Melt spinning apparatus

A technology of melt spinning and spinning components, which is applied in the direction of melt spinning, textile and paper making, spinneret assembly, etc., and can solve the problems of replacing the spinning component body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiment of the invention

[0025] Hereinafter, the present invention will be described in detail with reference to the drawings, but the present invention is of course not limited to the embodiments described below.

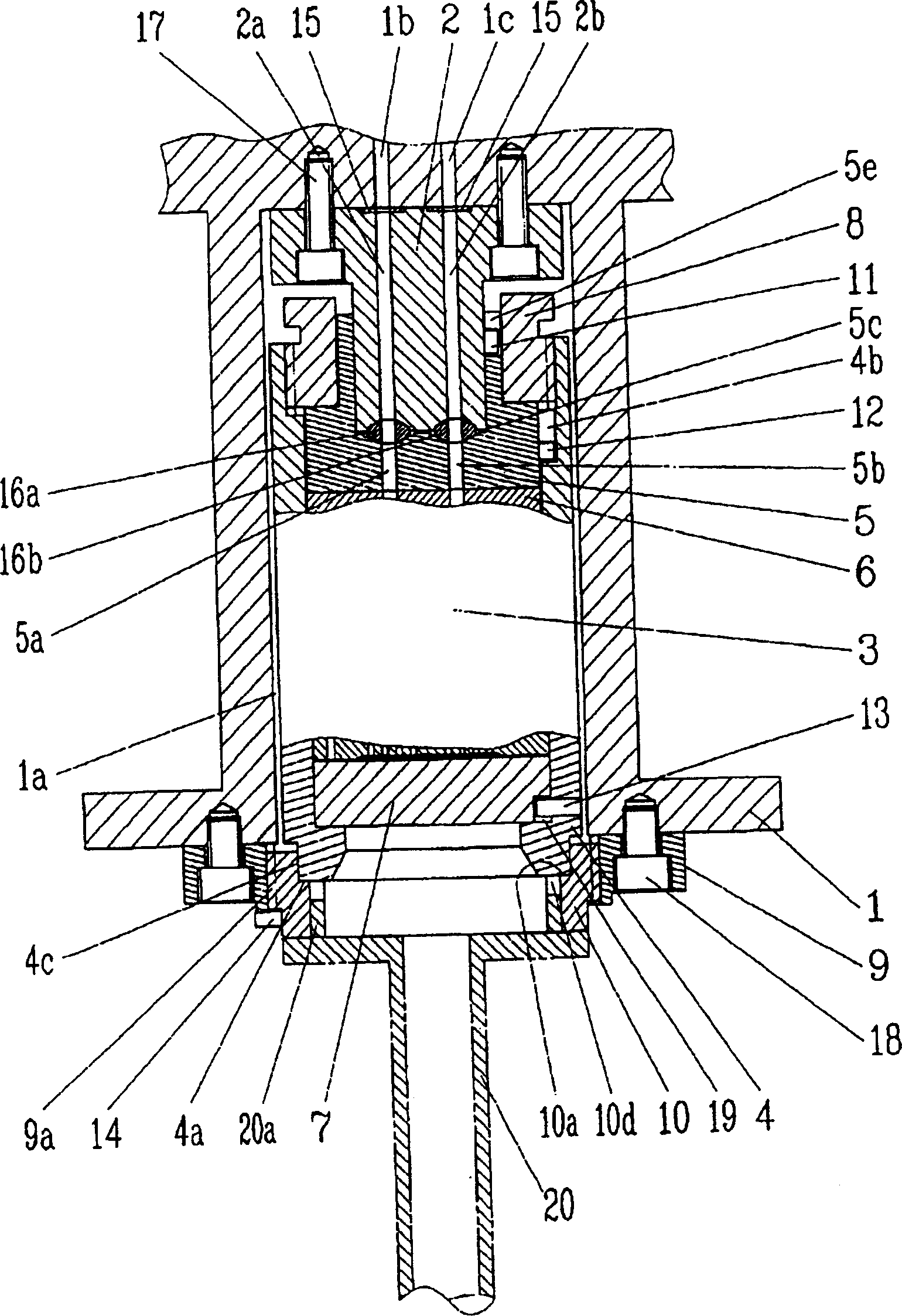

[0026] figure 1 It is a schematic cross-sectional view showing one embodiment of the structure of a melt spinning apparatus provided with a plurality of polymer flow paths according to the present invention. The melt spinning apparatus is composed of the following components, namely: a heating box provided with a spinning package housing portion 1a 1; the polymer introduction flow path 2a, 2b communicated with the polymer flow path 1b, 1c of the heating box body 1 is set penetratingly, and is installed in the heating box body 1 with the gasket 15 for sealing, with the bolt 17 Spinning assembly connecting body 2 on the upper wall of spinning assembly housing part 1a; spinning assembly 3 engaged with above-mentioned spinning assembly connecting body 2 by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com