Thermo-sensitive type train ticket printer

A technology for printers and train tickets, applied in printing and other directions, can solve problems such as customer dissatisfaction, reduce service speed and efficiency, and staff burden, and achieve the effect of improving efficiency, improving elimination efficiency, and reducing paper jams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In the following, the technical solution of the present invention will be further described in detail through embodiments.

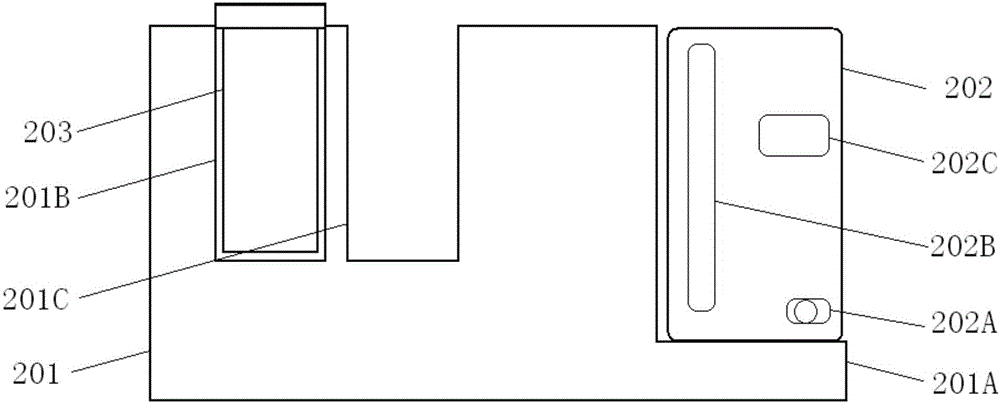

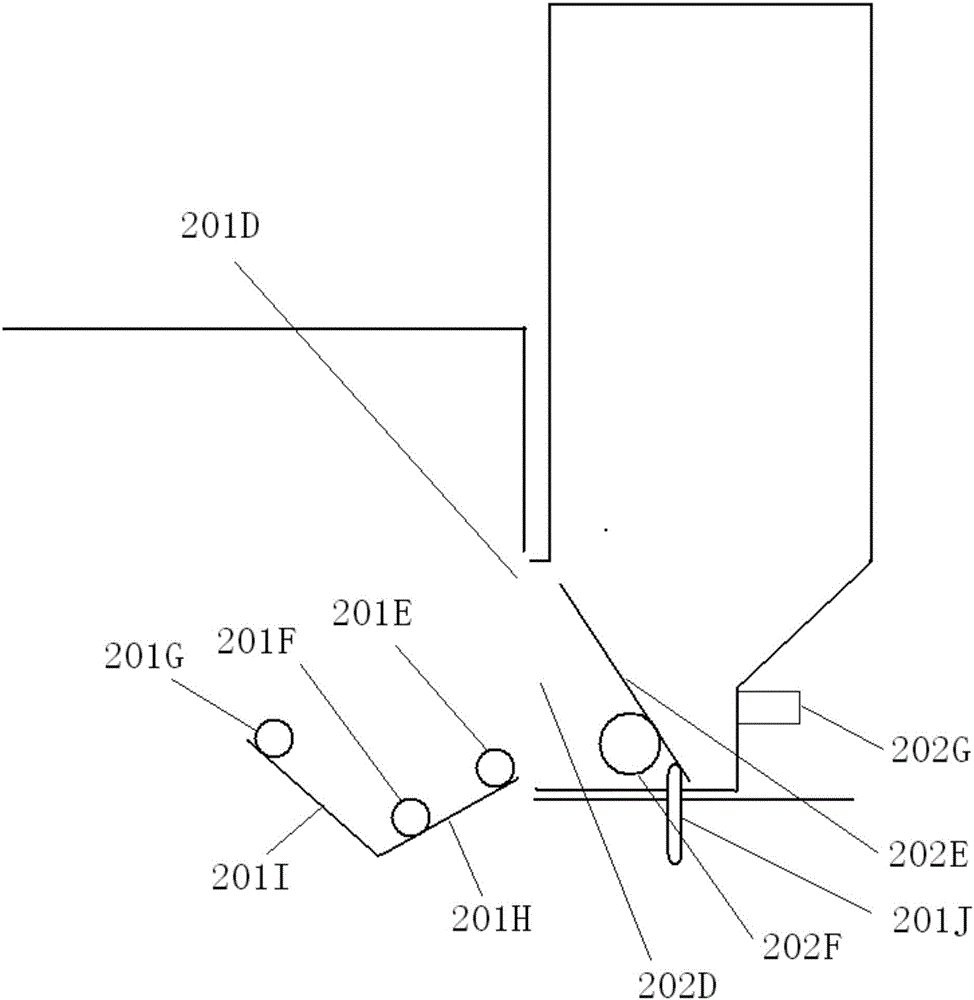

[0018] figure 2 It is a schematic diagram of the overall structure of a thermal train ticket printer in a preferred embodiment of the present invention. As shown in the figure, the thermal train ticket printer includes a printer host 201, an external paper feeding cassette 202, and a print head 203. The casing of the printer host 201 has a socket portion 201A for placing an external paper feed cassette 202, and the lower end of the external paper cassette 202 can be inserted and locked on the socket 201A by a buckle structure. After unlocking by sliding the unlock button 202A, it is unplugged from the socket portion 201A, so that the external hanging paper cassette 202 can be installed, removed and replaced in one step by plugging and unplugging operations. The external-hanging paper feeding cassette 202 contains a heat-sensitive ticket substrate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com