Low-low-nitrogen combustor for large and medium-sized pulverized coal boilers under wide-load operation, and using method

A pulverized coal boiler and load operation technology, which is applied in the combustion method, the combustion of lump fuel and powder fuel, the combustion of liquid fuel and powder fuel, etc., can solve the problem of increasing ammonia injection and decreasing utilization rate of coal-fired energy. , the furnace temperature is not up to standard and other problems, to achieve the effect of reducing the risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

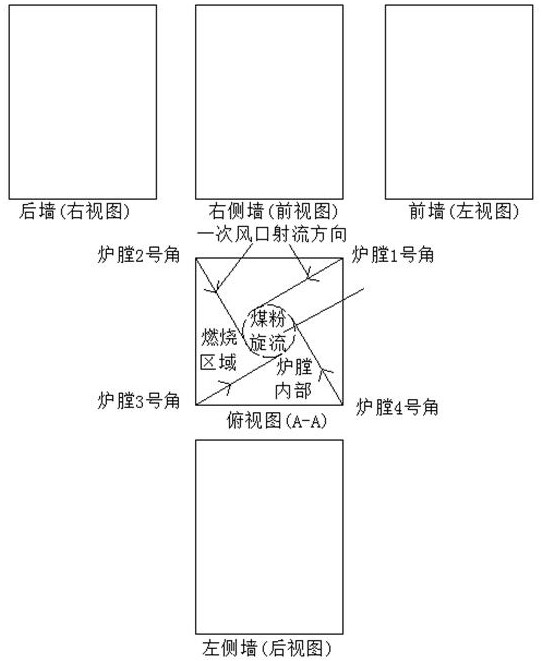

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

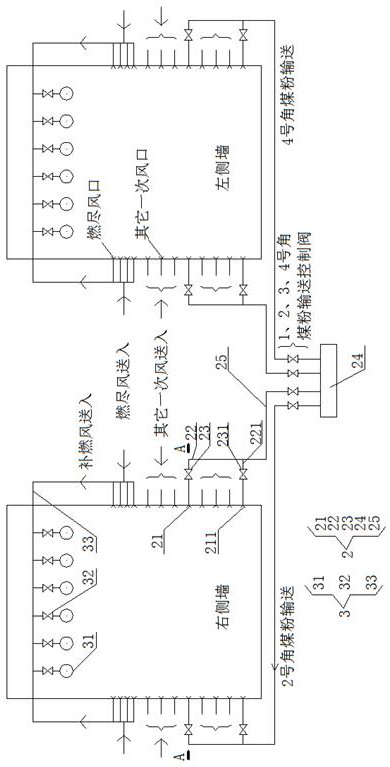

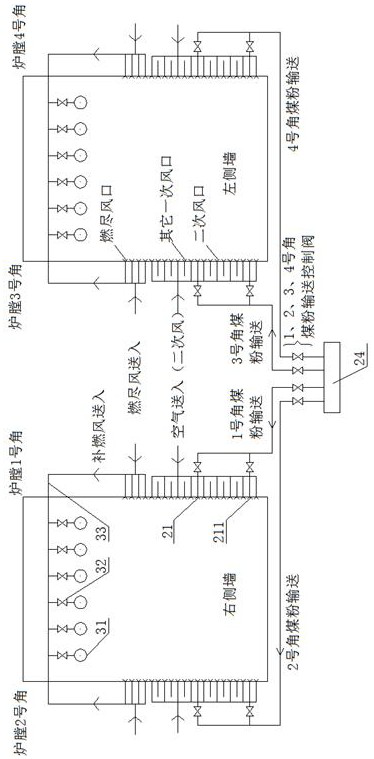

[0026] The invention discloses a low-low-nitrogen burner for large and medium-sized pulverized coal boilers under wide-load operating conditions. The primary air system 2 is set in the middle of the vertical direction. The primary air system 2 can meet the requirement that the interior of the furnace cross section at this position is always a high-concentration pulverized coal area and can burn stably without coking under any load or any coal type working condition. The high-concentration size standard meets the high-concentration pulverized coal area and belongs to the main combustion area of the boiler.

[0027] The primary air system 2 includes the first primary air port 21 connected to the furnace wall at the middle position of the furnace burner, the second primary air port 211 connected to the furnace wall at the bottom position of the furnace burner, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com