Biopolyethylene-containing packaging film and production process thereof

A bio-polyethylene and packaging film technology, applied in the field of packaging films, can solve the problems of polluting the natural environment and difficulty in degradation, and achieve the effects of less environmental pollution, simple production process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

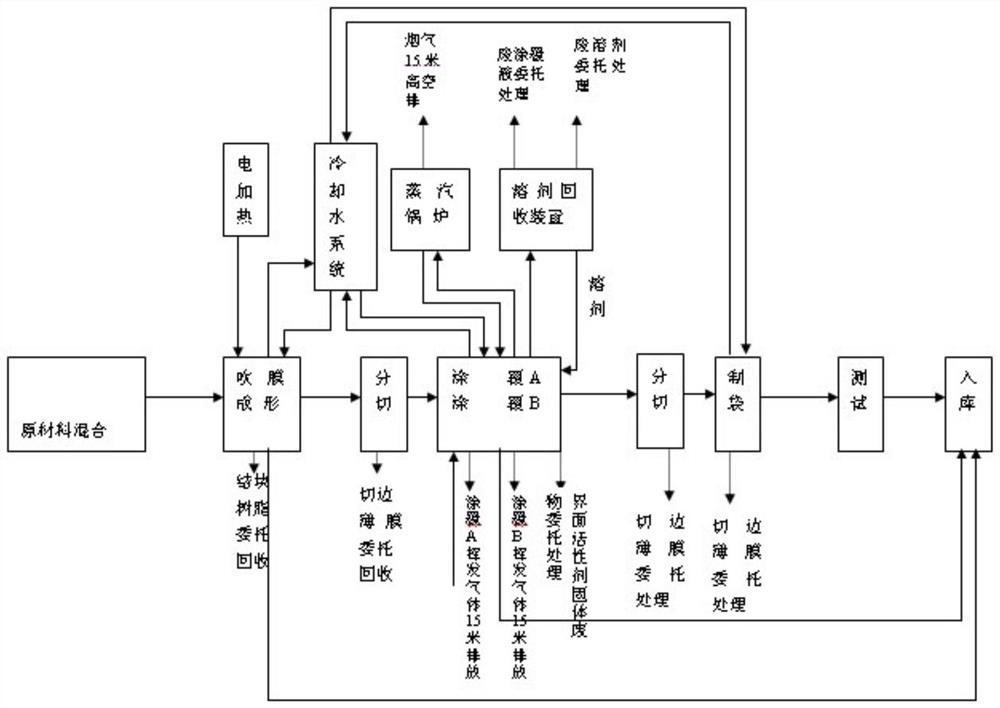

Image

Examples

Embodiment Construction

[0012] The invention provides a new environmental plant-type PE packaging film containing bio-polyethylene. The raw materials of the packaging film include bio-polyethylene, petroleum raw material polyethylene, additive color masterbatch, and the mass percentage of bio-polyethylene is 5-70%. , the mass percentage of petroleum raw material polyethylene is 25-85%, the mass percentage of additive color masterbatch is 5-10%; such as: the mass percentage of biological polyethylene is 5%, the mass percentage of petroleum raw material polyethylene is 85%, The mass percent of the additive color masterbatch is 10%. For example: the mass percentage of bio-polyethylene is 70%, the mass percentage of petroleum raw material polyethylene is 25%, the mass percentage of additive color masterbatch is 5%; the mass percentage of bio-polyethylene is 40%, the mass percentage of petroleum raw material polyethylene The percentage is 52%, and the mass percentage of the additive color masterbatch is 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com