Assembly line production method for single crane boom and assembly line production device

A production method and production device technology, which is applied in the field of single-section boom assembly line production method and assembly line production device, can solve the problems of long welding transfer time, low safety factor, low processing efficiency, etc., and achieve reduction of manual labor intensity and labor cost, realize flexible production and automated logistics, and reduce the effect of workpiece hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

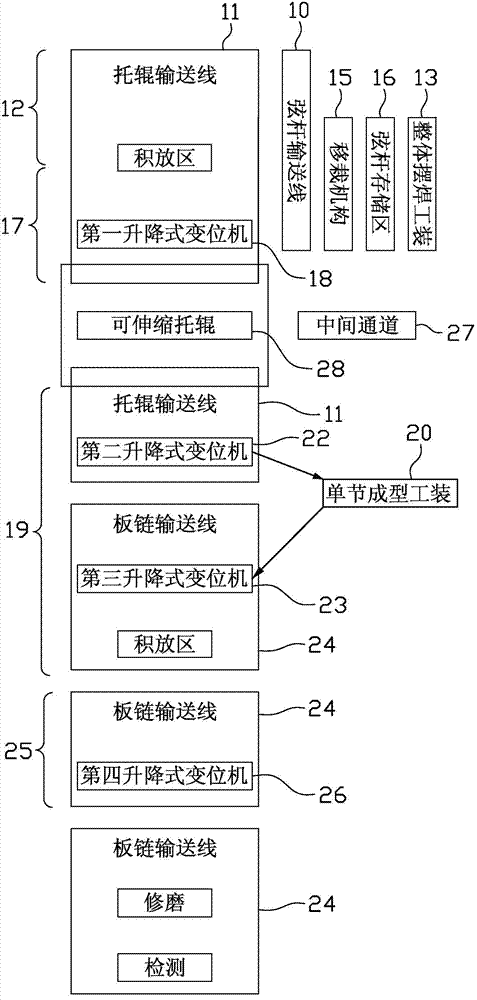

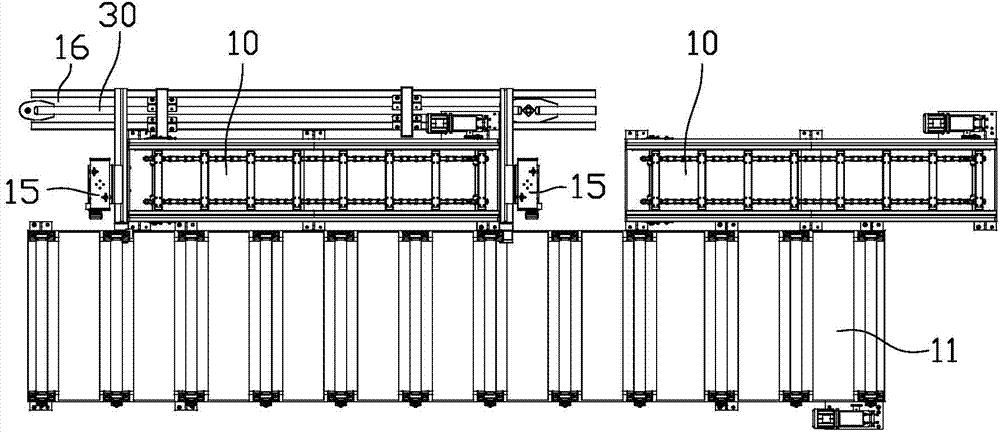

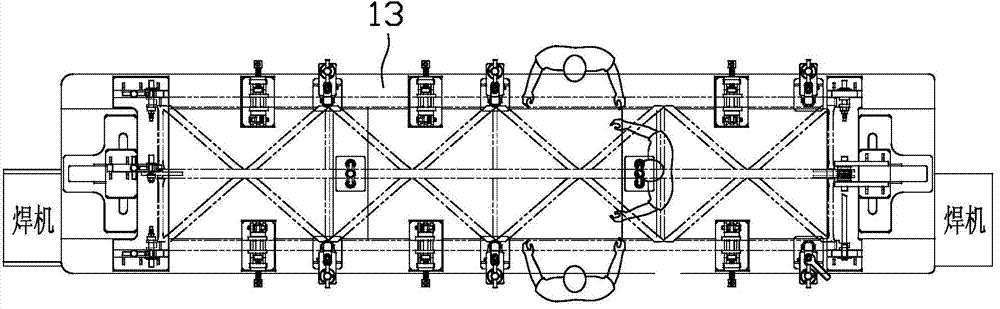

[0043] Please refer to figure 1, the single-section boom assembly line production method of the present invention can be applied to the automatic production line of the boom, and can complete the entire logistics process of the single-section boom from the overall swing welding of the boom section to the welding joint. The single-section jib includes an upper chord, two lower chords, multiple straight webs, multiple diagonal webs, and multiple joints connected to both ends of the upper chord and the lower chord. In this assembly line production method, the overall technological process of the single-section jib is: welding joint at one end of the upper chord → chord delivery → overall swing welding of the jib (upper chord, two lower chords...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com