Patents

Literature

129results about How to "Ease of biochemical treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for treating organic amine industrial waste water by Fenton-like oxidation-flocculation

InactiveCN102399032AHigh catalytic efficiencyAdd lessMultistage water/sewage treatmentNature of treatment waterHigh concentrationIndustrial waste water

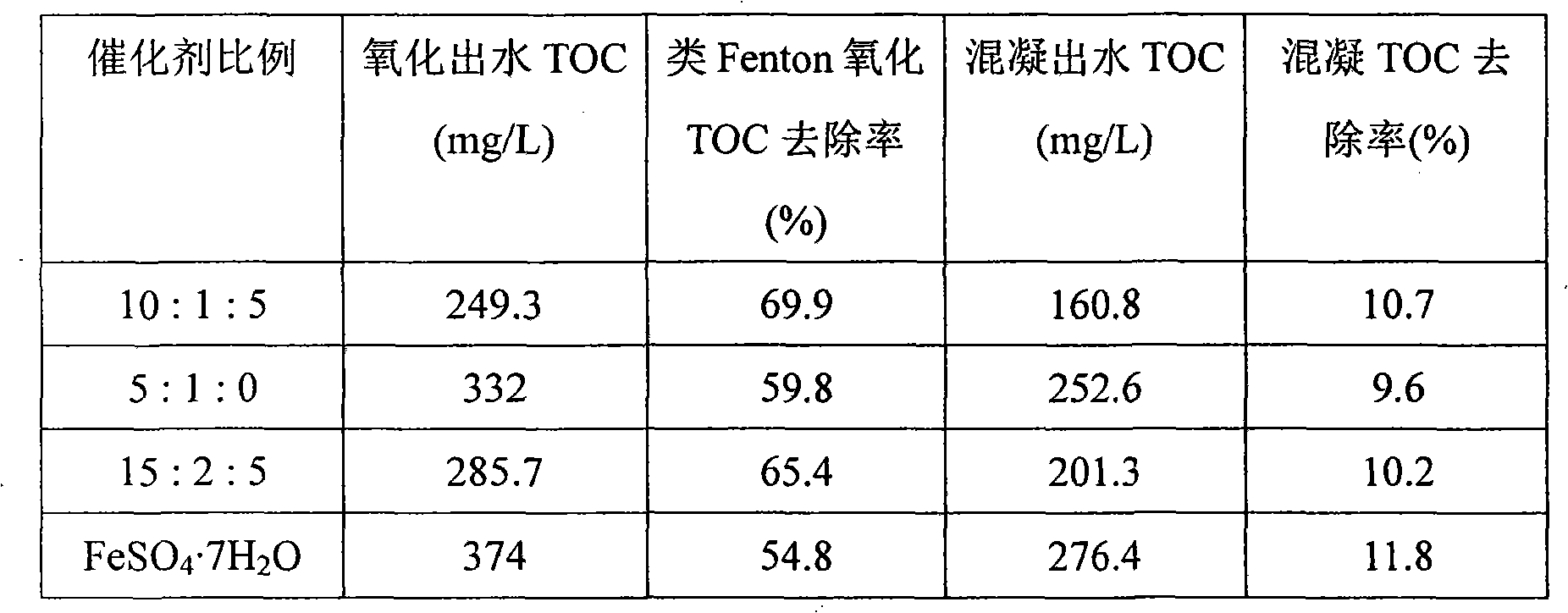

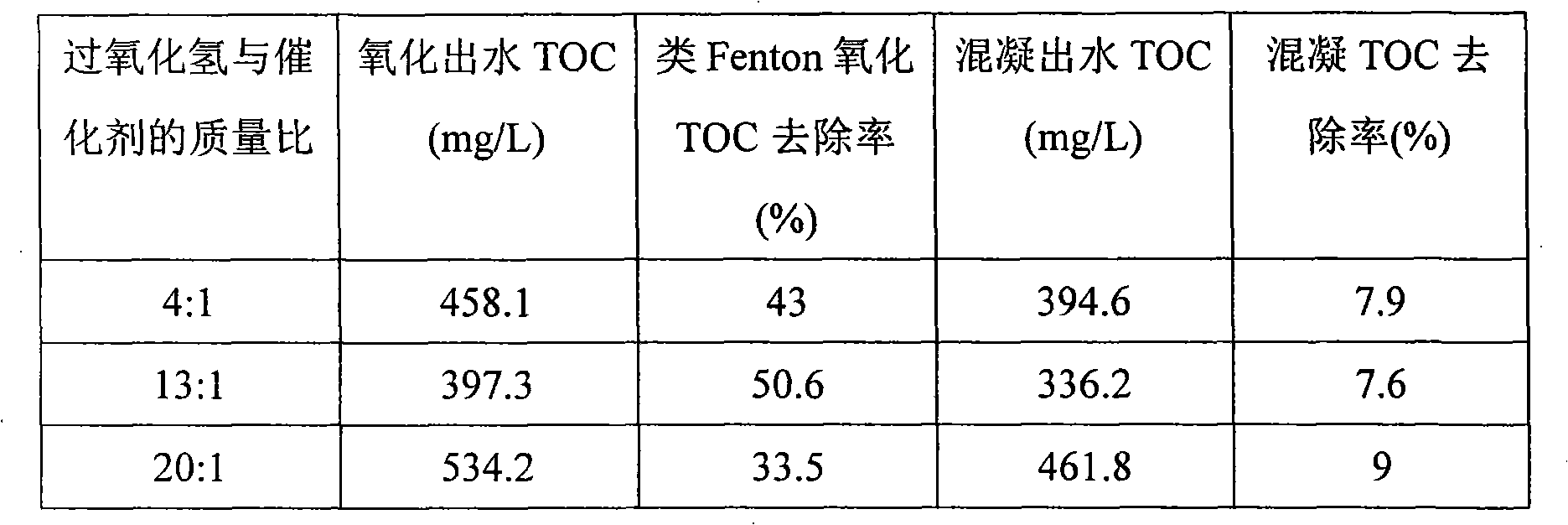

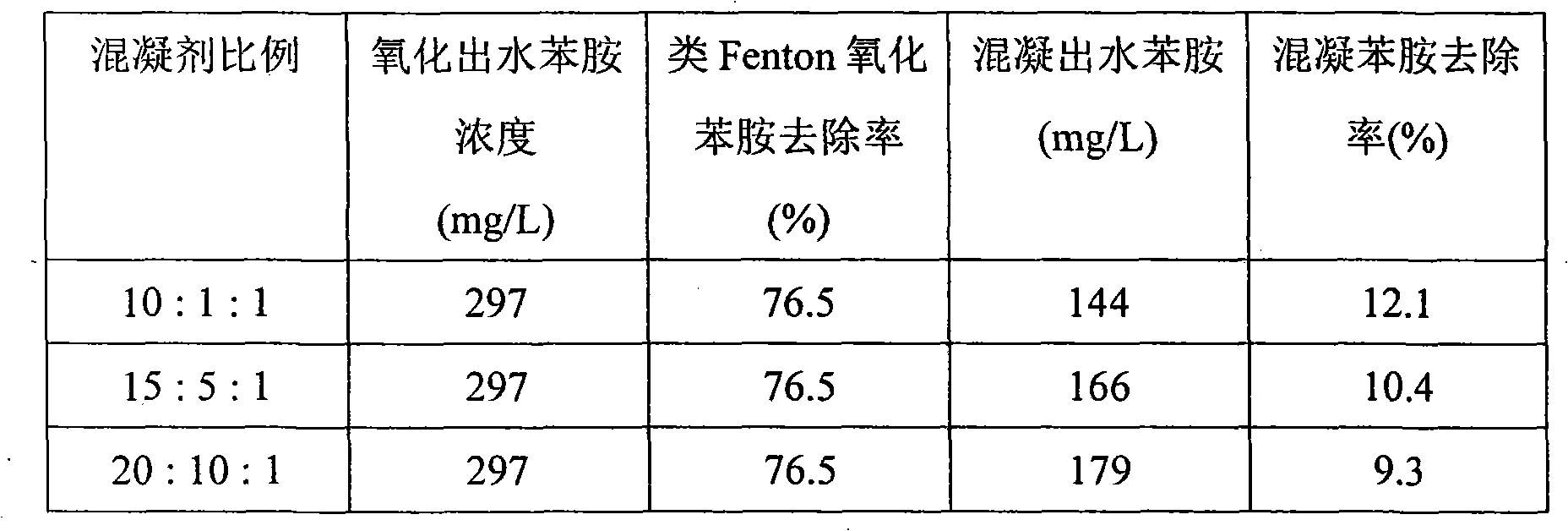

The invention relates to a method for treating organic amine industrial waste water by Fenton-like oxidation-flocculation. According to the method, the pH value of the waste water is adjusted to 3-5, and the temperature of the waste water is adjusted to 20-40 DEG C; a catalyst is added, wherein active ingredients of the catalyst comprise: ferrous sulfate, anhydrous cupric sulphate and manganese sulfate monohydrate, wherein the mass ratio of the ferrous sulfate to the anhydrous cupric sulphate to the manganese sulfate monohydrate is (5-10):1:(0-5); H2O2 (30%) is added, and the oxidation reaction time is 4 hours; after completing the oxidation reaction, sodium hydroxide is added to adjust the pH value of the waste water to 8-10; adding a chemical coagulant and an organic polymer flocculant, such that partial suspended solids, colloids and partial organic amines in the waste water are concurrently coagulated. According to the present invention, the Fenton-like oxidation-flocculation is adopted as the pretreatment for the organic amine waste water, such that the organic amines in the waste water can be effectively removed, the poison and the impact on microorganisms due to the high concentration organic amines in the wastewater can be reduced, the subsequent biological treatment is easily performed for the sewage.

Owner:CHINA PETROLEUM & CHEM CORP +1

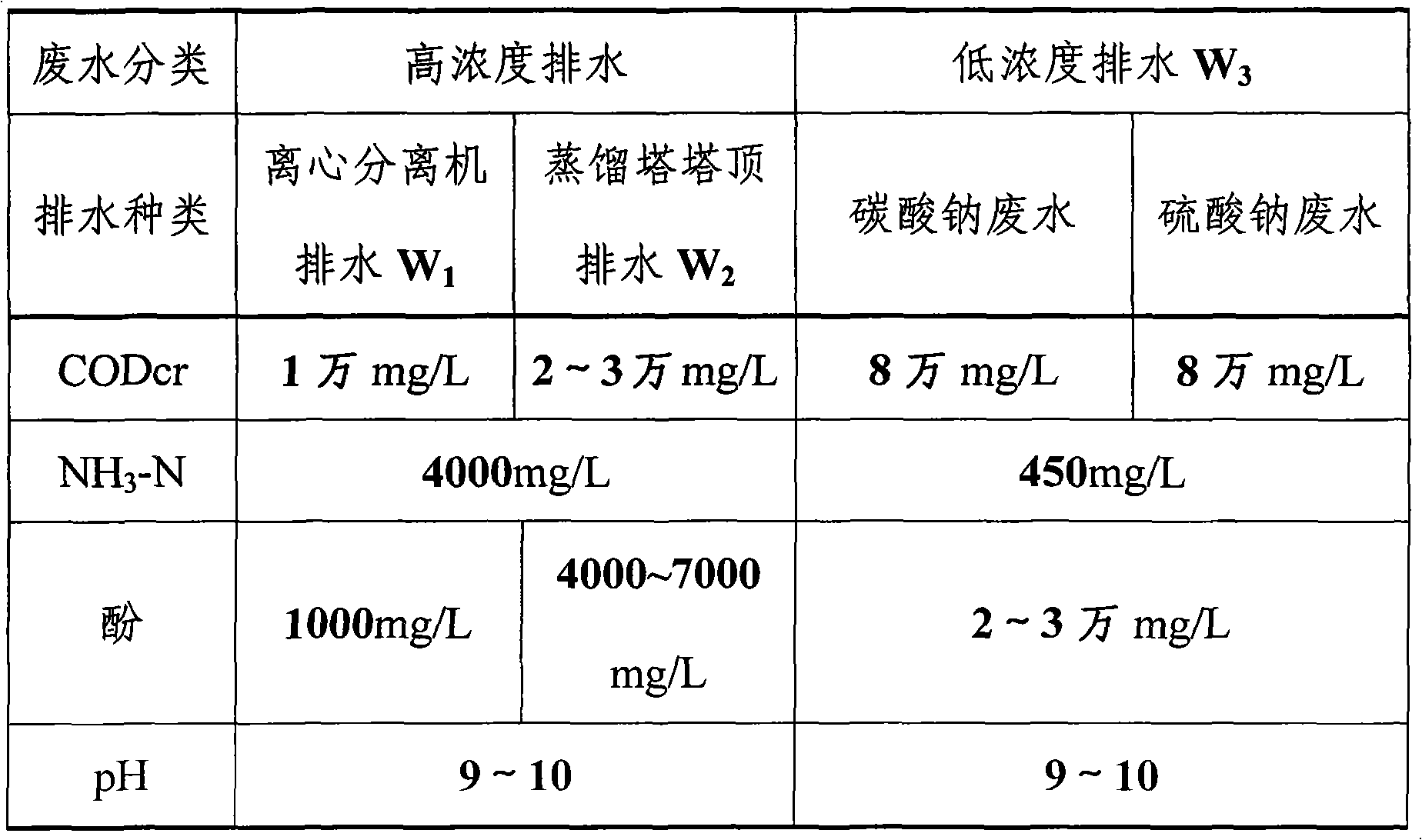

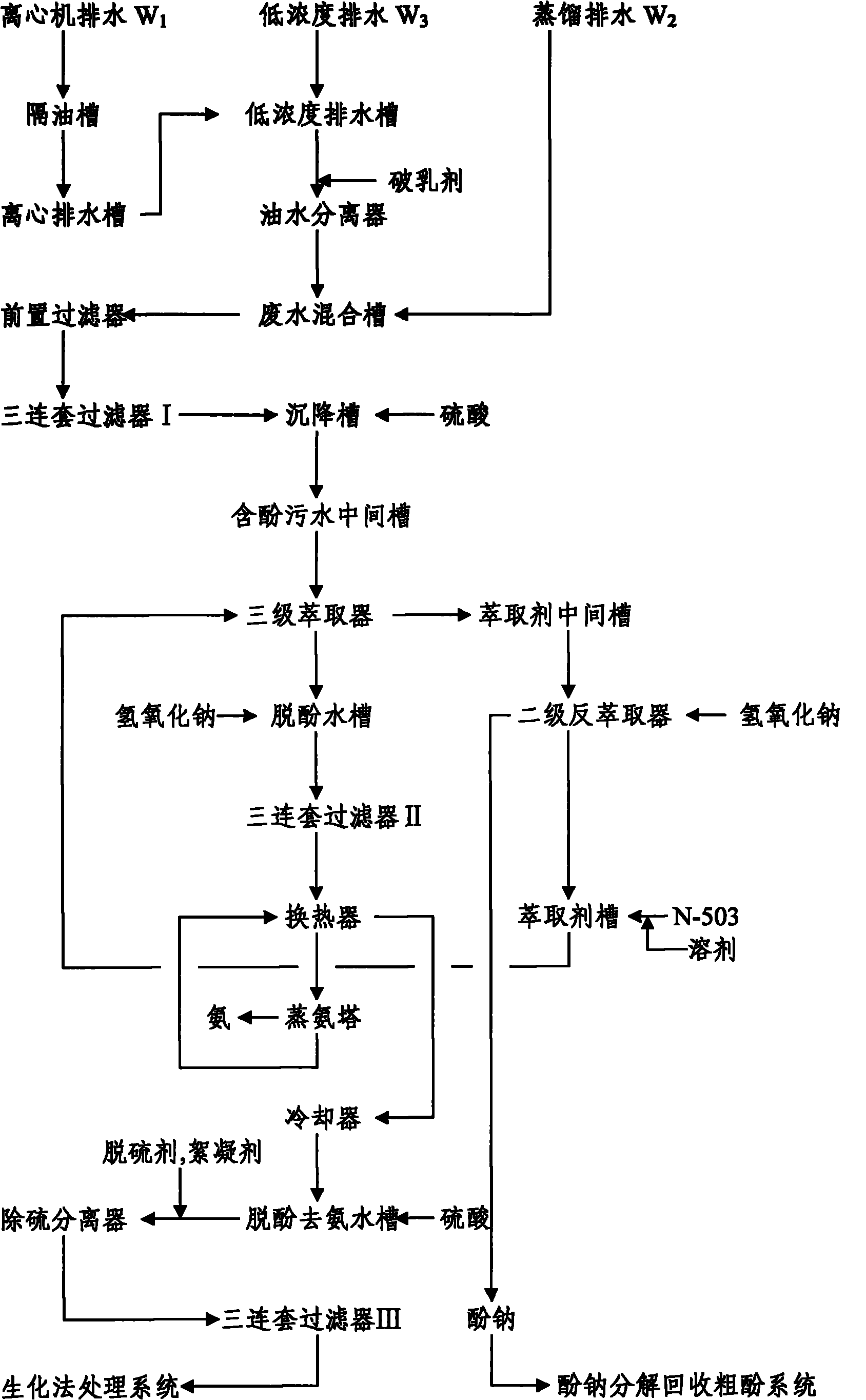

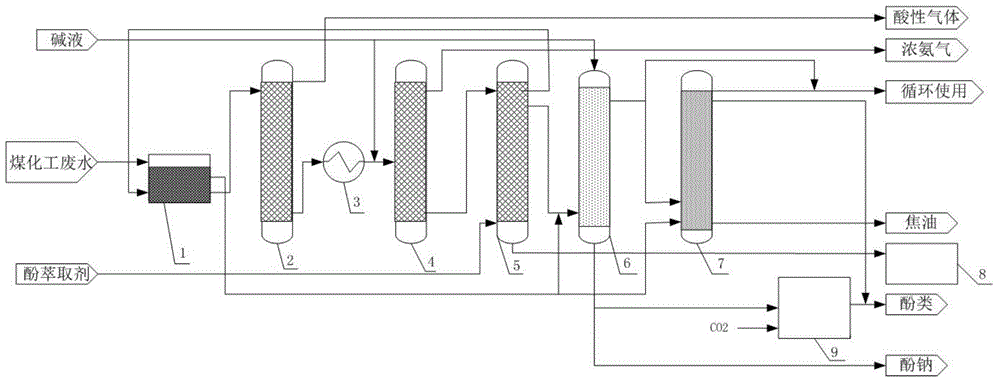

Coal tar processing wastewater treatment method and system

ActiveCN101875523AEfficient removalAchieve emission standardsFatty/oily/floating substances removal devicesMultistage water/sewage treatmentWater qualityEconomic benefits

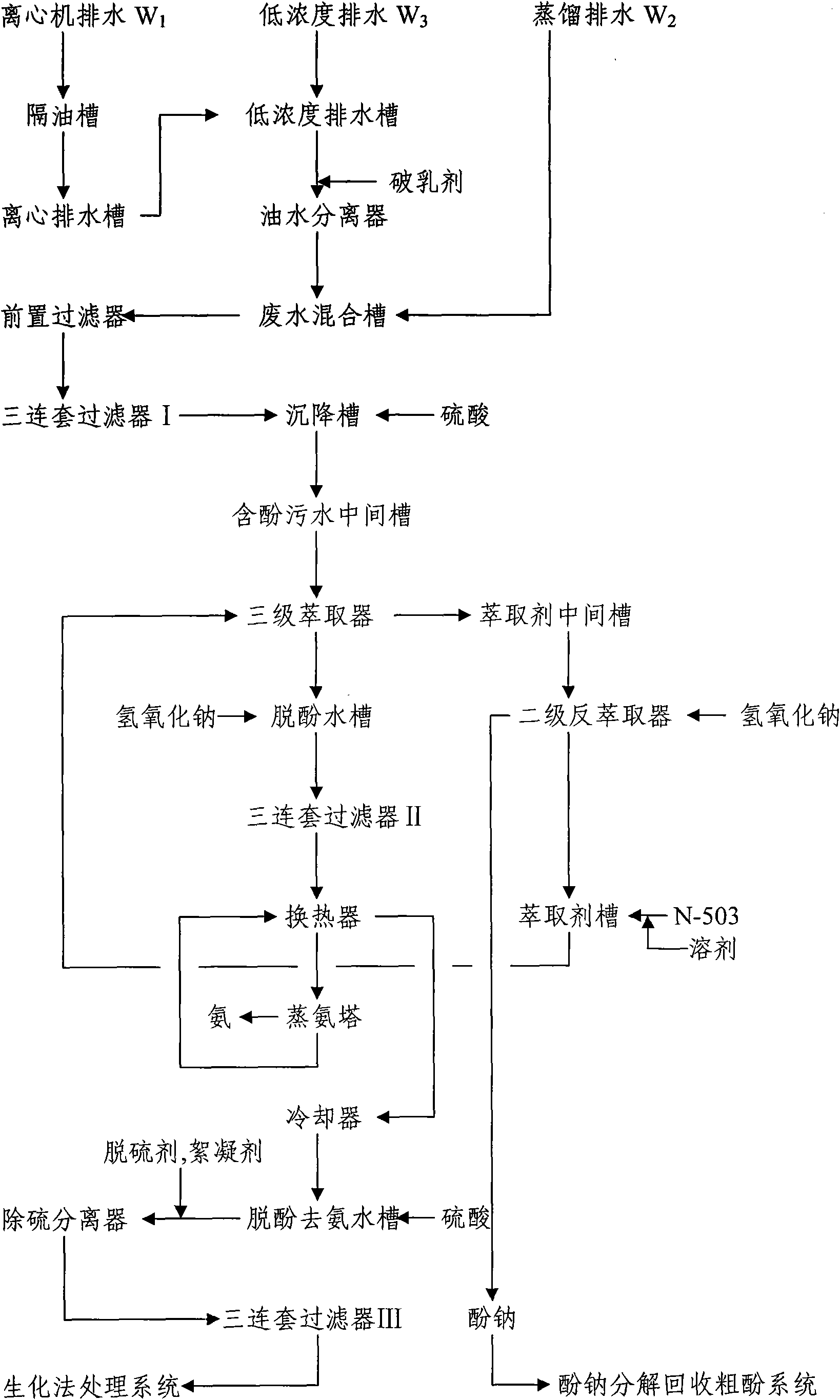

The invention relates to coal tar processing wastewater treatment method and system. The treatment method comprises materialization treatment comprising the following steps of: (1) removing free oil and emulsified oil which are contained in wastewater, filtering, regulating the pH value of the wastewater to 3-4, and then separating out depositions; (2) extracting and dephenolizing; (3) regulatingthe pH value of the dephenolized wastewater to 9-10, filtering, then carrying out steam stripping and deaminization by using steam, and besides, carrying out reextraction on extract phase containing phenol to respectively recover an extracting agent and phenate, and then recycling the extracting agent and decomposing the phenate to obtain crude phenol; and (4) cooling the deaminized wastewater, regulating the pH value to 7-8, and then filtering after adding a desulfurizing agent to remove sulfides. The water quality of the materialized wastewater achieves the requirement of a biochemical treatment system; meanwhile, the invention can recover a given amount of useful matter comprising the phenol, ammonia and the like and make the extracting agent recycled so that the economic benefit of wastewater treatment is improved.

Owner:高科环保工程集团有限公司

Clean production method of chromium-free automobile cushion leather

The clear production method for Cr-free vehicle seat cushion comprises: hair-saving, combing acid and base for expansion; ammonia-free deliming, dipping weak acid and low slat, Cr-free bating, composite batting, and adding strong-absorption fat for dyeing to treat skin from pig, cattle or sheep. The product has shrinkage temperature up to 110Deg, shows well hand feeling and resistance to thermal and age. This invention reduces material quantity and 30-50% sewage discharge, improves absorption rate, and brings a new way for Cr-free leather.

Owner:SICHUAN UNIV

Method for fabrication food wrap paper and cultural paper by using corn stalk to make no chlorin bleached pulp

InactiveCN1600989AEase of biochemical treatmentConducive to environmental protectionFlexible coversWrappersUreaChemistry

A process for preparing food packing paper and cultural paper with chlorine free bleached paper pulp includes using corn straw or its pitch free ones as raw material, then cutting, dust removing, presoaking, cooking and bleaching. The cooking reagent uses ammonium sulfite and potassium sulfite or sodium sulfite as main, sulfur or sulfourea as assistant and urea as well as sodium hydroxide as buffer. The bleaching is two sections or multisection bleaching by using urea or sulfourea to protect fibre and activate hydrogen peroxide.

Owner:田新 +1

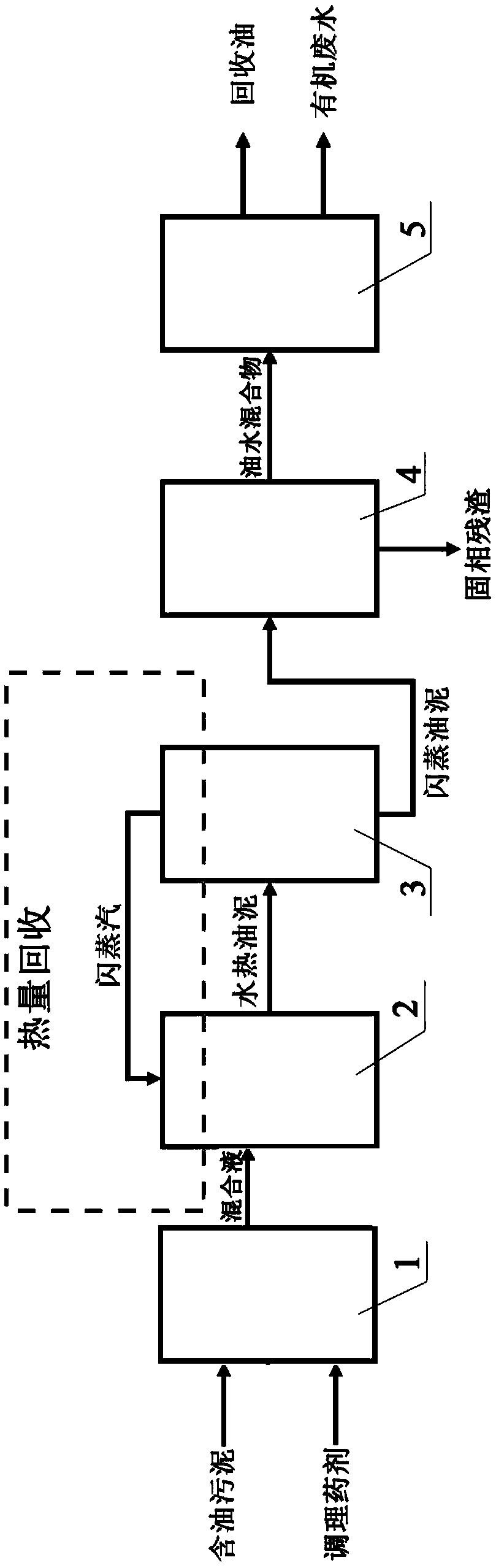

Method and device for synchronously dehydrating and recycling oil from oil-containing sludge

ActiveCN108892348AEfficient recyclingHigh recovery rateWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningChemical oxygen demandEvaporation

The invention provides a method and a device for synchronously dehydrating and recycling oil from oil-containing sludge. The method comprises the following steps: mixing oil-containing sludge with a conditioning chemical, and preheating; further heating the oil-containing sludge and the conditioning chemical to carry out a hydrothermal reaction so as to obtain hydrothermal oil sludge; carrying outflash evaporation rapidly to achieve separation of steam, oil gases and solid-phase residues, wherein generated flash vapor is adopted for preheating to achieve heat recycling; carrying out filter pressing dehydration on separated flash evaporation oil sludge, thereby obtaining a solid-phase residue and liquid-phase oil-water mixture; and standing and layering the oil-water mixture, recycling oilfrom an upper layer, and recycling organic wastewater from a lower layer, wherein the conditioning chemical is composed of a heat-sensitive metal oxide, a catalyst and a demulsifier. By adopting theprocess, good reduction and oil recycling effects can be achieved at a low hydrothermal temperature, the reaction energy consumption can be greatly reduced, the COD (Chemical Oxygen Demand) of a generated waste liquid can be greatly reduced, in addition, the toxicity is degraded, and biochemical treatment can be facilitated.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

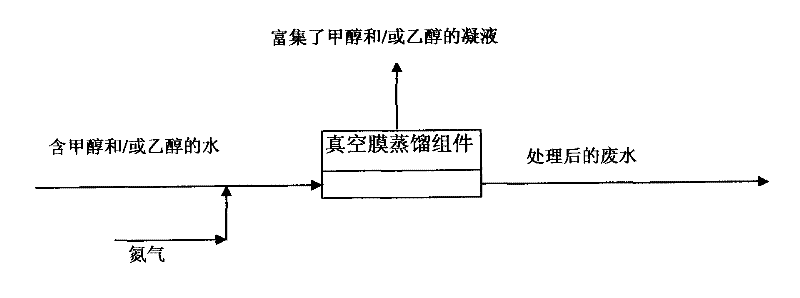

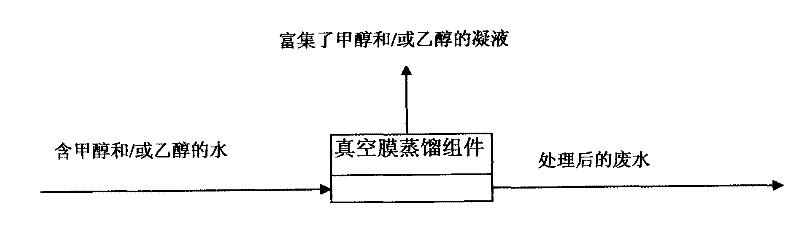

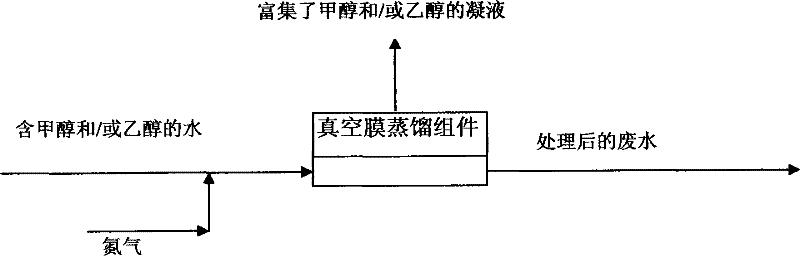

Method for removing and recycling volatile alcohol organic matters in water

InactiveCN102408140AImprove throughputReduce the effect of wettingWater/sewage treatment by heatingWater/sewage treatment by degassingRecovery methodAlcohol

The invention relates to a method for removing and recycling volatile alcohol organic matters in water. The method comprises the following steps of: 1, mixing a certain ratio of gas into feeding side waste water; 2, making gas and liquid continuously enter a vacuum film distilling assembly together, vacuumizing a seepage side, and condensing gas, water stream and organic matter steam in waste water on the seepage side through a seepage film hole; 3, making volatile organic matters pass through a hydrophobic film for enriching; and 4, directly reapplying waste water which reaches the use requirements to the production process, if the waste water does not reach the use requirements, performing further treatment. In the method, gas is mixed into a feeding liquid, and the gas and liquid continuously enter the vacuum film distilling assembly together, so that a layer of air film is formed more easily on the surface of a feeding side film, the wetting influence of water and an organic solvent on the hydrophobic film is lowered, the disturbance action in waste water is enhanced, the condensation of steam in the film hole is reduced simultaneously, the running cycle of the film assembly is prolonged, and the flux of the film is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

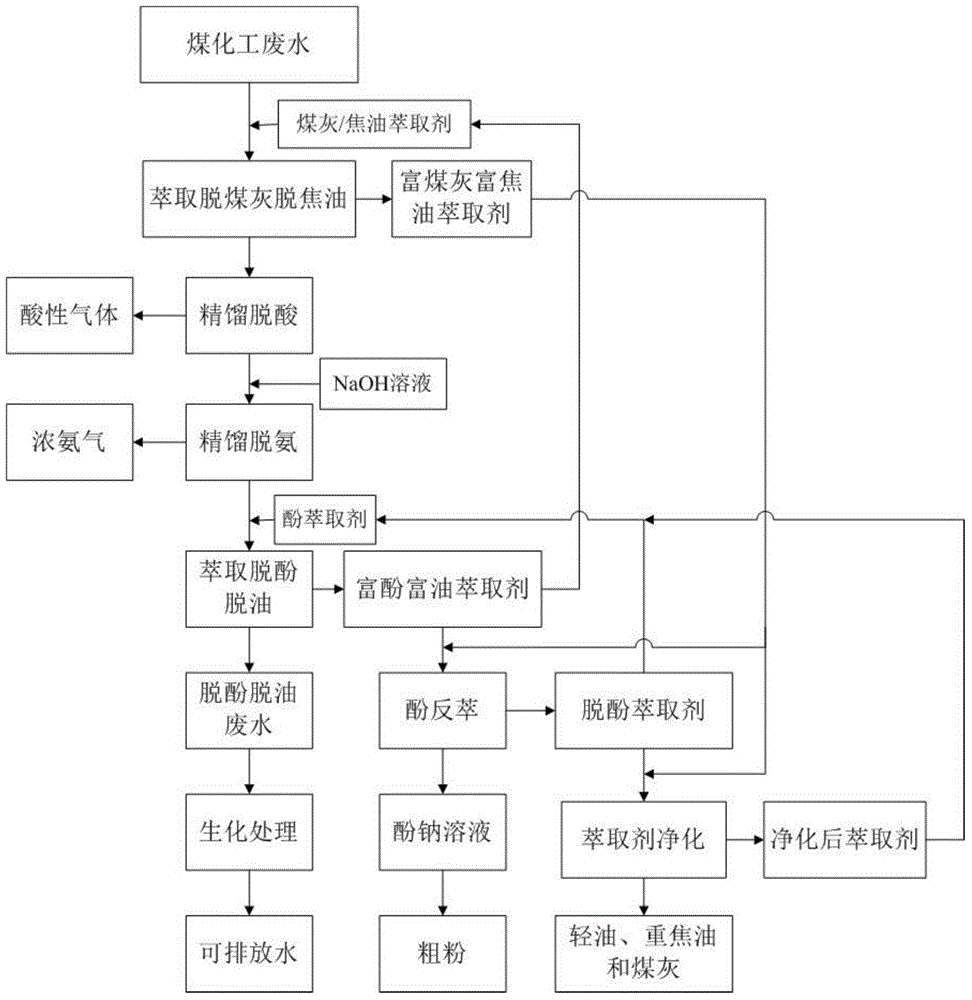

Method and device for removing coal ash, and oil, phenols and ammonia from coal chemical industry wastewater

ActiveCN106315906AReduce dosageAvoid the decline of dephenolization efficiencyMultistage water/sewage treatmentPulverized fuel ashPhenol

The invention provides a method for removing coal ash, and oil, phenols and ammonia from coal chemical industry wastewater and a device for removing coal ash, and oil, phenols and ammonia from coal chemical industry wastewater. The method comprises the steps: performing extracting on the coal chemical industry wastewater by using a coal ash / tar extractant so as to remove coal ash and tar and obtain coal ash and tar removed wastewater and a coal ash and tar enriched extractant; subjecting the coal ash and tar removed wastewater to deacidification treatment, and performing deamination treatment; then, performing extracting on the deaminated wastewater so as to dephenolize and deoil and obtain a phenol and oil enriched extractant and dephenolized and deoiled wastewater; and applying part of the phenol and oil enriched extractant to extracting so as to remove coal ash and tar so as to achieve reuse. According to the method, the coal ash and tar removal rate is high, towers are not blocked, phenols / ammonia / oil can be recovered step by step, the operation is stable, and the treatment cost is low, so that the method is particularly applicable to the treatment of the coal chemical industry wastewater with relatively high coal ash and tar concentration, and secondary pollution caused by the wastewater can be avoided; and the removal rate of total phenols in the wastewater is higher than 94%, the removal rate of ammonia is higher than 99%, the removal rate of oil is higher than 93%, the removal rate of coal ash is higher than 95%, and BOD<5> / COD<Cr> is increased by 30% compared with that of original coal chemical industry wastewater, so that favorable conditions are created for subsequent biochemical treatment.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Processing method of paper-making pulping black liquor

The invention discloses a processing method of paper-making pulping black liquor, and the method comprises polycondensation, acid precipitation, aging, precipitation, solid-liquid separation and drying of the pulping paper-making black liquor, and in the black liquor, the solid phase which mainly comprises lignin and the liquid phase which mainly comprises sodium salt solution are separated; and the Baume degree of the black liquor is larger than or equal to 15 Be degrees. The method has simple process, low cost and wide application range. The obtained lignin can be used as multiple industrial and agricultural raw materials; the chroma, CODcr and BOD5 of the obtained liquid phase are greatly reduced.

Owner:张仲伦

Clean production method of rubber vulcanizing accelerator TBBS

InactiveCN101717380AReduce consumptionImprove conversion rateOrganic chemistryPotassium iodineAccelerant

The invention discloses a clean production method of a rubber vulcanizing accelerator TBBS, relating to the clean production method of the rubber vulcanizing accelerator TBBS. The cleaning production method is characterized by comprising the following steps of: a, preparing mixing liquid by 1 wt% of accelerators M, 1.5 to 2.4 wt% of tert-butylamine, 0.01 to 0.02 wt% of catalysts and 8 to 14 wt% of water; b, dropwise adding 27.5 wt% hydrogen peroxide in the solution with the flow rate of 50 to 110 ml / min, wherein the oxidizing temperature is 30 to 50 DEG C, and the oxidizing time is 120 to 180 min; c, sampling, detecting by using ammonium sulfate and starch potassium iodide reagents, and stopping adding the hydrogen peroxide when materials are brown in color through detection; and d, filtering and drying to obtain the rubber vulcanizing accelerator TBBS. The invention has the advantages of simple production process, low raw material consumption, high yield, cleanness, environment protection and energy saving; the yield of the accelerator TBBS is higher than 99%, and the product quality is higher than the national primary standard; waste water generated in the technology contains no salt and is easy for biochemical treatment; and the invention reduces environmental pollution and equipment corrosion.

Owner:河南省开仑化工有限责任公司

Energy saving and emission reduction method for retanning and dyeing high-strength cow split leather furniture

ActiveCN101798605AReduce pollutionImprove labor productivity and product qualityTanning treatmentPre-tanning chemical treatmentChromiumDyeing

The invention relates to the field of leather production and discloses an energy saving and emission reduction method for retanning and dyeing high-strength cow split leather furniture. The method comprises the following steps of: conditioning; chromium retanning; neutralizing; retanning; dyeing and greasing; and obtaining a finished product by standing, wetly toggling, oscillating, stuffing leather, lightly wrestling and lightly toggling. The invention effectively overcomes the defects that the traditional Y-shaped drum is mainly applied to the dyeing process of leather with small area (not more than 1 square meter) and less load capacity (not more than 60 percent), can be applicable for retanning, dyeing and greasing a leather pelt with larger area (not less than 5 square meters) and high loading capacity (not less than 70 percent), and solves the technical problems that furniture leather has all-area tone and saturated uniformity when produced by retanning and dyeing cow leather, thereby being a leather producing technology with high efficiency and low pollution.

Owner:浙江通天星集团股份有限公司

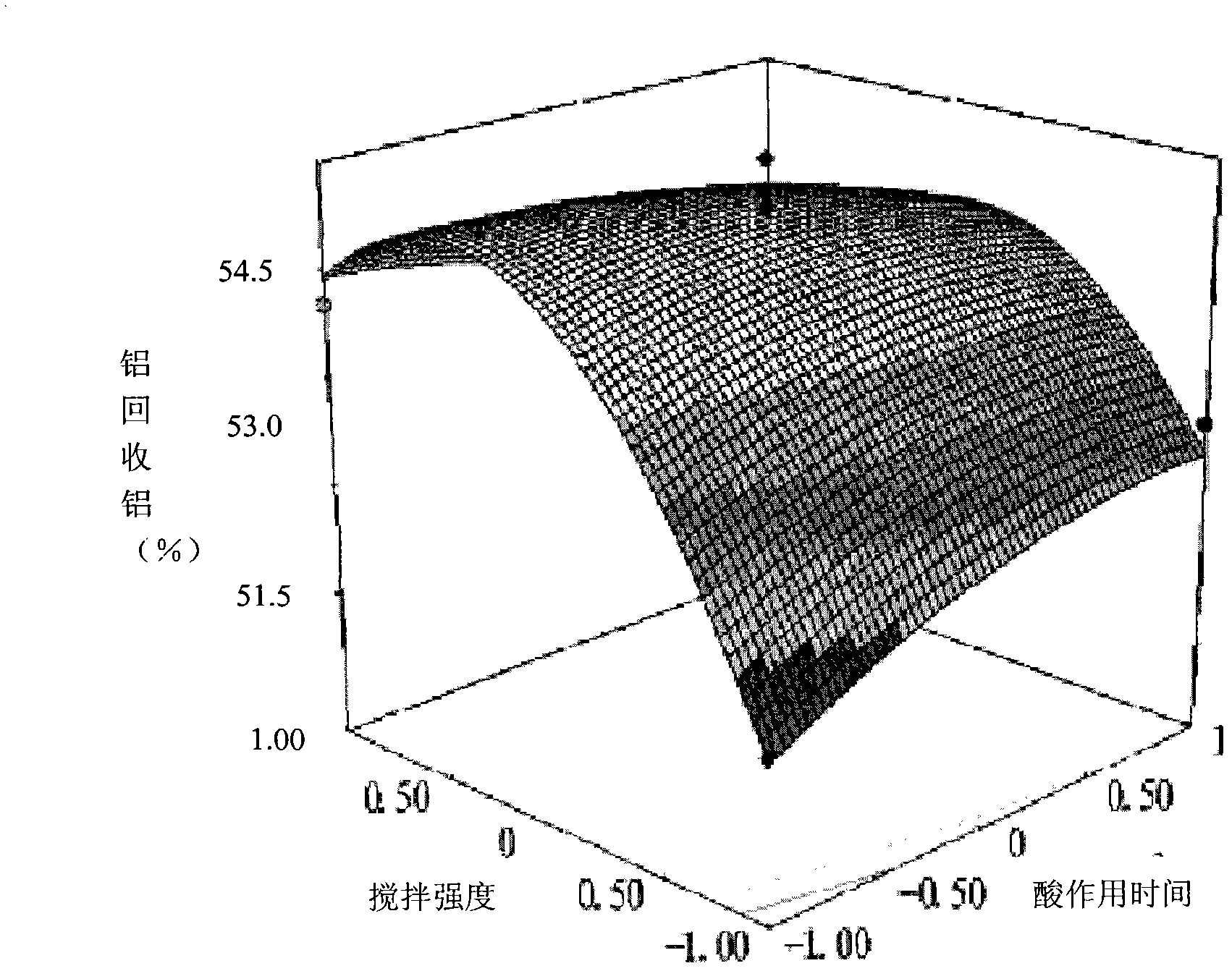

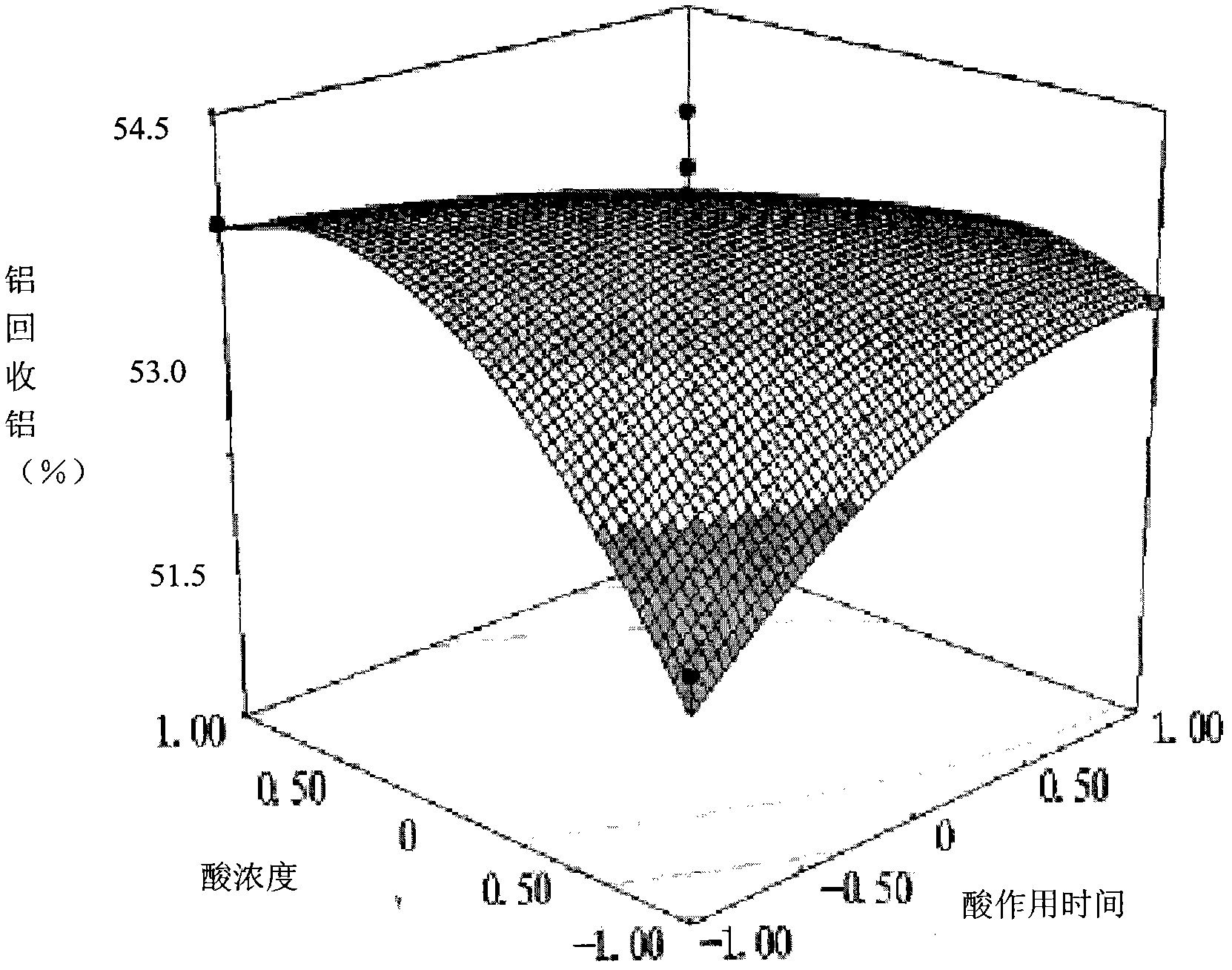

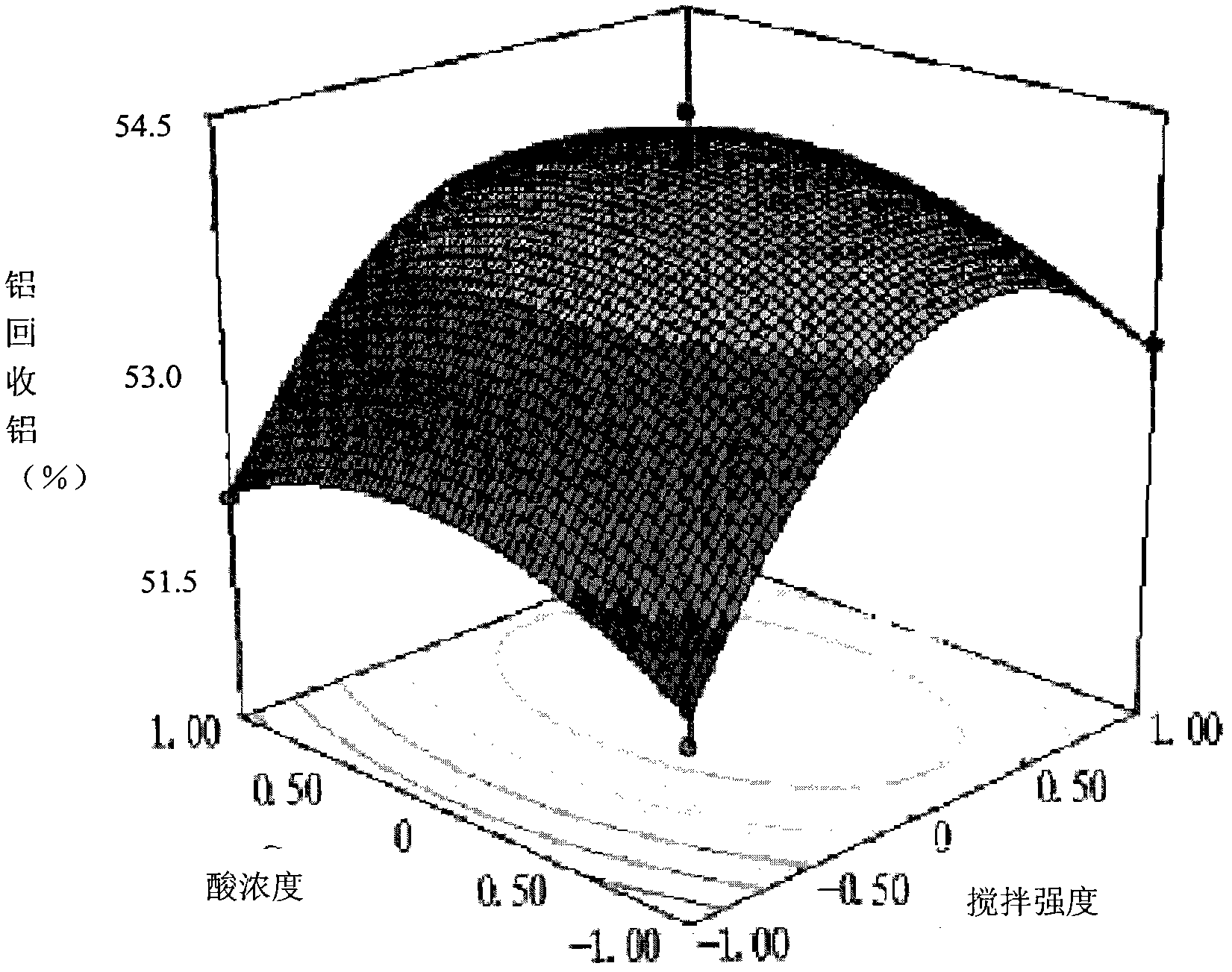

Acid lixiviation based recycling treatment method of aluminum circulating coagulation sludge

InactiveCN102583951ALower Disposal CostsEasy to recycleSludge treatment by de-watering/drying/thickeningAluminium compoundsFlocculationChemical oxygen demand

The invention provides an acid lixiviation based recycling treatment method of aluminum circulating coagulation sludge. The method is characterized by comprising the following steps of: dehydrating sludge to reduce water content of the aluminum circulating coagulation sludge to be lower than 80%; drying and baking; carrying out acidifying treatment: adding mixture of water and acid to adjust pH value of sludge slurry to 3, controlling reaction temperature to be 38 DEG C and agitating sludge and acid in mixed liquid so that the sludge and the acid sufficiently contacts; separating and purifying; and finally, filtering, evaporating and crystallizing to obtain crystal aluminum salt with a flocculation effect. According to the acid lixiviation based recycling treatment method of the aluminum circulating coagulation sludge, a large part of water and aluminum in the sludge is converted into a flocculating agent and impurities are further removed by separating to purify the flocculating agent, thereby improving the recycling of an aluminum salt flocculating agent, greatly reducing sludge disposal cost and further reducing COD (Chemical Oxygen Demand), pH value, residual organic matters and chromaticity of the sludge wastewater; and therefore, the aim of recycling is realized, the subsequence biochemical treatment is easy to implement and the damage of wastewater discharging to the environment is reduced.

Owner:NANJING UNIV

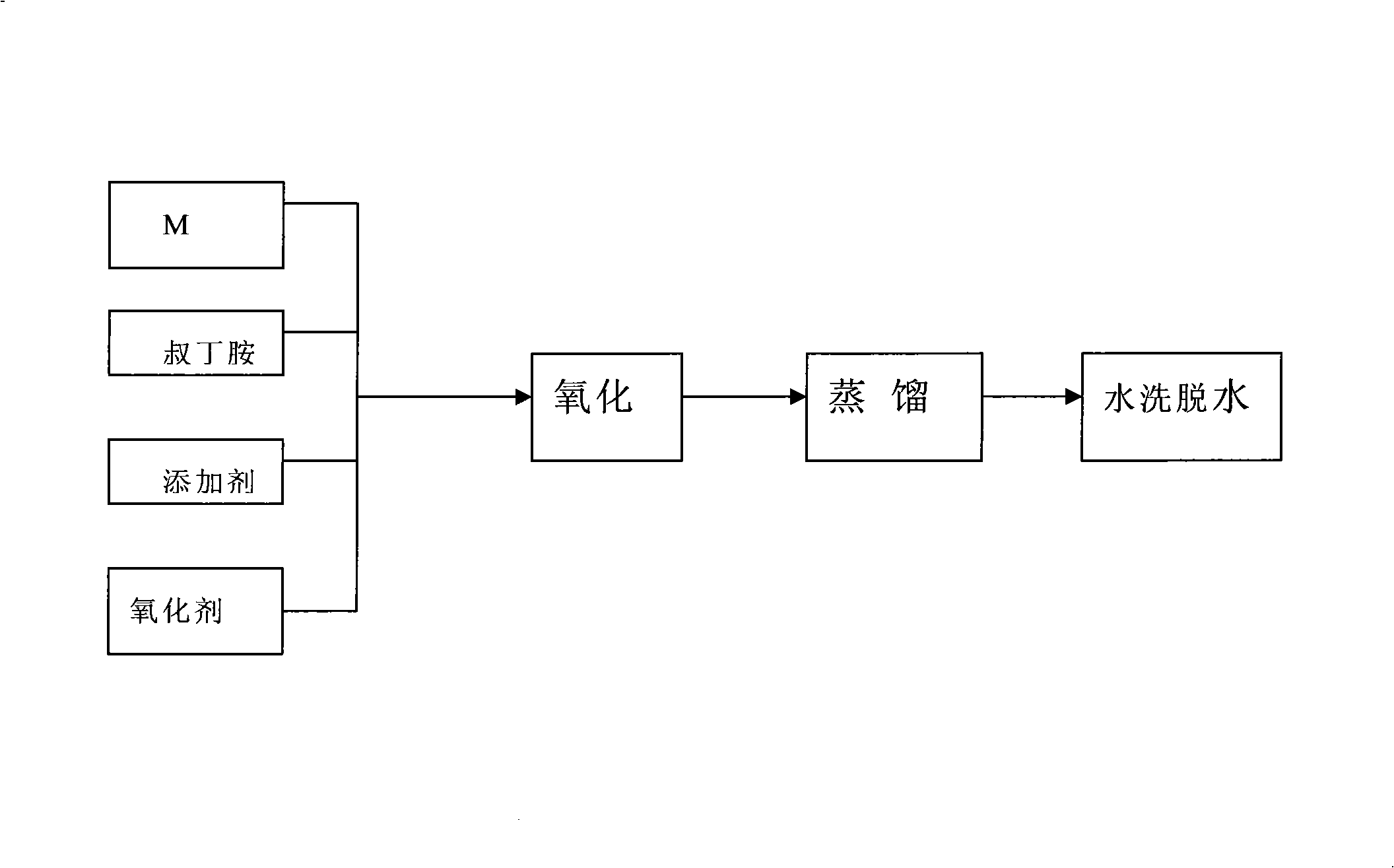

Process for preparing rubber accelerator TBBS

InactiveCN101343257AReduce consumptionEmission reductionOrganic chemistryTert-ButylamineDistillation

The invention provides a production method of a rubber promoter TBBS, sequentially comprising the following steps of: a. oxidation reaction: materials of M, tert-butylamine and an additive are added with water for even agitation and is then added with an oxidizing agent for oxidation, all materials are present in a weight ratio of M: tert-butylamine: water=1:1.2-4.0: 11-15; b. recovery of tert-butylamine through material distillation after the oxidation; and c. putting the distillated residual material in a centrifuge for dewatering by washing until the pH value is equal to 7, so as to obtain the TBBS finished product. The production method has the advantages of optimized process flow, increased M conversion rate, reduced dissolution of product in tert-butylamine, greatly reduced tert-butylamine consumption, lowered distillation load by 70 percent, reduced energy consumption, reduced wastewater discharge by over two third, saved energy, more importantly, non saline matter in the process wastewater, and easy biochemical treatment.

Owner:SHANDONG SUNSINE CHEM

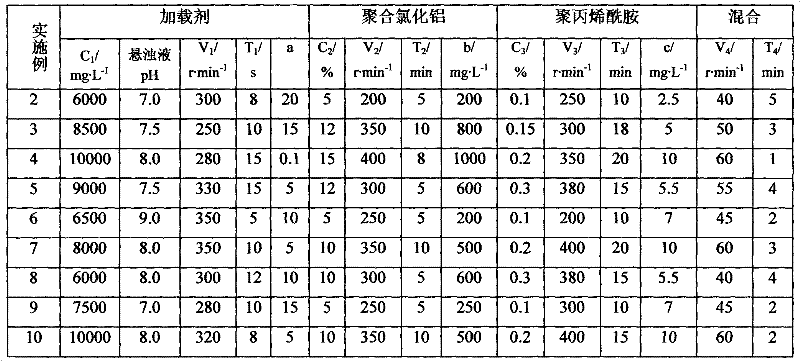

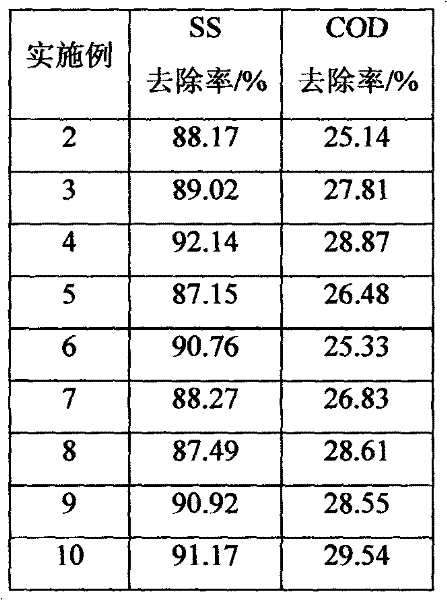

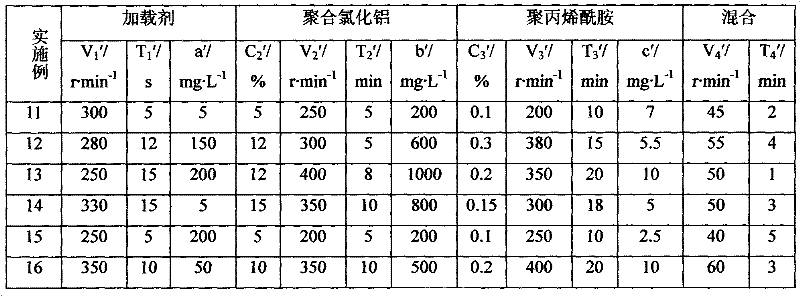

Loading flocculation pretreatment method of antibiotic fermentation wastewater

ActiveCN102351368AImprove flocculation effectImprove collision efficiencyMultistage water/sewage treatmentChemistryPolyacrylamide

The invention discloses a loading flocculation pretreatment method of antibiotic fermentation wastewater and is suitable for processing mixed wastewater discharged during each antibiotic fermentation technological section. By the adoption of the loading flocculation technology, flocculation pretreatment is carried out on mixed wastewater of a crystallization solution, waste mother liquor, dona tub washing wastewater and washing wastewater for a fermentation cylinder during the antibiotic production process. A flocculating agent contains polyaluminum chloride and polyacrylamide; and the addition sequence of the flocculating agent is to add polyaluminum chloride at first and then add polyacrylamide. A loading agent contains one or two mixtures selected from active carbon, fly ash, activatedsludge and settling sludge. By the adoption of the method provided by the invention, the flocculation treatment can be effectively carried out on high-density organic wastewater generated during the antibiotic fermentation production. The method provided by the invention is simple, requires low cost and has a stable effect. By the adoption of the method, the treated wastewater can reach the requirement of subsequent biochemical treatment.

Owner:河北协同环境科技有限公司

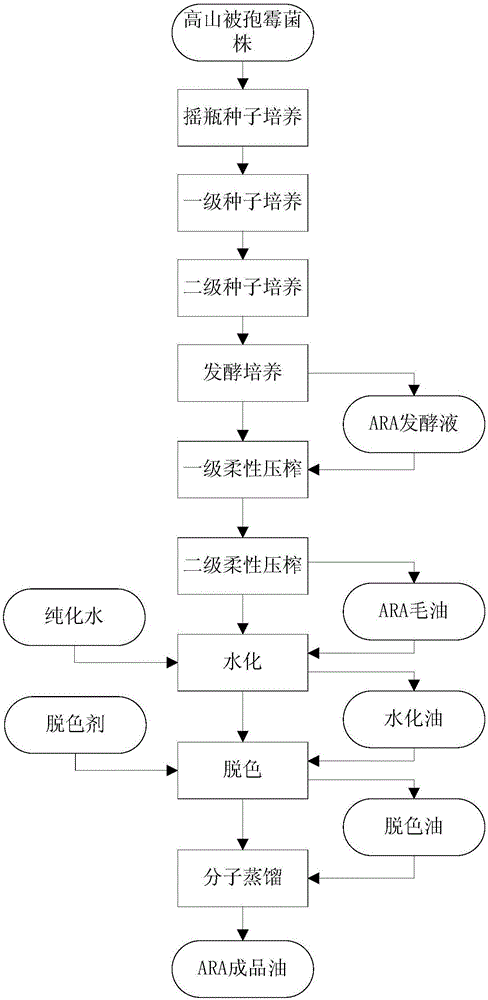

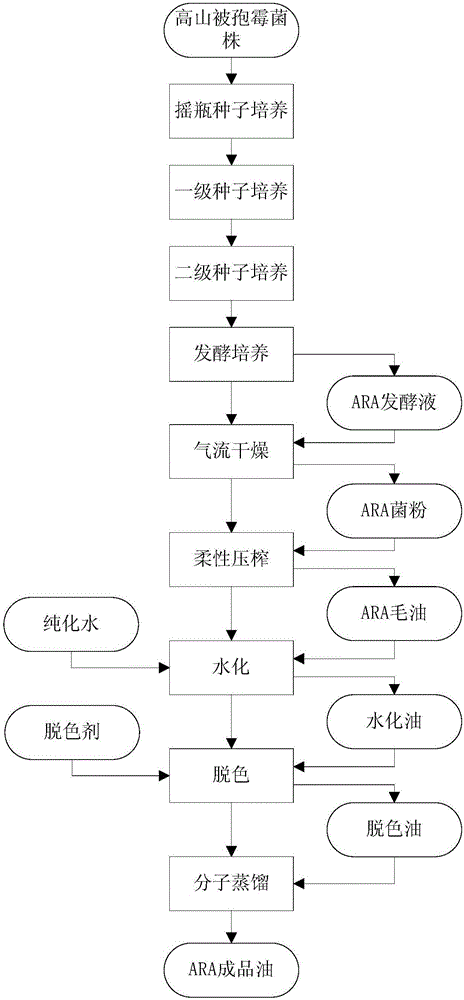

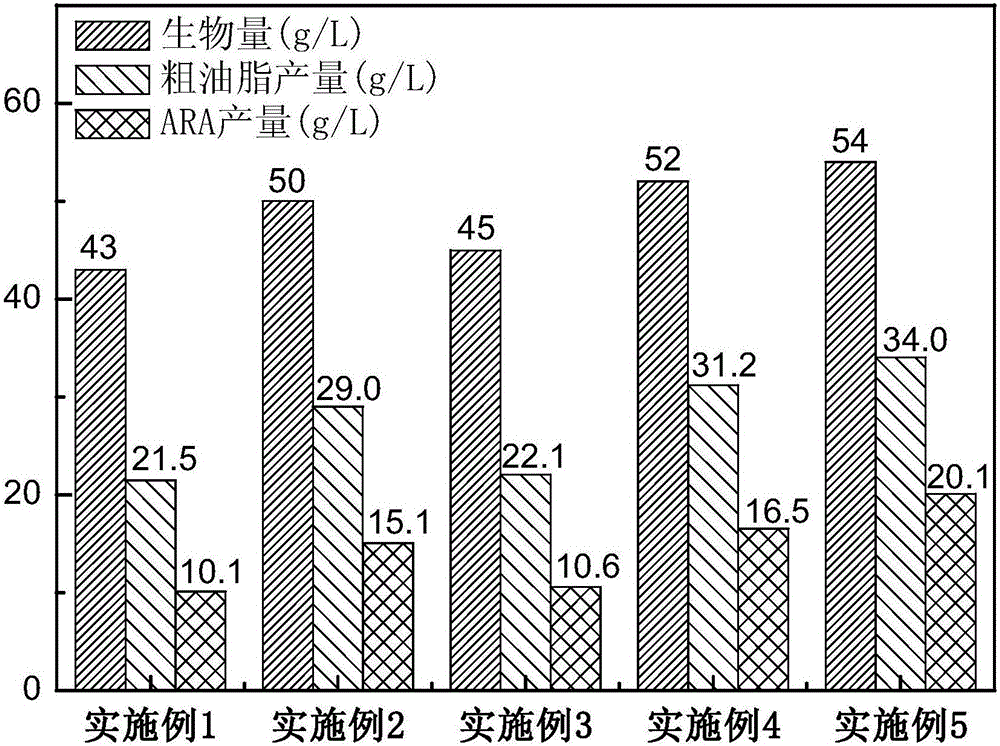

Method for producing ARA (arachidonic acid) through microbial fermentation

ActiveCN106755151AConducive to large-scale industrial productionReduce the cost of fermentation productionFatty-oils/fats refiningMicroorganism based processesMicroorganismBiotechnology

The invention belongs to the field of fermentation engineering, relates to a method for producing ARA (arachidonic acid) through microbial fermentation, and particularly relates to a method for producing compound fat containing the ARA through industrial fermentation of a mortierella alpine strain. More particularly, the invention relates to a method for culturing microorganisms for producing the ARA, wherein the method for culturing the microorganisms for producing the ARA comprises the steps of controlling the fermentation temperature to be 20 to 25 DEG C after culturing in a fermentation tank for 100 to 140h; and / or, stopping ventilation or reducing the ventilatory capacity by not less than 50 percent at the 8th to 10th day of the culturing in the fermentation tank. The method for preparing the ARA has the advantages that the yield is high, the purity is high, and the large-scale industrial production of the ARA is facilitated.

Owner:INNER MONGOLIA KINGDOMWAY PHARMA LTD +1

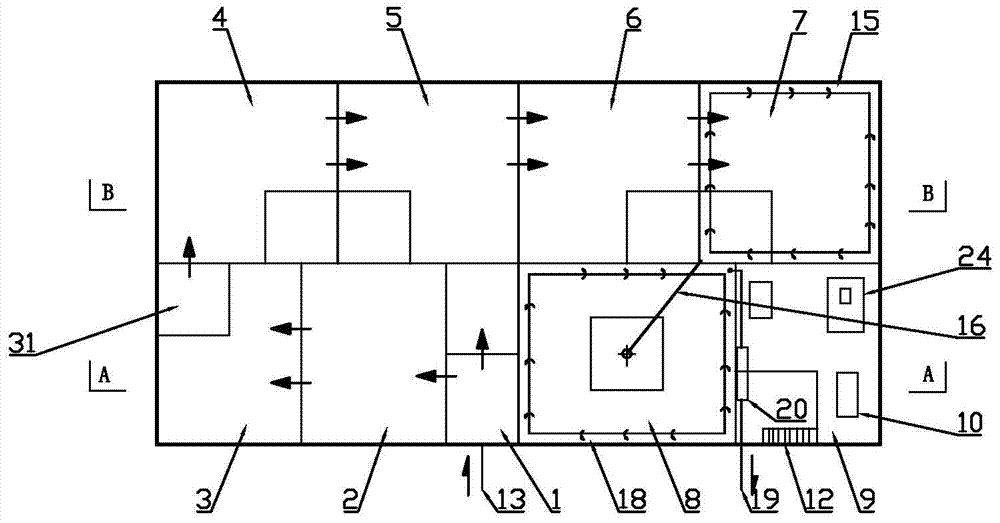

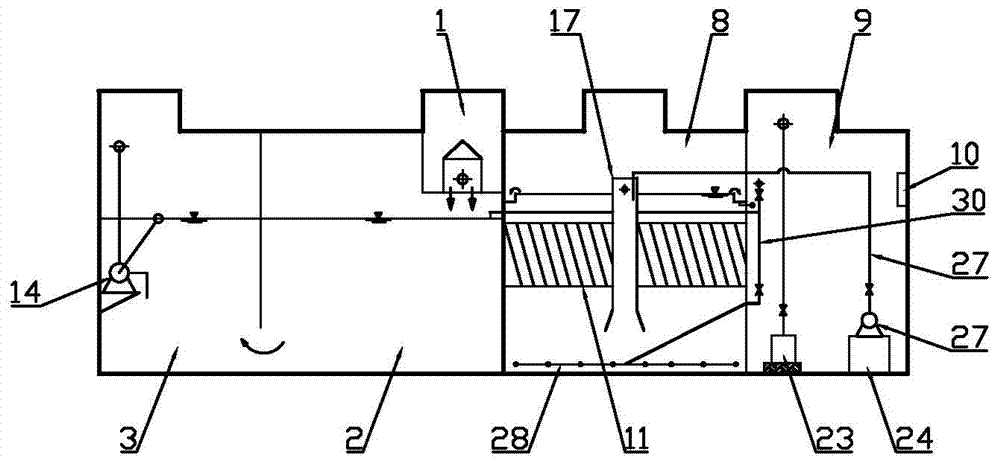

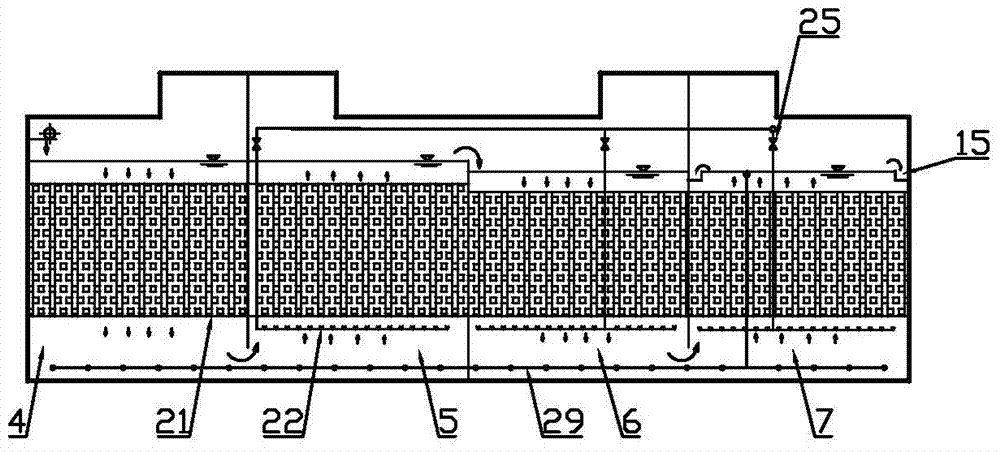

Underground integrated domestic sewage treatment device and method thereof

ActiveCN104710078AShort engineering cycleEasy to check and maintainMultistage water/sewage treatmentSmall footprintIntegrated devices

The invention discloses an underground integrated domestic sewage treatment device and a method thereof, and belongs to the field of purification of the domestic sewage. The underground integrated domestic sewage treatment device comprises a grilling tank, an adjusting tank, an anaerobic digestion tank, an anaerobic biological filtration tank, an aerobiotic biological filtration tank I, an aerobiotic biological filtration tank II, an aerobiotic biological filtration tank III, a vertical flow sedimentation tank and a control chamber, wherein the underground integrated domestic sewage treatment device is an underground stereoscopic integrated device; the control chamber comprises an upper layer part and a lower layer part; the upper layer part is arranged at the upper part of the control chamber; an electric control box and an ultraviolet device are arranged in the upper layer part; a fan and a chemical adding device are mounted at the lower layer part. The underground integrated domestic sewage treatment device is small in occupied area, convenient in drainage and low in energy consumption; the energy conservation and environment protection are facilitated; by virtue of the auxiliary adoption of the chemical treatment process on the main basis of biological degradation, the emission of the water with the up-to-standard water quality is ensured.

Owner:DALIAN JIAOTONG UNIVERSITY

Method for deeply treating aromatic nitro-compound wastewater through photo-assisted catalysis

InactiveCN102701502AImprove catalytic oxidation efficiencyShort reaction timeWater contaminantsMultistage water/sewage treatmentNitro compoundChemical oxygen demand

The invention relates to a method for deeply treating aromatic nitro-compound wastewater through photo-assisted catalysis and belongs to the technical field of catalytic oxidation wastewater treatment. The method comprises the following steps: (1) adjusting a potential of hydrogen (pH) value of the wastewater to be in a range of 1.5-5.5, (2) adding a compound containing ferrous iron ions or ferric iron ions, wherein the adding amount of the iron ions is 5-75 mg / L, (3) adding an oxidizing agent to perform catalytic oxidation reaction at the temperature of 5-65 DEG C for 10-30 minutes, (4) using ultraviolet light with dominant wavelength of 252.7nm to perform irradiation for 5-30 minutes, and (5) continuing to perform the catalytic oxidation reaction at the temperature of 5-65 DEG C, wherein the adding mount of the oxidizing agent is 0-50% of total oxidizing agent amount. By applying a small amount of iron-ionic catalyst and with the assist of ultraviolet light irradiation, oxidation treatment of the low-concentration aromatic nitro-compound wastewater is efficiently performed, the time required by reaction for reducing chemical oxygen demand (COD) and removing a toxicant aromatic nitro-compound is shortened, and biochemical treatment is easily performed.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

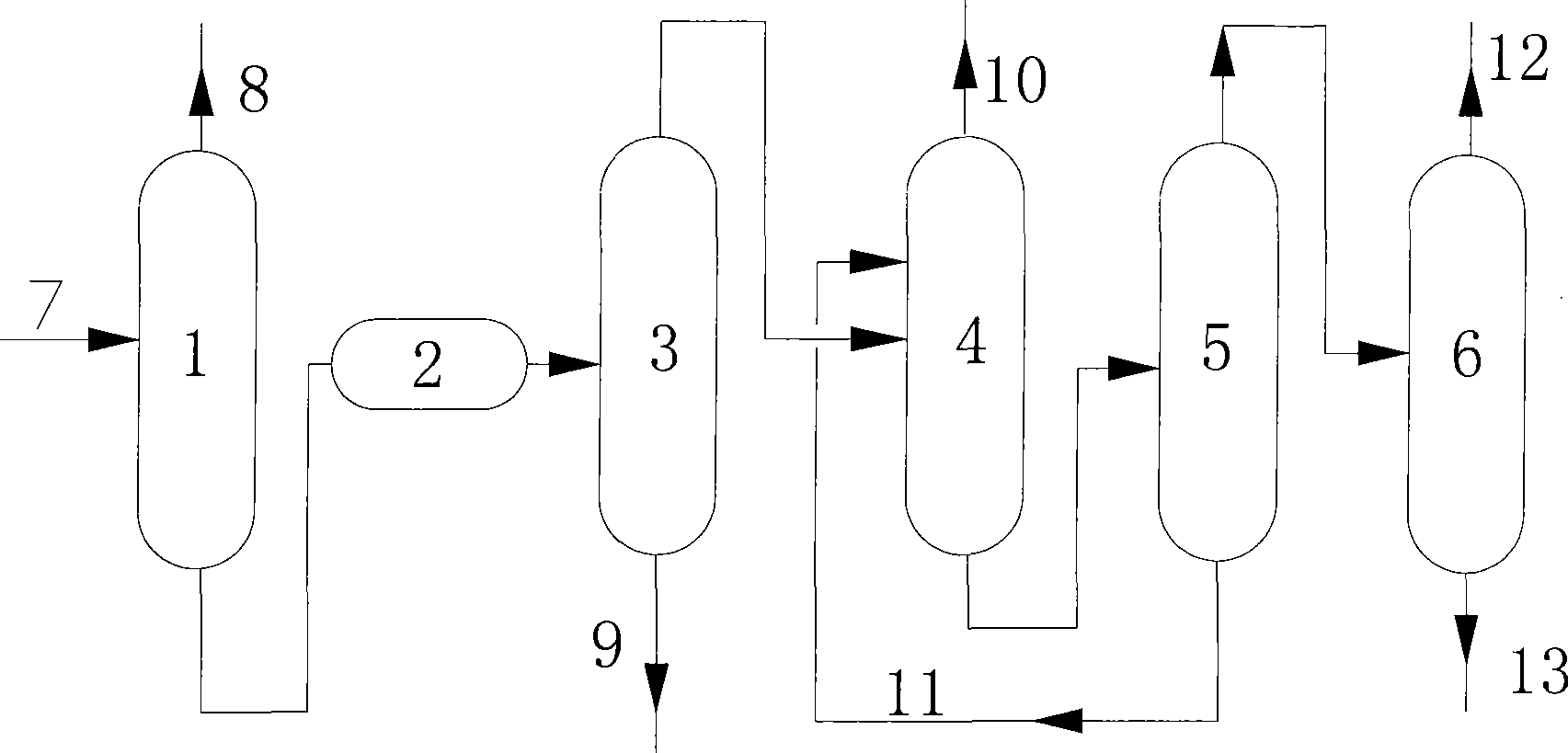

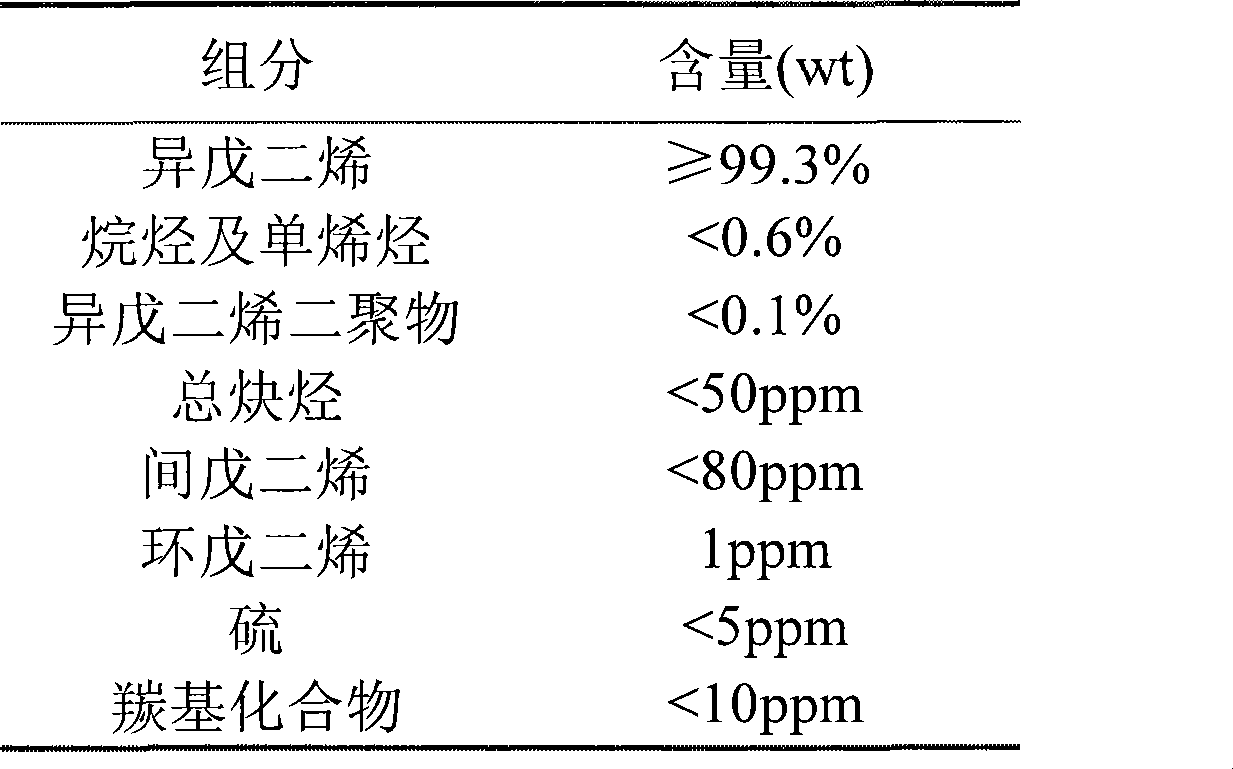

Method for separating carbon 5 fraction by NMP method and one-stage extraction and rectification

ActiveCN101423450AAvoid corrosionAvoid problems such as cloggingHydrocarbon purification/separationHydrocarbons from unsaturated hydrocarbon addition2-methylbutaneDehydrogenation

The invention discloses a method for separating C5 fraction through first-stage extraction rectification by a NMP method. The method comprises the steps of dehydrogenation, dimerization reaction, deheavy, extraction rectification, steam stripping and refining, wherein isopentane is utilized to take most of acetylene hydrocarbon away from the tower top in the dehydrogenation step; and a mixed solvent of NMP and a saline solution is adopted as an extracting agent in the step of extraction rectification. The method improves the extracting agent, increases the selectivity of the extracting agent, cancels a two-stage extraction rectification unit, and reduces the using amount and the regeneration amount of the solvent, thereby reducing operating cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Clean production process of xylose

InactiveCN104498559AEasy to separateStrong penetrating powerSugar derivativesFermentationSulfate radicalsSulphate Ion

The invention provides a clean production process of xylose. The clean production process of xylose mainly comprises the following steps of: pretreating, namely steaming and exploding; hydrolyzing with an enzyme; refining by separating chromatographically; concentrating continuously with a membrane; and concentrating by evaporating steam. Due to the adoption of the clean production process of xylose, the problems in the prior art that sewage contains sulfate ions and can not be treated biochemically can be solved, and the problems of high consumption of water, acids, alkalis and energy, large discharge amount of wastewater, serious pollution to environment, high cost and long production cycle can be also solved.

Owner:山东福田科技集团有限公司

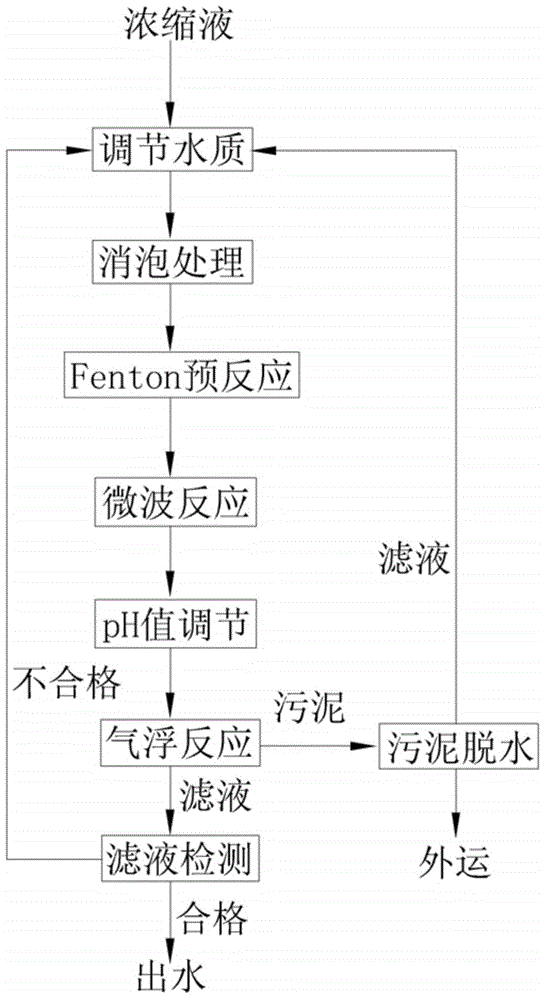

Microwave-assisted Fenton strengthened landfill leachate membrane filtration concentrated solution treatment method

InactiveCN104529026AAltered biodegradabilityChange coagulation performanceSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentSolution treatmentFiltration

The invention discloses a microwave-assisted Fenton strengthened landfill leachate membrane filtration concentrated solution treatment method with the advantages of low cost, high treatment speed and good treatment effect. The method comprises the following steps: (1) adding a certain amount of sulfuric acid into a regulating reservoir stored with a concentrated solution until the pH value of the concentrated solution is 2.0-4.0; (2) adding an antifoaming agent into the concentrated solution for performing antifoaming treatment; (3) adding a Fenton reagent into the concentrated solution for carrying out an aeration pre-reaction; (4) feeding the concentrated solution into a microwave reactor to carry out a microwave-induced oxidizing reaction; (5) adding an alkaline substance into the concentrated solution until the pH value of the concentrated solution is 10.0; (6) carrying out an air floatation reaction on the concentrated solution so as to realize mud-water separation; (7) performing up-to-standard release on the separated effluent, and if not, feeding the filtrate into the regulating reservoir in the step (1); and (8) drying and dewatering the sludge subjected to the air floatation reaction, conveying the dried mud cake, and feeding the dried filtrate into the regulating reservoir in the step (1) to perform the repeated recycling operation.

Owner:GUANGDONG ENG TECH INST

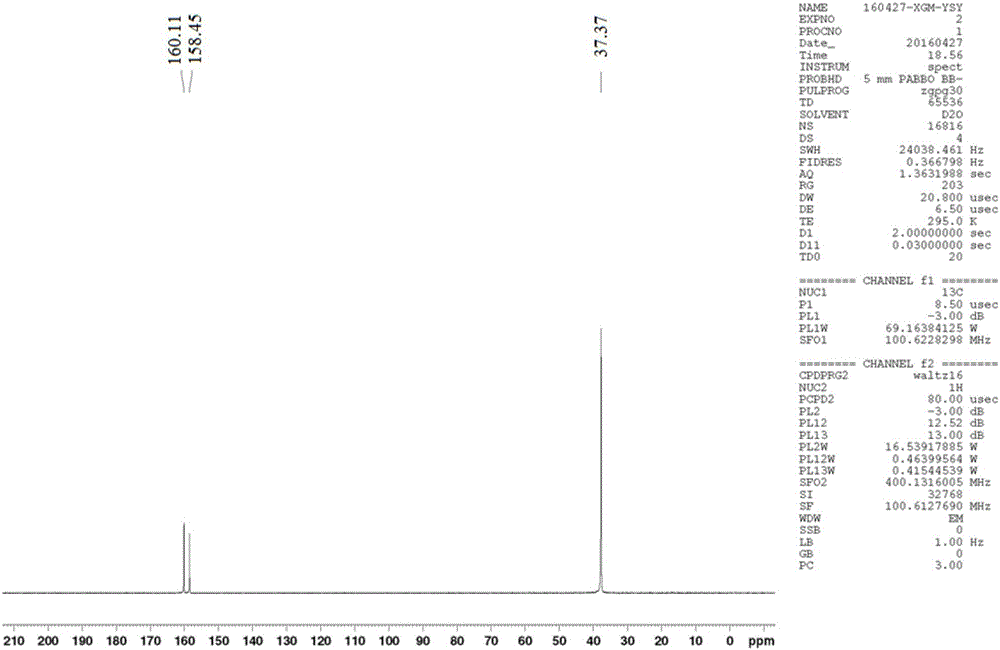

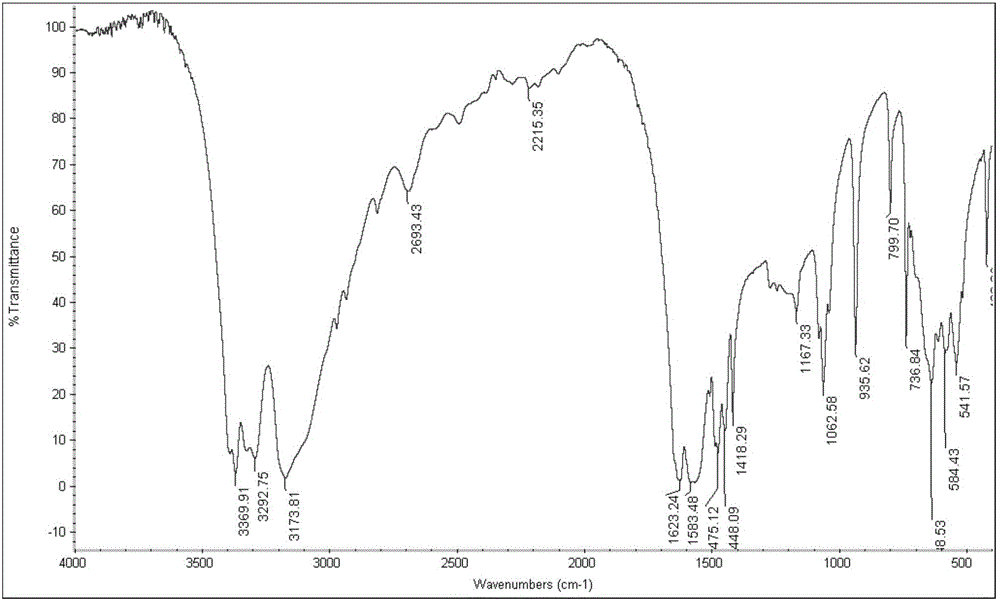

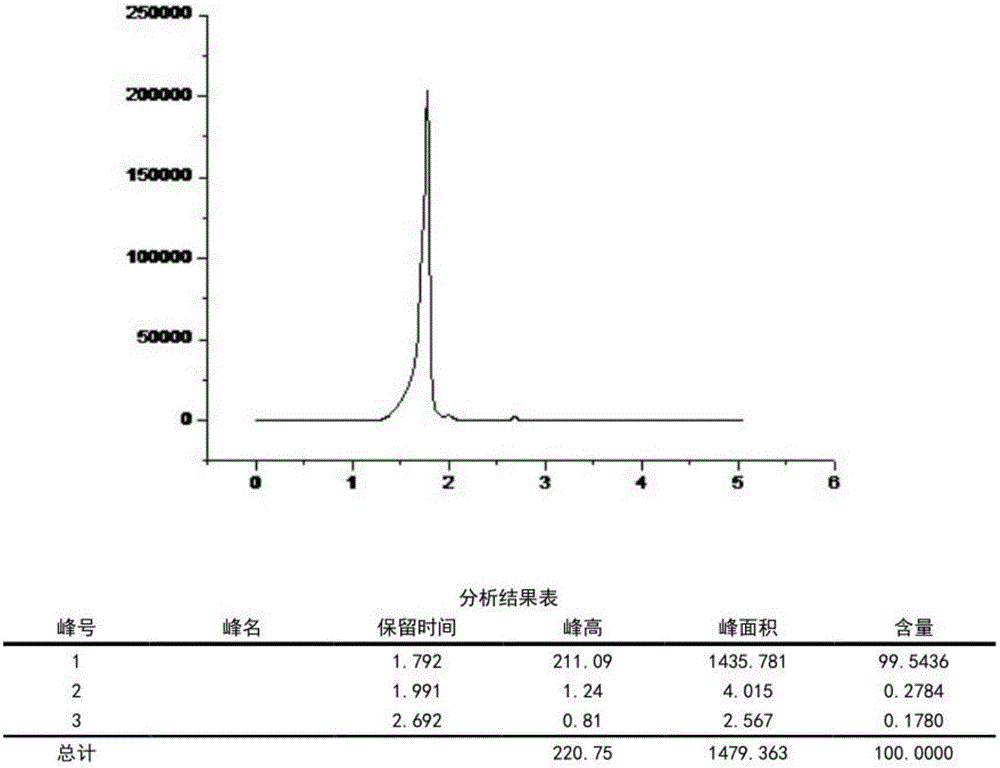

Synthetic method of metformin hydrochloride

ActiveCN105968032ALow reaction temperatureEmission reductionOrganic chemistryOrganic compound preparationMetformin HydrochlorideReaction temperature

The invention discloses a synthetic method of metformin hydrochloride. The method comprises the following steps: (1) in a high pressure enclosed environment, dimethylamine, dicyandiamide, a hydrochloric acid solution, and a catalyst organic acid are added, and a heating reaction is carried out in order to obtain metformin hydrochloride; (2) metformin hydrochloride is obtained by refining with ethyl alcohol. The pressure generated by heating in a high pressure reaction vessel is used, so that dimethylamine in a water system and dicyandiamide are reacted in order to generate metformin hydrochloride, reaction temperature is effectively reduced, and according to dicyandiamide, the reaction yield is higher than 90%. Water is used as a reaction solvent, and compared with traditional technology, the method has the advantages of low raw material cost, low toxicity, simple reaction process, low energy consumption, small waste liquid discharge, easy industrial production, and substantially reduced production cost and environment cost . A trace amount of an organic acid catalyst is used, so that stability of dicyandiamide in a high temperature water system is effectively improved, generation of side reaction of cyanamide is reduced, and the purification process is simplified.

Owner:NINGXIA SIKEDA BIOTECH CO LTD

Treatment method for high salt content and high COD alkaline residue neutralization water

ActiveCN102452696ANo impactPromote emission standardsWater contaminantsNature of treatment waterSalt contentDesalination

The present invention relates to a treatment method for high salt content and high COD alkaline residue neutralization water. According to the method, an extraction treatment is performed at a temperature of -5-5 DEG C, wherein an extraction agent is a petroleum fraction and / or an organic amine; the extracted material is subjected to settlement separation to obtain the oil phase, the water phase and the solid substance. With the method of the present invention, the high COD removal efficiency can be obtained by using the simple extraction method, the high desalination effect can be obtained, the biodegradability of the treated effluent is improved, and the impact on the wastewater treatment plant is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for pretreatment of propylene oxide wastewater by using micro-electrolysis

InactiveCN103204569AReduce pollutionLower pHWater/sewage treatmentNature of treatment waterActivated sludgeCooling tower

The invention relates to a method for pretreatment of propylene oxide wastewater by using micro-electrolysis. The method comprises the following steps: firstly enabling the process wastewater produced from the production of propylene oxide to pass through a cooling tower, cooling water temperature to below 40 DEG C, then entering an aluminum-silicon micro-electrolysis device to perform low-pressure catalytic electrolysis treatment, enabling the wastewater to enter from the bottom of the aluminum-silicon micro-electrolysis device and exit from the upper part of the aluminum-silicon micro-electrolysis device, performing electrolysis for 10-15 minutes, and simultaneously introducing air into the aluminum-silicon micro-electrolysis device for aeration, wherein the flow rate of introducing the air is 5000m<3> / h; and enabling the wastewater after the treatment by the aluminum-silicon micro-electrolysis device to enter a precipitation tank for precipitating for 0.5-1 hour, and enabling the wastewater after precipitation to enter a biochemical tank for performing biological treatment. According to the method, the concentration of organic chlorides in the propylene oxide wastewater can be effectively reduced, the pollution load and the pH value of the wastewater are simultaneously reduced, sewage can be prevented from causing an impact on a treatment device, the treatment efficiency of the wastewater by a late-stage active sludge method is improved, the wastewater can achieve the emission standard, the environmental pollution is reduced, and the method has good social benefits and environmental benefits.

Owner:BEFAR GROUP CO LTD

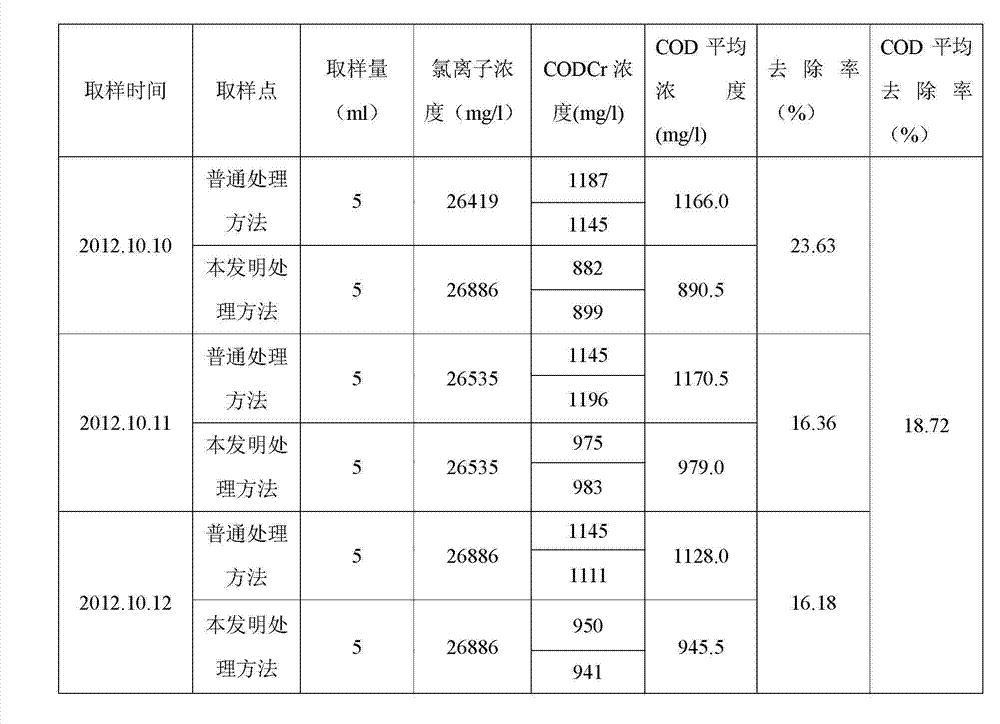

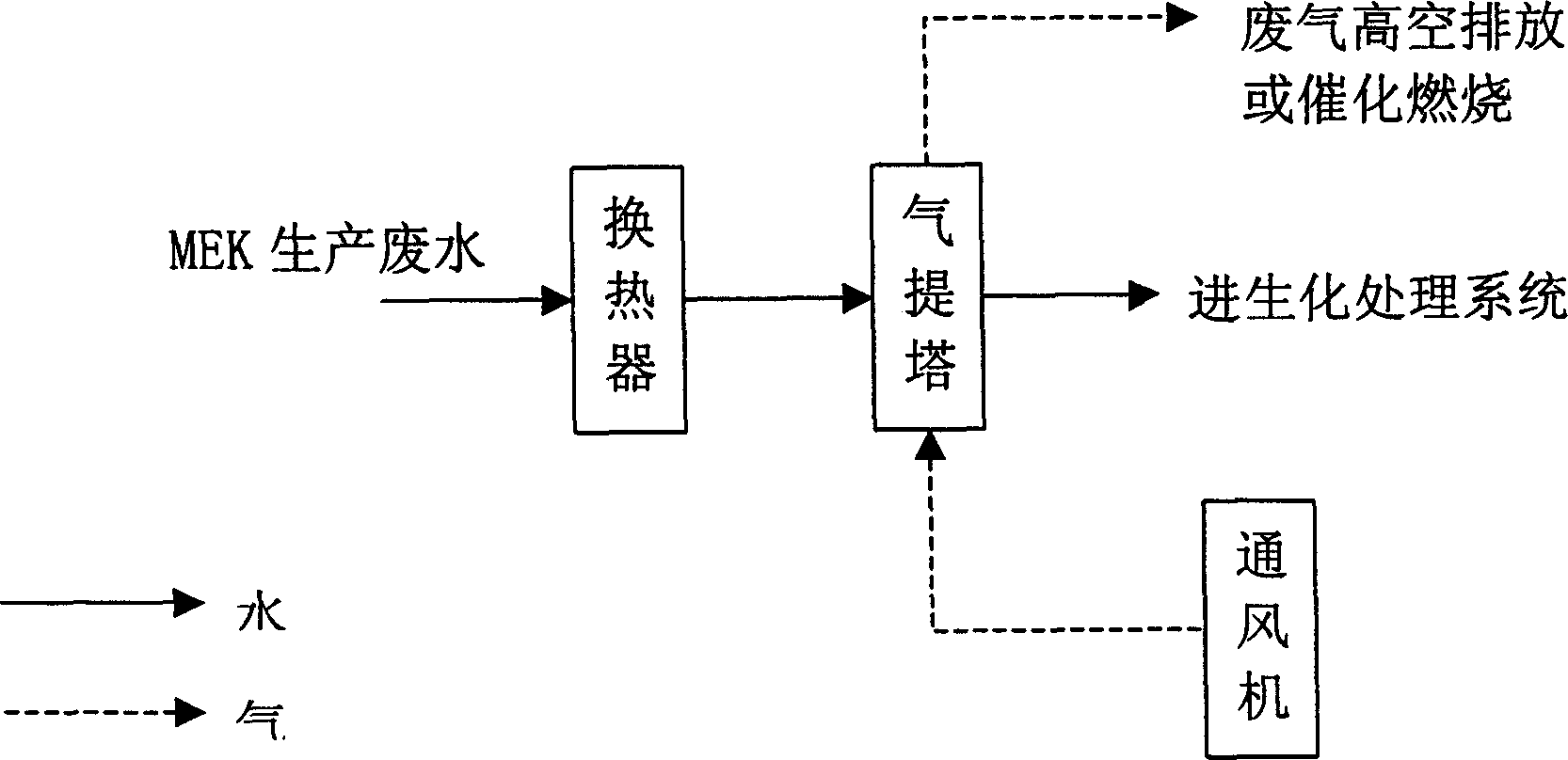

Waste water treating method for methyl ethyl ketone production

InactiveCN1490253AEasy to handleImprove processing efficiencyWater/sewage treatmentMultistage water/sewage treatmentPretreatment methodBiochemical engineering

A process for treating the sewage discharged in production of paramethadione includes such steps as heating it to a certain temp, pumping it in stripping tower containing filler, counter-current stripping, biochemical treating, and exhausting the waste gas to high space or catalytic burning it. Its advantages are high effect and high biochemical treating efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

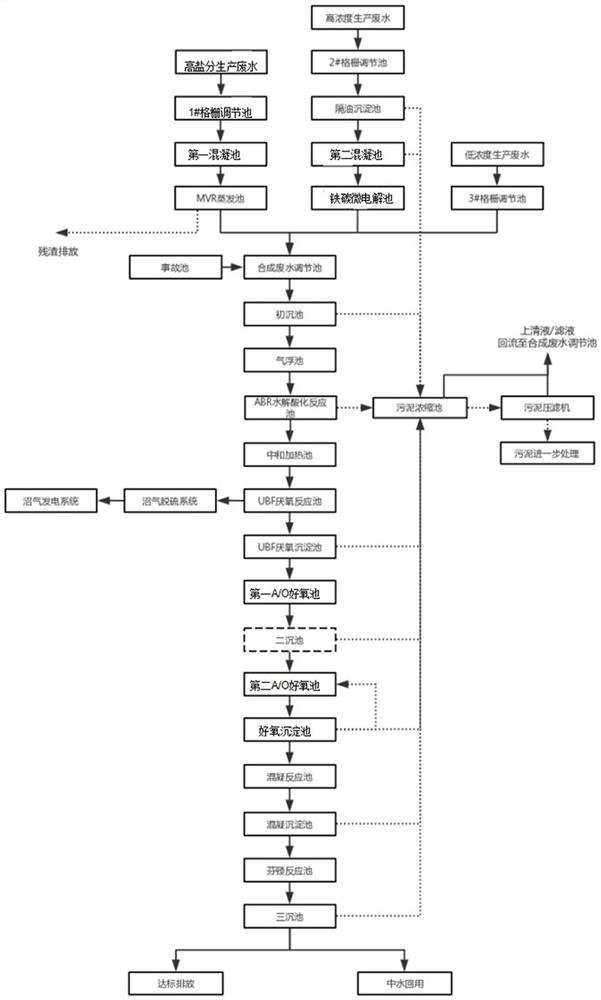

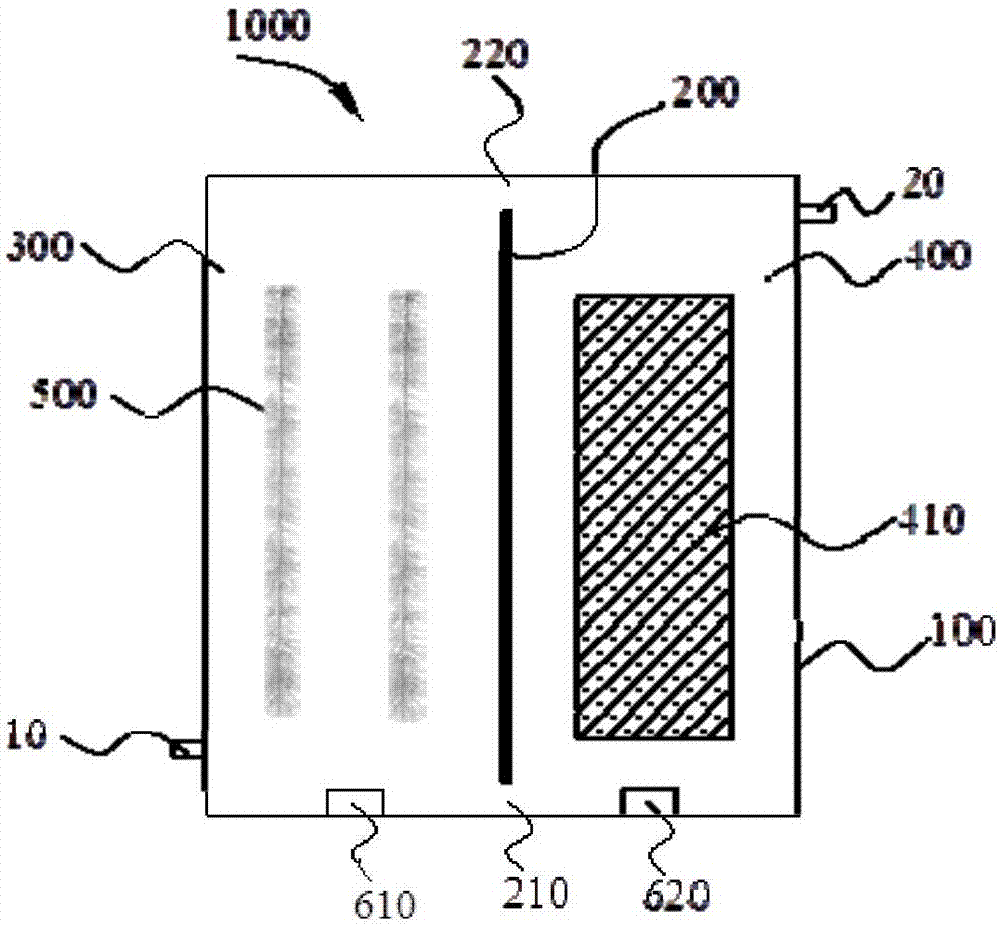

Chemical synthesis pharmaceutical wastewater treatment system and treatment method

ActiveCN112390479AImprove biodegradabilitySolve intractableFatty/oily/floating substances removal devicesWater treatment compoundsChemical synthesisPulp and paper industry

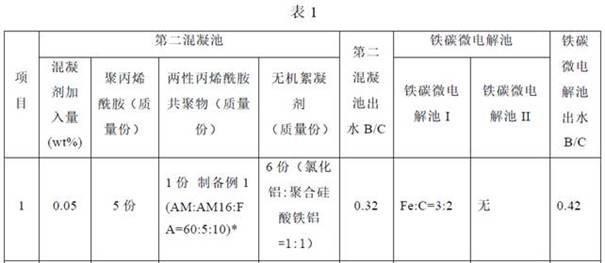

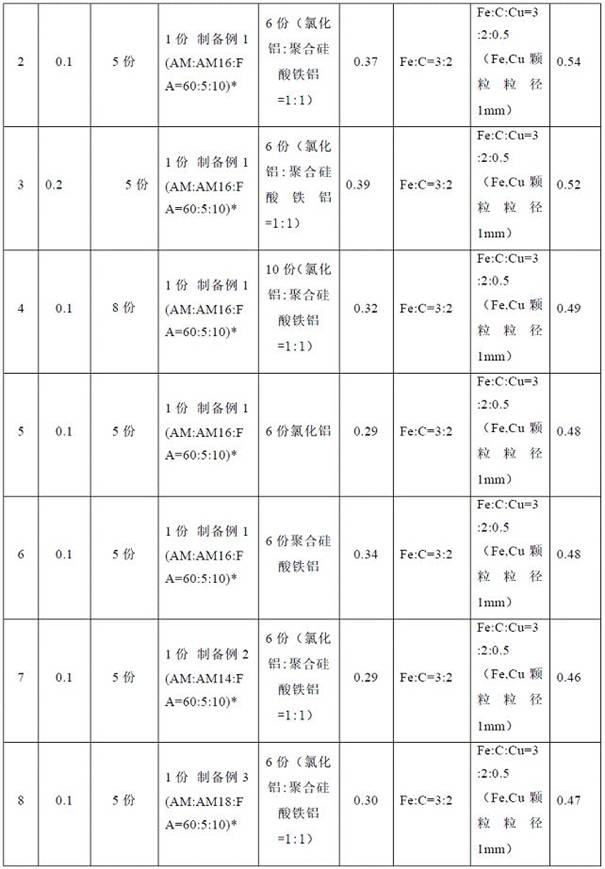

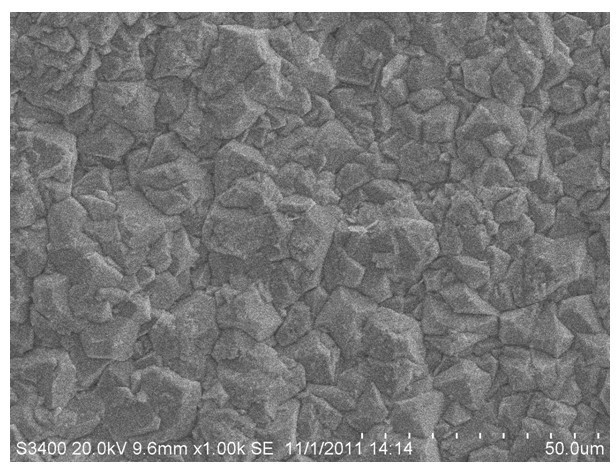

The invention relates to a chemical synthesis pharmaceutical wastewater treatment system and treatment method, the treatment system comprises a pretreatment module and a biochemical treatment module,the pretreatment module comprises a high -salinity production wastewater pretreatment unit, a high- concentration production wastewater pretreatment unit and a low concentration production wastewaterpretreatment unit; the high-salinity production wastewater pretreatment unit sequentially comprises a first coagulation tank and an MVR evaporation tank; the high-concentration production wastewater pretreatment unit sequentially comprises an oil separation sedimentation tank, a second coagulation tank and an iron-carbon micro-electrolysis tank; and a coagulant of the second coagulating tank comprises polyacrylamide, an amphoteric acrylamide copolymer and an inorganic flocculant, and the amphoteric acrylamide copolymer is obtained by copolymerization of acrylamide, hydrophobic cation modifiedacrylamide and fumaric acid. According to the method, the high-concentration production wastewater is subjected to a pretreatment mode of combined use of coagulation and iron-carbon micro-electrolysis, so that the biodegradability of the high-concentration production wastewater is remarkably improved, and subsequent biochemical treatment is facilitated.

Owner:华夏碧水环保科技有限公司北京分公司

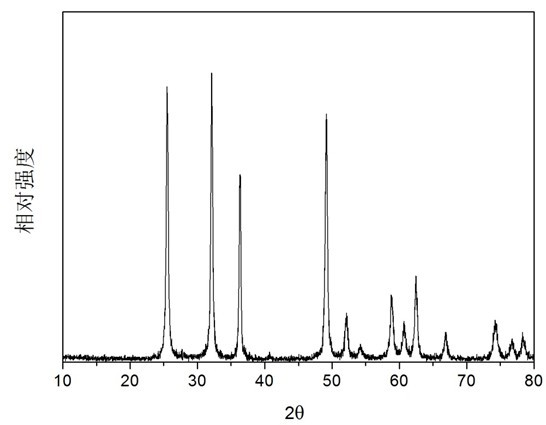

Anode electrode material, preparation method thereof, application and working method of anode electrode material in treating wastewater containing phenol by electrochemical oxidation

InactiveCN102515315AQuick and efficient destructionEffective destructionWater contaminantsWater/sewage treatmentElectrolysisWastewater

The invention discloses an anode electrode material, a preparation method thereof, the application and a working method of the anode electrode material in treating wastewater containing phenol by electrochemical oxidation; and an electrode is prepared from grinding, alkali washing, acid washing, electrolysing and calcinating a titanium plate. When the wastewater containing the phenol is treated, under a constant current condition, the phenol in the water is removed by controlling the amount of added Cl-, current density, electrification time and other factors. An analysis result shows that: the electrode material can effectively remove the phenol simulated wastewater in quite a large concentration scope under a low energy consumption condition. The electrode material used in the method has long service life, can make the wastewater containing the phenol reach regulated emission requirements in a shorter time, chemical substances which produce negative impact on the environment are not introduced during the process, no secondary pollution is produced, and the anode electrode material has the advantages of low energy consumption, mild reaction conditions, convenience in operation, reliability in operation and the like.

Owner:NANJING UNIV

Dephenolization method for phenol-containing wastewater by extraction

ActiveCN106865675AReduce difficultyHigh removal rateWater contaminantsMultistage water/sewage treatmentWastewaterWater quality

The invention provides a dephenolization method for phenol-containing wastewater by extraction. The dephenolization method comprises the following step: subjecting the phenol-containing wastewater to multistage countercurrent extraction with an extractant at 20 to 35 DEG C so as to obtain an extraction phase and a raffinate phase, wherein the extractant is cyclic ketone, and the pH value of the phenol-containing wastewater is 6 to 7. The dephenolization method by extraction provided by the invention has the following advantages: the removal rate of phenol in the phenol-containing wastewater can reach 96.5% or above, and more phenols can be recycled; meanwhile, the removal rate of polyphenol in phenols is significant; the concentration of residual phenol in wastewater is greatly reduced, thereby facilitating subsequent biochemical treatment; the quality of biochemical effluent is improved; the difficulty of reusing treatment of the wastewater is greatly reduced; and the change to operating conditions of equipment is small, thereby facilitating rapid application to the process of dephenolization by extraction.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +2

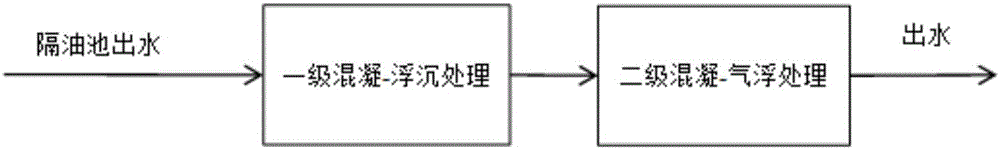

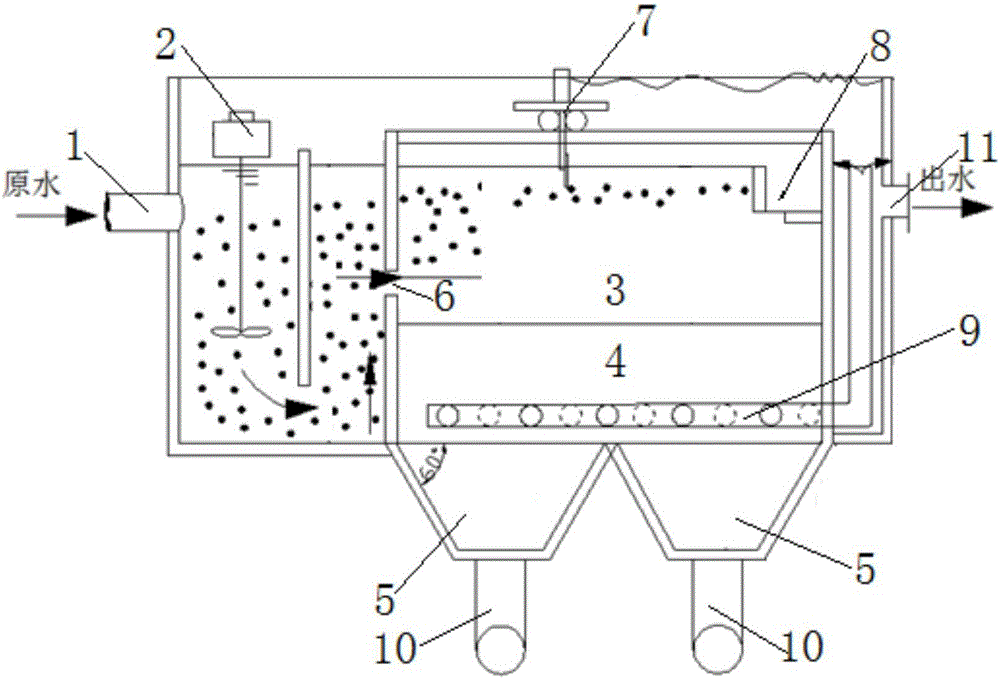

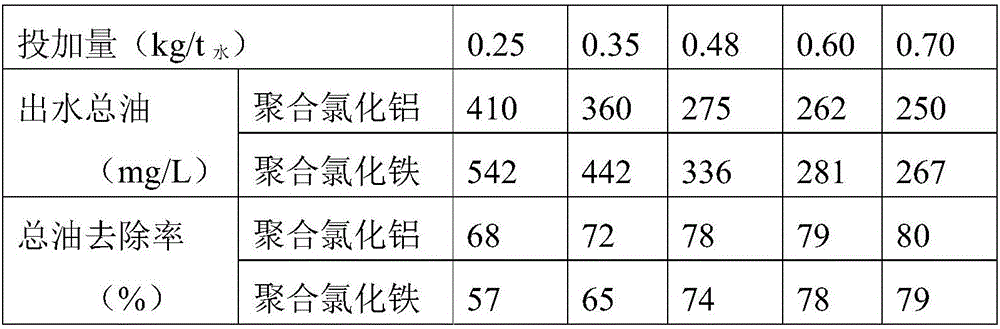

Pretreatment method of two-stage enhanced coagulation deoiling for coal chemical industry wastewater

ActiveCN105923830AReduce turbidityReduce chromaWaste water treatment from quariesMultistage water/sewage treatmentPretreatment methodOil separation

The invention relates to a pretreatment method of two-stage enhanced coagulation deoiling for coal chemical industry wastewater, comprising the specific steps: (1), first-stage coagulation and bouncing treatment: introducing effluent of an oil separation tank into a first-stage coagulating tank, adding an inorganic polymeric coagulant into the first-stage coagulating tank to form small coagulations, adding an organic polymeric coagulant to enlarge the coagulations, and charging the effluent of the first-stage coagulating tank into a bouncing tank for oil-water separation; (2), second-stage coagulation and gas floatation treatment: introducing effluent of the bouncing tank into a second-stage coagulating tank, adding an inorganic polymeric coagulant and an organic polymeric coagulant successively into the second-stage coagulating tank, charging effluent of the second-stage coagulating tank into a gas flotation tank, and carrying out second-stage enhanced coagulation deoiling treatment by means of gas flotation in the gas flotation tank so that the effluent of the gas flotation tank is lower than 80-100 mg / L and adapts to subsequent biochemical treatment. Compared with the prior art, the method has the advantages such as good deoiling effect, good operation stability and low treatment cost.

Owner:EAST CHINA UNIV OF SCI & TECH

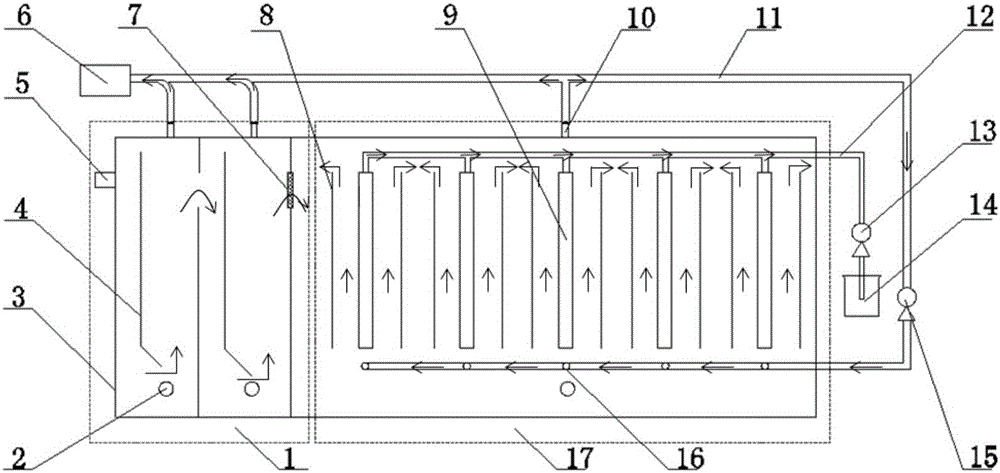

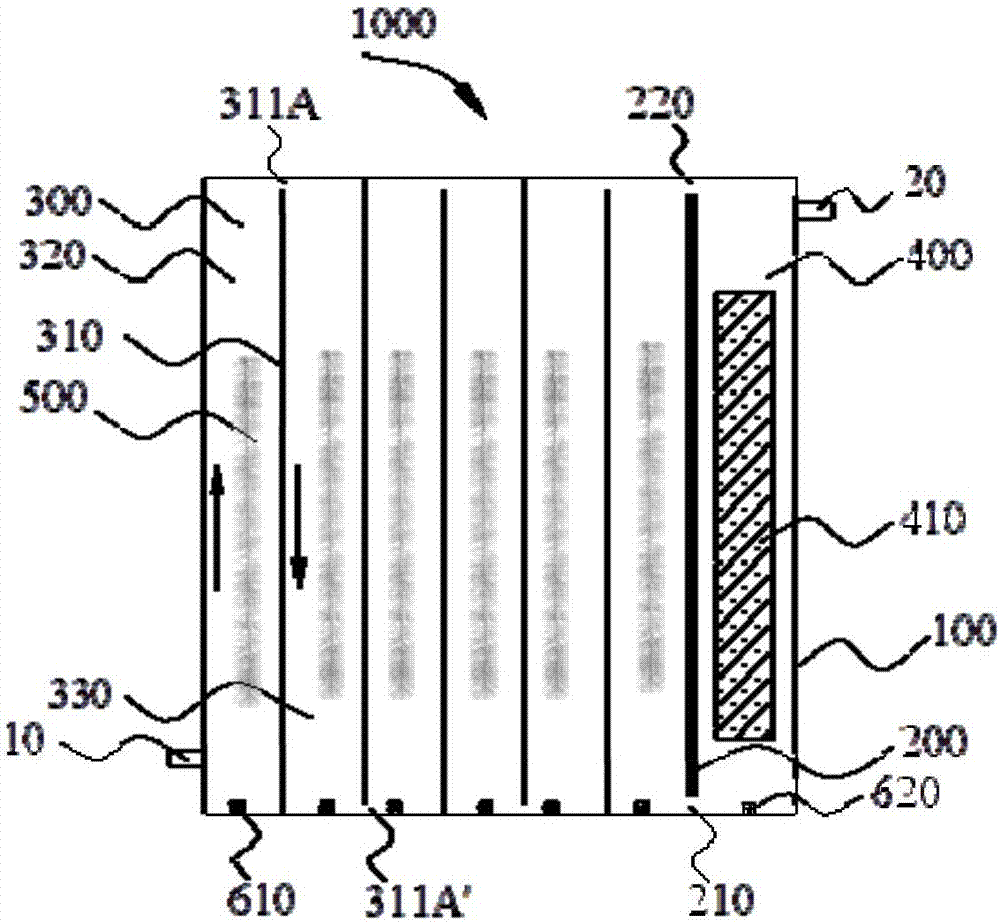

Integrated gas internal circulating anaerobic baffle membrane bioreactor

PendingCN106630138AReduce pollutionConducive to long-term operation and maintenanceTreatment with anaerobic digestion processesMembrane bioreactorSewage

The invention discloses an integrated gas internal circulating anaerobic baffle membrane bioreactor which comprises an anaerobic baffle reaction region and an anaerobic membrane bioreaction region, wherein a water inlet and a sludge discharge opening I are formed in the sidewall of the anaerobic baffle reaction region, and a gas collection opening I is formed in the top of the anaerobic baffle reaction region; the anaerobic baffle reaction region comprises a plurality of compartments, a baffle is arranged in each compartment, and each compartment is divided into a falling region and a rising region by the corresponding baffle in the flowing direction of sewage to be treated; a sludge discharge opening II is formed in the sidewall of the anaerobic membrane bioreaction region, and a gas collection opening II is formed in the top of the anaerobic membrane bioreaction region; a plurality of anaerobic membranes are arranged in the anaerobic membrane bioreaction region, and a membrane water outlet is formed in the upper part of each anaerobic membrane, and is communicated with a water outlet pipe; both the gas collection openings I and II are communicated with a gas collection bag. After the sewage is biodegraded by an anaerobic fixed bed, suspending solids entering a membrane separation region are greatly reduced, the membrane pollution degree is greatly reduced, long-term running and maintenance of the membranes are facilitated, and the economy is improved.

Owner:CHINA AGRI UNIV

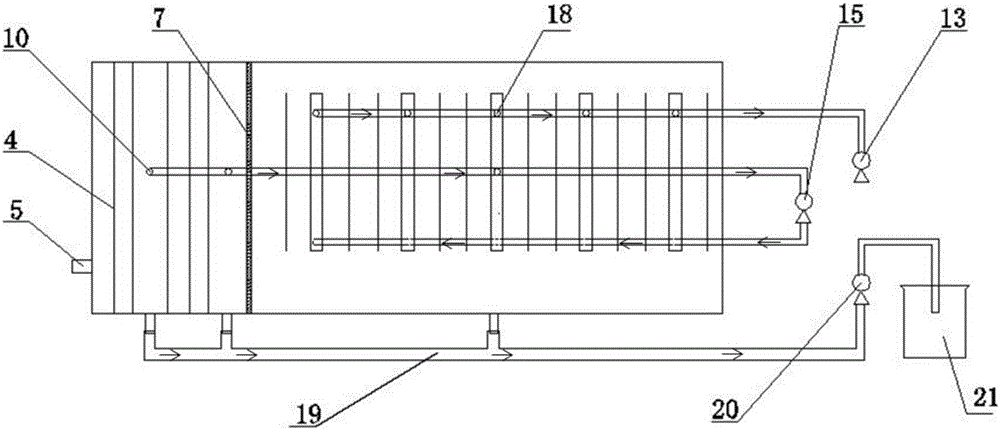

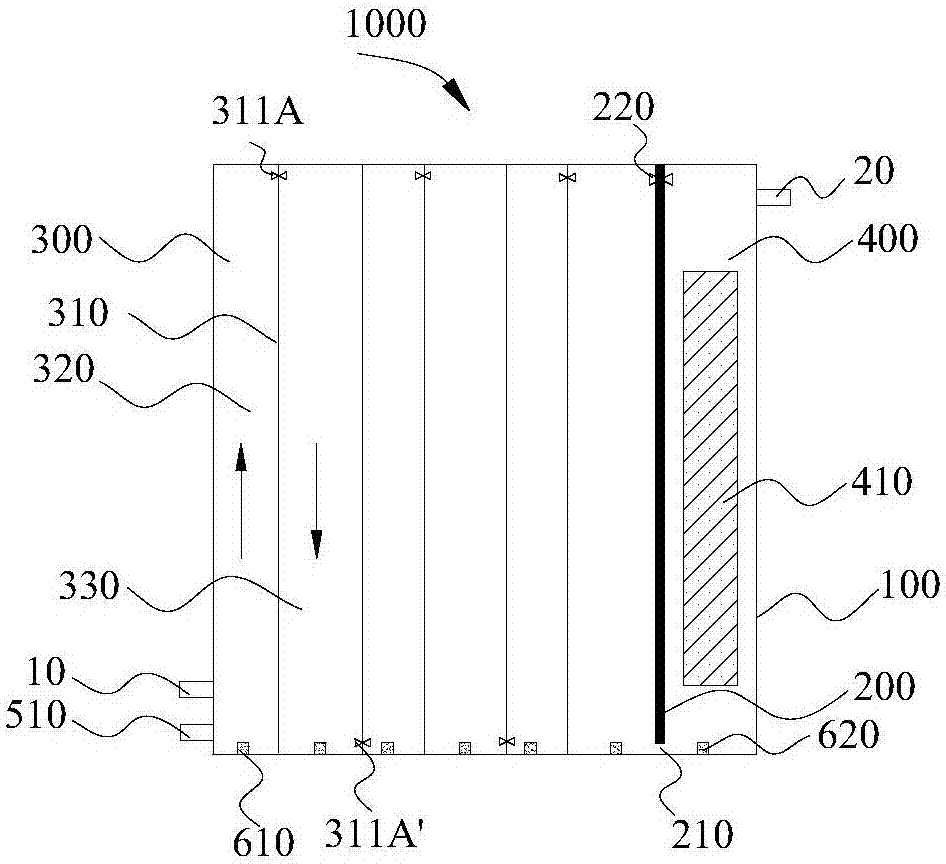

Biological film-film biological coupling sewage treatment device

PendingCN107986436AImprove processing efficiencyIncrease contact areaSustainable biological treatmentBiological water/sewage treatmentSludgeEngineering

The invention discloses a biological film-film biological coupling sewage treatment device. The biological film-film biological coupling sewage treatment device specifically comprises a shell body, biological carrier filler and a membrane assembly, wherein a separation plate is arranged in the shell body; a biological reaction space and a membrane filtering space are limited in the shell body by the separation plate; a first water flow through hole is formed in the bottom of the separation plate; a water inlet is formed in one side, close to the biological reaction space, of the shell body; awater outlet is formed in the top of one side, close to the membrane filtering space, of the shell body; the biological carrier filler is arranged in the biological reaction space; an aeration openingis formed in the bottom of the biological reaction space; the membrane assembly is vertically arranged in the membrane filtering space; a membrane filtering aeration opening is formed in the bottom of the membrane filtering space. Therefore, the sewage treatment device disclosed by the invention not only has the advantages of impact load resistance, simple and compact structure, small occupied area, low sludge expansion ratio and, and output water has better quality and is more stable; furthermore, the membrane pollution can be reduced and the energy consumption and the operation cost are reduced.

Owner:TSINGHUA UNIV

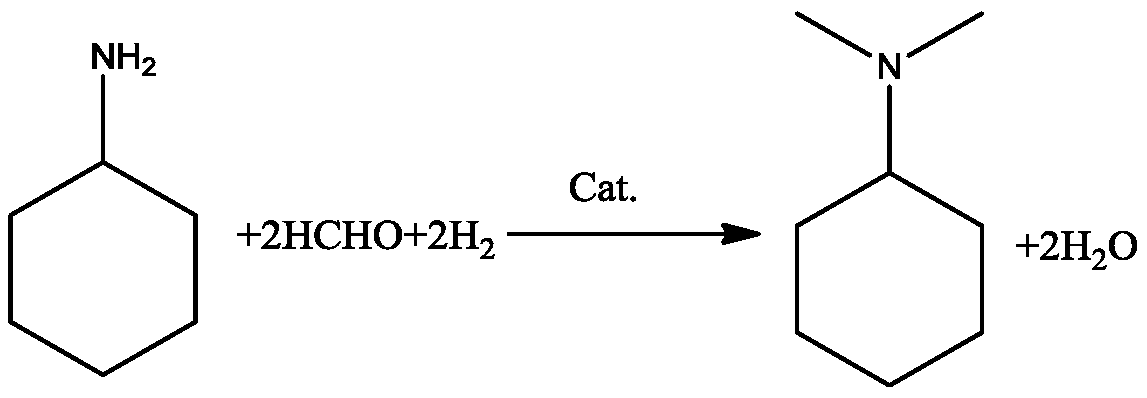

Method for preparing N,N-dimethyl cyclohexylamine

ActiveCN111333520ANot prone to side effectsSimple processAmino compound purification/separationMolecular sieve catalystsCyclohexylaminesCycleanine dimethobromide

The invention discloses a method for preparing N,N-dimethyl cyclohexylamine. The method comprises the following steps: (1) adding cyclohexylamine, a solvent and a supported palladium-based catalyst into a reaction kettle, slowly adding a formaldehyde aqueous solution into the reaction kettle, and carrying out a reaction at a certain reaction temperature under a certain hydrogen pressure; (2) afterthe formaldehyde is dropwise added, raising the reaction temperature to continue the reaction to obtain a N,N-dimethyl cyclohexylamine reaction liquid; and (3) carrying out high-temperature phase splitting on the reaction liquid to obtain an oil-phase crude product, and dehydrating and rectifying the oil-phase crude product to obtain the N,N-dimethylcyclohexylamine product. The method has the advantages of cheap and easily available raw materials, high product yield, high product purity, simple process and low production cost, and is suitable for industrial mass production.

Owner:WANHUA CHEM GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com