Positioning method of scanning sampling starting point

A positioning method and starting point technology, which are used in measuring devices, material analysis by optical means, instruments, etc., can solve the problems of scanning imaging starting point drift, etc., and achieve the effect of improving accuracy, improving accuracy and accurate positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

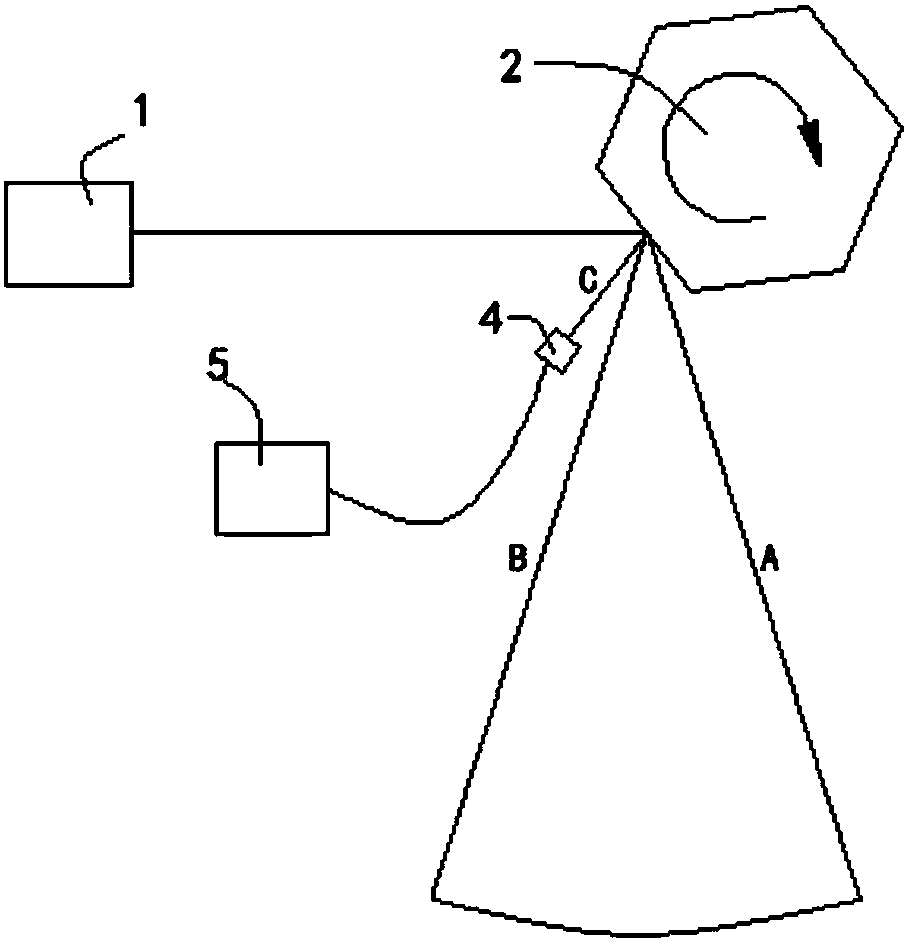

[0025] see figure 1 , a method for positioning a scanning sampling starting point, comprising the following steps:

[0026] First, the light source 1 is set opposite to the scanning mirror 2. The light source 1 is not limited to a laser light source, and can also be any collimated light source, such as LED, halogen lamp; The scanning mirror 2 forms the light scanning area A-C from the outside to the inside, where the area covered by light A to light B is within the effective range of optical scanning, and the area between light B to light C is within the effective range of optical scanning outside the area;

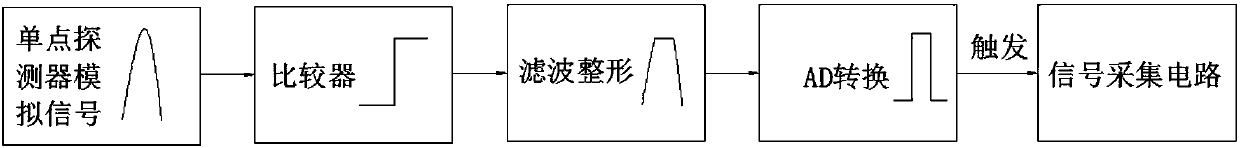

[0027] Single-point detector 4 is set on the position of light C inside the light scanning area, and described single-point detector 4 is photodiode, avalanche diode or photomultiplier tube; reflected light signal; see figure 2 , a comparator is connected to the output terminal of the single-point detector 4, and the comparator discriminates signals exceeding the ampl...

Embodiment 2

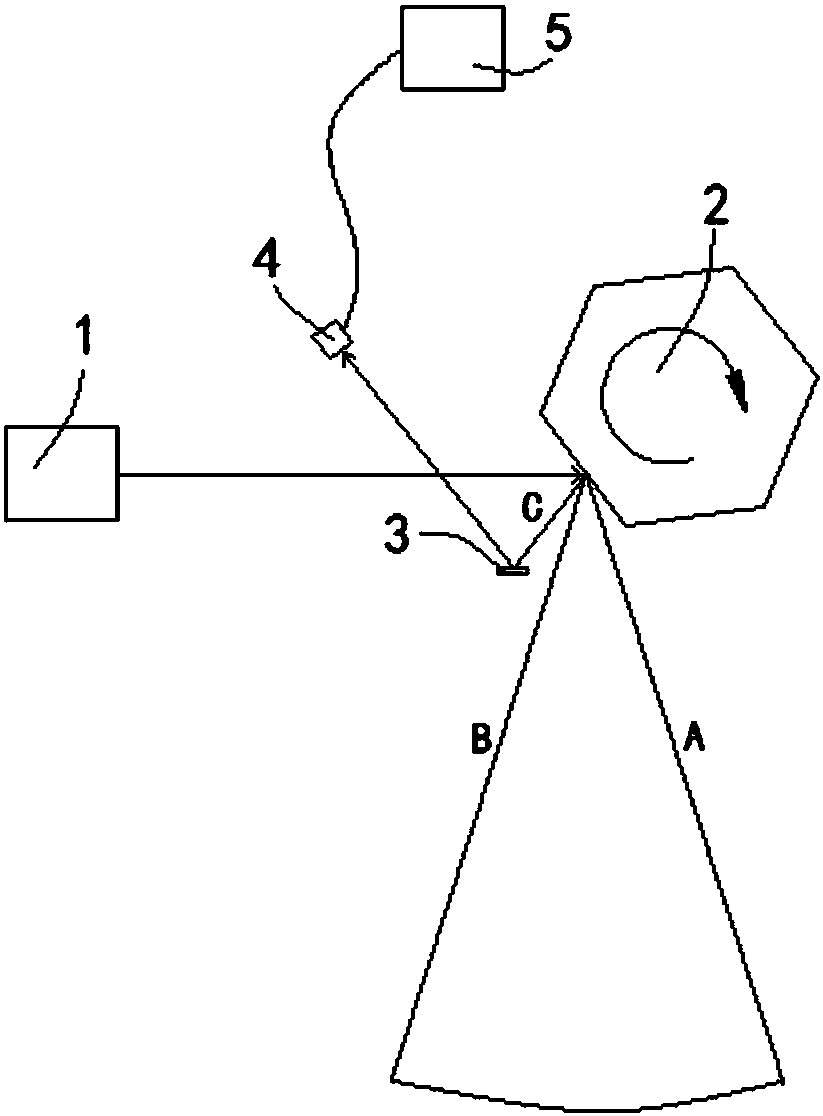

[0031] see image 3 , the refraction member 3 is set at the position of the light C of the scanning mirror 2, the refraction member 3 is a coated mirror, a metal polished mirror surface or a film surface; the refraction member 3 reflects the light C, and the single point detector 4 is arranged on the refraction member 3 On the position of the reflected light of light C; the rest are the same as in Embodiment 1.

[0032] During work, each frame of image will have an analog signal generated by a single-point detector 7. After the comparator discriminates the signal exceeding the amplitude h1, the noise filtering of the filter and the conversion of the signal by the AD converter, the signal The sampling of the acquisition circuit is accurate, and the critical reflection at the light C of the scanning mirror is always collected, so as to ensure that the images collected in each frame can be effectively spliced, improve the accuracy of photoelectric recognition, and make the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com