Integrated gas internal circulating anaerobic baffle membrane bioreactor

A membrane bioreactor, anaerobic baffle technology, applied in anaerobic digestion treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problems of difficult management, long process flow, difficult treatment, etc. To achieve the effect of reducing the degree of membrane fouling, improving economy and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

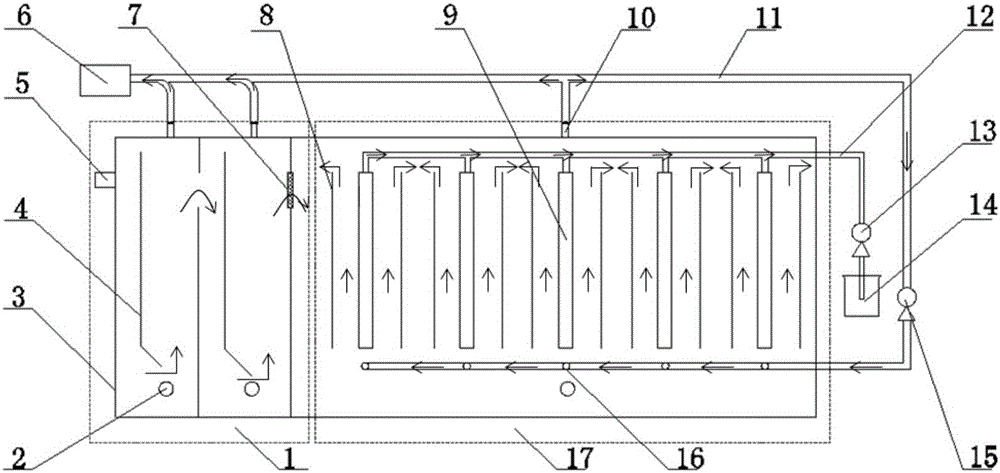

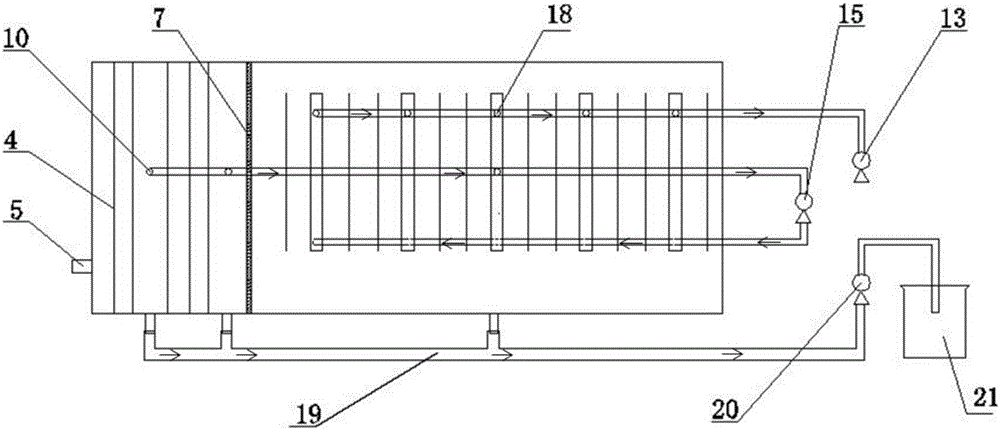

[0036] The integrated gas internal circulation anaerobic baffle membrane bioreactor is a cuboid, and the length ratio of the anaerobic baffle reaction zone to the anaerobic membrane bioreactor is 1:3.

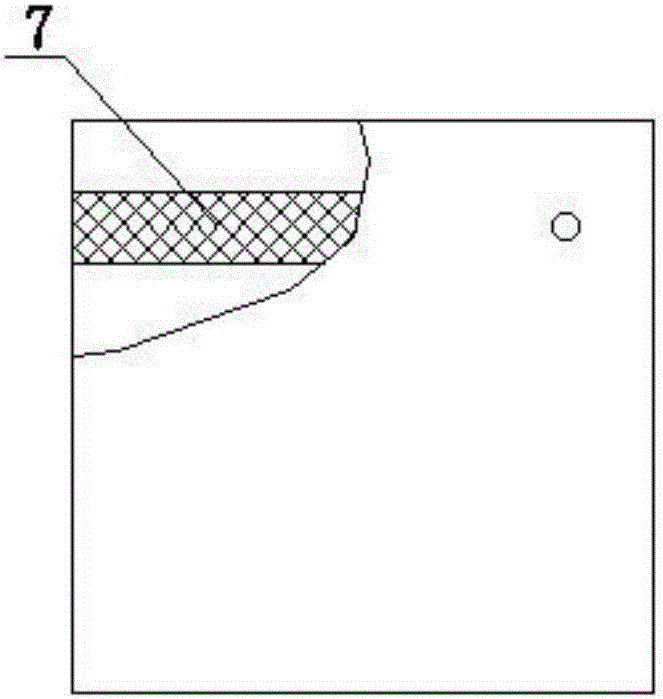

[0037] The anaerobic sludge is inoculated according to the different sludge concentrations in the anaerobic baffle reaction zone 1 and the anaerobic membrane biological reaction zone 17 . Pump the pig farm waste water (COD=10000-15000mg / L, SS=1000-2000mg / L) from the water inlet 5, pump it to the first compartment of the anaerobic baffle reaction zone 1, and then pass through the second compartment (each compartment passes through the downflow zone and upflow zone in turn), the removal rates of COD and SS are 90-93% and 75-80% respectively, that is, after COD and SS pass through the anaerobic baffle reaction zone, they enter the anaerobic The concentration of membrane bioreaction zone 17 is respectively 700-1500mg / L and 200-500mg / L; Pig farm waste water will pass through grid 7 ...

Embodiment 2

[0040]The integrated gas internal circulation anaerobic baffle membrane bioreactor is a cuboid, and the length ratio of the anaerobic baffle reaction zone to the anaerobic membrane bioreactor is 1:3.

[0041] The anaerobic sludge is inoculated according to the different sludge concentrations in the anaerobic baffle reaction zone 1 and the anaerobic membrane biological reaction zone 17 . Pump cattle farm wastewater (COD=20000-22000mg / L, SS=25000-28000mg / L) from water inlet 5, pump to the first compartment of anaerobic baffle reaction zone 1, and then pass through the second compartment (each compartment passes through the downflow zone and upflow zone in turn), the removal rates of COD and SS are 85-90% and 80-85% respectively, that is, after COD and SS pass through the anaerobic baffle reaction zone, they enter the anaerobic The concentration of membrane bioreaction zone 17 is 2000-3300mg / L and 3750-5600mg / L respectively; Cattle farm waste water will pass through grid 7 when e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com