Method and device for conditioning paper

A technology of paper and equipment, applied in the field of conditioning paper, can solve problems such as system failure, achieve the effects of minimizing scrap, reducing loss and maintenance, and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

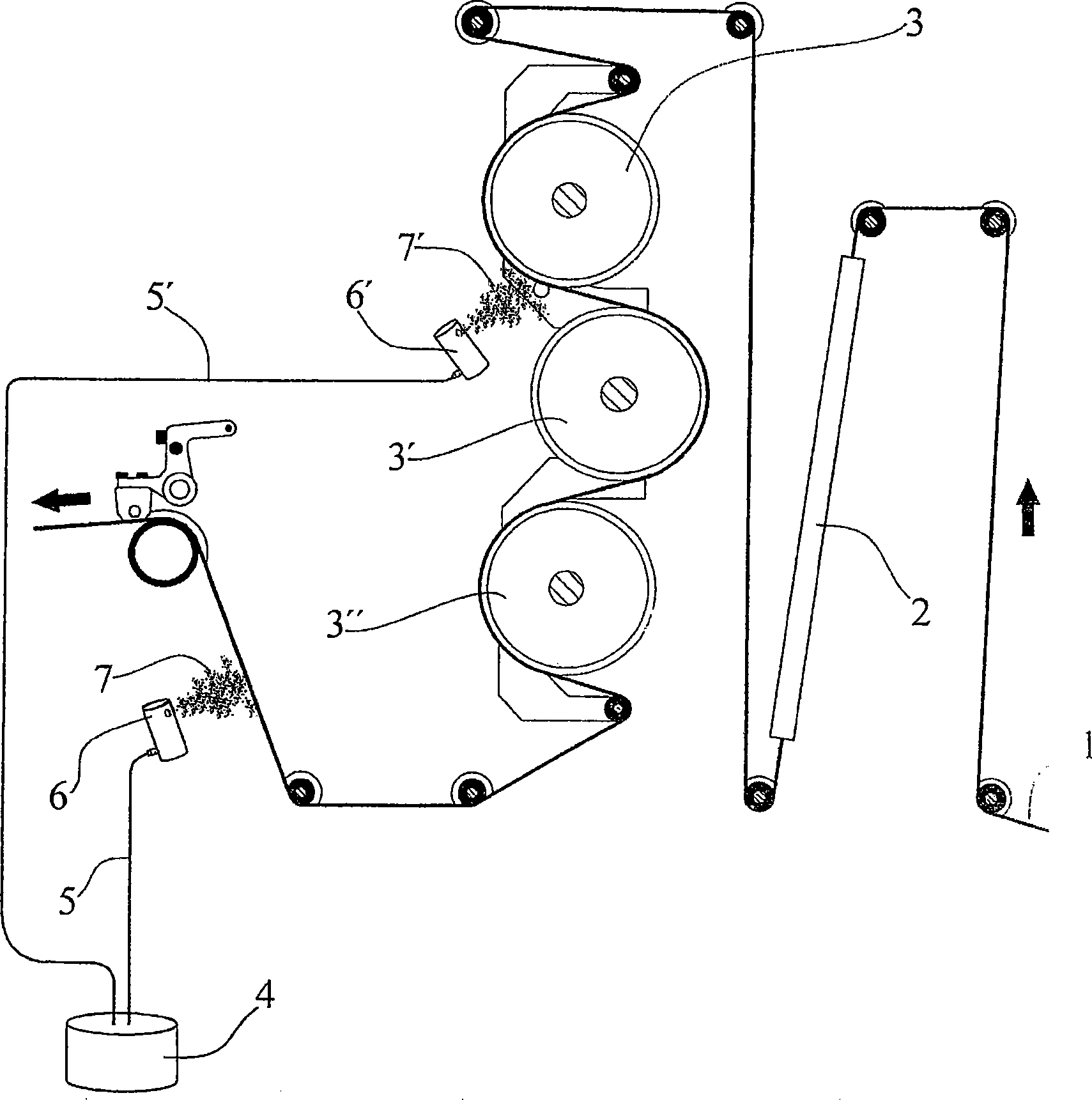

[0025] figure 1 A schematic diagram is shown of a possible embodiment of the invention, where the invention may be provided, for example, as a successor to a digital printing device. It is also possible to integrate the device shown as an accessory into a digital printer or device. In the device shown, the printing substrate or paper 1 enters the primary cooling zone 2 after entering the device through the entry zone. This cooling zone may comprise a cooling plate close to the paper 1 in a dry cold gas stream, or any other known system. In this first cooling zone, in the embodiment shown, there is a second zone where cooling is provided by three rolls 3, 3', 3", the central roll of which has a movement to vary the cooling rolls 3, 3', 3". Capability of contact angle between 3" and paper 1. The role of these rollers may be similar to that disclosed in documents ES2222089 and ES2222110, both of which correspond to the invention of the inventor of this patent.

[0026] The devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com