Coal tar processing wastewater treatment method and system

A technology for processing wastewater and treatment methods, which is applied in the fields of degassed water/sewage treatment, extraction water/sewage treatment, neutralized water/sewage treatment, etc. The effect of convenience and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

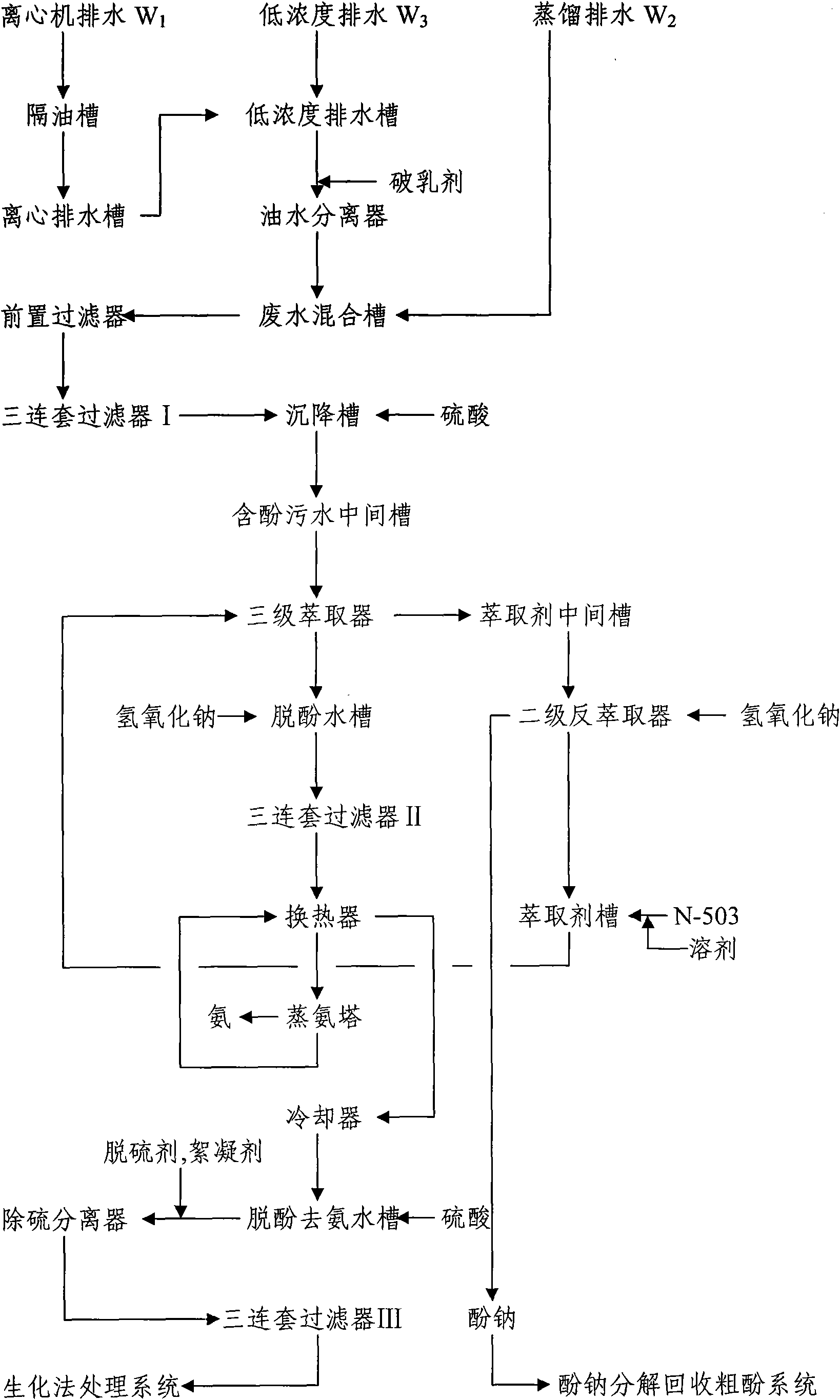

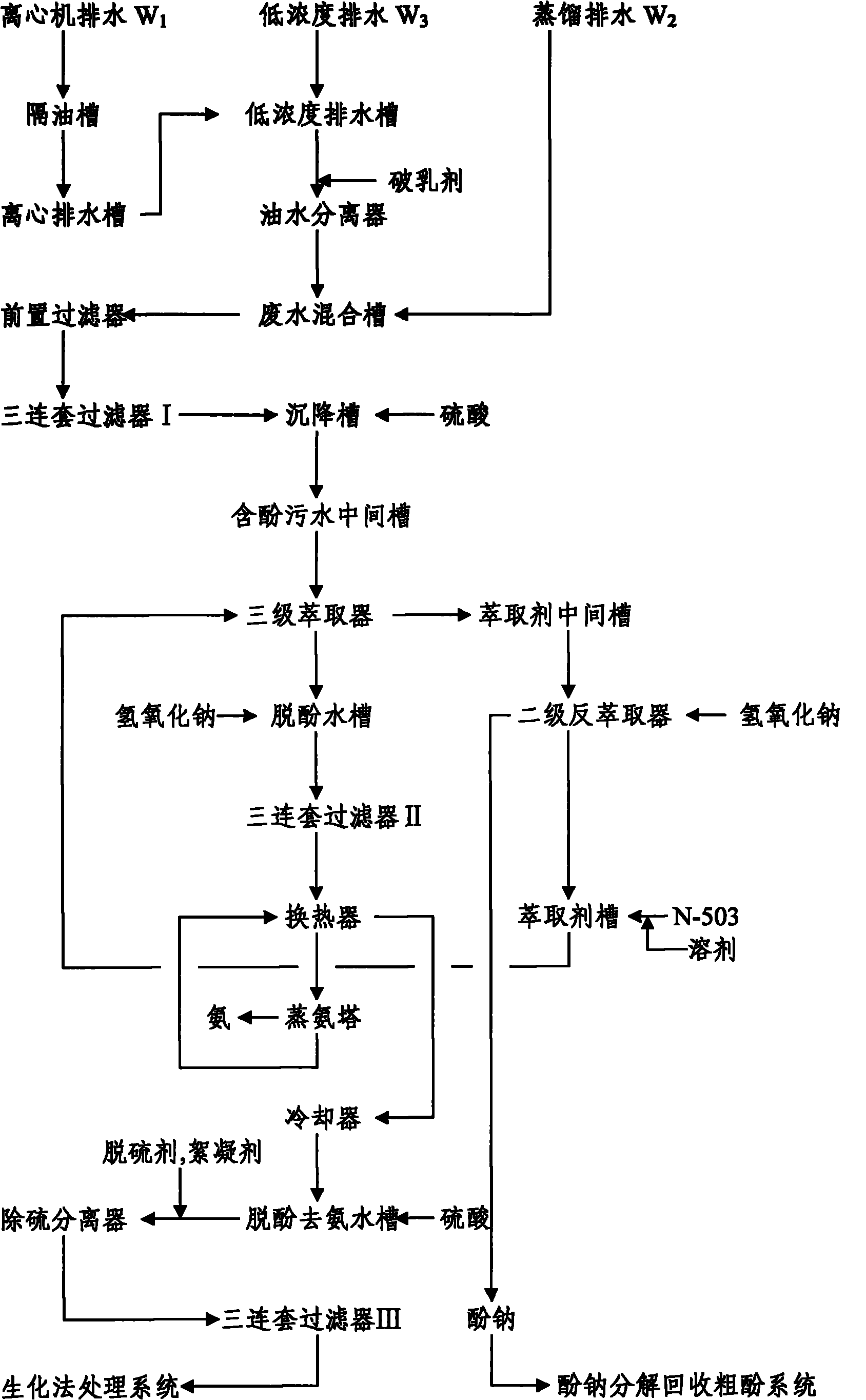

Image

Examples

Embodiment Construction

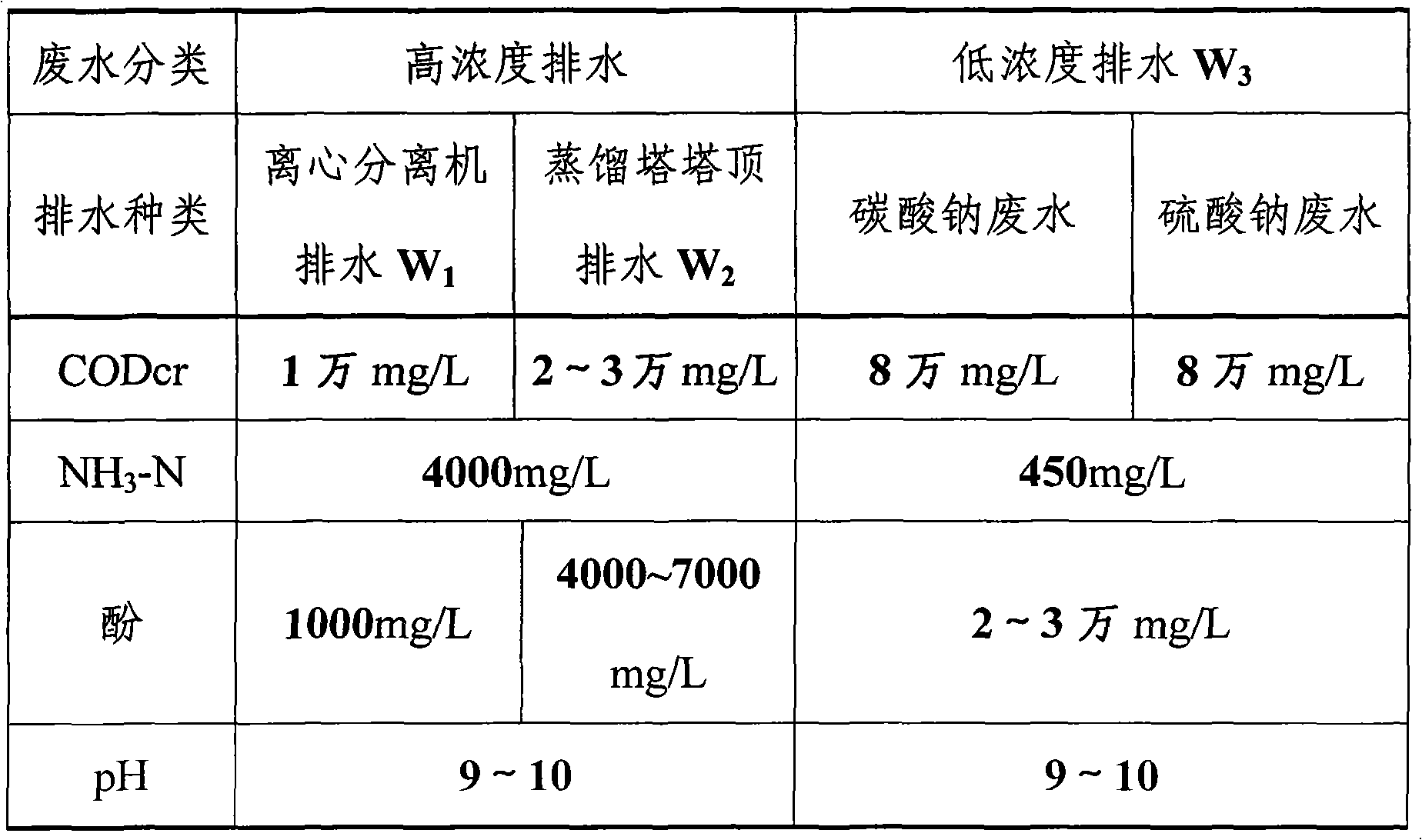

[0027] The treatment method and treatment system provided by the invention are used for treating the waste water produced in the coal tar processing process. The treatment method includes a physicochemical treatment process, preferably, a combination of physicochemical treatment and secondary biochemical treatment. Because the physicochemical treatment method has the characteristics of high pollutant removal efficiency and stable and reliable operation, but the operating cost is high; law is much lower. The invention creatively adopts the physicochemical method to pretreat the coal tar processing waste water to make it reach the acceptable level of the biochemical treatment, and then uses the biochemical method for further treatment to make it discharge up to the standard. There are many well-known methods and systems for biochemical treatment, which will not be repeated here. Only the physicochemical treatment method will be described in detail below.

[0028] It is well k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com