Quartz clock and watch rotor wheel

A technology of rotor wheel and quartz clock, which is applied in the field of rotor wheel, can solve the problems of high power consumption, easy inclination, and high starting voltage, and achieve the effects of low power consumption, reduced rotation volume and low starting voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

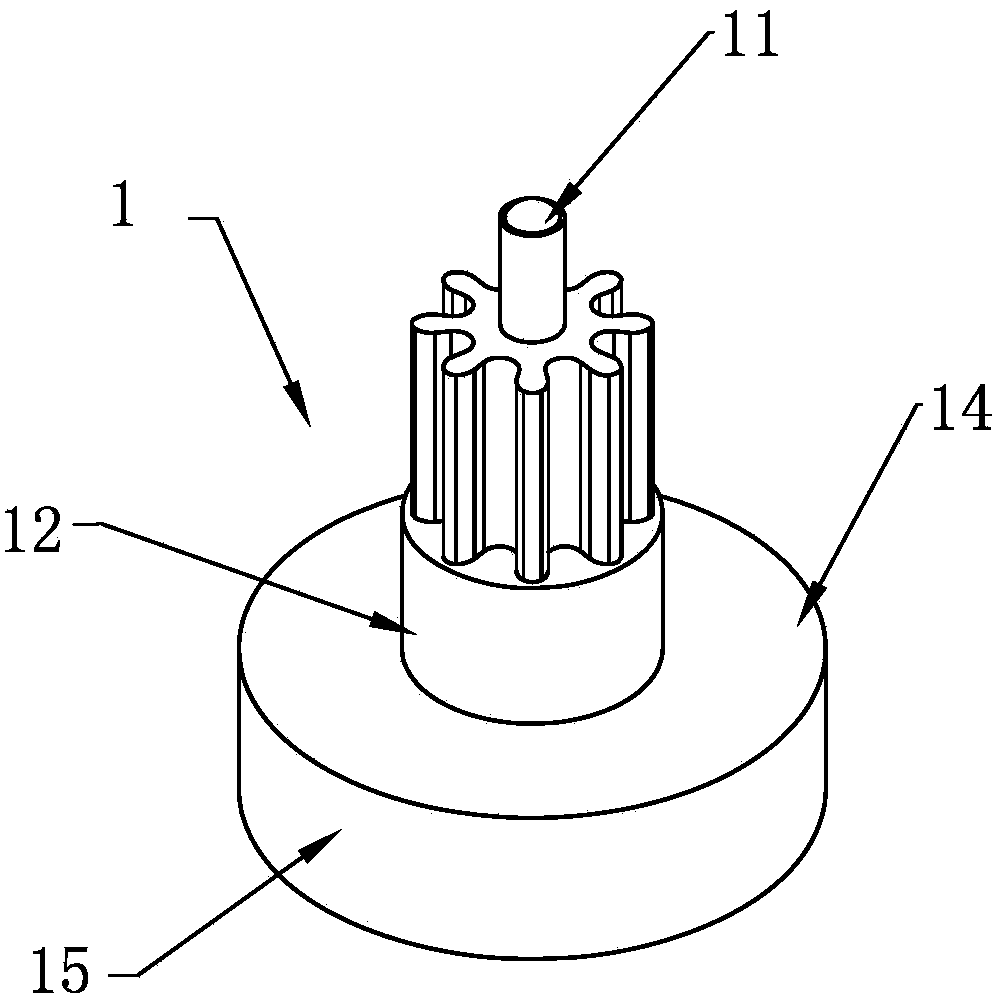

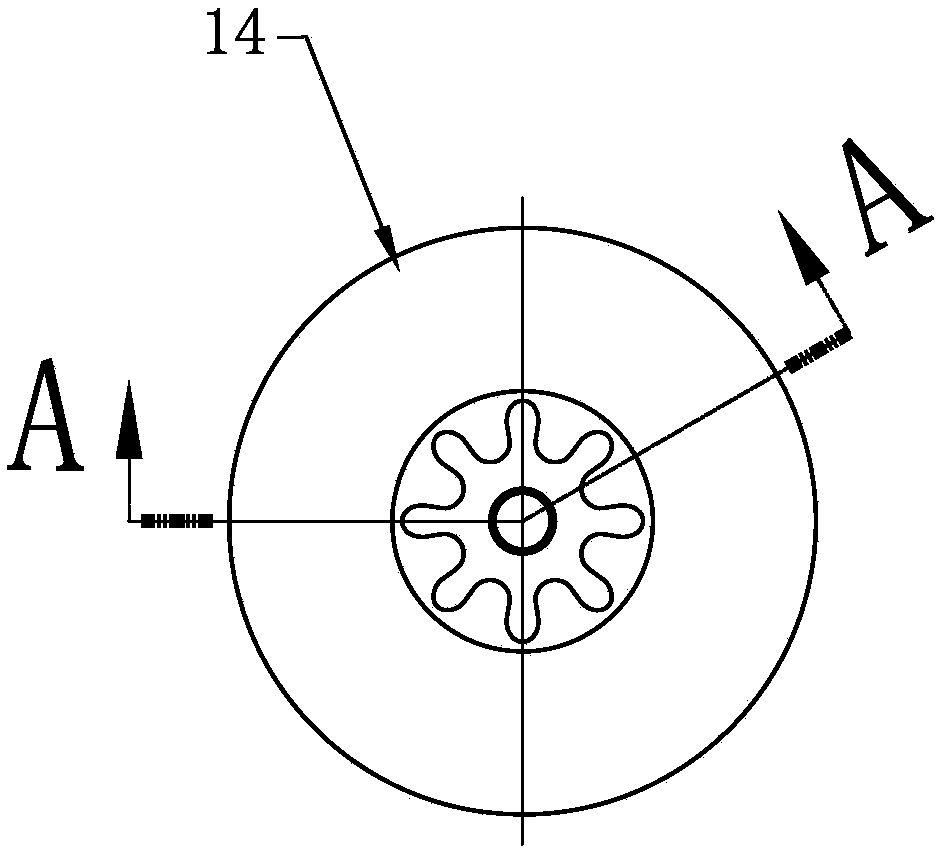

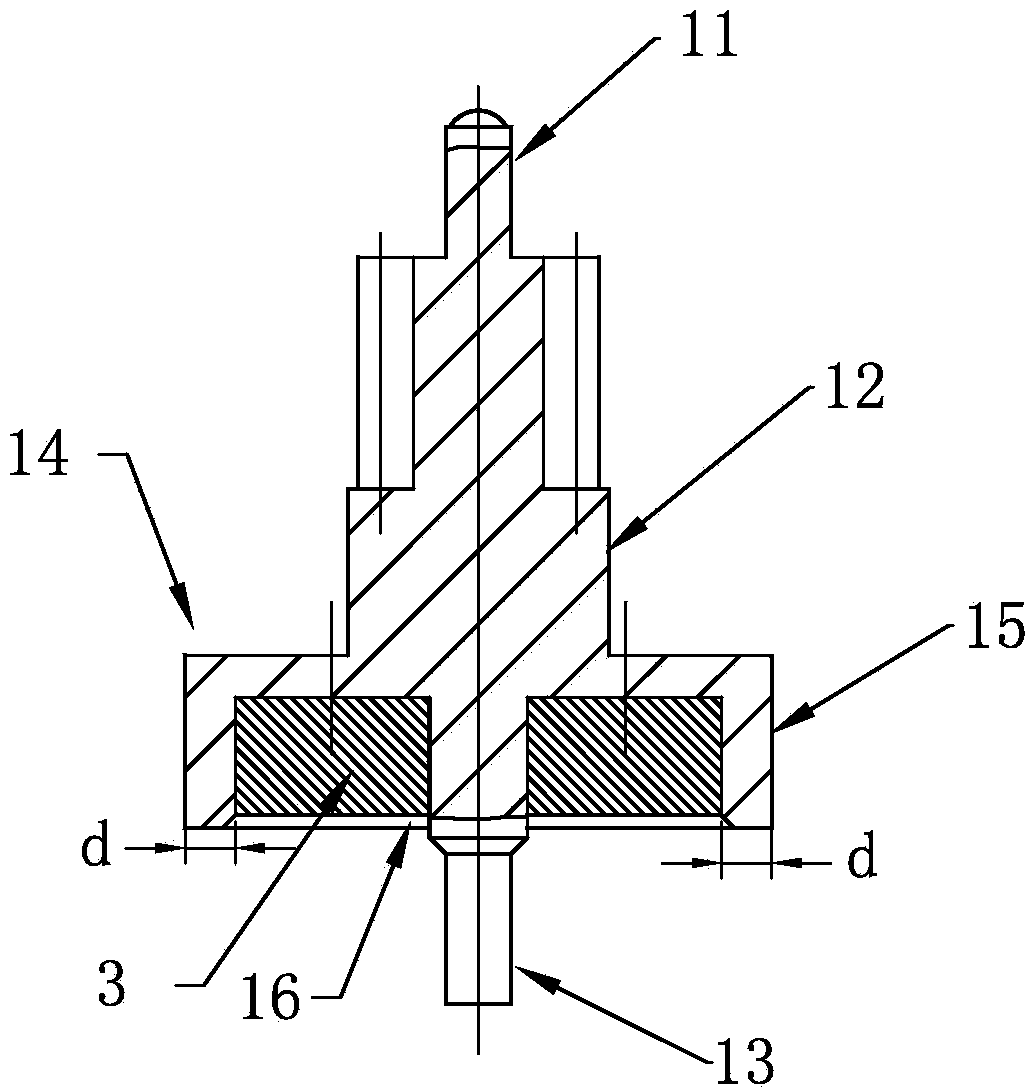

[0052] Such as Figure 4 , 5 Shown in and 6, quartz clock of the present invention, table rotor wheel 1 are also provided with upper end shaft 11, central axis 12, wheel disc 14, wheel disc 14 inner groove 16 and lower end shaft 135 the same as rotor wheel 1 of the prior art Part, except that the other four parts of the disc 14 are the same as the rotor wheel 1 of the prior art, only its disc 14 is different in shape from the circular disc 14 of the rotor wheel 1 in the prior art, and the inner groove of the disc 14 16 The cross-sectional shape is also circular as in the prior art, and the magnetic steel 3 is fixedly installed in the inner groove 16 . The profile cross-sectional shape of wheel disc 14 can be regular quadrilateral to regular octagon, and the inner groove 16 of described wheel disc 14 is the circular groove concentric with regular quadrilateral to regular octagon inscribed circle, as Figure 7 , 8As shown in and 9, the cross-sectional shape of a regular quadr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com