Loading flocculation pretreatment method of antibiotic fermentation wastewater

A technology for fermenting wastewater and antibiotics, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., which can solve the problems of substandard treatment, increasing the amount of flocculant added, and increasing treatment costs. , to achieve the effect of improving flocculation effect, improving removal efficiency and improving collision efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The wastewater in the terminal adjustment tank of antibiotic fermentation process in a pharmaceutical factory has a temperature of 36°C, a pH of 7.69, a COD of 11514mg / L, and a SS of 2355mg / L. The treatment process is as follows:

[0023] Disperse a certain amount of polyaluminum chloride in water to prepare a mixed solution with a mass concentration of 5%, and add the mixed solution to the waste water while stirring, so that the content of polyaluminum chloride in the waste water is 300mg / L, the stirring speed is 300r / min, and the stirring time is 10s.

[0024] Disperse a certain amount of polyacrylamide in water to prepare a mixed solution with a mass concentration of 0.1%, and add the above mixed solution to the above-mentioned waste water treated with polyaluminum chloride under stirring to make the polyacrylamide The content in the waste water is 2.5mg / L, the stirring speed is 300r / min, and the stirring time is 20s.

[0025] Take a certain amount of sedimentation...

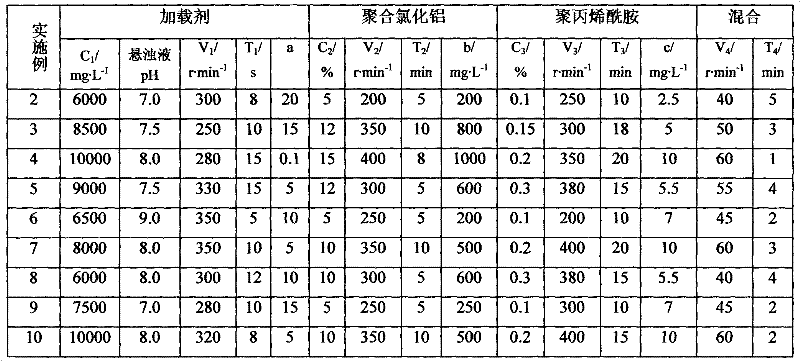

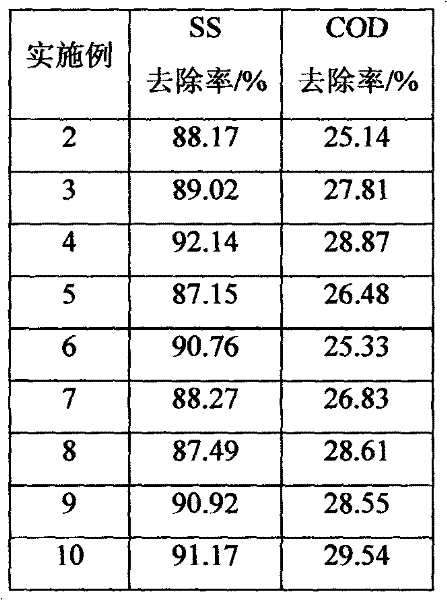

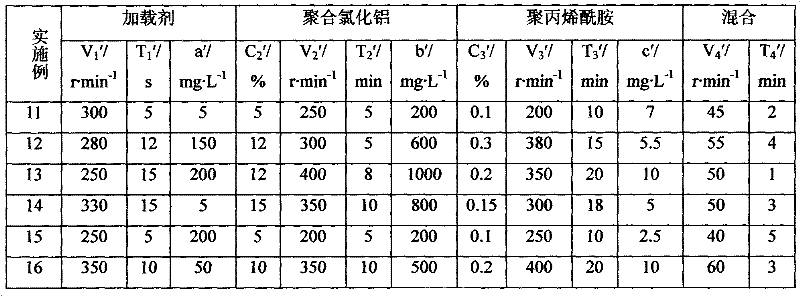

Embodiment 2~10

[0028] The waste liquid in the terminal adjustment tank of antibiotic fermentation process in a pharmaceutical factory has a temperature of 34°C, a pH of 7.06, a COD of 14264 mg / L, and a SS of 1724 mg / L. The treatment process is as follows:

[0029] Take a certain amount of loading agent, disperse it in water, and prepare the concentration as C 1suspension, adjust the pH of the suspension. Add the above-mentioned suspension to the waste liquid under the condition of stirring, the stirring speed is V 1 , the stirring time is T 1 . The volume ratio of waste liquid to suspension liquid is 100:a.

[0030] Disperse a certain amount of polyaluminum chloride in water to prepare a mass percentage of C 2 The mixed solution of polyaluminum chloride is added to the above-mentioned waste water treated with activated sludge under the condition of stirring, and the stirring speed is V 2 , the stirring time is T 2 . The amount of the polyaluminum chloride mixed solution is such that t...

Embodiment 8

[0035] The loading agent in Example 8 is activated sludge produced by biochemical treatment of the supernatant obtained by solid-liquid separation after flocculation treatment of antibiotic fermentation wastewater and sedimentation sludge obtained by solid-liquid separation after flocculation pretreatment of antibiotic fermentation wastewater. 1:1 ratio mixing;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com