Application of a High Efficiency Inhibitor 5′-atp-2na in Decalcification of Magnesite by Positive Flotation

A technology of -atp-2na and magnesite, applied in flotation, solid separation, etc., can solve the problem of hindering the comprehensive utilization of low-grade magnesite, high calcium content of magnesite concentrate products, and magnesite flotation Calcium difficulty and other problems, to achieve good industrial feasibility, reduce calcium content, easy operation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

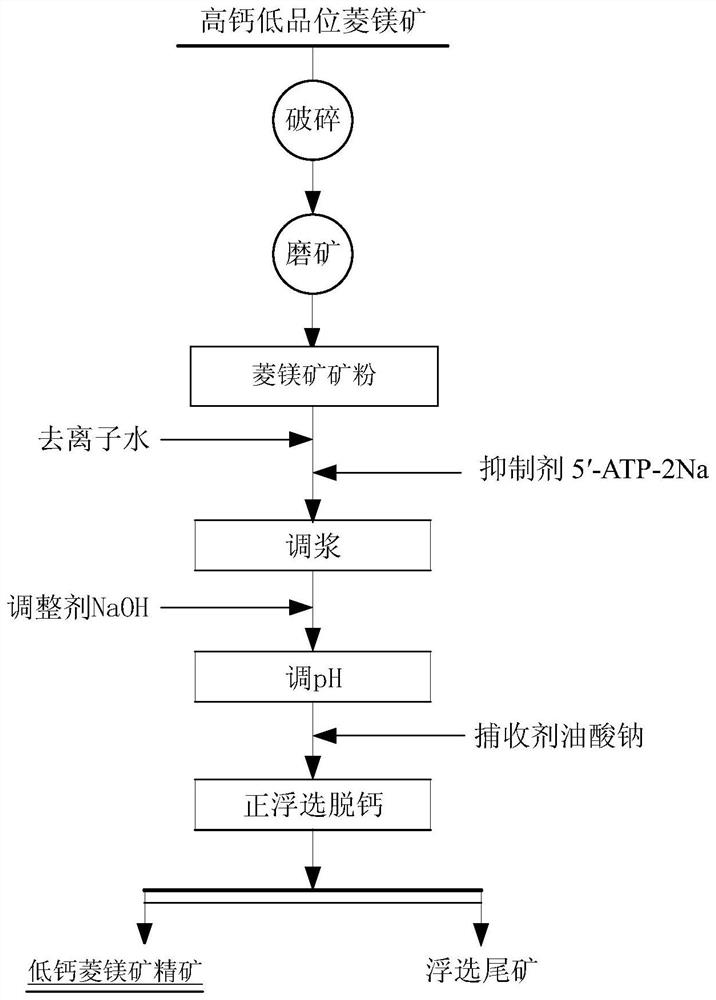

[0042] The application of a highly effective inhibitor 5′-ATP-2Na in the positive flotation decalcification of magnesite, the schematic diagram of the process is shown in figure 1 , including the following steps:

[0043] Step 1: Grinding

[0044] The high-calcium and low-grade magnesite ore blocks are crushed by a roller crusher to a particle size of less than 2 mm, and ball milled by a ceramic ball mill to obtain magnesite ore powder; among them, for Magnesite ore powder, the mass of magnesite particles smaller than 74μm accounts for 70% of the total mass of magnesite ore powder;

[0045] Step 2: Blending

[0046] Place the above-mentioned magnesite ore powder in the flotation cell of a single-cell flotation machine, add deionized water and a molar concentration of 0.015mol / L inhibitor 5'-ATP-2Na solution, and stir for 3 minutes to mix evenly, and carry out Slurry adjustment to obtain magnesite pulp; wherein, for magnesite pulp, the mass percent concentration of magnesite...

Embodiment 2

[0054] A kind of application of efficient inhibitor 5'-ATP-2Na in magnesite positive flotation decalcification, comprises the following steps:

[0055] Step 1: Grinding

[0056] The high-calcium and low-grade magnesite ore blocks are crushed by a roller crusher to a particle size of less than 2 mm, and ball milled by a ceramic ball mill to obtain magnesite ore powder; among them, for Magnesite ore powder, the mass of magnesite particles smaller than 74μm accounts for 75% of the total mass of magnesite ore powder;

[0057] Step 2: Blending

[0058] Place the above-mentioned magnesite ore powder in the flotation cell of a single-cell flotation machine, add deionized water and a molar concentration of 0.02mol / L inhibitor 5'-ATP-2Na solution, and stir for 3 minutes to mix evenly, and carry out Slurry adjustment to obtain magnesite pulp; wherein, for magnesite pulp, the mass percent concentration of magnesite solids is 20%; the amount of added inhibitor 5'-ATP-2Na accounts for th...

Embodiment 3

[0065] A kind of application of efficient inhibitor 5'-ATP-2Na in magnesite positive flotation decalcification, comprises the following steps:

[0066] Step 1: Grinding

[0067] The high-calcium and low-grade magnesite ore blocks are crushed by a roller crusher to a particle size of less than 2 mm, and ball milled by a ceramic ball mill to obtain magnesite ore powder; among them, for Magnesite ore powder, the mass of magnesite particles smaller than 74μm accounts for 80% of the total mass of magnesite ore powder;

[0068] Step 2: Blending

[0069] Put the above-mentioned magnesite ore powder in the flotation cell of a single-cell flotation machine, add deionized water and a molar concentration of 0.018mol / L inhibitor 5'-ATP-2Na solution, and stir for 3 minutes to mix evenly, and carry out Slurry is adjusted to obtain magnesite pulp; wherein, for magnesite pulp, the mass percent concentration of magnesite solids is 20%; the amount of adding inhibitor 5 '-ATP-2Na accounts for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com