Packaging box material plate automatic positioning device and punching and waste discharging production line

An automatic positioning and packing box technology, applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve problems such as positioning defects, and achieve the effects of convenient maintenance, reliable positioning, and compact structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

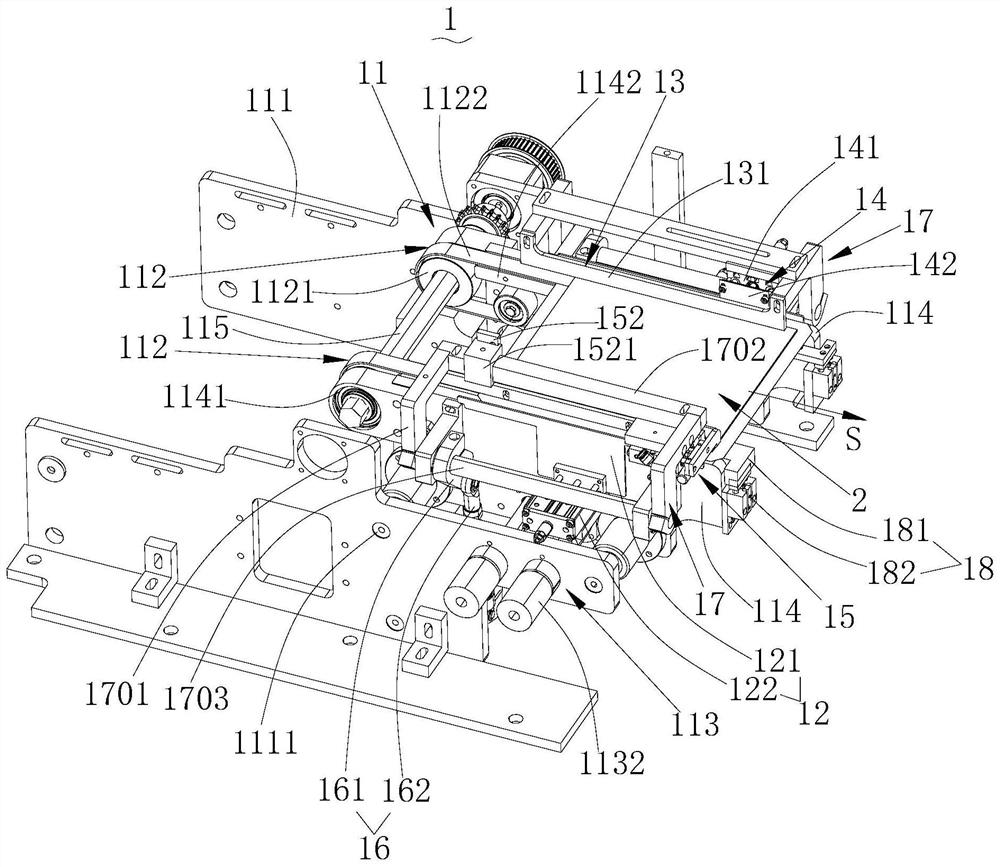

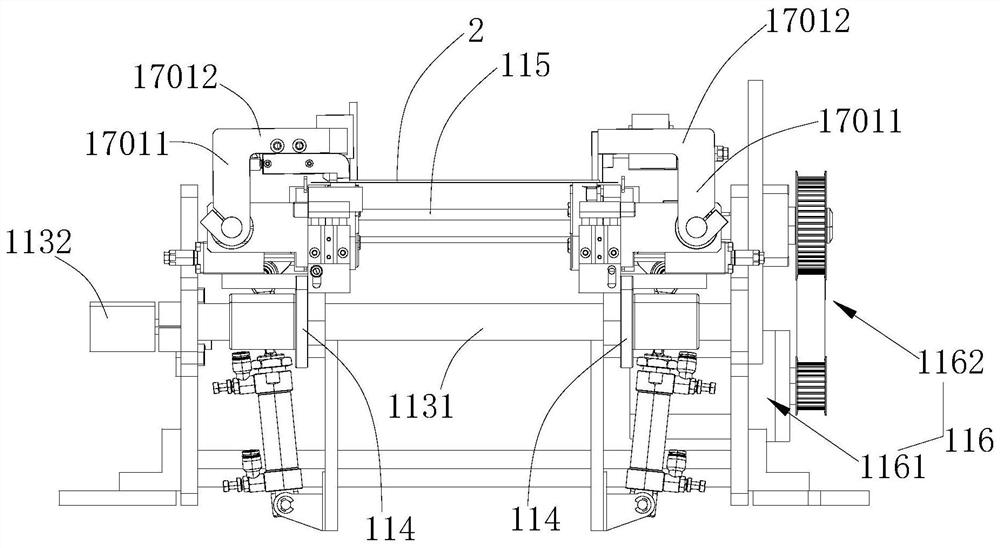

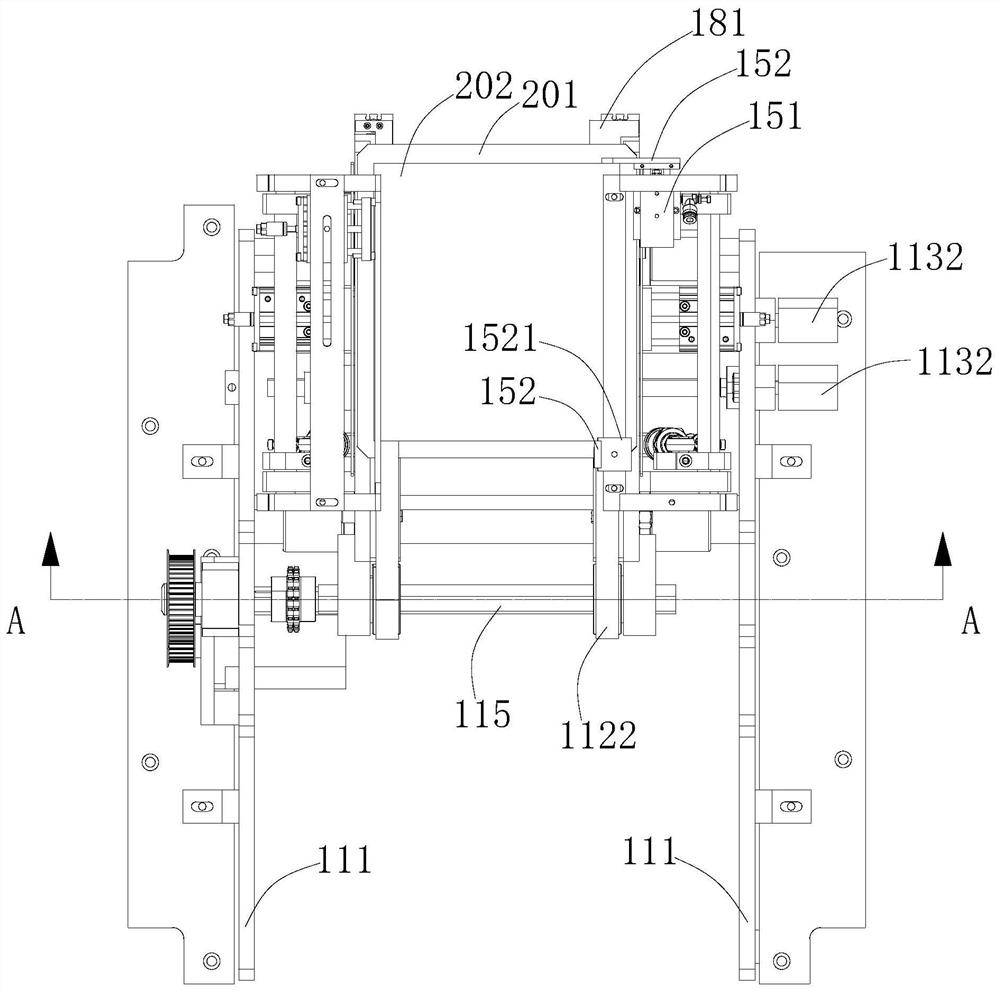

[0046] refer to figure 1 , figure 2 , image 3 , Figure 4 , the invention discloses an automatic positioning device 1 for packaging box material boards, comprising a frame, a material conveying component 11 arranged on the frame, a pre-positioning component 12, an incoming material detection sensor (not shown in the figure), a pressing component 13. The horizontal positioning component 14 and the vertical positioning component 15, wherein, the feeding component 11 is used to convey the glued packaging box material board 2, and the packaging box material board 2 is a material board commonly used in the prior art, including facial tissue 201 And the cardboard 202 glued with the face paper 201, the area of the cardboard 202 is smaller than the face paper 201;

[0047] The packaging box material plate automatic positioning device 1 of the present invention is used for positioning a rectangular packaging box material plate 2. In some possible implementations, the packaging b...

Embodiment 2

[0108] refer to Figure 7 , this embodiment discloses a packaging box punching and waste discharge production line, including a punching device 3, a blanking and waste discharge device 4, and the packaging box material plate automatic positioning device 1 in embodiment 1, and the packaging box material plate automatic positioning device 1 , the punching device 3 and the blanking and waste discharging device 4 are arranged in sequence, and the packaging box punching and waste discharging production line also includes a feeding device 5 and a feeding device 6, and the feeding device 5 is used to accurately position the packaging box material plate automatic positioning device 1 The positioned packaging box material plate 2 is taken and placed on the punching device 3, and the unloading device 6 is used to take and place the package box material plate 2 punched by the punching device 3 on the blanking and waste discharge device 4 , in this embodiment, the feeding device 5 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com