Crank press ball head screw and spherical bowl combined grinder

A crank press and ball screw technology, applied in the field of machinery, can solve the problems of low grinding precision, laborious and time-consuming grinding of spherical surfaces, etc., and achieve the effect of improving grinding efficiency and improving grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

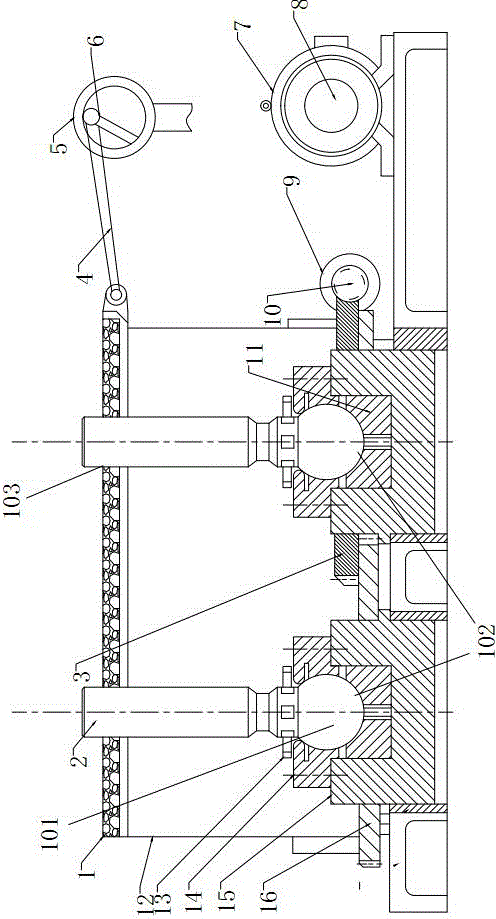

[0019] like figure 1 As shown, the crank press ball screw and ball bowl joint grinder is used to grind the ball head 101 of the ball screw and the ball bowl 11 that works with the ball head 101. The grinder includes a power source 7, a ball head Driving mechanism and bowl driving mechanism; the output end of the power source 7 is the first pulley 8 .

[0020] Described ball bowl driving mechanism comprises worm and gear mechanism, second pulley 9, ball bowl support 15 and bowl baffle plate 13, and described ball bowl work piece 11 is fixed on the ball bowl support 15, and described ball bowl work piece 11 Grinding sand is placed in the bowl cavity 102 of the ball screw workpiece, and the ball end of the ball screw workpiece is placed at the bowl cavity 102 of the ball bowl workpiece 11. 14. The bowl baffle 13 limits the position of the ball end to prevent it from breaking away from the bowl cavity 102; the ball bowl support is connected with the worm gear 3 of the worm gear m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com