Biologic polycarbonate and preparation method thereof

A polycarbonate, bio-based technology, applied in the direction of fatty acid preparation/refining, fatty acid esterification, fatty acid production, etc., can solve the problems of insufficient environmental protection, etc., to achieve increased specific gravity, good flexibility and biodegradability, process can be highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

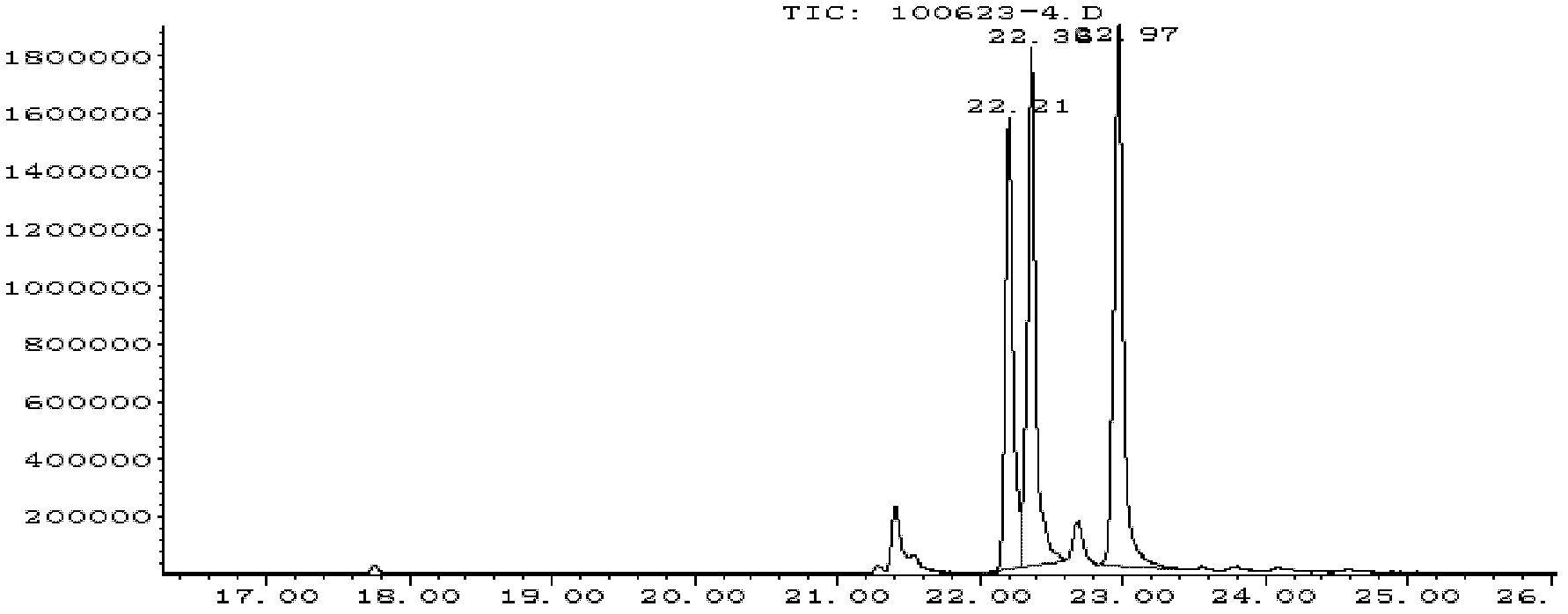

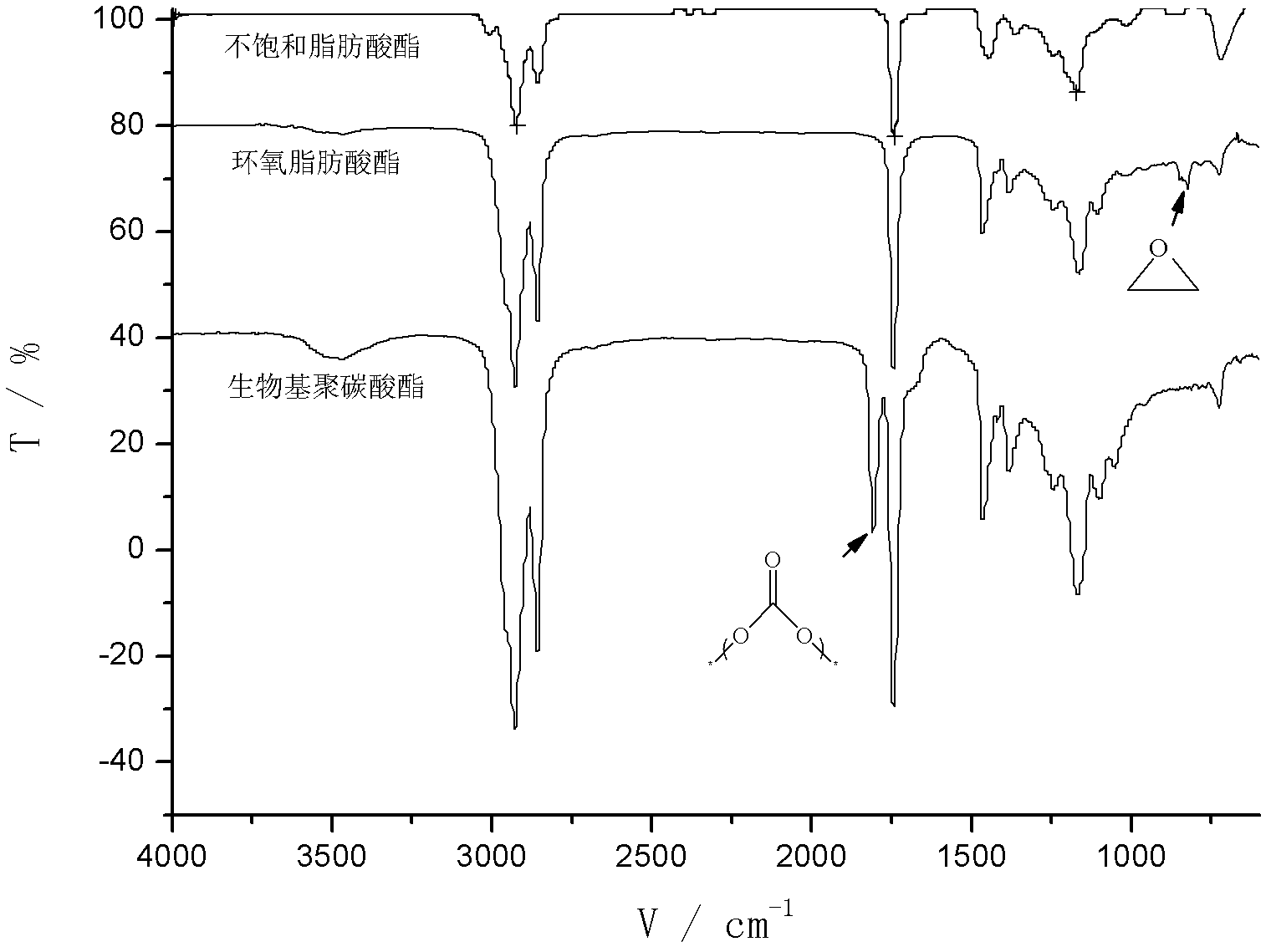

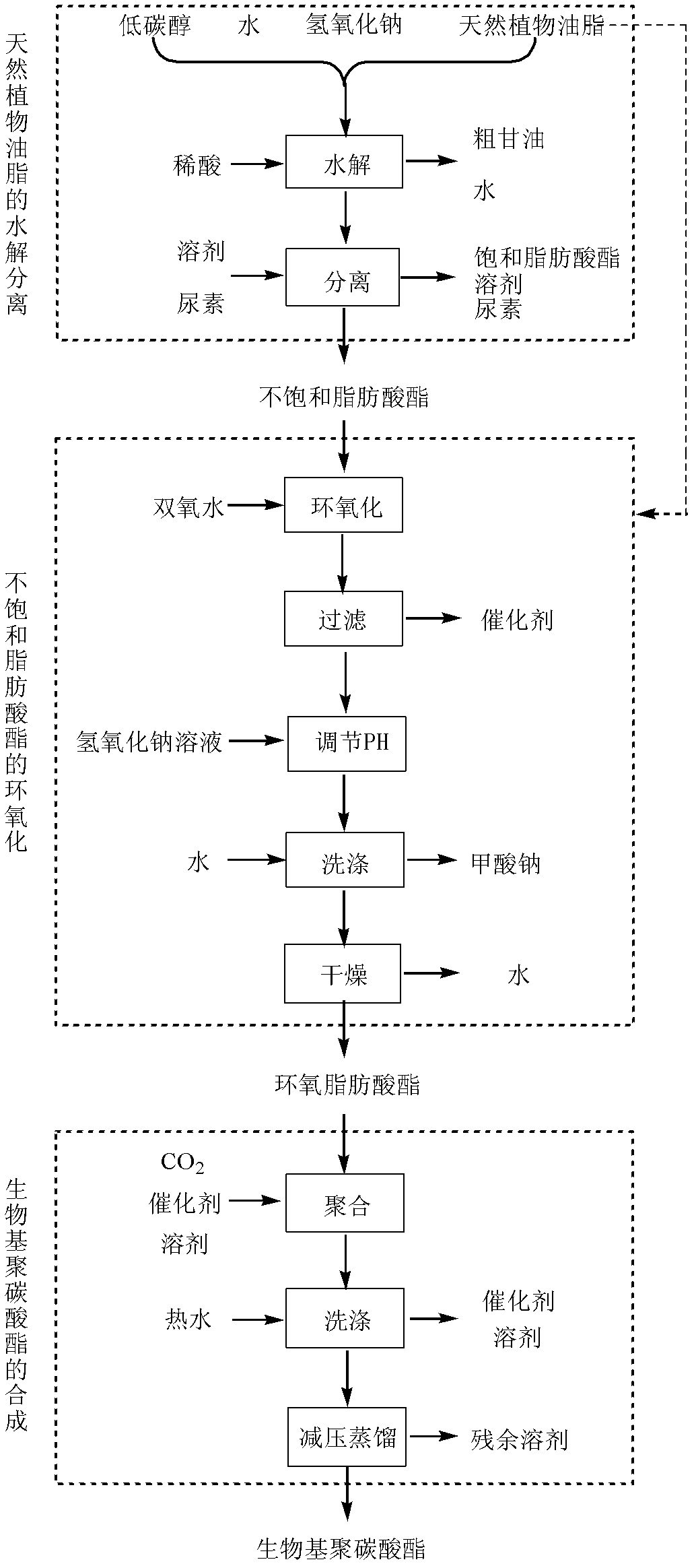

[0042] A preparation method of bio-based epoxy fatty acid ester, the following are the specific synthesis steps of first hydrolyzing, freezing and separating, then epoxidizing and then polymerizing with carbon dioxide:

[0043] The first step is the hydrolysis separation of natural vegetable oils: the molar ratio of natural vegetable oils to sodium hydroxide is 1: 1 to 1: 5, and the proportion of low-carbon alcohol is slightly excessive. Dissolve NaOH in distilled water and add it together with low-carbon alcohol In a three-necked flask, oil is added dropwise from the separatory funnel to the three-necked flask at a constant speed, mechanically stirred evenly, the reflux temperature is generally 60°C-80°C and the reaction is added dropwise for 0.5h-3h, kept for 1h-2h, cooled to room temperature and added dropwise Adjust the pH value to 3-4 with hydrochloric acid, stand at room temperature and separate layers, the lower layer is the crude glycerin phase, which can be recovered t...

Embodiment 1

[0052] The first step is the hydrolysis separation of natural vegetable oils: the molar ratio of tung oil to sodium hydroxide is 1: 3, methanol is slightly excessive, NaOH is dissolved in distilled water and added to a three-necked flask together with methanol, and the oil is added dropwise from the separatory funnel at a constant speed Transfer to a three-necked flask, mechanically stir evenly, reflux temperature is generally at 60°C dropwise reaction for 3h, keep warm for 2h, after cooling to room temperature, dropwise add hydrochloric acid to adjust the pH value to 3-4, stand at room temperature and separate layers, the lower layer is the crude glycerin phase Glycerin can be recovered and extracted, the separated upper crude fatty acid and low-carbon alcohol are mixed and sealed at a mass ratio of 1: 3, pre-cooled at 0°C and low-temperature frozen at -20°C for 2 hours each, filtered at low temperature to obtain a clear filtrate, after the filter cake is dissolved Distilled u...

Embodiment 2

[0056] The first step, the hydrolysis separation of natural vegetable oils: the molar ratio of Pistacia chinensis oil to sodium hydroxide is 1: 1, methanol is slightly excessive, NaOH is dissolved in distilled water and added to a three-necked flask together with methanol, and the oil is discharged from the separatory funnel at a constant rate. Add dropwise to a three-necked flask, mechanically stir evenly, reflux temperature is generally at 70°C for 2 hours, keep warm for 5 hours, after cooling to room temperature, add hydrochloric acid dropwise to adjust the pH value to 3-4, stand at room temperature to separate layers, the lower layer is coarse Glycerin phase, glycerin can be recovered and extracted, the separated upper crude fatty acid and methanol are mixed and sealed at a mass ratio of 1: 5, pre-cooled at 1°C and low-temperature frozen at -15°C for 2 hours each, filtered at low temperature to obtain a clear filtrate, after the filter cake dissolves Distilled under reduced...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com