Device and method for treating high-salinity wastewater containing phenol and aniline

A treatment method, high-salt wastewater technology, applied in biological treatment devices, chemical instruments and methods, special treatment targets, etc., can solve problems such as device leakage and blockage, strong corrosion of equipment, high salt content in wastewater, and achieve oil-water separation interface Clear, strong impact resistance, uniform aeration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

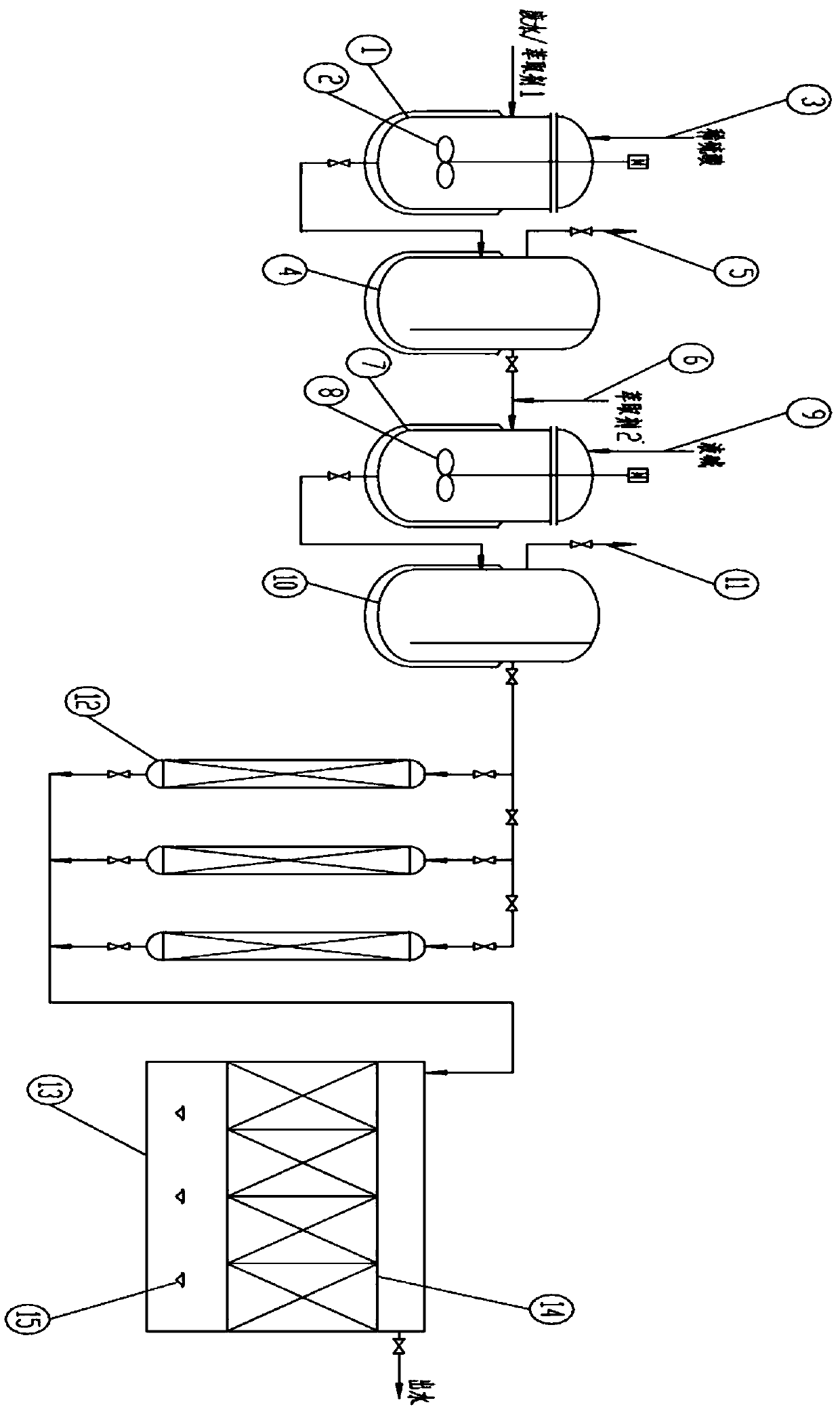

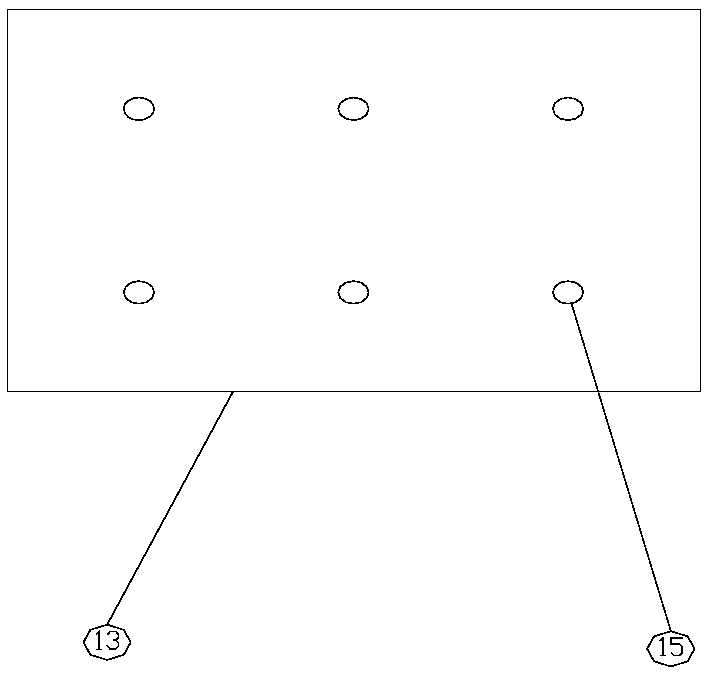

[0047] like figure 1 As shown, the device includes an extraction pretreatment unit, a resin adsorption unit and a high-salt biochemical system unit, wherein the extraction pretreatment unit includes No. 1 extraction kettle 1, No. 1 separation tank 4, No. 2 extraction kettle 7 and No. 2 separation tank 10, The resin adsorption unit includes a resin adsorption column device 12, and the high-salt biochemical system unit includes a high-salt biochemical device 13, packing 14, and aeration 15; the No. 1 extraction tank 1, No. 1 separation tank 4, and No. 2 extraction tank Kettle 7 and No. 2 separation tank 10, resin adsorption column device 12, and high-salt biochemical device 13 are connected in sequence through pipelines; the pipeline of No. 1 extraction kettle 1 is connected with the middle part of No. 1 separation tank 4, and the pipeline of No. 2 extraction kettle 7 It is connected with the middle part of No. 2 separation tank 10.

[0048] The primary extraction includes No. ...

Embodiment 2

[0058] The wastewater is taken from the regulating tank of a fine chemical production plant in Shandong. According to the staged production characteristics of the factory, the quality of the wastewater in the regulating tank will fluctuate to a certain extent over time. The 2,6-dichlorotoluene replaced the wastewater. The wastewater manufacturer had removed the copper ions in the wastewater by ion exchange process. The pH value was 4-5, TOC 3122mg / L, phenol 1630mg / L, aniline 1261mg / L, salt The concentration is 78056mg / L.

[0059] The preparation of extractant 1: based on the total weight percentage of extractant 1, 10% of tetradecylamine, 15% of isomeric 22 alcohol, and the balance is aviation kerosene; the preparation of extractant 2: based on the total weight percentage of extractant 2 , 15% of P204, 15% of isomerized 20 alcohol, and the balance is aviation kerosene.

[0060] The above treatment process,

[0061] (1) Extraction pretreatment unit:

[0062] ① Put the waste ...

Embodiment 3

[0075] The wastewater is taken from the regulating tank of a fine chemical production plant in Shandong. According to the staged production characteristics of the factory, the quality of the wastewater in the regulating tank will fluctuate to a certain extent over time. The 2,6-dichlorotoluene replaced the wastewater. The wastewater manufacturer had removed the copper ions in the wastewater by ion exchange process, the pH value was 4-5, TOC 2764mg / L, phenol 1430mg / L, aniline 1031mg / L, salt The concentration is 73220mg / L.

[0076] The preparation of extractant 1: based on the total weight percentage of extractant 1, 10% of tetradecylamine, 15% of isomeric 22 alcohol, and the balance is aviation kerosene; the preparation of extractant 2: based on the total weight percentage of extractant 2 , 15% of P204, 15% of isomerized 20 alcohol, and the balance is aviation kerosene.

[0077] The above treatment process,

[0078] (1) Extraction pretreatment unit:

[0079] ① Put the waste ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com