Pretreatment method of two-stage enhanced coagulation deoiling for coal chemical industry wastewater

A technology for coal chemical wastewater and pretreatment, applied in mining wastewater treatment, water/sewage multi-stage treatment, water/sewage treatment and other directions, can solve the problems of complex operation, material blockage, easy entrainment and escape, etc., and achieves a clear process principle. Reasonable, low processing cost and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

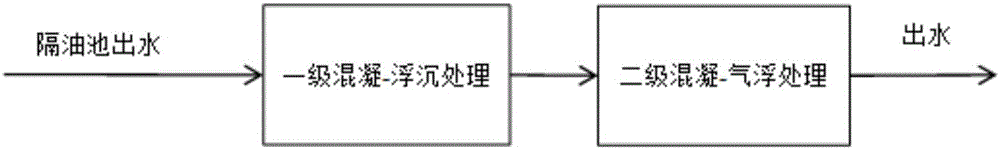

[0039] In this example, a certain coal-gas wastewater in Xinjiang is treated as the treatment object. The COD concentration in the treated wastewater is 17061mg / L, the TN concentration is 6992mg / L, the ammonia nitrogen concentration is 3135mg / L, the total oil concentration is 1496mg / L, and the pH value is 8.82. After gravity degreasing, the total oil concentration in the effluent water of the grease trap is 1284mg / L, and the total oil removal rate is 14.2%.

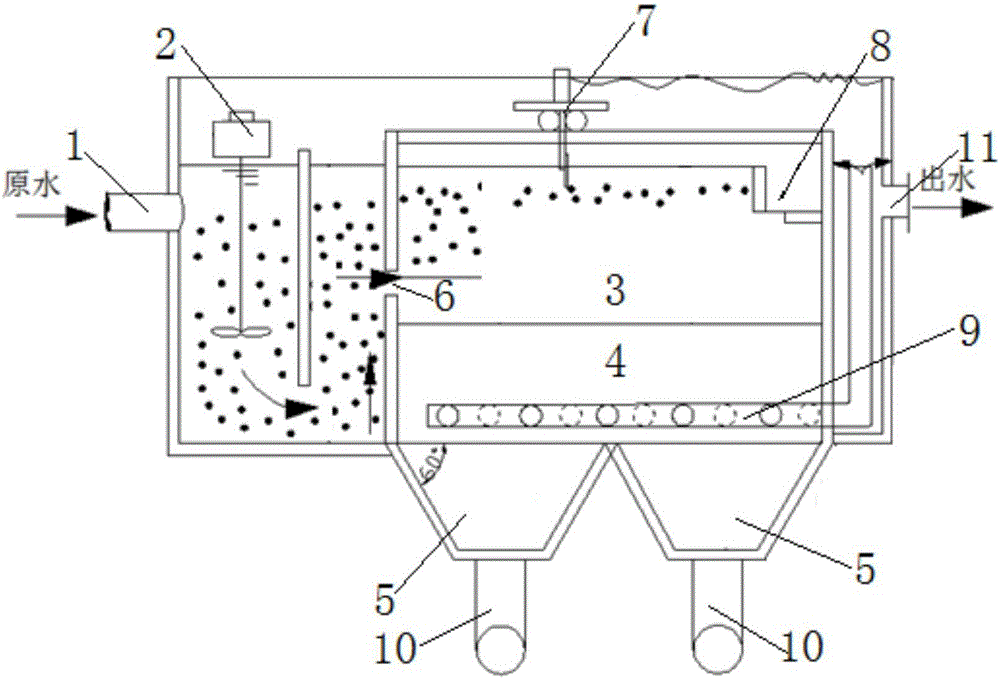

[0040] (1) Introduce the effluent from the grease trap into the first-level coagulation tank, and add inorganic polymer coagulant to the first-level coagulation tank to form small flocs, then add organic polymer flocculants to make the flocs larger , the effluent from the primary coagulation tank flows into the floating sink tank for oil and water separation;

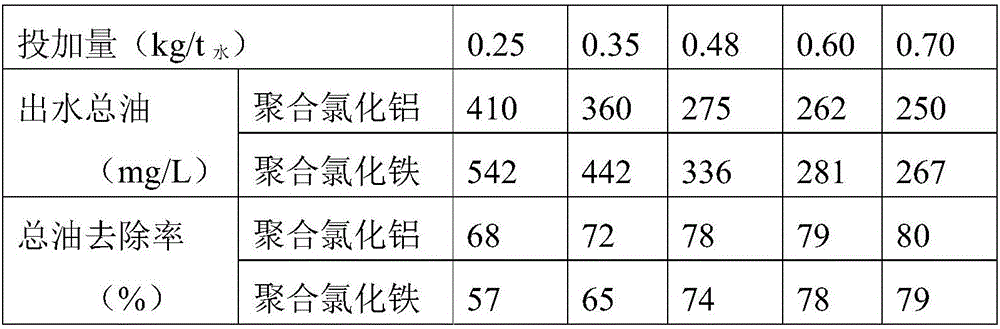

[0041] A. Examine the removal of COD and total oil by using polyaluminum chloride and polyferric chloride as coagulants under different dosage conditions. The res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com