Method for extracting gold from alkaline cyanide solution

An extraction and alkaline technology, applied in the field of gold extraction, can solve the problems of easy failure, high price of reversed-phase bonded silica gel, and difficult cost, and achieve the effects of low organic solvent consumption, easy operation and automation, and low pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

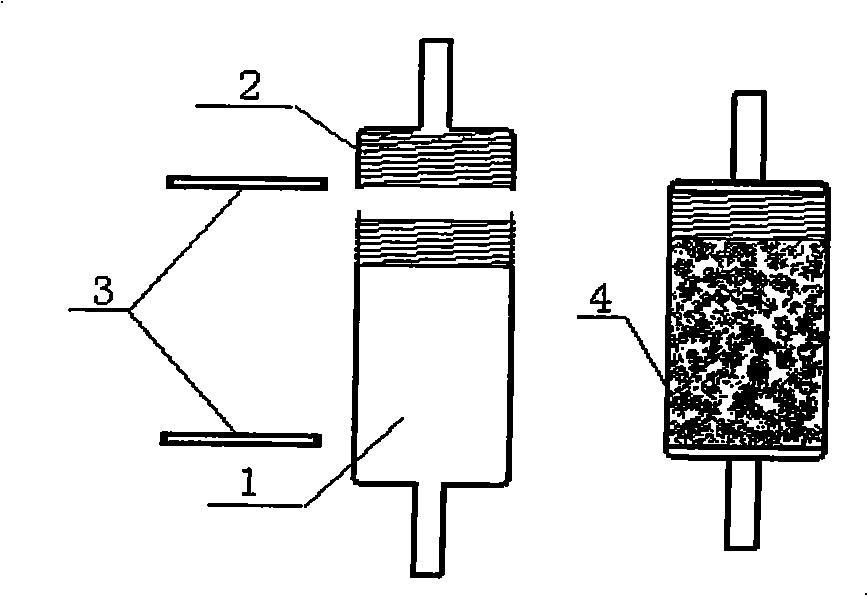

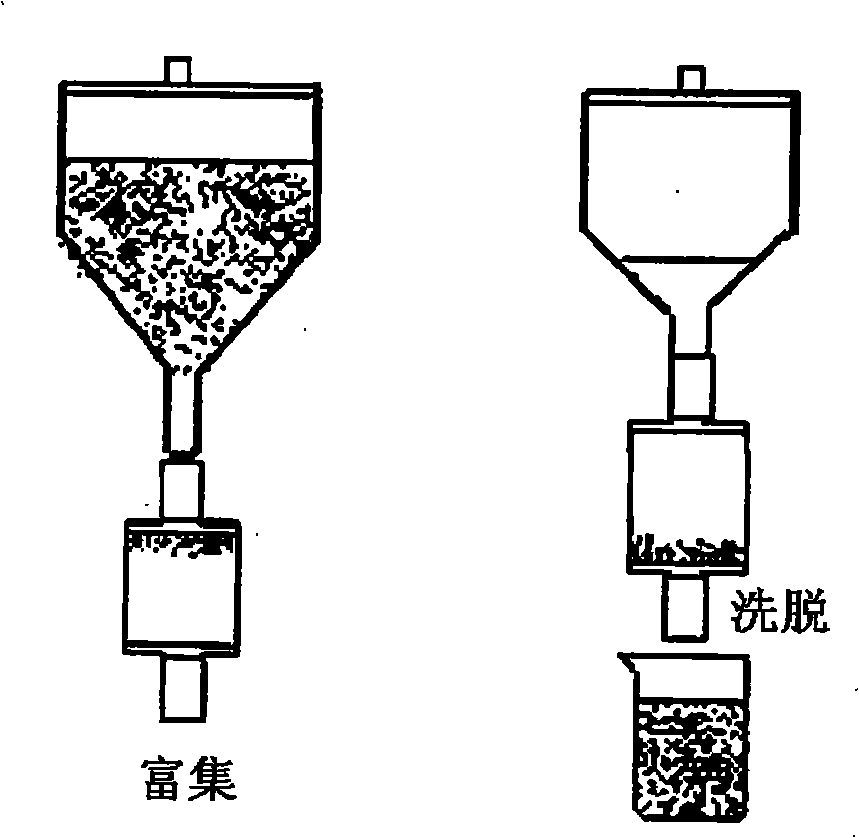

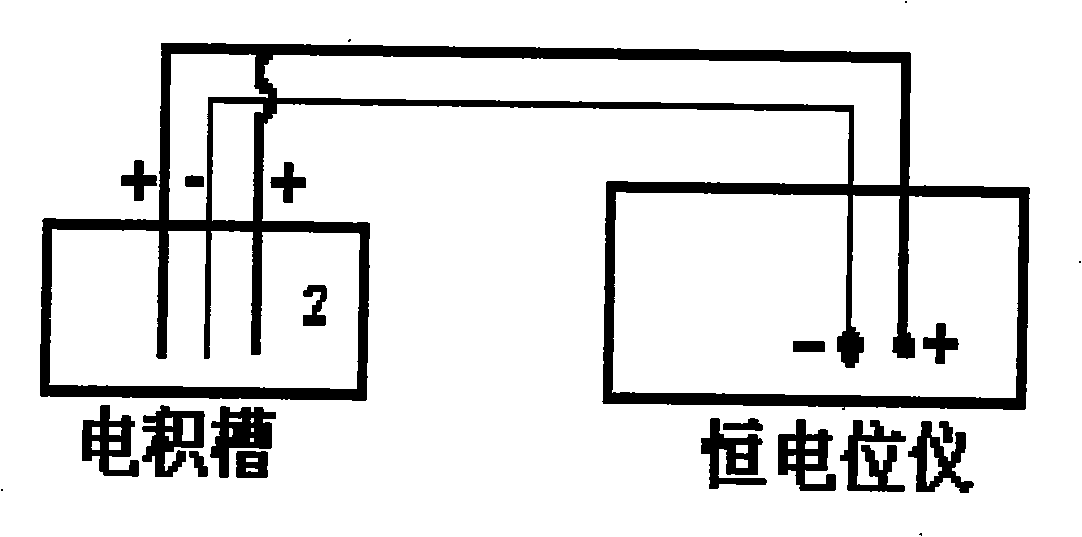

[0026] Extraction of gold from alkaline cyanide solution. Weigh the porous graphitized carbon black of 100g particle size 30 μm and place in a 500mL dry beaker, add 50mL of 10% (m / v) dihexadecyldimethylammonium chloride acetone solution under constant stirring, Evaporate to dryness in a water bath at 65°C to obtain graphitized carbon black loaded with dihexadecyldimethyl. The specification of the solid phase extraction column is 20×25mm, and the filling material is 8.2g (see figure 1 ). Install a sieve plate at one end of the filling tube, load graphitized carbon black with dihexadecyl dimethyl and compact it, then install a sieve plate at the other end, and tighten the column cap. The extraction cartridge was washed with dilute sodium hydroxide at pH 9.4. Solid phase extraction (see figure 2 ): Prepare KAu(CN) 2 The solution, with a concentration of 2 mg / L, was adjusted to a pH of 9.4, enriched by a solid-phase extraction column at a flow rate of 10 mL / min, and then elu...

Embodiment 2

[0029] Example 1 was repeated with the following difference: the particle size of the porous graphitized carbon black was 45 μm. The surfactant is octadecyltrimethylammonium chloride. Evaporate to dryness in a 60°C water bath with stirring. Solid phase extraction column specifications: 8mm diameter x 10mm column length, 0.5g packing. The extraction cartridge was washed with dilute sodium hydroxide at pH 11. Prepare KAu(CN) with a concentration of 15mg / L 2 The solution was adjusted to have a pH of 11, enriched by a solid-phase extraction column at a flow rate of 50 mL / min, and then eluted in the reverse direction at a flow rate of 30 mL / min with 300 mL of eluent.

Embodiment 3

[0031] Example 1 was repeated with the following difference: the particle size of the porous graphitized carbon black was 60 μm. The surfactant is octadecyl dimethyl benzyl ammonium chloride. The specification of the solid phase extraction column is 12mm diameter × 15mm, and the filling material is 200g. The extraction cartridge was washed with dilute sodium hydroxide at pH 13. Prepare KAu(CN) with a concentration of 24mg / L 2 The solution was adjusted to have a pH of 13, enriched by a solid-phase extraction column at a flow rate of 100 mL / min, and then eluted in the reverse direction at a flow rate of 50 mL / min with 500 mL of eluent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com