A kind of smithsonite type zinc oxide ore flotation desiliconization method

A zinc oxide and ore-type technology, applied in flotation, solid separation, etc., can solve the problems of complex flotation process and difficult control, and achieve the effect of simple chemical system, convenient operation, and good industrial feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

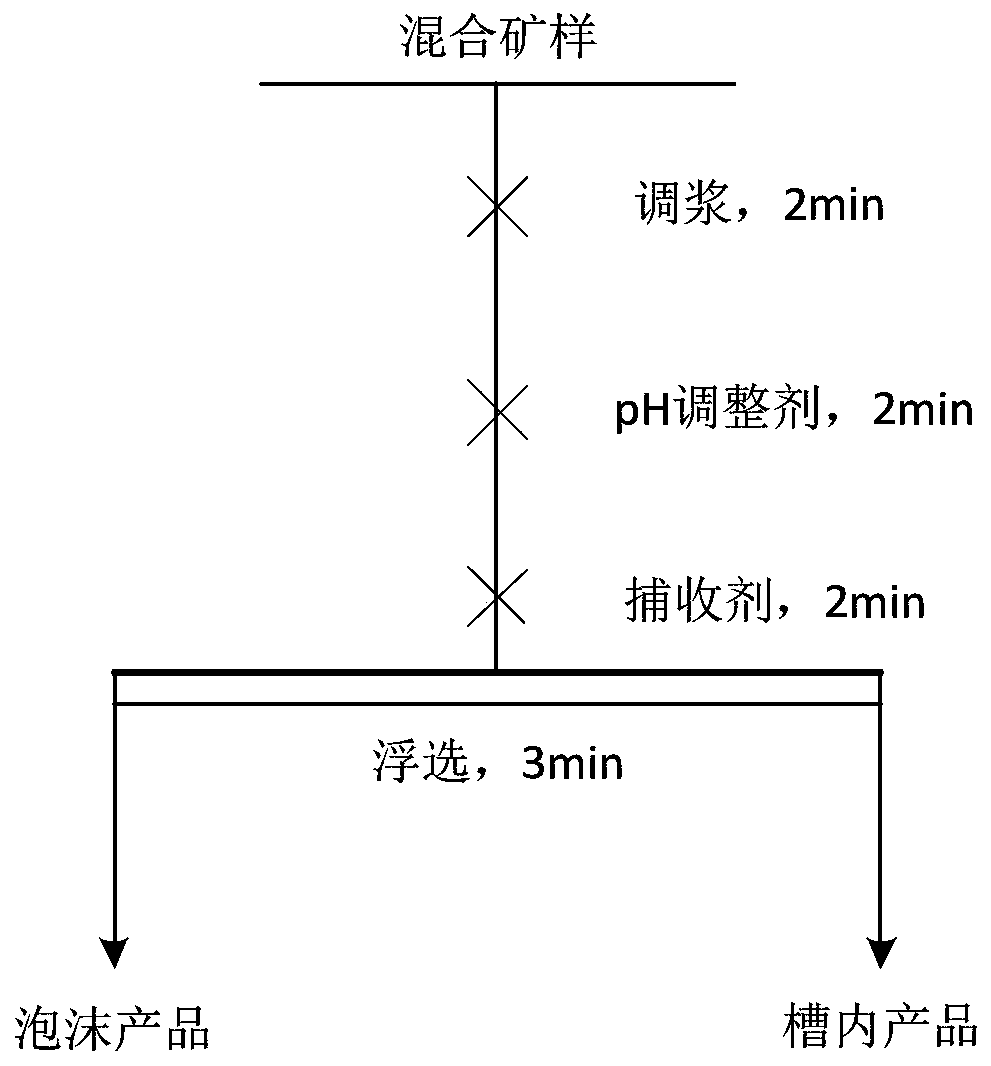

[0026] (1) smithsonite and quartz with a mass ratio of 3:17 are configured into a mixed ore sample, and 5g of the ore sample is weighed and put into a flotation cell, and then deionized water is added, wherein the amount of ore sample and deionized water The mass ratio is 1:5; using a hanging tank flotation machine, under the condition of 1992r / min, stirring and pulping for 2min;

[0027] (2) After pulping, add 1mol / L sodium carbonate solution as a pH adjuster at room temperature at 13°C, adjust the pH of the pulp to 10.82, stir for 2 minutes, and then add 300g / t of N,N'-difatty acyl Sodium ethylenediamine dipropionate was used as a collector, and after stirring for 2 minutes, flotation was carried out, and the flotation time was 3 minutes. After the flotation, dry and weigh the foam product, which is the concentrate, and the tailings, which is the product in the tank, and take samples to test the grade and calculate the recovery rate. The Zn grade in the flotation concentrate...

Embodiment 2

[0029] (1) smithsonite and quartz with a mass ratio of 3:17 are configured into a mixed ore sample, and 5g of the ore sample is weighed and put into a flotation cell, and then deionized water is added, wherein the amount of ore sample and deionized water The mass ratio is 1:5; using a hanging tank flotation machine, under the condition of 1992r / min, stirring and pulping for 2min;

[0030] (2) After pulping, add 1mol / L sodium carbonate solution as a pH adjuster at room temperature at 13°C, adjust the pH of the pulp to 10.25, stir for 2 minutes, and then add 300g / t of N,N'-difatty acyl Sodium ethylenediamine dipropionate was used as a collector, and after stirring for 2 minutes, flotation was carried out, and the flotation time was 3 minutes. After the flotation, dry and weigh the foam product, which is the concentrate, and the tailings, which is the product in the tank, and take samples to test the grade and calculate the recovery rate. The Zn grade in the flotation concentrate...

Embodiment 3

[0032] (1) smithsonite and quartz with a mass ratio of 3:17 are configured into a mixed ore sample, and 5g of the ore sample is weighed and put into a flotation cell, and then deionized water is added, wherein the amount of ore sample and deionized water The mass ratio is 1:5; using a hanging tank flotation machine, under the condition of 1992r / min, stirring and pulping for 2min;

[0033] (2) After pulping, add 1mol / L sodium carbonate solution as a pH adjuster at room temperature at 25°C, adjust the pH of the pulp to 11.20, stir for 2 minutes, and then add 360g / t of N,N'-difatty acyl Sodium ethylenediamine dipropionate was used as a collector, and after stirring for 2 minutes, flotation was carried out, and the flotation time was 3 minutes. After the flotation, dry and weigh the foam product, namely the concentrate, and the tailings, the product in the tank, respectively, and take samples to test the grade, and calculate the recovery rate, among which the Zn grade in the flota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com