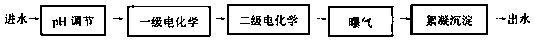

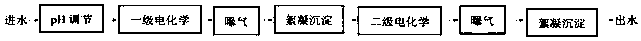

Process for electrochemically treating high-protein wastewater

An electrochemical, high-protein technology, applied in chemical instruments and methods, precipitation treatment, multi-stage water treatment, etc. Remarkable COD removal effect, outstanding oxidation effect, outstanding treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Pump the high-protein waste water into the pH adjustment tank for comparison test, the pH value is not adjusted, and the pH value is measured to be 7.00.

[0041] (2) Put the high-protein wastewater without adjusting the pH value in step (1) into the first-level electrochemical reaction tank (the reaction electrode is an iron electrode), set 10min. Automatic phase change (switch the positive and negative polarity of the electrode), and turn on the electric regulator Current density 5mA / cm 2 , reaction 20min..

[0042] (3) Pump the high-protein wastewater after the electrochemical reaction in step (2) into the aeration tank, and aerate for 30 minutes.

[0043] (4) Pump the high-protein wastewater after aeration in step (3) into the fast mixing tank and slow mixing tank (flocculation tank), without adjusting the pH value, the actual measurement is 7.30, add polyaluminum chloride (PAC) to stir, and then add anion Polyacrylamide (PAM) precipitated after stirring, and ...

Embodiment 2

[0045] (1) Pump high-protein wastewater into a pH adjustment tank, add sulfuric acid with a concentration of 20% to adjust the pH value, and measure the pH value to 3.01.

[0046] (2) Pump the high-protein wastewater after adjusting the pH value in step (1) into the first-level electrochemical reaction tank (the reaction electrode is an iron electrode), set 10min. Automatic phase change (switch the positive and negative polarity of the electrode), and turn on the electric regulator Current density 15mA / cm 2 , reaction 20min..

[0047] (3) Pump the high-protein wastewater after the electrochemical reaction in step (2) into the aeration tank, and aerate for 30 minutes.

[0048] (4) Pump the high-protein wastewater after aeration in step (3) into the fast mixing tank and slow mixing tank (flocculation tank), add alkali (NaOH) to stir, adjust the pH value to 8.67, add polyaluminum chloride (PAC) to stir , add anionic polyacrylamide (PAM) to stir and then precipitate, take the cl...

Embodiment 3

[0050] (1) The high-protein waste water after embodiment 2 step (3) aeration is pumped into fast mixing tank and slow mixing tank (flocculation tank), adds alkali (NaOH) and stirs, adjusts pH value 10.15, adds polyaluminum chloride ( PAC) was stirred, and anionic polyacrylamide (PAM) was added to precipitate after stirring, and the clear liquid was taken to obtain water sample 3, and the test is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com