Nozzle type disc separator blockage prevention system and control method thereof

A disc separator and nozzle technology, applied in centrifuges and other directions, can solve problems such as nozzle blockage, and achieve the effects of prolonging service life, low production cost and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

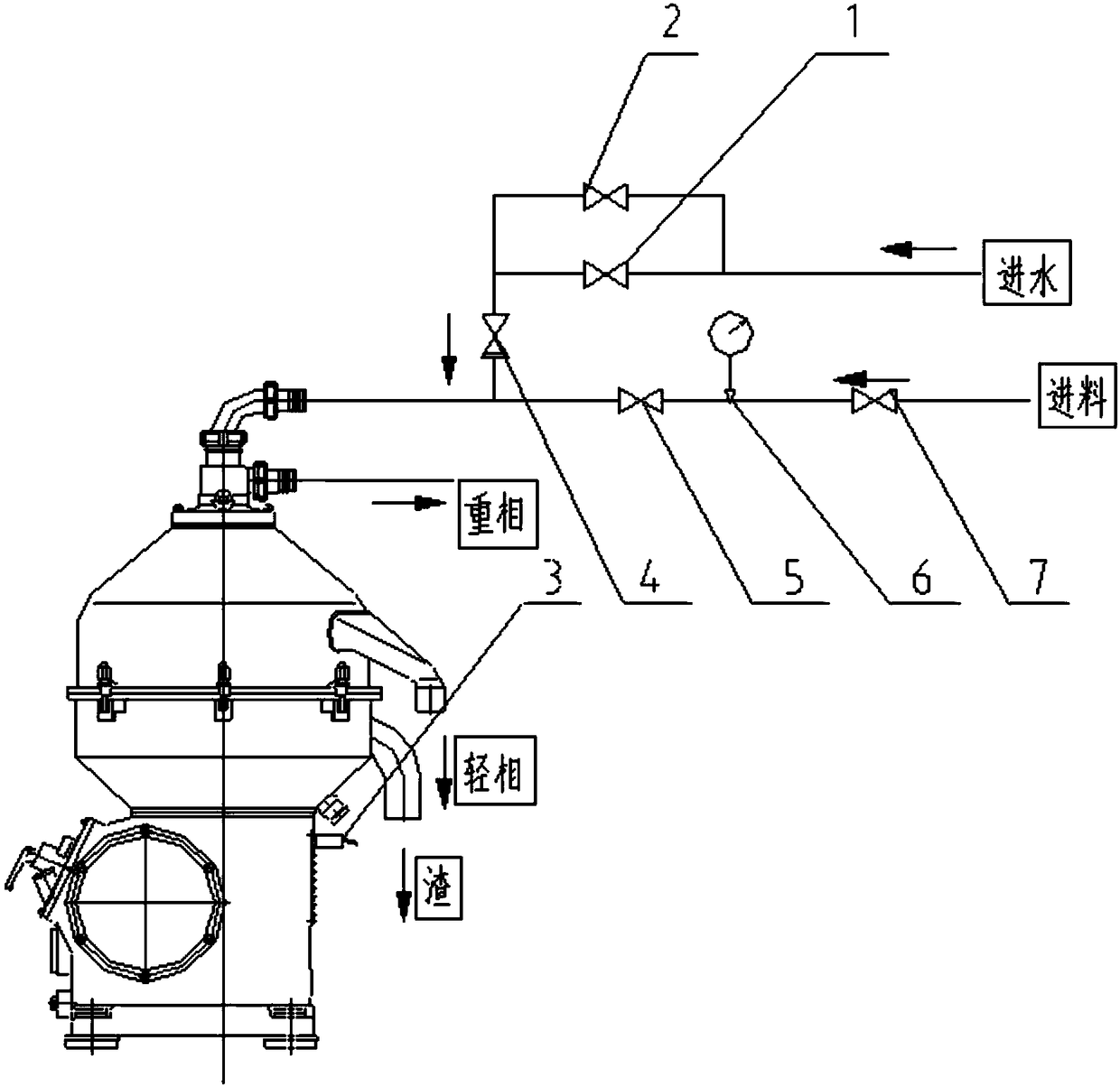

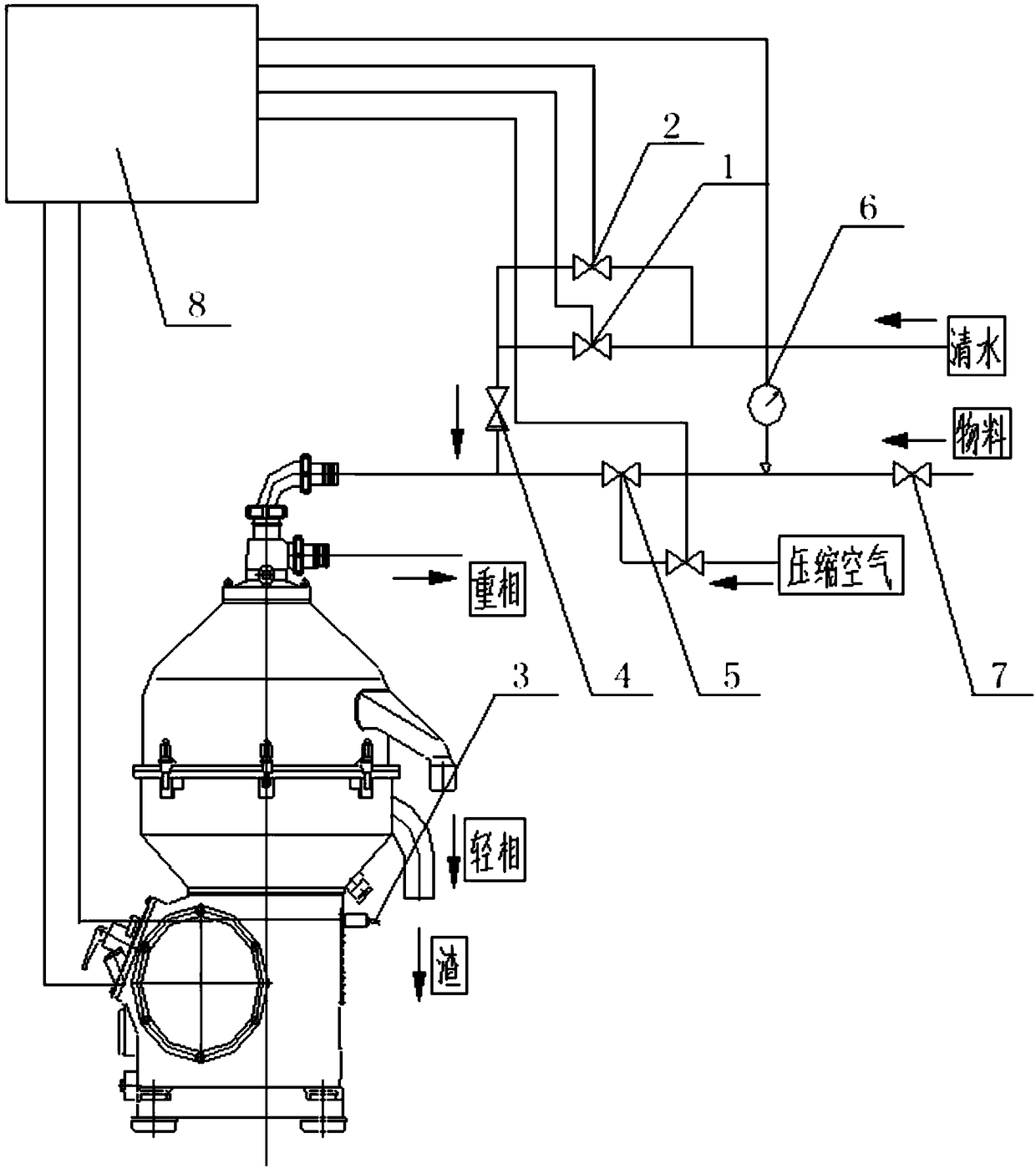

[0029] The invention provides an anti-clogging system for a nozzle-type disc separator, the structure of which is as follows: figure 1 Shown: It includes a nozzle-type disc separator, and the feed pipe joint of the nozzle-type disc separator is sequentially connected with an actuator composed of a plurality of valves through the feed pipeline, including sequentially along the feeding direction of the feed pipeline. It is equipped with a manual ball valve, a pneumatic V-type switch ball valve and a check valve. The check valve is connected with a cleaning pipeline, and the check valve is used to prevent the feed liquid from flowing back into the cleaning pipeline. The cleaning pipeline is connected in parallel with a first solenoid valve and a The second electromagnetic valve, a detection module for detecting fluid flow is also provided between the manual ball valve and the pneumatic V-type switch ball valve,

[0030] The lower part of the shell frame of the base of the nozzle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com