Double-sided printer

A printer and double-sided technology, applied in the field of printing, can solve the problems of long printing time and cumbersome printing steps, and achieve the effect of improving printing efficiency, shortening the required time, and improving work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

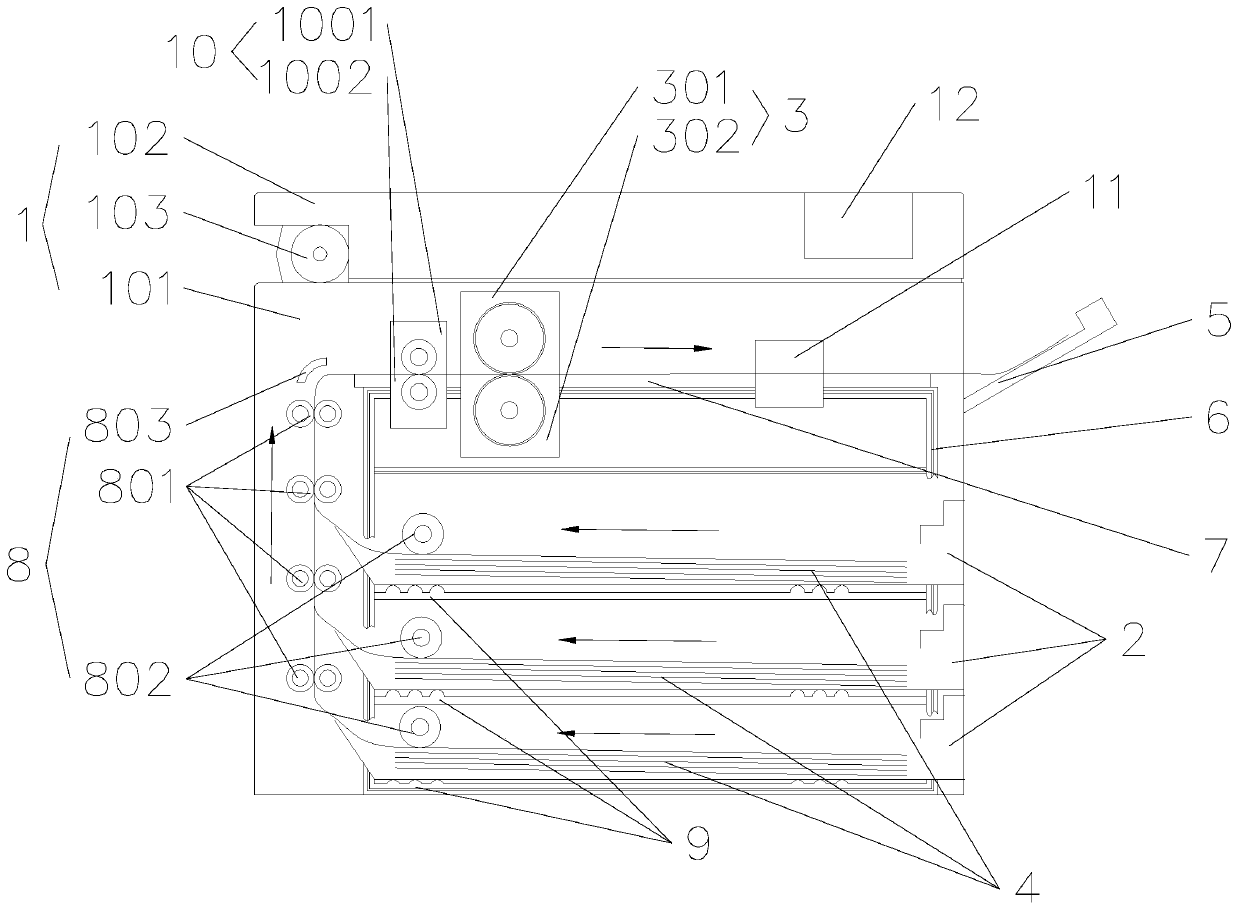

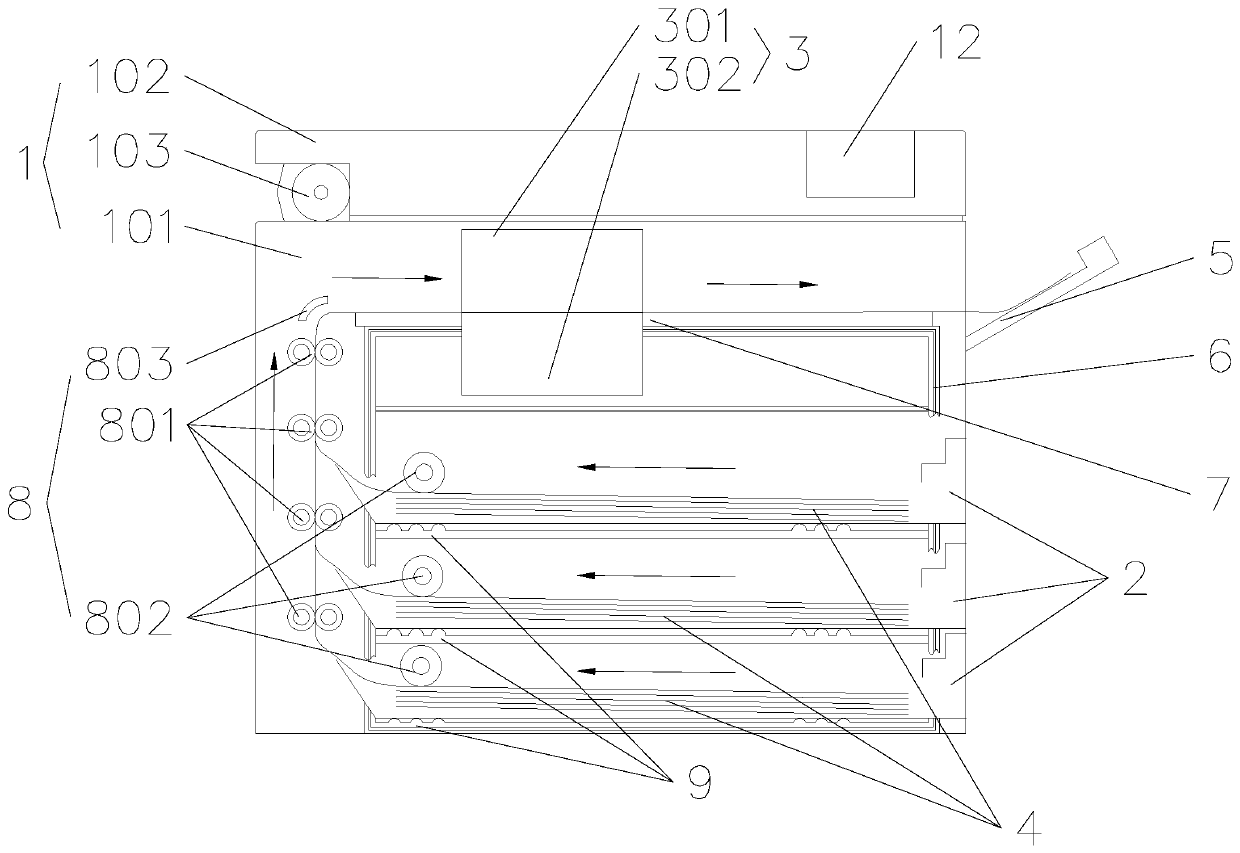

[0022] The present invention is specifically described below in conjunction with accompanying drawing, as Figures 1 to 2 As shown, a duplex printer includes a casing 1 , a paper box 2 and a printing module 3 .

[0023] The feature of this embodiment is that the printing module 3 includes a printing module I301 and a printing module II302, the printing module I301 and the printing module II302 are arranged opposite to each other on both sides of the printing medium 4, and the printing of the printing module I301 face down, the printing surface of the printing module II302 faces upward, and the printing module I can print red characters or black characters; setting the printing surfaces of the printing module I301 and the printing module II302 in this way realizes the Simultaneous printing of the front and back sides of the same position on the above-mentioned printing medium 4 shortens the time required for a single double-sided printing and improves the printing efficiency of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com