Flexible, environmentally-friendly, transparent and adjustable-illuminant-color film material and preparation method thereof

A thin-film material and luminescent color technology, applied in the field of photoelectric functional polymer materials, can solve the problems of polluted environment and poor transparency, and achieve the effects of simple preparation method, low cost and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1. After diluting mercaptopropionic acid with DMF solvent, mix with quantum dot CuInS 2 / ZnS chloroform solution mixed, ultrasonic treatment, to realize the transfer of the organic phase to the water phase, to obtain the DMF colloidal solution of quantum dots.

[0027] Step 2, disperse cyanoethyl cellulose with a dielectric constant of 15 in a DMF solvent, stir until completely dissolved, so that the concentration of cyanoethyl cellulose is 10g / L, and obtain a DMF solution of cyanoethyl cellulose;

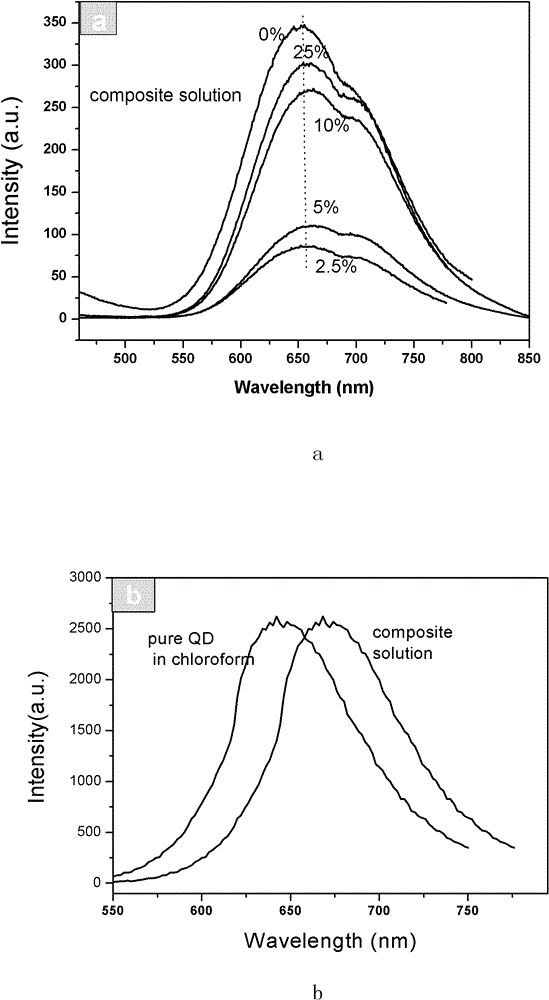

[0028] Step 3. Add the DMF colloidal solution of quantum dots that emit red light to the DMF solution of cyanoethylcellulose at room temperature, so that the quantum dots account for 2.5%, 5%, 10% and 25% of the mass of cyanoethylcellulose respectively. %, stirring, so that the quantum dots are evenly distributed in the DMF solution of cyanoethyl cellulose to obtain a mixed solution, and its fluorescence spectrum is as follows figure 1 shown;

[0029] Step 4. Prepare ...

Embodiment 2

[0032] Step 1. After diluting mercaptopropionic acid with DMF solvent, mix with quantum dot CuInS 2 / ZnS chloroform solution mixed, ultrasonic treatment, to realize the transfer of the organic phase to the water phase, to obtain the DMF colloidal solution of quantum dots.

[0033] Step 2, disperse cyanoethyl cellulose with a dielectric constant of 25 in a DMF solvent, stir until completely dissolved, so that the concentration of cyanoethyl cellulose is 100g / L, and obtain a DMF solution of cyanoethyl cellulose;

[0034] Step 3. Add quantum dots CuInS emitting yellow-green, orange, pink to red light to the DMF solution of cyanoethylcellulose at room temperature 2 The DMF colloidal solution of / ZnS, all make quantum dot account for 10% of cyanoethyl cellulose quality, stir, make quantum dot evenly distribute in the DMF solution of cyanoethyl cellulose, obtain the mixed solution of four different colors;

[0035]Step 4. Prepare a luminescent film material by casting the mixed sol...

Embodiment 1

[0037] For the comparative example of embodiment one:

[0038] 1) Disperse cyanoethyl cellulose in N,N dimethylformamide, stir at 60°C to dissolve it completely, and prepare a cyanoethyl cellulose DMF solution with a concentration of 10g / L.

[0039] 2) Add oleic acid-modified red-emitting CuInS directly to the cyanoethylcellulose DMF solution at room temperature 2 / ZnS chloroform solution, control the quantum dots to account for 10% of the mass fraction of the cyanoethyl cellulose DMF solution, stir the mixed solution for half an hour, so that the quantum dots are dispersed in the cyanoethyl cellulose DMF solution;

[0040] 3) Cast the above mixed solution into a glass vessel with a flat bottom, control the temperature at 70° C. under vacuum conditions, and dry to obtain a film material.

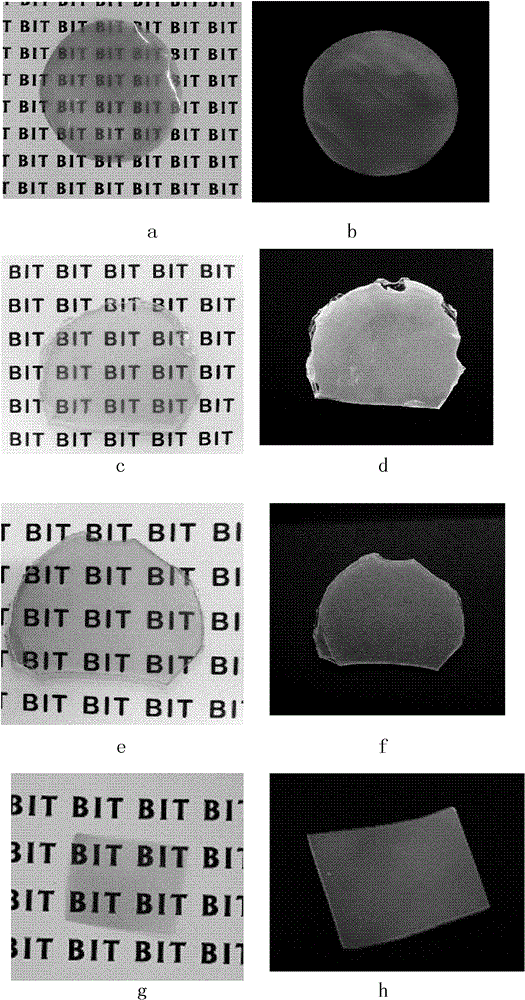

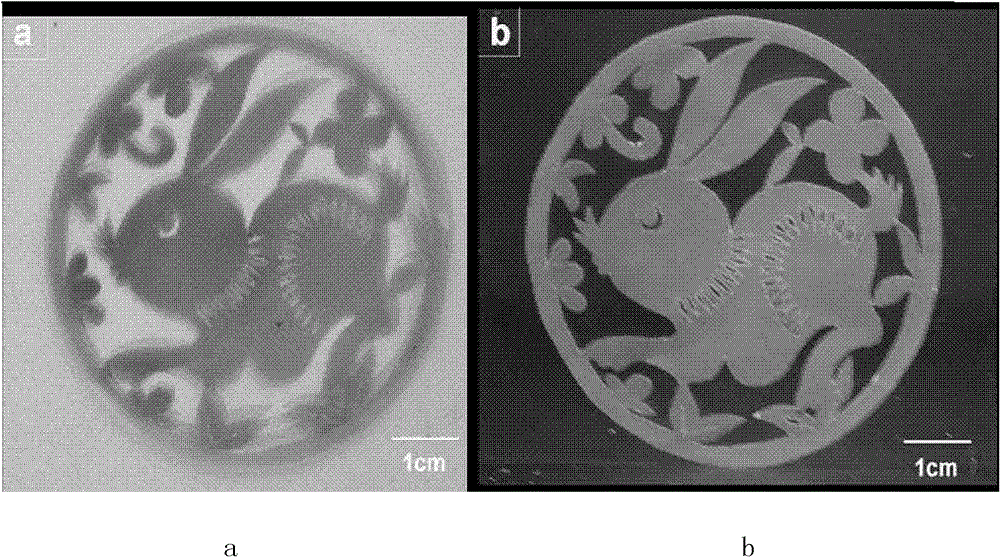

[0041] The film material obtained in the above-mentioned embodiment 1 is uniform and transparent, and the quantum dots have good dispersibility in the DMF solution of cyanoethylcellulose. E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com