Biological film-film biological coupling sewage treatment device

A sewage treatment system and sewage technology, applied in the direction of biological water/sewage treatment, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve the problems of sewage treatment methods that need to be improved, so as to improve the efficiency of sewage treatment, increase the Large contact area, effect from a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

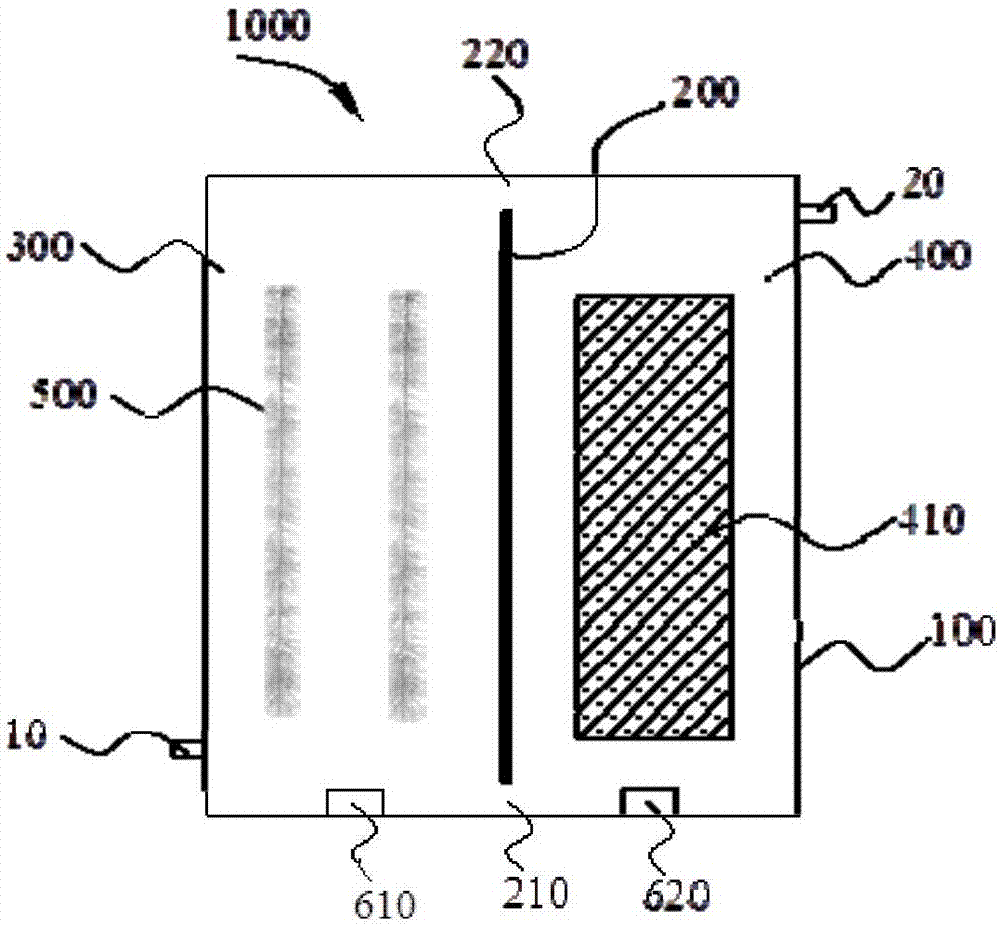

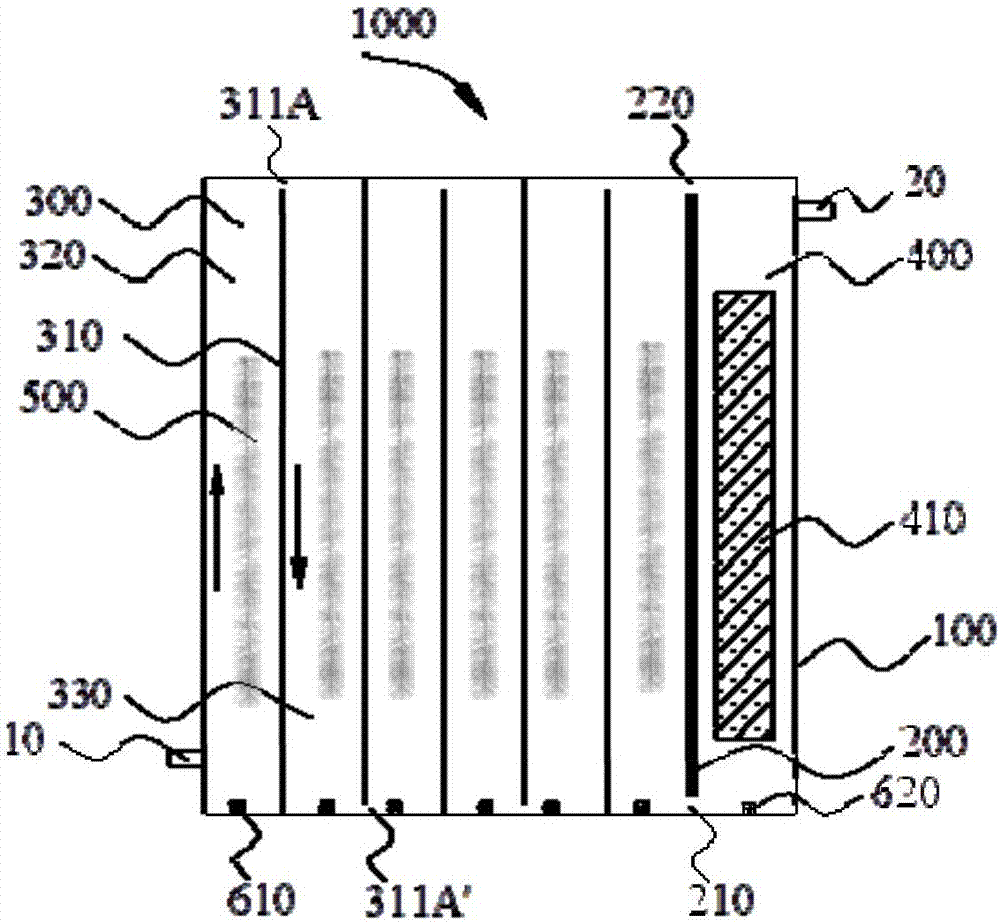

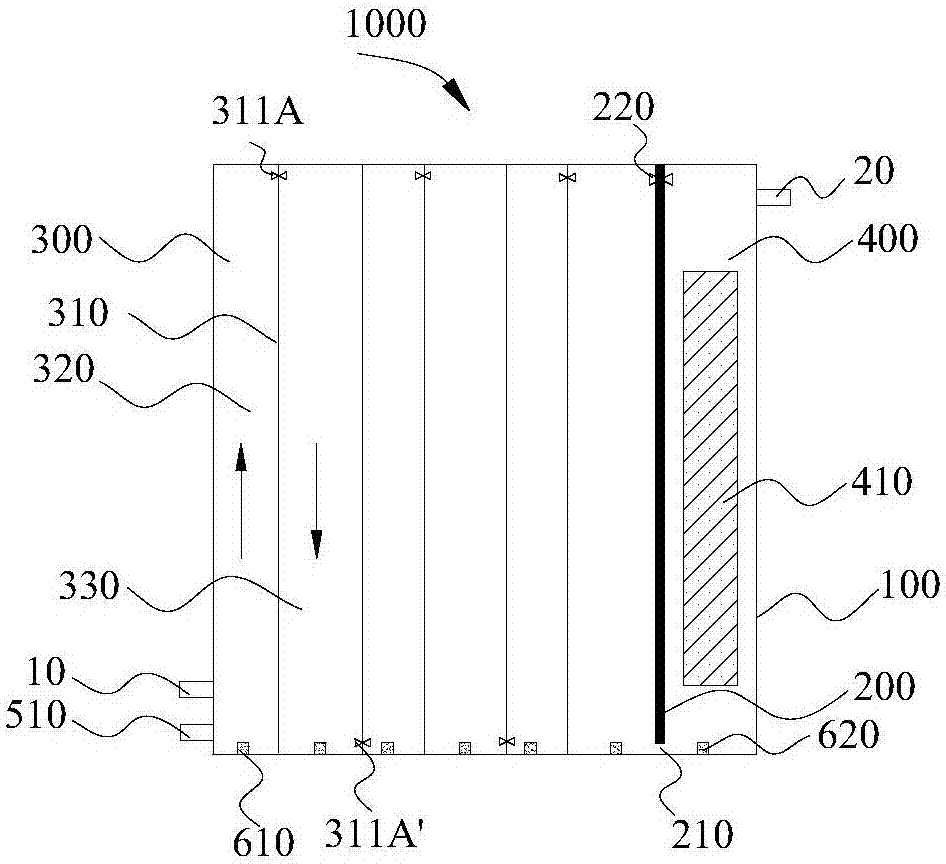

[0085] Can refer to Figure 7 process shown.

[0086] (1) Pump the sewage in the water inlet tank 700 to the water inlet 10 at the bottom of the housing 100 through the water inlet pump 710, and the water inlet flow rate is 0.2m 3 / h.

[0087] (2) The sewage flows through the upflow zone 320 and the downflow zone 330 in sequence. There is a perforated aeration pipeline 630 at the bottom of the upflow zone 320, and the air outlet 610 at the bottom of the upflow zone 320 is opened. The air-water lift force generated by aeration can push the water upward, and at the same time, the aeration can provide dissolved oxygen to the upflow zone 320 , when the water flow rises to the top of the upflow area 320, it can flow into the downflow area 330 through the water flow channel 311A, close the air outlet 610 at the bottom of the downflow area, and the water in the downflow area 330 flows to the bottom, and then passes through the water flow channel 311A there 'Enter the next upflow...

Embodiment 2

[0093] Pump the sewage in the water inlet tank 700 to any auxiliary water inlet 80 on the housing 100 through the water inlet pump 710, and close the water flow path between the top of the first partition near the front end of the auxiliary water inlet 80 and the housing 100 311. Refer to Embodiment 1 for other operating modes. In this embodiment, the minimum hydraulic retention time of the sewage can be as low as 3 hours.

Embodiment 3

[0095] Close the aeration pipe 630 and the aeration ports 610 corresponding to the first two upflow areas 320, and close all the air outlets 610 of the downflow areas 330, and pass the sewage in the terminal downflow area 330 through the backflow outlet 30 through the backflow pump Return to the return water inlet 40, or directly return to the water inlet 10, and refer to Embodiment 1 for other operating modes. In this embodiment, the distribution of dissolved oxygen in the biological reaction space 300 is adjusted through the aeration pipeline 630, the aeration ports 610 corresponding to the first two upflow areas 320 are closed, and the air outlets 610 of all downflow areas are closed , the first two upflow zones 320 and all downflow zones 330 are in anaerobic / anoxic state, therefore, microbial anaerobic and denitrification reactions can occur in them; aeration in the upflow zone at the end of the biological reaction space 300 If the port 610 is kept open, the corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com