Packaging film with high biomass content and production process therefor

A packaging film and production process technology, which is applied in the field of high biomass content packaging film and its production process, can solve the problems of difficult degradation and pollution of the natural environment, and achieve the effects of simple production process, less environmental pollution, and stable material performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

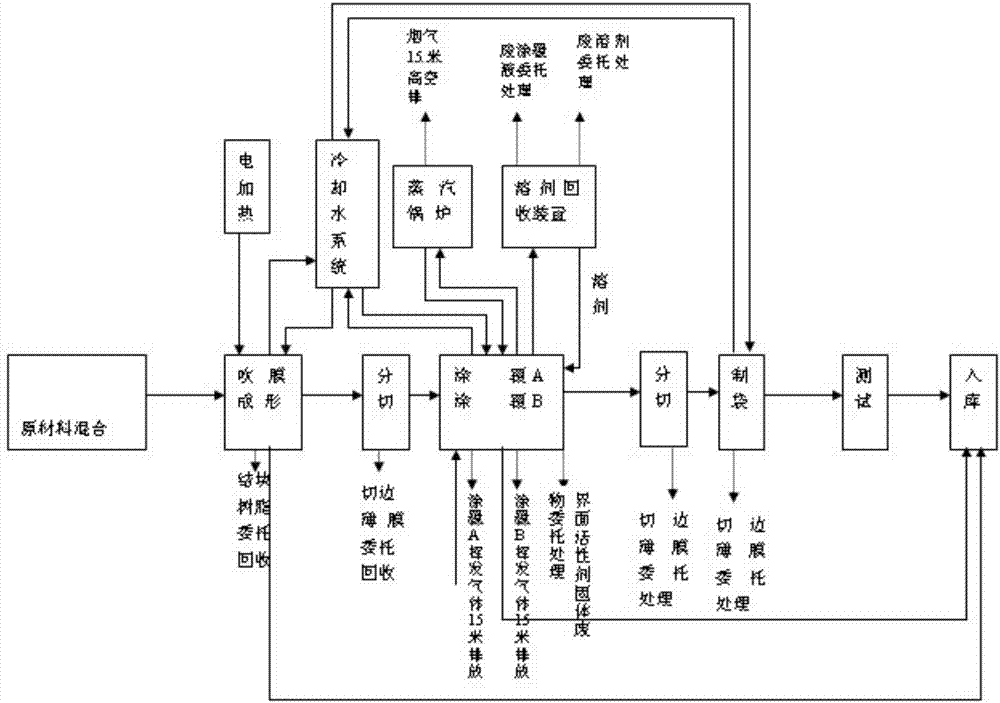

Method used

Image

Examples

Embodiment Construction

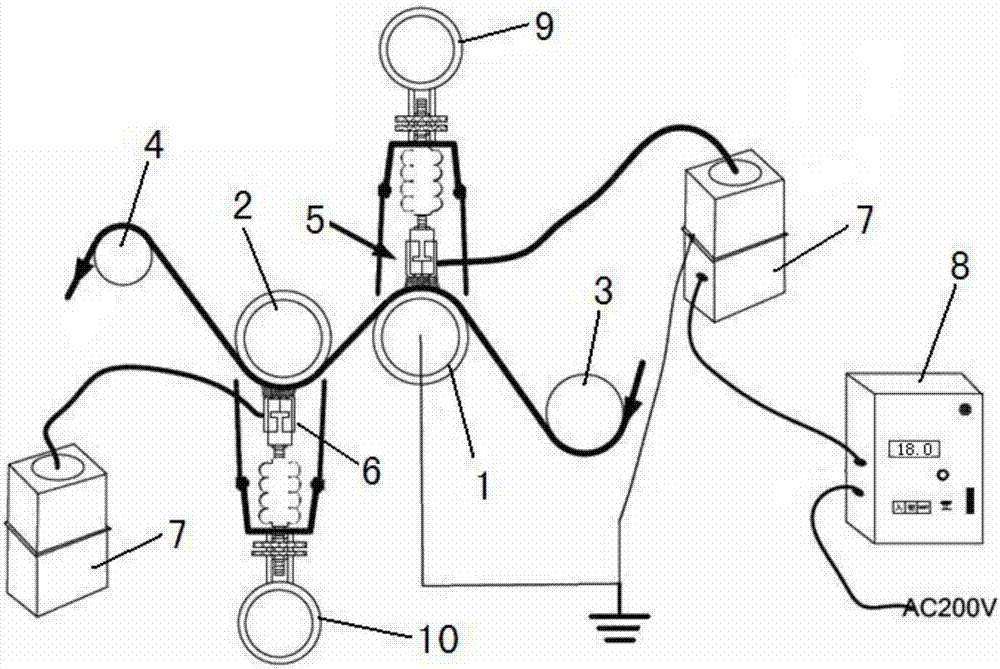

[0018] The invention provides a new environmental plant-type PE packaging film with high biomass content. The raw materials of the packaging film include biomass raw materials, petroleum-based raw materials, and additive color masterbatches. Low-density polyethylene, low-density polyethylene, high-density polyethylene, the mass percentages are: straight-locked very low-density polyethylene (LLD) 30-60%, low-density polyethylene (LD) 5-30%, high Density polyethylene (HD) 5-30%, petroleum-based raw material is straight-locked very low-density polyethylene (LLD) from petroleum, its mass percentage is 10-20%, the mass percentage of additive color masterbatch (MB) 5-10%. Such as: (1) Straight-locked very low-density polyethylene made from plants 44%, low-density polyethylene 16%, high-density polyethylene 11%, straight-locked very low-density polyethylene from petroleum 20% , additive color masterbatch 9%; (2) 52% straight-locked very low-density polyethylene, 16% low-density poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com