Rare earth cationic-compound aluminium organic heteropolymeric flocculant

A cationic, composite aluminum technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, mining wastewater treatment, etc., can solve the problem of the amount of floating flocculant, etc., and achieve the effect of improving the flocculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

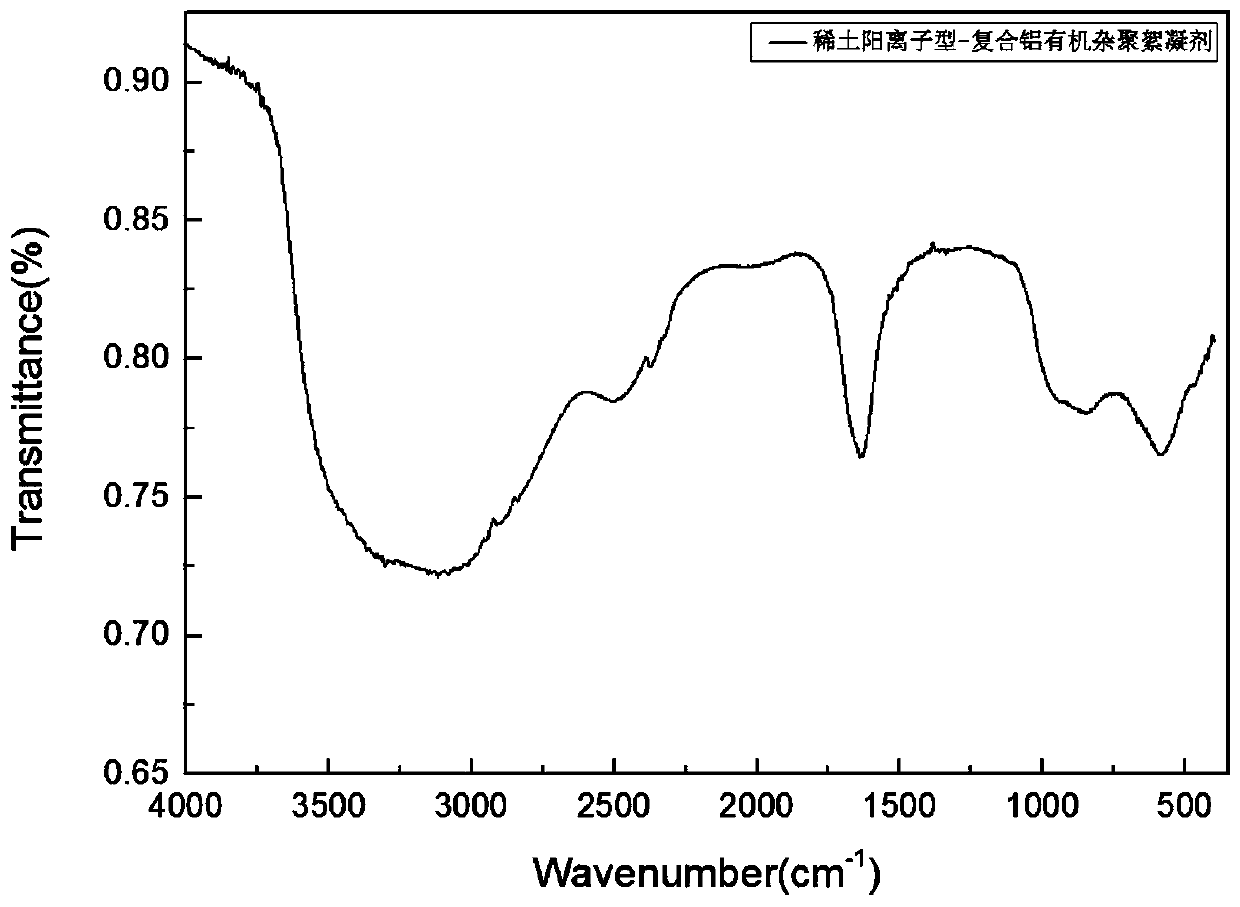

Image

Examples

Embodiment 1

[0032] 1. Raw material composition

[0033] In terms of mass components, 54.3 parts of aluminum chloride hexahydrate, 5.5 parts of rare earth chloride, 2.5 parts of sodium hydroxide, 8 parts of acrylamide, 4.8 parts of dimethyl diallyl ammonium chloride, 0.02 parts of ammonium persulfate, 0.012 parts of sodium bisulfite, 76 parts of water.

[0034] 2. Preparation steps

[0035] (1) Using a beaker, add 54.3 parts of aluminum chloride hexahydrate to 76 parts of water, and use a magnetic stirring paddle to stir for 10 minutes. After the aluminum chloride hexahydrate is completely hydrolyzed, the mark of dissolution is transparent and clear;

[0036] (2) After the dissolution of aluminum chloride hexahydrate is completed, 5.5 parts of rare earth chlorides are added to the above solution, and the hydrolysis of the rare earth chlorides is completed after continuing to stir for 10 minutes. The mark of the completion of the dissolution is that there is no solid in the solution;

[0...

Embodiment 2

[0045] 1. Raw material composition

[0046] In terms of mass components, 45.25 parts of aluminum chloride hexahydrate, 4.58 parts of rare earth chloride, 2.25 parts of sodium hydroxide, 8 parts of acrylamide, 3.2 parts of dimethyl diallyl ammonium chloride, 0.02 parts of ammonium persulfate, 0.012 parts of sodium bisulfite, 76 parts of water.

[0047] 2. Preparation steps

[0048](1) Using a beaker, add 45.25 parts of aluminum chloride hexahydrate to 76 parts of water, use a magnetic stirring paddle to stir for 10 minutes, and then completely hydrolyze the aluminum chloride hexahydrate;

[0049] (2) After the dissolution of aluminum chloride hexahydrate is completed, 4.58 parts of rare earth chlorides are added to the above solution, and the hydrolysis of rare earth chlorides is completed after continuing to stir for 10 minutes;

[0050] (3) Slowly add 2.25 parts of sodium hydroxide to the solution in step (2), while stirring, the addition time is 25 minutes, after the addit...

Embodiment 3

[0055] 1. Raw material composition

[0056] In terms of mass components, 36.2 parts of aluminum chloride hexahydrate, 3.7 parts of rare earth chloride, 2 parts of sodium hydroxide, 8 parts of acrylamide, 1.6 parts of dimethyl diallyl ammonium chloride, 0.02 parts of ammonium persulfate, 0.012 parts of sodium bisulfite, 76 parts of water.

[0057] 2. Preparation steps

[0058] (1) Using a beaker, add 36.2 parts of aluminum chloride hexahydrate to 76 parts of water, use a magnetic stirring paddle to stir for 10 minutes, and then completely hydrolyze the aluminum chloride hexahydrate;

[0059] (2) After the dissolution of aluminum chloride hexahydrate is completed, 3.7 parts of rare earth chlorides are added to the above solution, and the hydrolysis of the rare earth chlorides is completed after continuing to stir for 10 minutes;

[0060] (3) Slowly add 2 parts of sodium hydroxide to the solution in step (2), while stirring, the addition time is 20 minutes, after the addition i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com