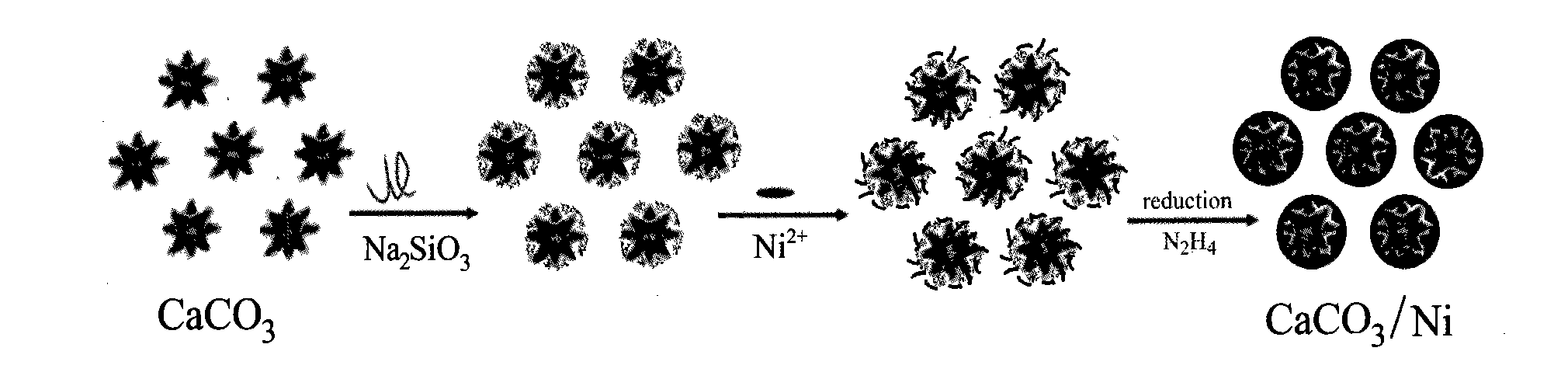

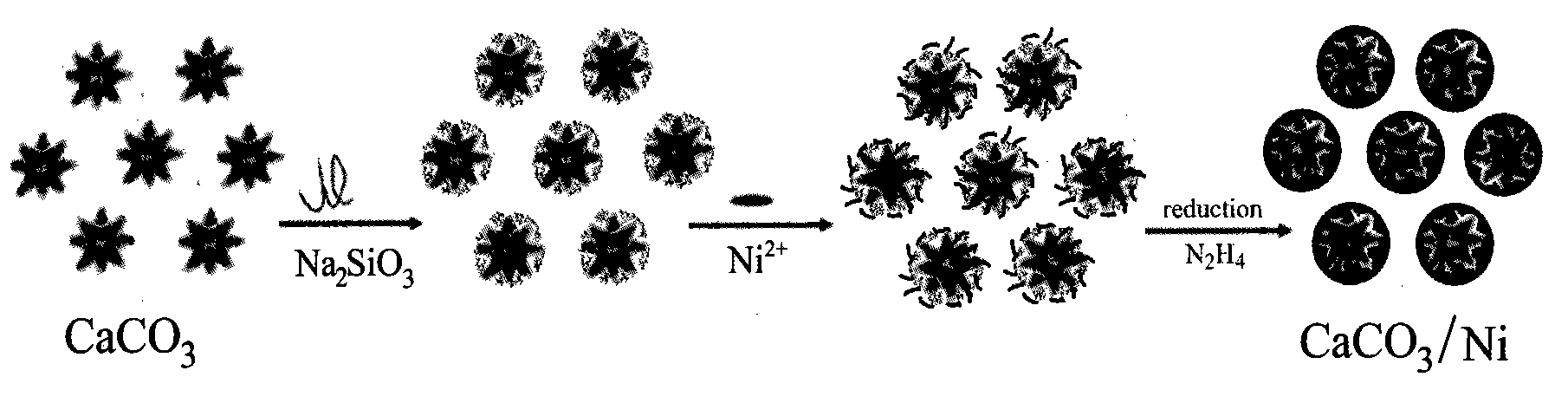

Calcium carbonate/nickel composite conductive powder and preparation method thereof

A technology of composite conductive powder and calcium carbonate, which is applied in the direction of conductors, conductive materials, conductive materials, etc., can solve problems such as insufficient nickel resource reserves, and achieve the effects of increasing economic added value, increasing thickness, and stabilizing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take 10 g of calcium carbonate nano-assembled spheres, add 0.1 mL of 5% sodium silicate aqueous solution as a coupling agent, and then add 2 mol / L of NiSO 4 ·6H 2 O solution 50mL, stir 10min, allow nickel ion to be adsorbed by calcium carbonate, fully let stand and make it reach adsorption saturation; The density of hydrazine hydrate is 1.03g / mL, according to the quality that adds hydrazine hydrate is 30g and takes by weighing hydrazine hydrate 29mL, to Add dropwise to the system, keep the system temperature at 70°C, use NaOH solution to adjust and keep the system pH=14, carry out the in-situ reduction reaction of the adsorbed nickel ions, and coat the surface of calcium carbonate; after the system is fully reacted, The obtained product is suction filtered, washed and dried to obtain black calcium carbonate / nickel composite conductive powder; the product has good conductivity and dispersibility, and the resistivity is about 150Ω / cm.

Embodiment 2

[0033] Take 10 g of calcium carbonate nano-assembled spheres, add 0.5 mL of 5% sodium silicate aqueous solution as a coupling agent, and then add 2 mol / L of NiSO 4 ·6H 2 O solution 100mL, stir 10min, allow nickel ion to be adsorbed by calcium carbonate, fully let stand and make it reach adsorption saturation; The density of hydrazine hydrate is 1.03g / mL, according to the quality that adds hydrazine hydrate is 12g, takes by weighing hydrazine hydrate 12mL, to Add dropwise to the system, keep the system temperature at 70°C, use NaOH solution to adjust and keep the system pH=14, carry out the in-situ reduction reaction of the adsorbed nickel ions, and coat the surface of calcium carbonate; after the system is fully reacted, The obtained product is suction filtered, washed and dried to obtain black calcium carbonate / nickel composite conductive powder; the product has good conductivity and dispersibility, and the resistivity is about 120Ω / cm.

Embodiment 3

[0035] Take 10 g of calcium carbonate nano-assembled spheres, add 1.0 mL of 5% sodium silicate aqueous solution as a coupling agent, and then add 2 mol / L of NiCl 2 ·6H 2O solution 40mL, stir 10min, allow nickel ion to be adsorbed by calcium carbonate, fully let it stand and make it reach adsorption saturation; The density of hydrazine hydrate is 1.03g / mL, according to the quality that adds hydrazine hydrate is 50g and takes by weighing hydrazine hydrate 49mL, to Add dropwise to the system, keep the system temperature at 90°C, use NaOH solution to adjust and keep the system pH = 13, carry out the in-situ reduction reaction of the adsorbed nickel ions, and coat the surface of calcium carbonate; after the system is fully reacted, The obtained product is suction filtered, washed and dried to obtain black calcium carbonate / nickel composite conductive powder; the product has good conductivity and dispersibility, and the resistivity is about 250Ω / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com