Separation method of 2-methylpyridine

A separation method, picoline technology, applied in the purification/separation of amino compounds, organic chemistry, etc., can solve the problems that are not conducive to energy saving, increase the difficulty of operation, and it is not easy to pan the tower, so as to reduce the risk of coking in the tower kettle and have good application Prospect and effect, effect of reducing coking tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

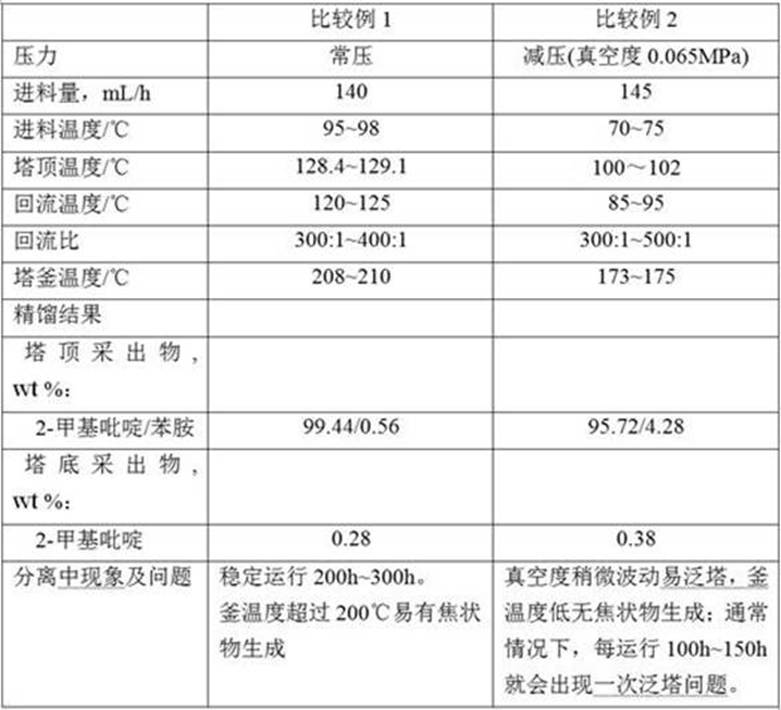

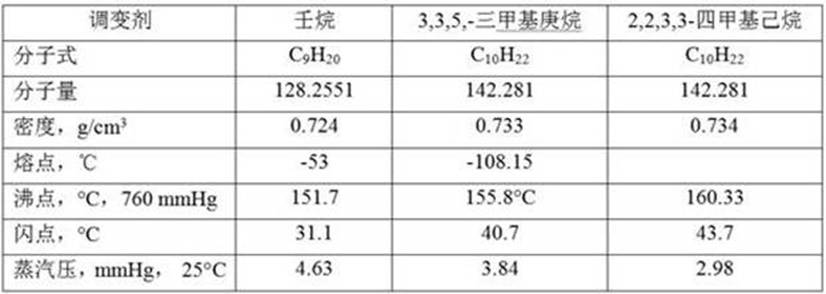

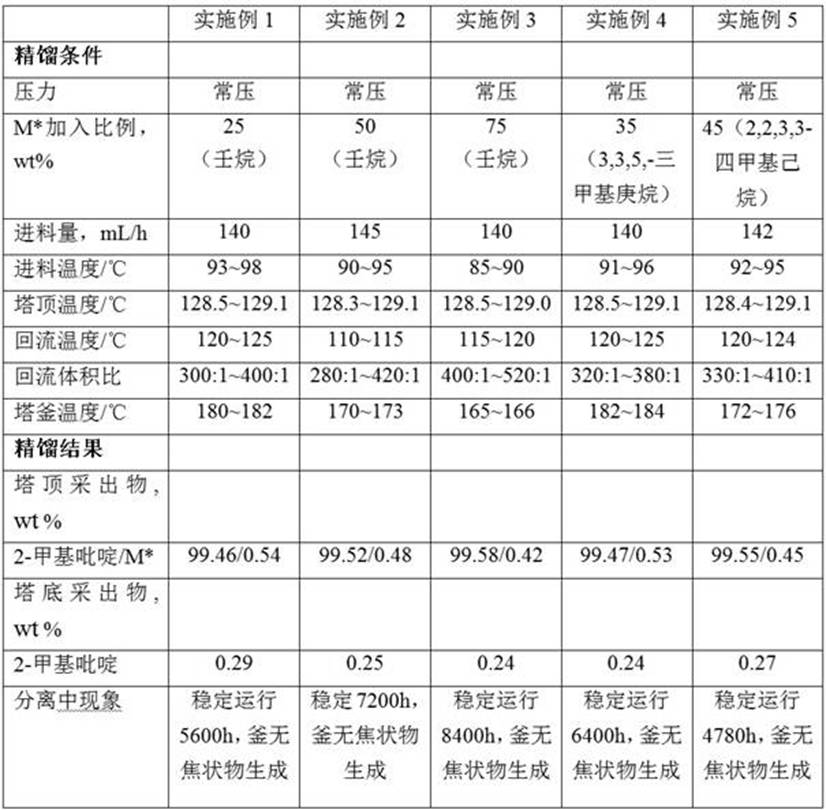

[0053] The rectification column and operation method used in the experiment were the same as those in Comparative Example 1. The difference is that nonane or 3,3,5,-trimethylheptane or 2,2,3,3-tetramethylhexane was added to the experimental raw materials in Table 2. Nonane, 3,3,5 ,-trimethylheptane and 2,2,3,3-tetramethylhexane are analytical standards with a purity of ≥99.8%, and their physical properties are shown in Table 7. The experimental raw materials after adding Modulator M to the raw materials in Table 2 are shown in Table 8. The specific operation process is the same as that described in the above experiment. After the rectifying tower was operated stably, samples were taken to analyze the product purity. The specific operating conditions of the tower and the results of product analysis are shown in Table 9.

[0054] Table 7 Physical properties of modulators.

[0055]

[0056] Table 8 Experimental raw materials (composition, wt%) after adding modulator.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com