Cam link paper stopping mechanism

A cam link and cam technology, applied in the direction of object separation, pile separation, thin material processing, etc., can solve the problems of unfavorable product production, increase the difficulty and time of assembly, reduce business efficiency, etc., to reduce the cost of components, The effect of improving the profitability of the enterprise and simplifying the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

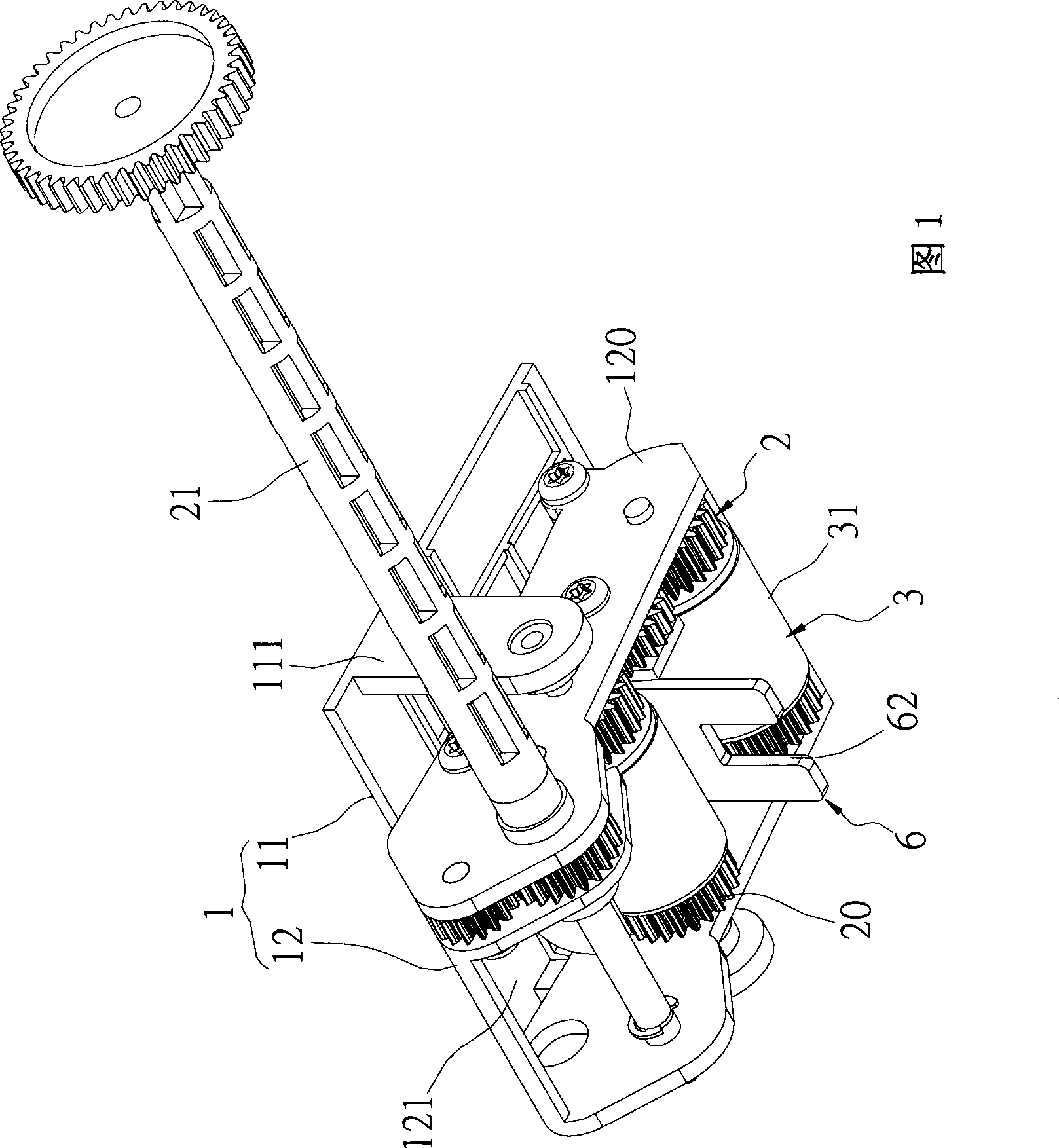

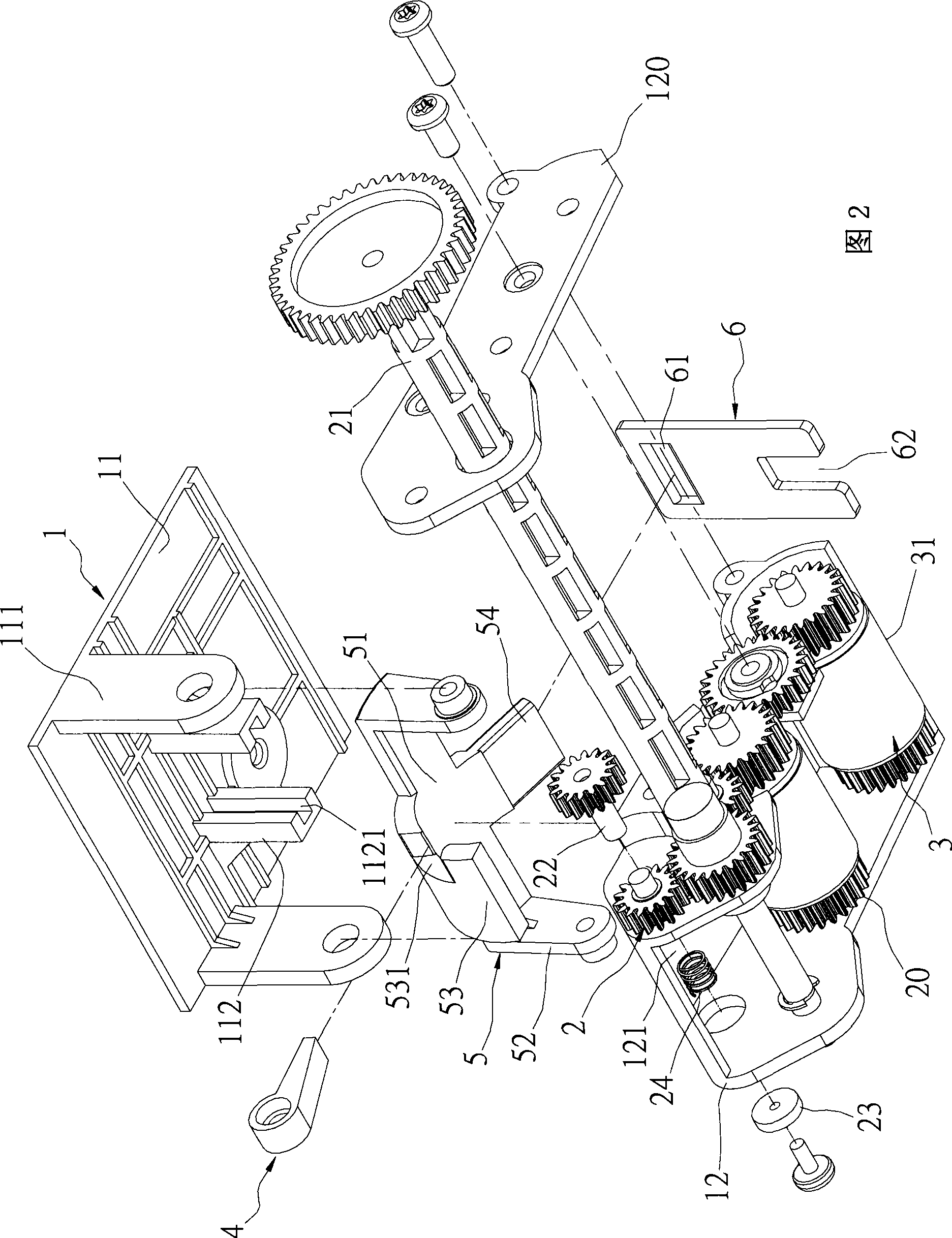

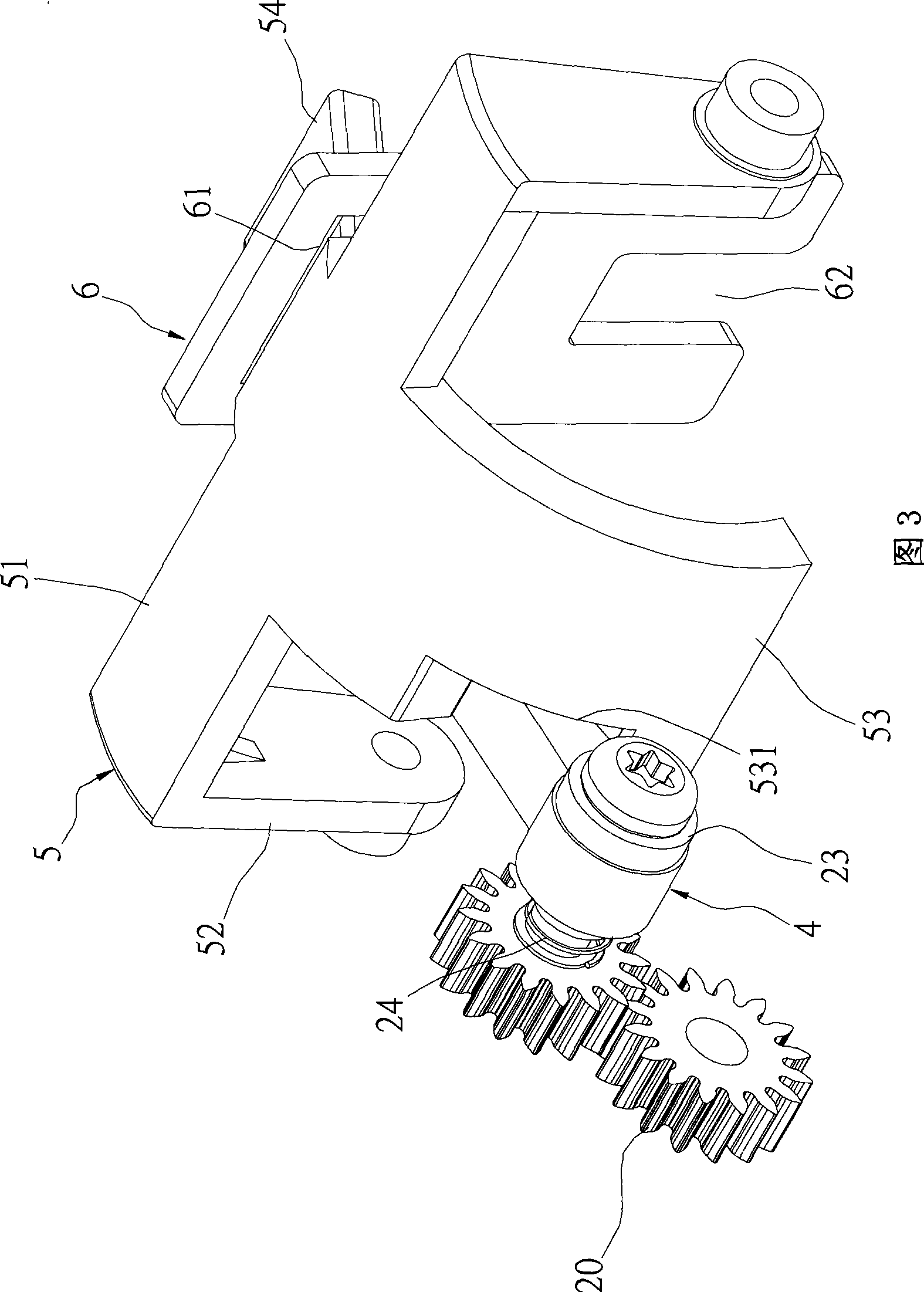

[0053] Please refer to Fig. 1 to Fig. 6, which is the cam-link paper blocking mechanism of the present invention, which is arranged on the body 7 of the business machine, and is necessary for printing operations by various transmission mechanisms, electronic components, and others. As an assembly composed of components, the machine body 7 has a paper placement area 71 for supporting stacks of paper 8 for use when the business machine intends to perform printing operations. The cam-link paper blocking mechanism includes a housing set 1 , a transmission gear set 2 , two paper feeding rollers 3 , a cam 4 , a rotating part 5 and a baffle plate 6 .

[0054] Please refer to FIG. 1 and FIG. 2, the housing set 1 is molded with plastic material, and it includes an upper housing 11 and a lower housing 12, and the upper housing 11 is fixed on the paper placement area 71 of the machine body 7. At the top (as shown in FIG. 4 ), the upper housing 11 has a pair of pivot plates 111 and a pair...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com