Waste water treating method for methyl ethyl ketone production

A methyl ethyl ketone and wastewater technology, which is applied in biological water/sewage treatment, water/sewage treatment, sustainable biological treatment, etc., can solve the literature reports of no methyl ethyl ketone production discharge wastewater treatment method, the guiding significance is not strong, and the treatment effect is not good. and other problems, to achieve the effect of stable and reliable treatment effect, low equipment requirements and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

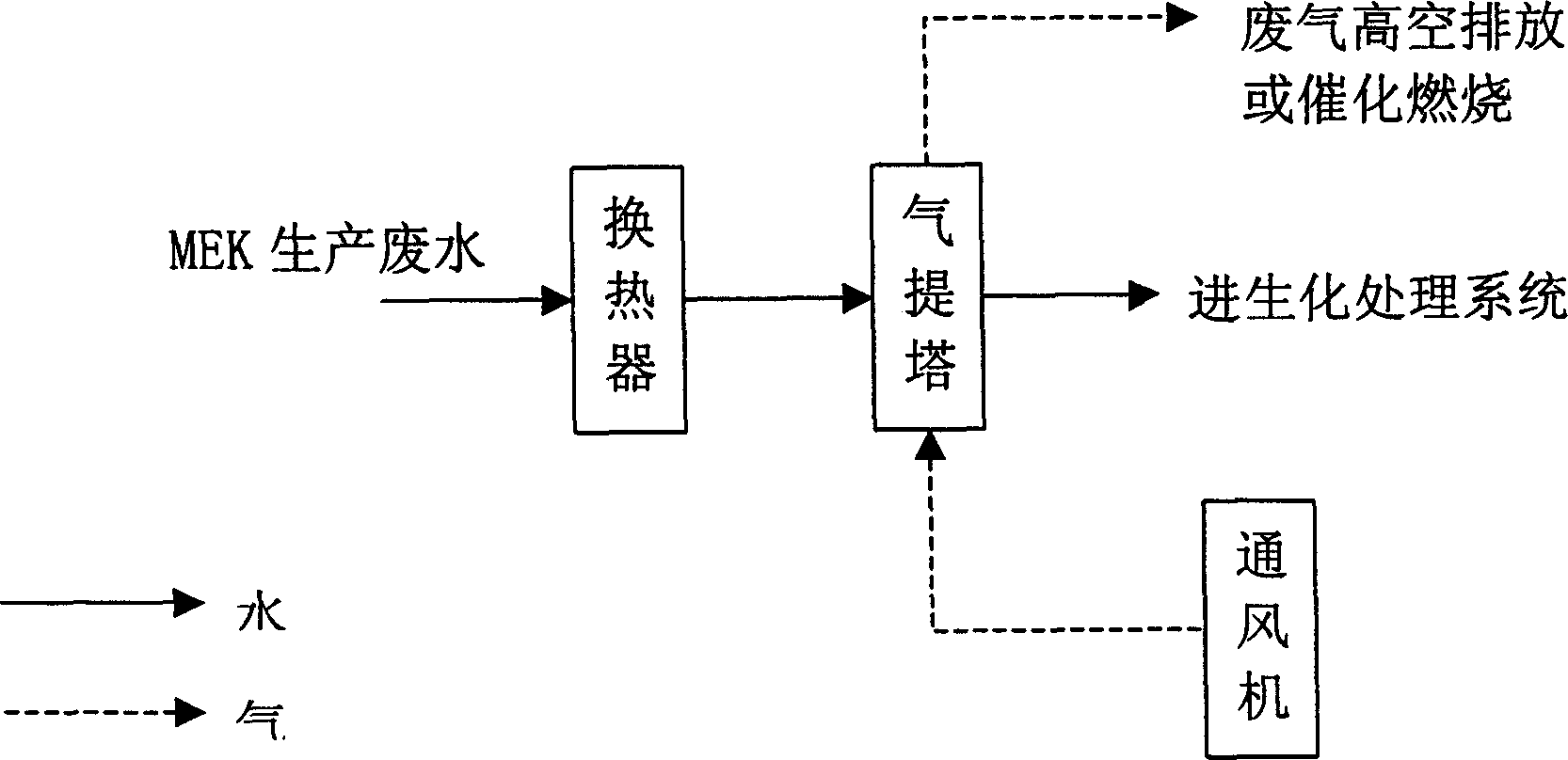

Method used

Image

Examples

Embodiment 1

[0029] The wastewater discharged from MEK production is heated to 50°C and then enters the stripping tower. The raw water CODcr is 14963mg / L. The waste water flows down from the top of the tower through the liquid distribution device, the air enters from the bottom of the tower, and the waste water spray density is 40m 3 / m 2 h, the gas-water ratio is 50, and the theoretical plate number of the stripper is 18.

[0030] After air stripping treatment, the CODcr of MEK production wastewater is reduced to 4300mg / L, reaching the pretreatment target.

[0031] After the air stripping treatment water is subjected to contact oxidation treatment, the CODcr of the effluent is reduced to 80mg / L, which meets the national secondary discharge standard.

Embodiment 2

[0033] The wastewater discharged from MEK production is heated to 90°C and then enters the stripping tower. The raw water CODcr is 14963mg / L. The waste water flows down from the top of the tower through the liquid distribution device, the air enters from the bottom of the tower, and the waste water spray density is 5m 3 / m 2 h, the gas-water ratio is 150, and the theoretical plate number of the stripper is 30.

[0034] After air stripping treatment, the CODcr of wastewater discharged from MEK production was reduced to 2100mg / L, reaching the pretreatment target.

[0035] After the air stripping treatment water is subjected to contact oxidation treatment, the CODcr of the effluent is reduced to 70mg / L, which meets the national secondary discharge standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com