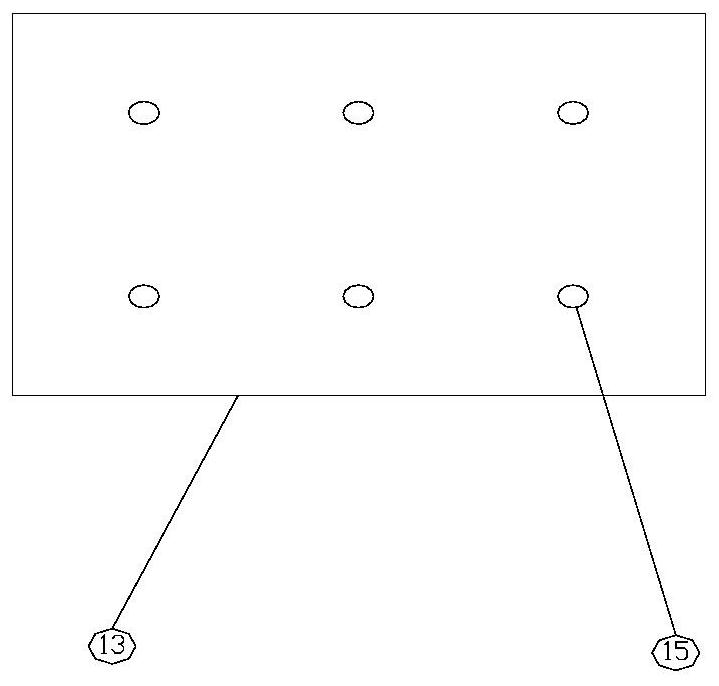

[0047] Such as figure 1 As shown, the device includes an extraction pretreatment unit, a resin adsorption unit and a high-salt biochemical system unit, wherein the extraction pretreatment unit includes No. 1 extraction kettle 1, No. 1 separation tank 4, No. 2 extraction kettle 7 and No. 2 separation tank 10, The resin adsorption unit includes a resin adsorption column device 12, and the high-salt biochemical system unit includes a high-salt biochemical device 13, packing 14, and aeration 15; the No. 1 extraction tank 1, No. 1 separation tank 4, and No. 2 extraction tank Kettle 7 and No. 2 separation tank 10, resin adsorption column device 12, and high-salt biochemical device 13 are connected in sequence through pipelines; the pipeline of No. 1 extraction kettle 1 is connected with the middle part of No. 1 separation tank 4, and the pipeline of No. 2 extraction kettle 7 It is connected with the middle part of No. 2 separation tank 10.

[0048] The primary extraction includes N...

Embodiment 2

[0058] The wastewater is taken from the regulating tank of a fine chemical production plant in Shandong. According to the staged production characteristics of the factory, the quality of the wastewater in the regulating tank will fluctuate to a certain extent over time. The 2,6-dichlorotoluene replaced the wastewater. The wastewater manufacturer had removed the copper ions in the wastewater by ion exchange process. The pH value was 4-5, TOC 3122mg / L, phenol 1630mg / L, aniline 1261mg / L, salt The concentration is 78056mg / L.

[0059] The preparation of extractant 1: based on the total weight percentage of extractant 1, 10% of tetradecylamine, 15% of isomeric 22 alcohol, and the balance is aviation kerosene; the preparation of extractant 2: based on the total weight percentage of extractant 2 , 15% of P204, 15% of isomerized 20 alcohol, and the balance is aviation kerosene.

[0060] The above treatment process,

[0061] (1) Extraction pretreatment unit:

[0062] ① Put the waste ...

Embodiment 3

[0075] The wastewater is taken from the regulating tank of a fine chemical production plant in Shandong. According to the staged production characteristics of the factory, the quality of the wastewater in the regulating tank will fluctuate to a certain extent over time. The 2,6-dichlorotoluene replaced the wastewater. The wastewater manufacturer had removed the copper ions in the wastewater by ion exchange process, the pH value was 4-5, TOC 2764mg / L, phenol 1430mg / L, aniline 1031mg / L, salt The concentration is 73220mg / L.

[0076] The preparation of extractant 1: based on the total weight percentage of extractant 1, 10% of tetradecylamine, 15% of isomeric 22 alcohol, and the balance is aviation kerosene; the preparation of extractant 2: based on the total weight percentage of extractant 2 , 15% of P204, 15% of isomerized 20 alcohol, and the balance is aviation kerosene.

[0077] The above treatment process,

[0078] (1) Extraction pretreatment unit:

[0079] ① Put the waste ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com