Chemical synthesis pharmaceutical wastewater treatment system and treatment method

A wastewater treatment system and pharmaceutical wastewater technology, which is applied in chemical instruments and methods, special compound water treatment, natural water treatment, etc., can solve problems such as poor biodegradability, complex components, and difficult treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

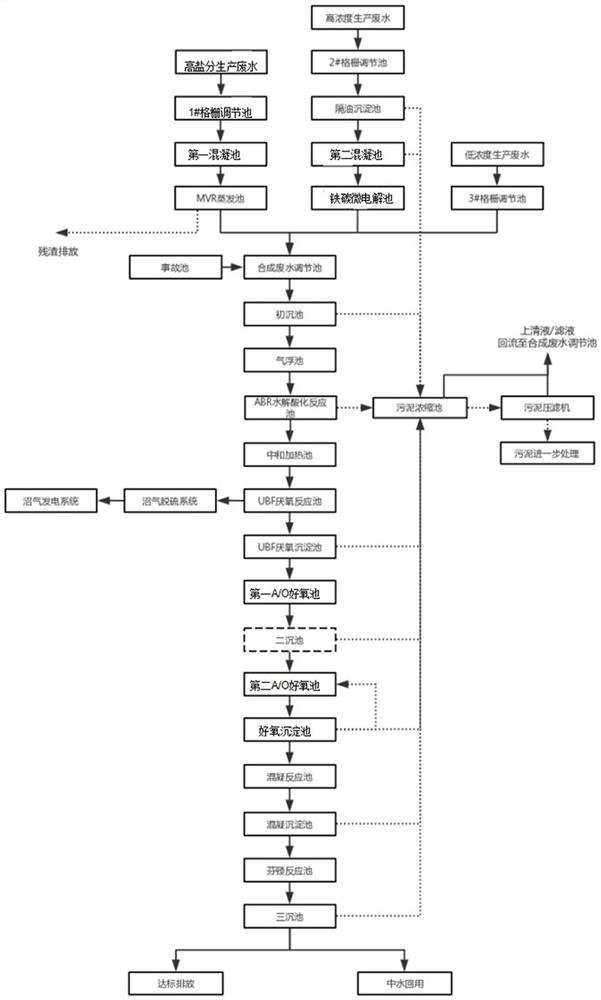

Image

Examples

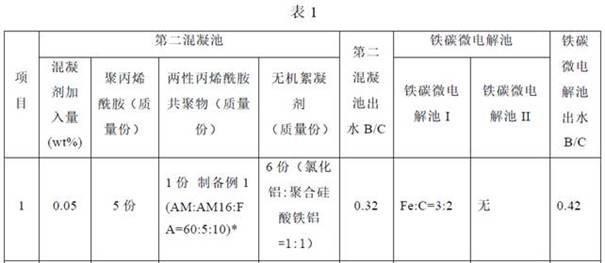

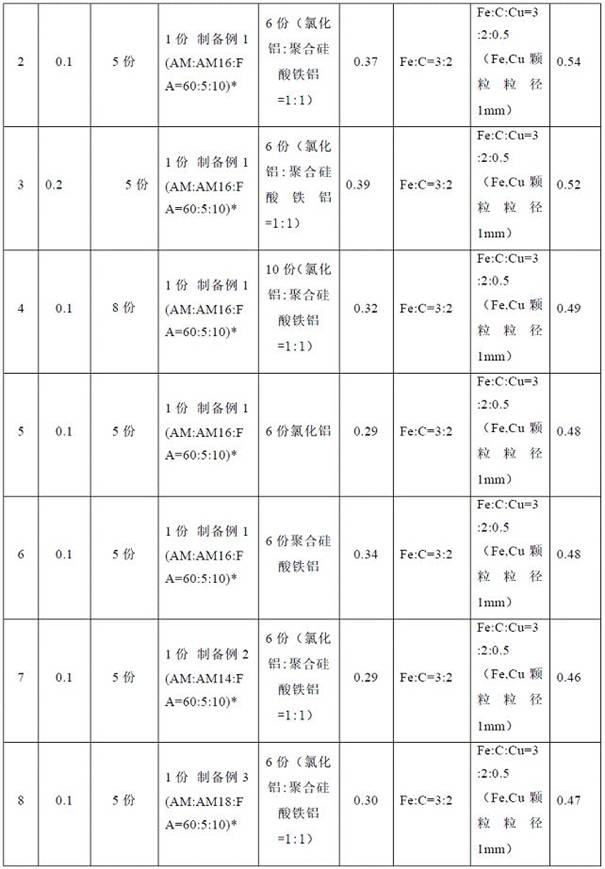

preparation example 1

[0051] Preparation Example 1 Use petroleum ether as the continuous phase and Tween 60: Span 40 = 1:1 as the compound emulsifier to prepare the oil phase. According to the mass ratio of acrylamide (AM): dimethylhexadecyl (2-methyl Acrylamidopropyl) ammonium bromide (AM16):fumaric acid (FA)=60:5:10 disperses the monomer in water, the total mass concentration of the monomer is controlled at 40wt%, and the aqueous phase is prepared.

[0052] Under the condition of stirring and nitrogen, slowly add the water phase into the oil phase, the volume ratio of the oil phase and the water phase is 1.7:1, raise the temperature to 50°C, and then add 0.7wt% of the total mass of the monomers Sodium bisulfate and peroxide According to the aqueous solution of the composite initiator of ammonium sulfate with a mass ratio of 1:2, heat preservation and react for 6h, cool to room temperature and discharge to obtain a solution of the copolymer, break the emulsion with ethanol, and wash with a solvent ...

preparation example 2

[0055] Other conditions and steps are the same as in Preparation Example 1, except that dimethyltetradecyl (2-methacrylamidopropyl) ammonium bromide (AM14) is used to replace dimethylhexadecyl (2-methyl Acrylamidopropyl) Ammonium Bromide (AM16).

preparation example 3

[0057] Other conditions and steps are the same as in Preparation Example 1, except that dimethyloctadecyl (2-methacrylamidopropyl) ammonium bromide (AM18) is used to replace dimethylhexadecyl (2-methyl Acrylamidopropyl) Ammonium Bromide (AM16).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com