Full-automatic efficient packing box production line

A packaging box, fully automatic technology, applied in the direction of packaging, transportation and packaging, box making operations, etc., can solve the problem of low automation of packaging boxes, achieve the effect of avoiding paper jams and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

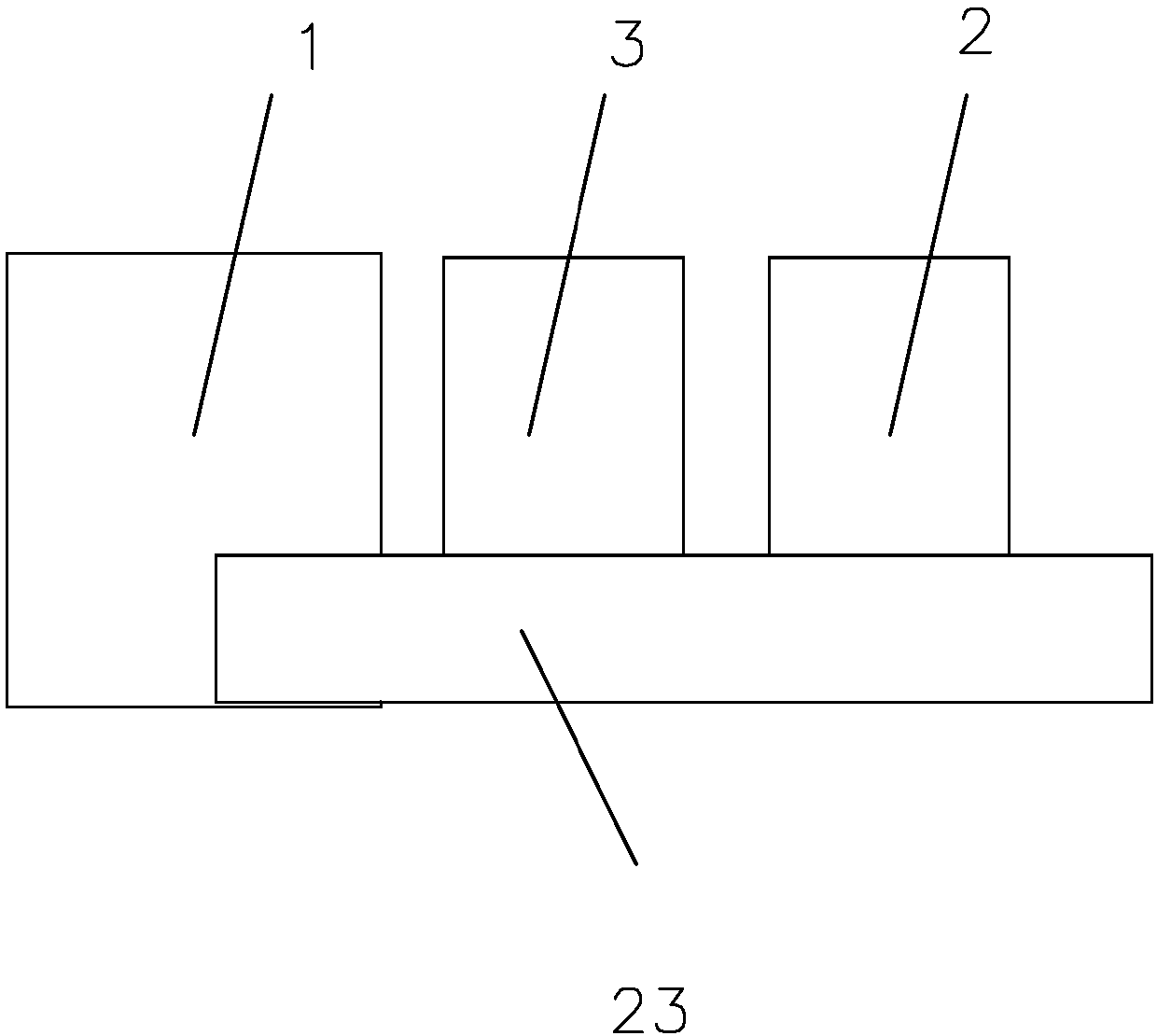

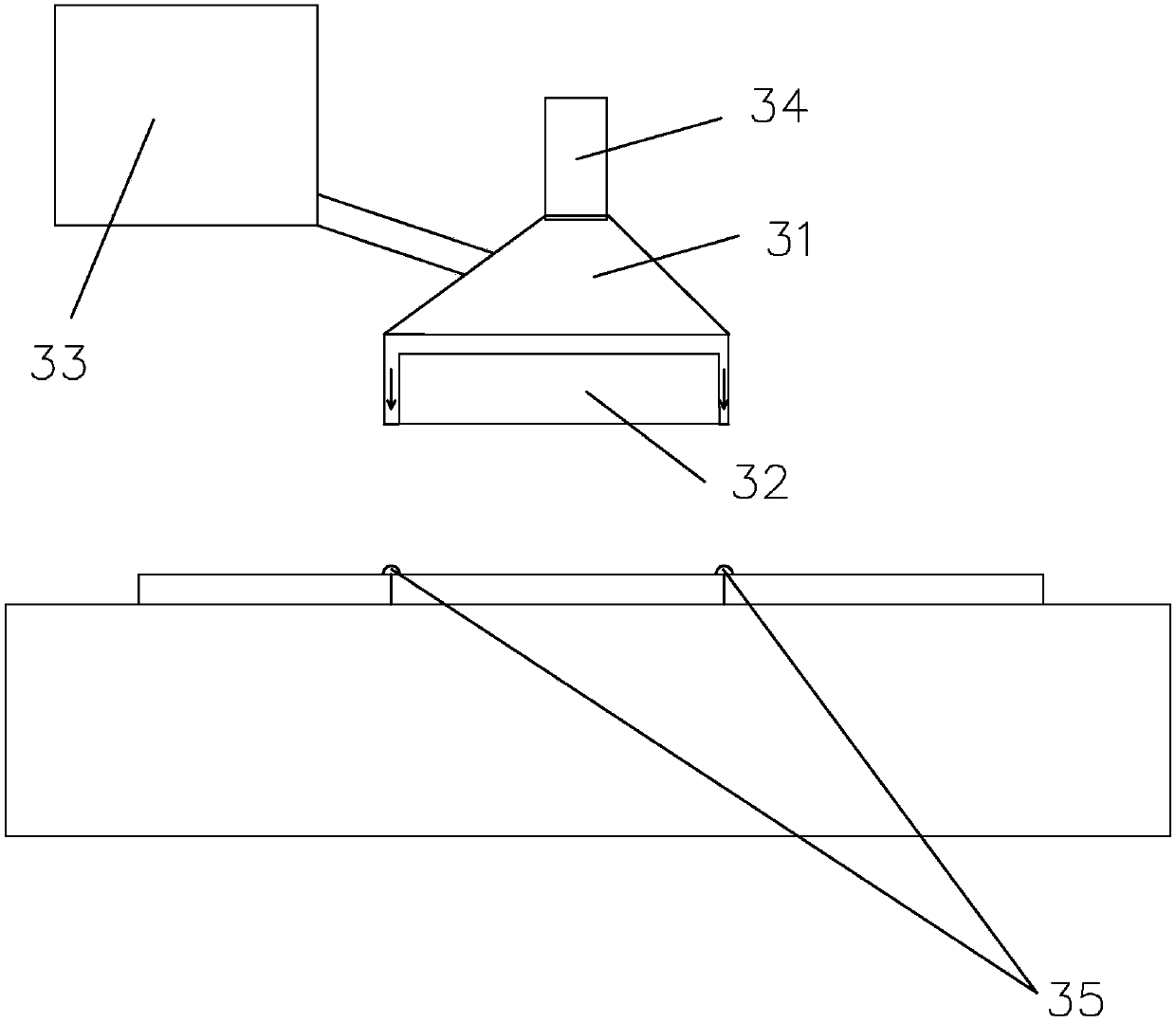

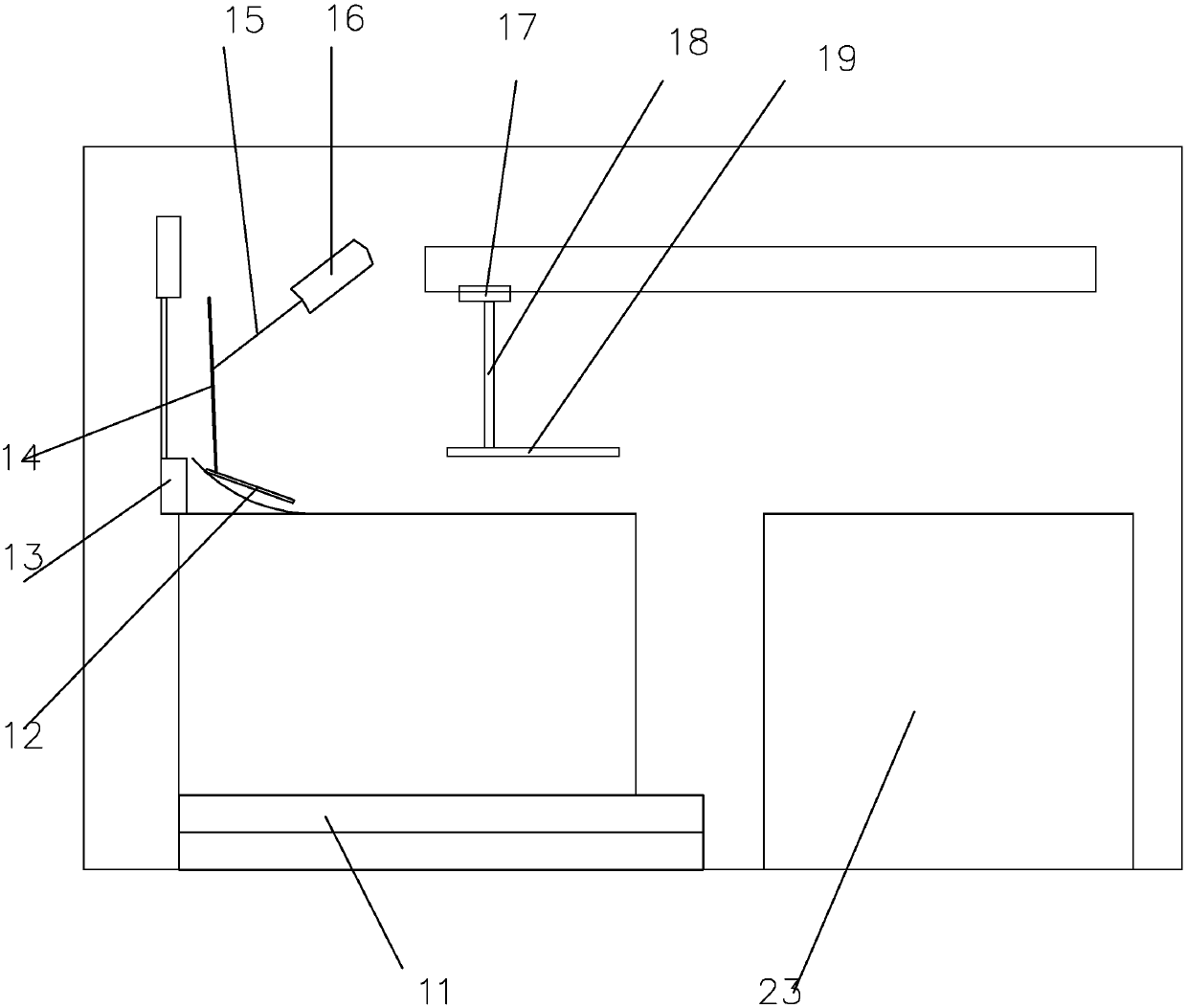

[0028] The present invention provides a fully automatic high-efficiency packaging box production line, including a paper feeding device 1, a gluing device 3, and a bonding device 2 connected in sequence by an endless conveyor belt; a vertically ascending and descending glue gun 31 including a rectangular glue spray port 32. The above The glue gun 31 is connected to the glue tank 33 . The top of the above-mentioned glue gun 31 is connected with a vertical lifter 34 . Through the rectangular glue spraying port 32, a rectangular glue strip 35 matching the size and shape of the rectangular frame is formed on the bottom plate at one time.

[0029] The feeding device includes a pressing mechanism, a first suction mechanism, a second suction mechanism, and a moving mechanism; the pressing mechanism includes a pressing push rod and a pressing foot 13 that can move up and down; the first suction mechanism includes the second A suction cup 12, the above-mentioned first suction cup 12 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com