Patents

Literature

31results about How to "Less blocked" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

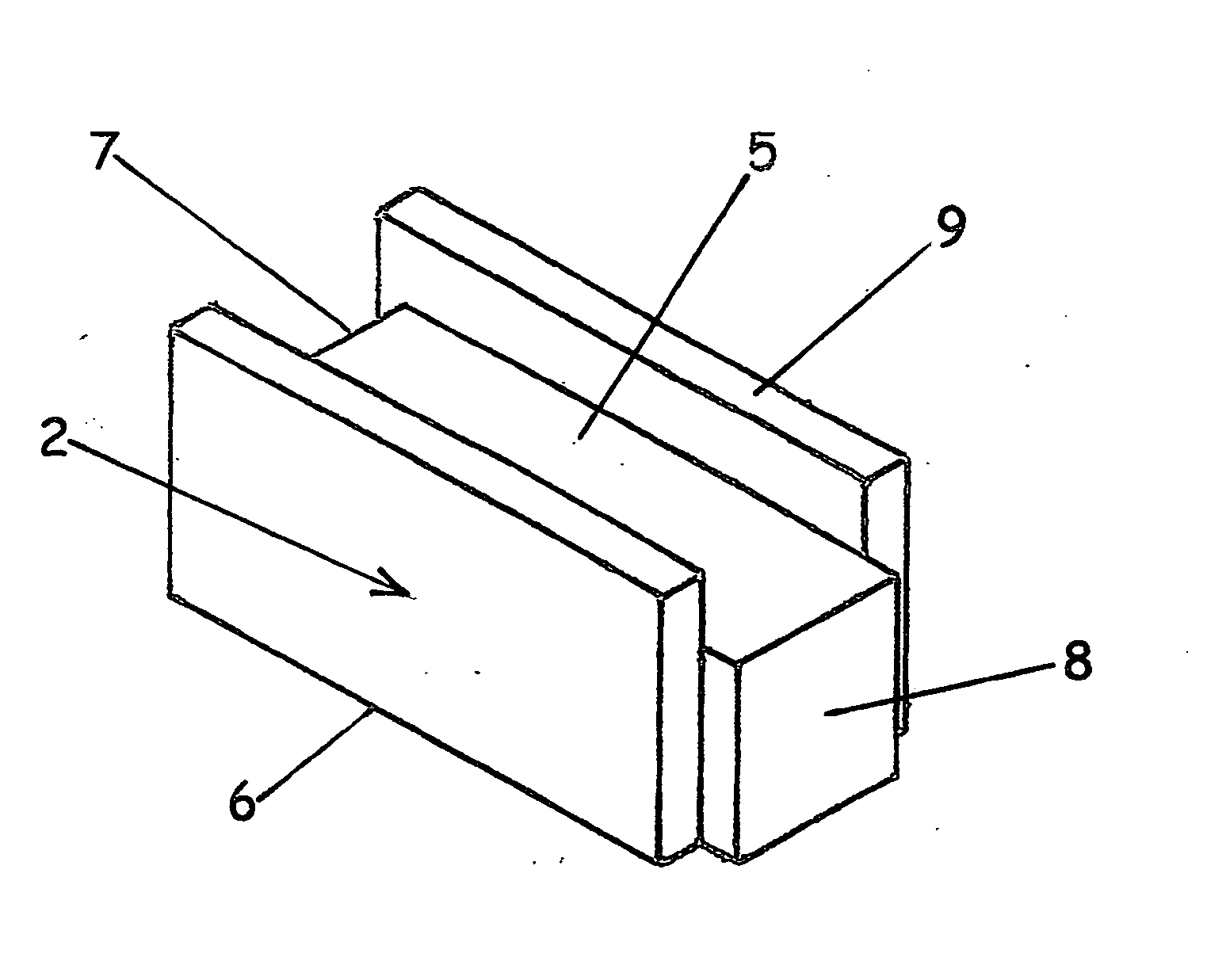

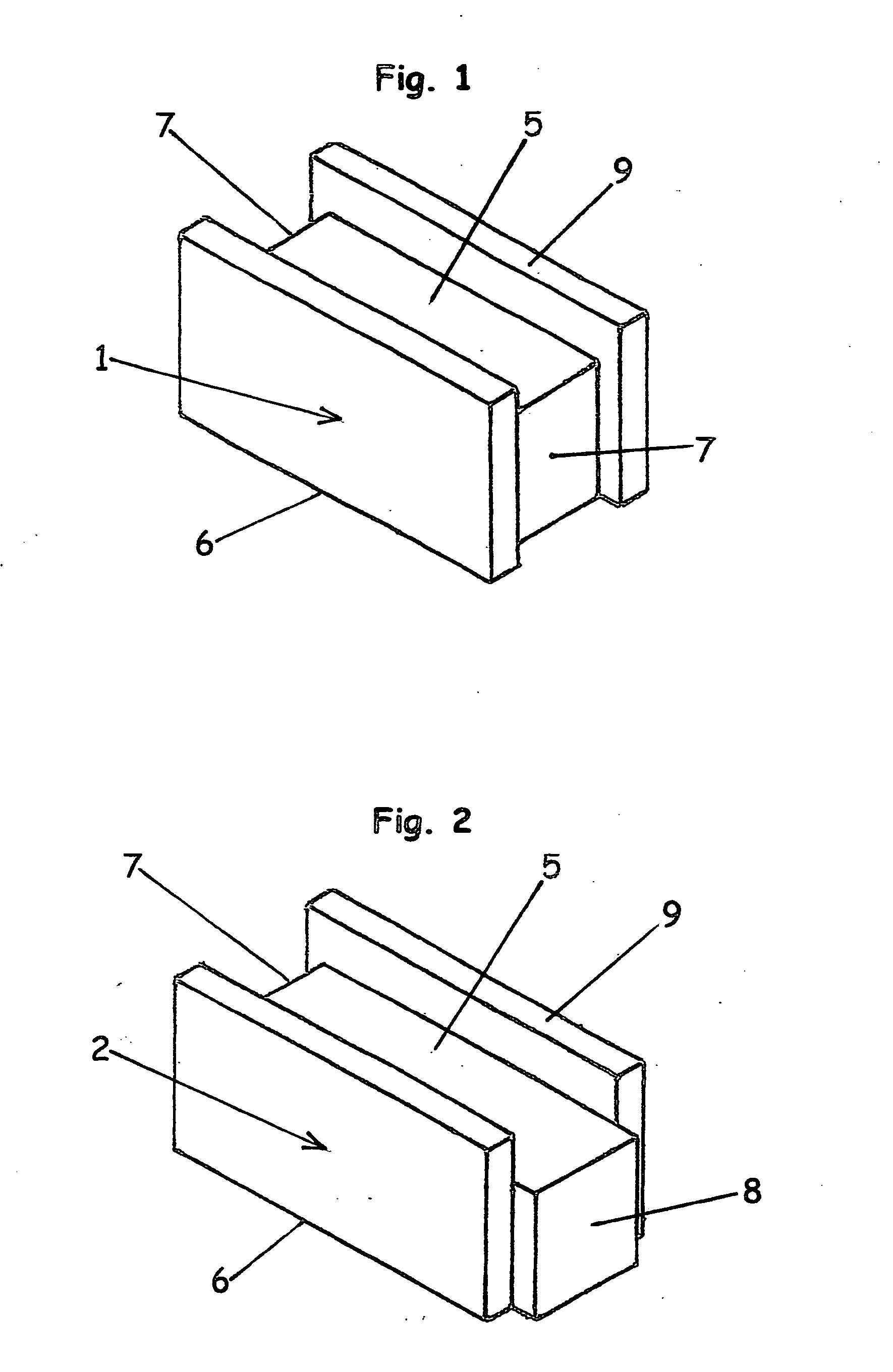

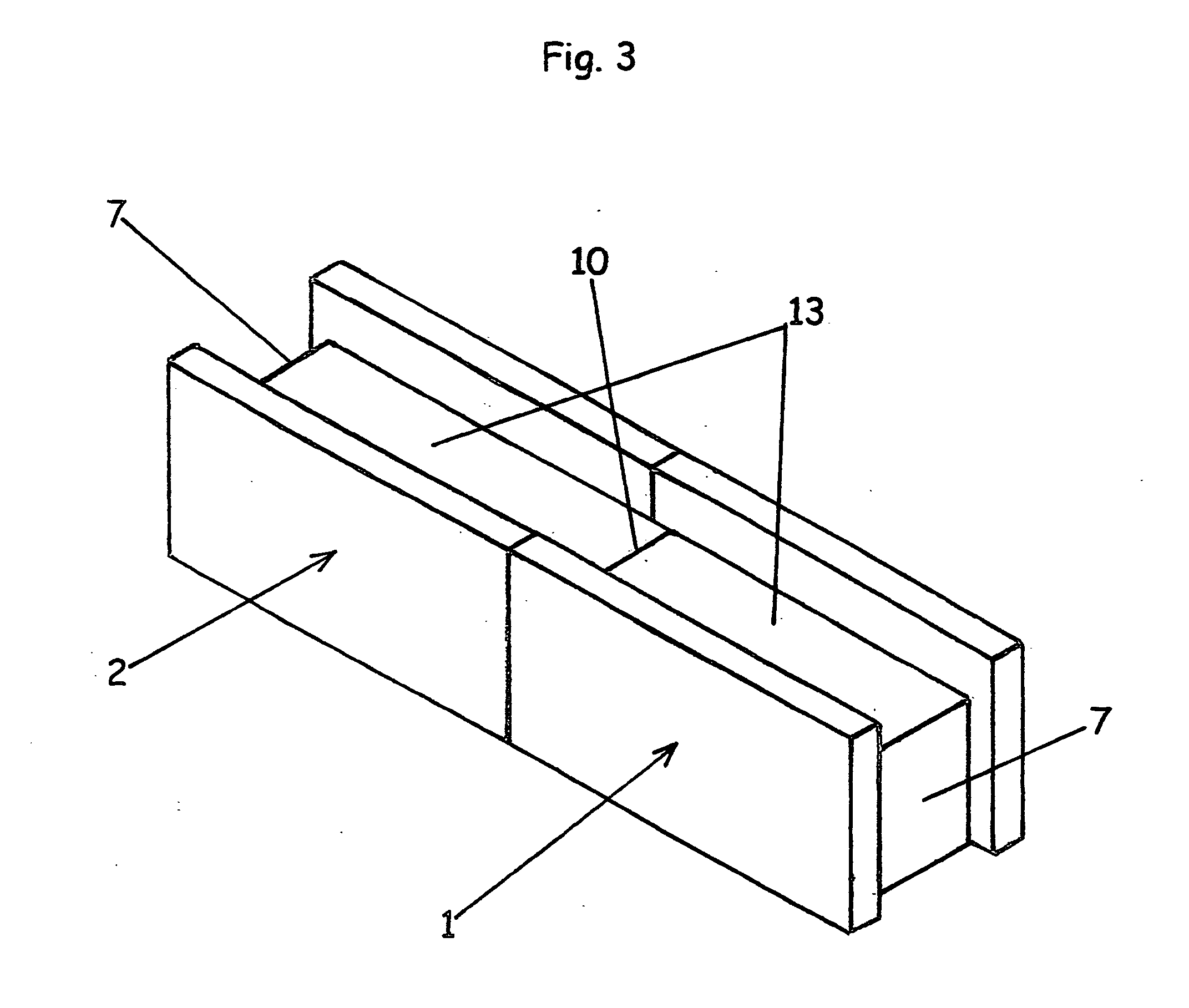

Building blocks with integrated assembling design

InactiveUS20070204548A1Less cementHigh insulation valueConstruction materialWallsStructural engineeringUltimate tensile strength

A new building material made of chopped straw, cement, mortar cement or lime combined together with a bonding agent is pressed into building blocks of different sizes and shapes. The blocks come in different sizes and shapes to serve different building needs and / or to fit an integrated assembly system. The blocks are interlocked or fitted to correspond to specific requirements. Depending on the proportions of the elements and the pressure exercised to make the blocks, the density can be controlled to increase either the insulation value or the structural value. The grooves, which are part of the interlocking system, can also be filled with concrete either vertically or horizontally or both to create a stronger structure calibrated according to additional structural needs. The resulting concrete structure can also be reinforced with steel rod to further increase its strength. This building material is highly adaptable and environmentally friendly.

Owner:GAGNE LOUIS

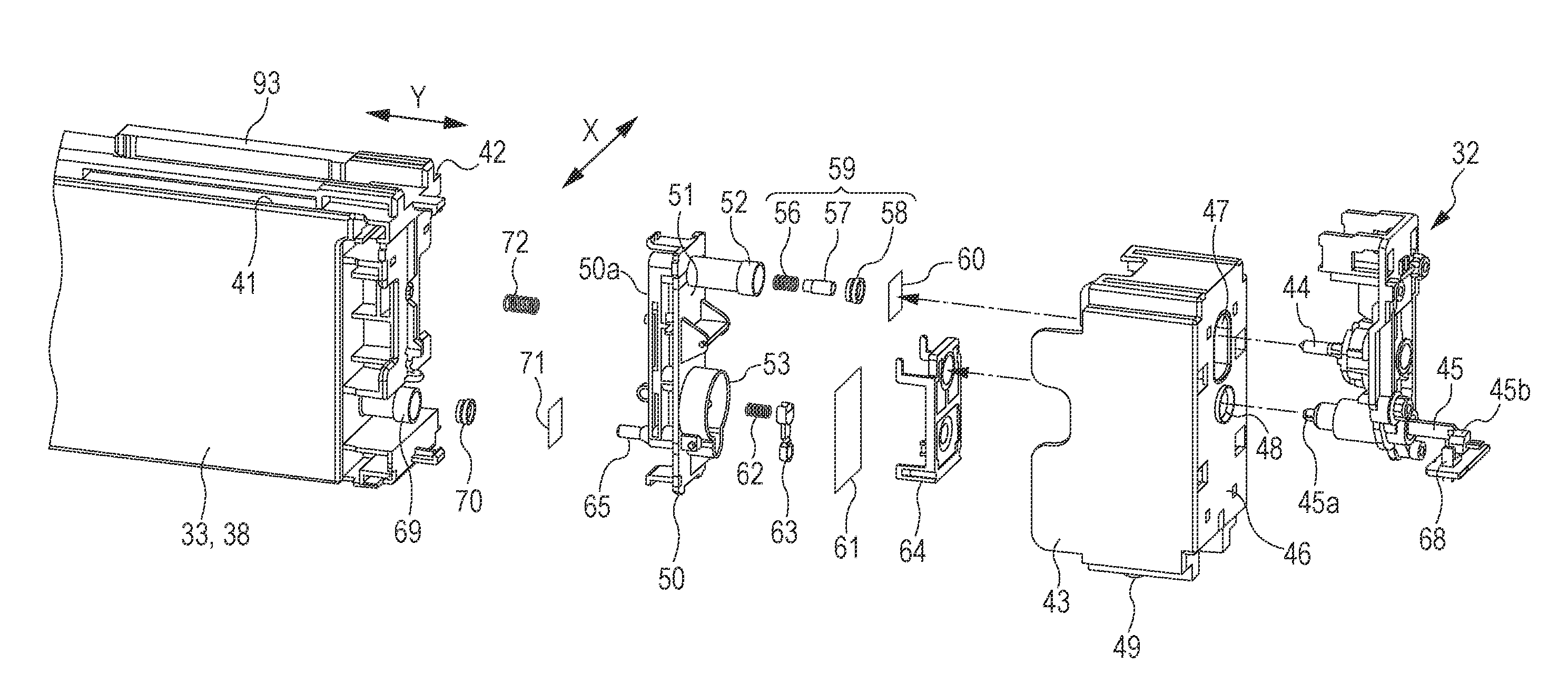

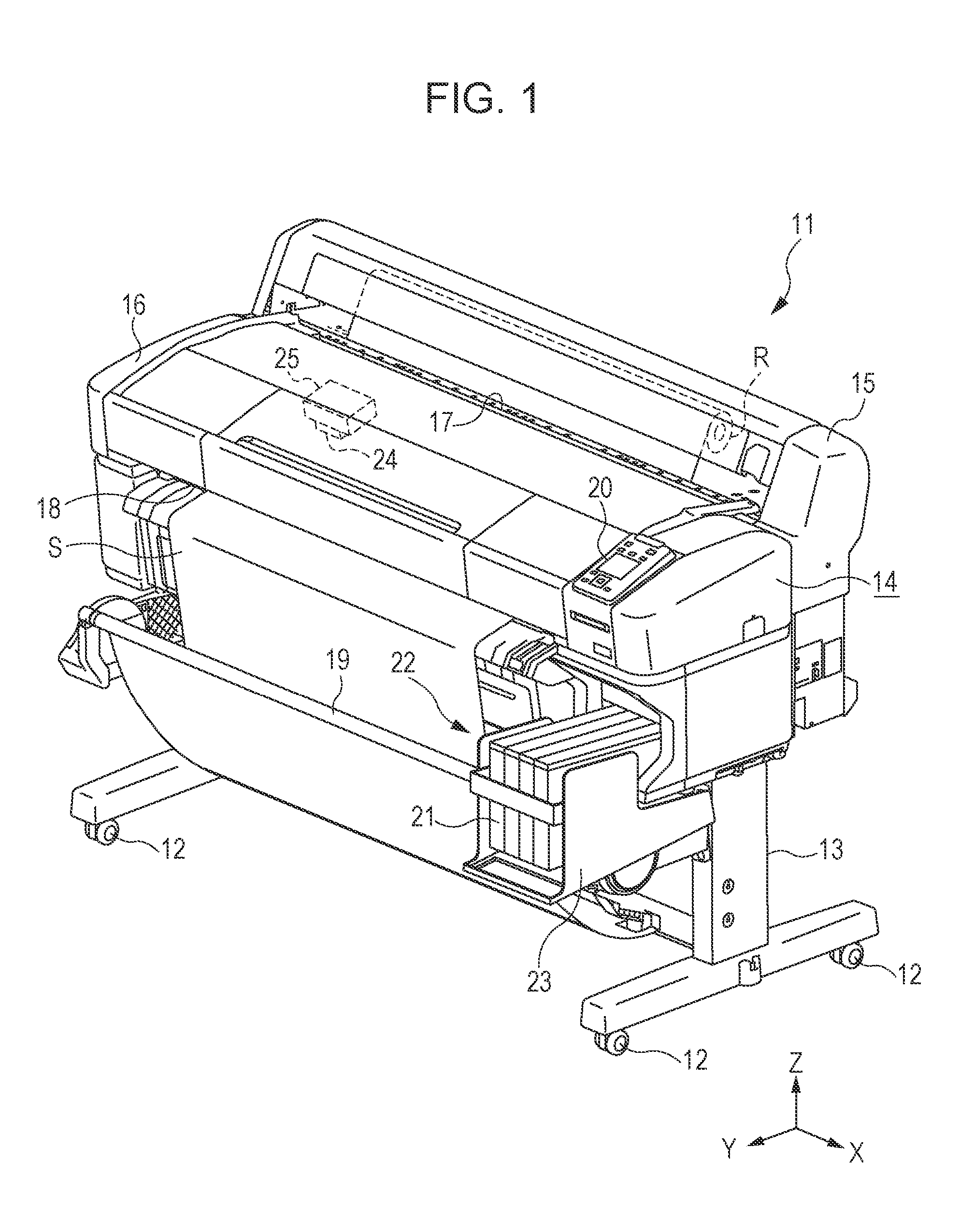

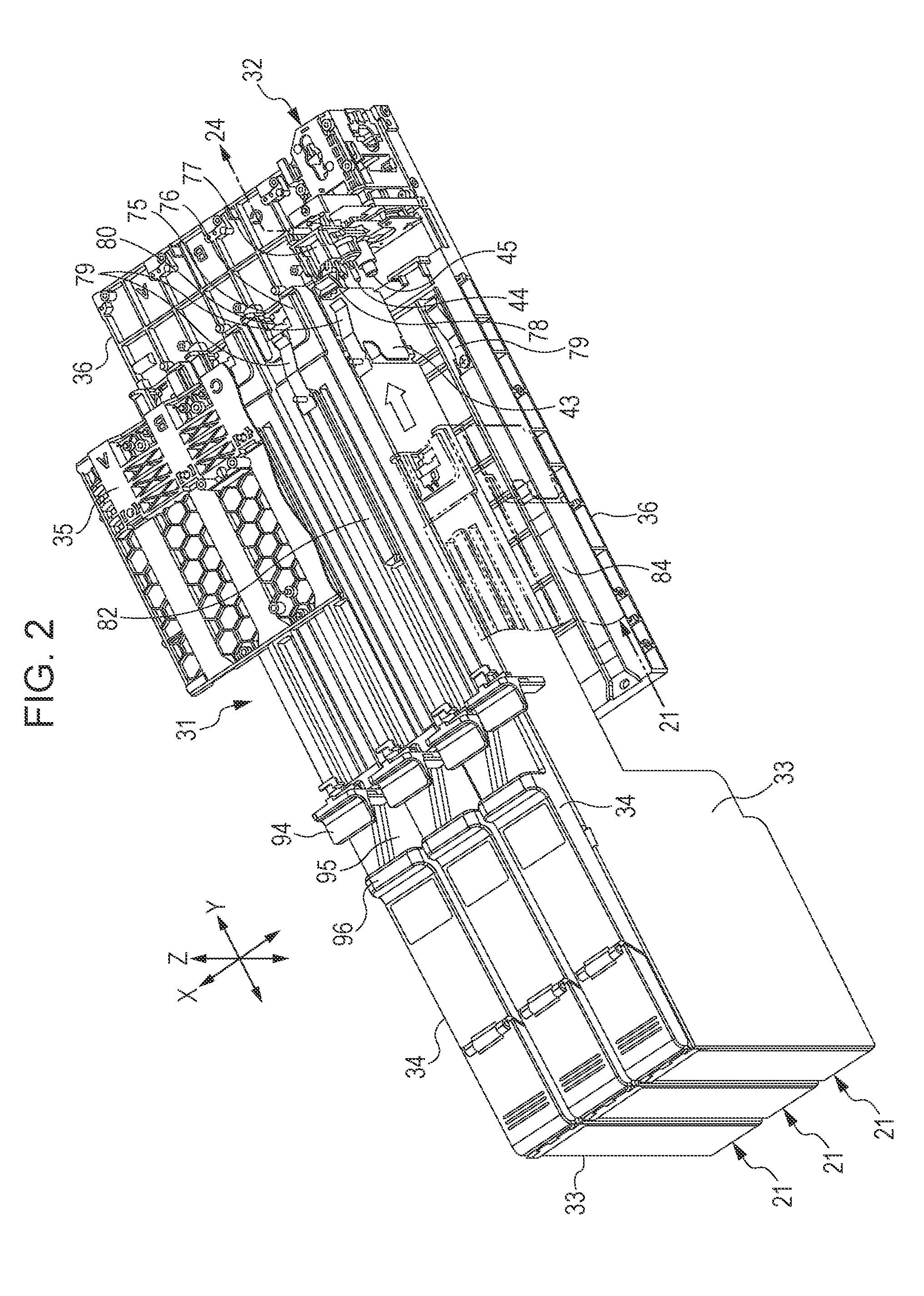

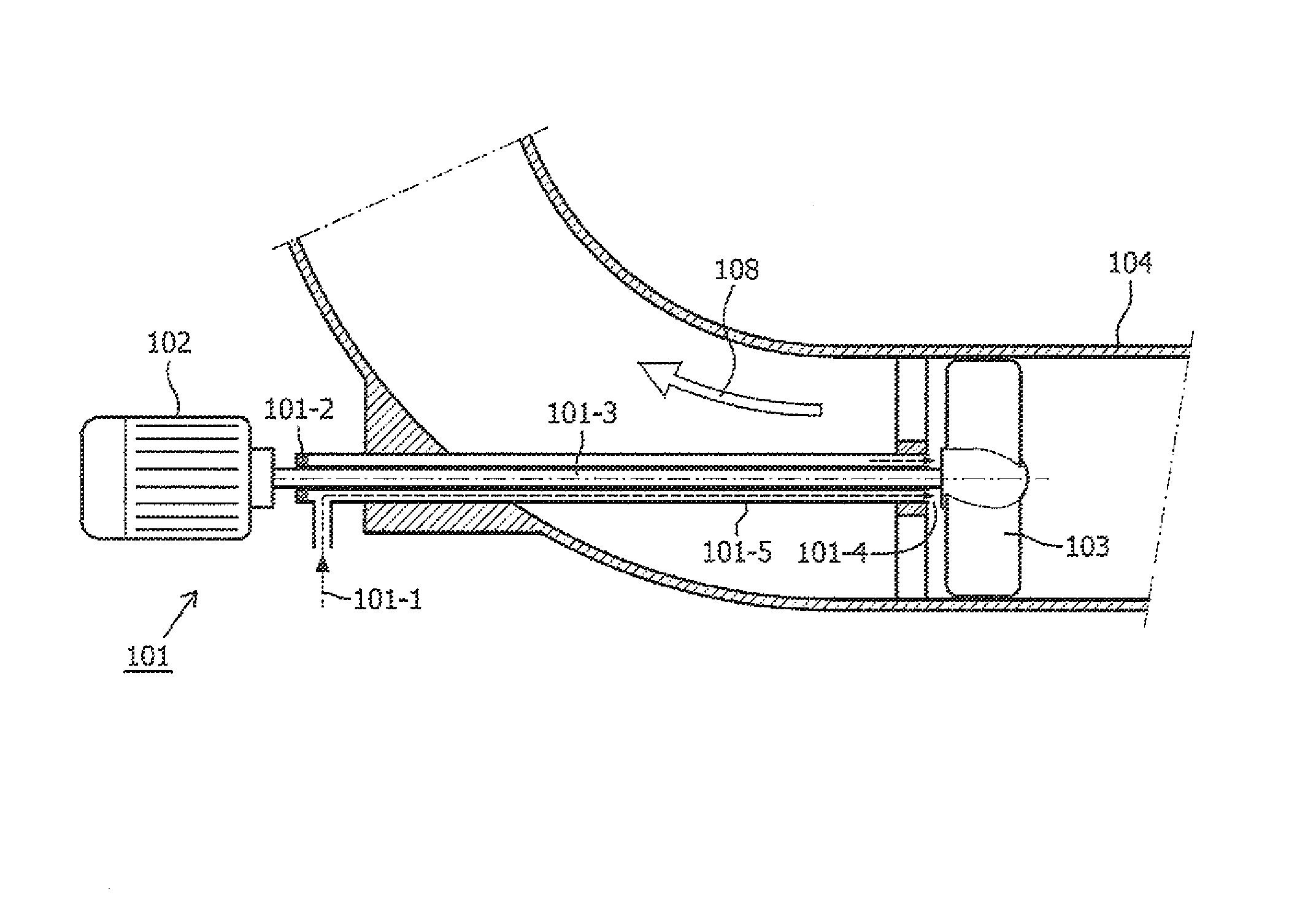

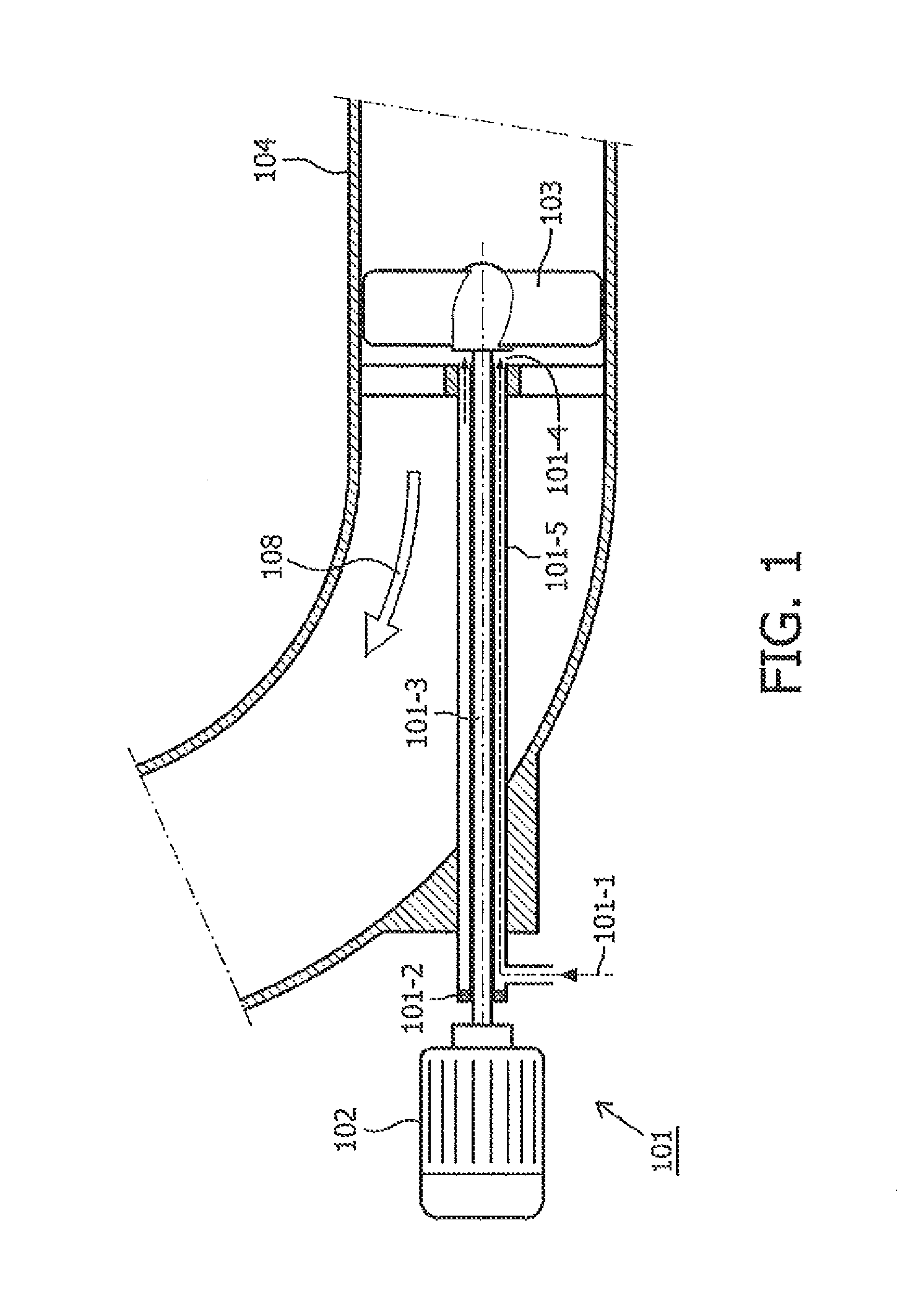

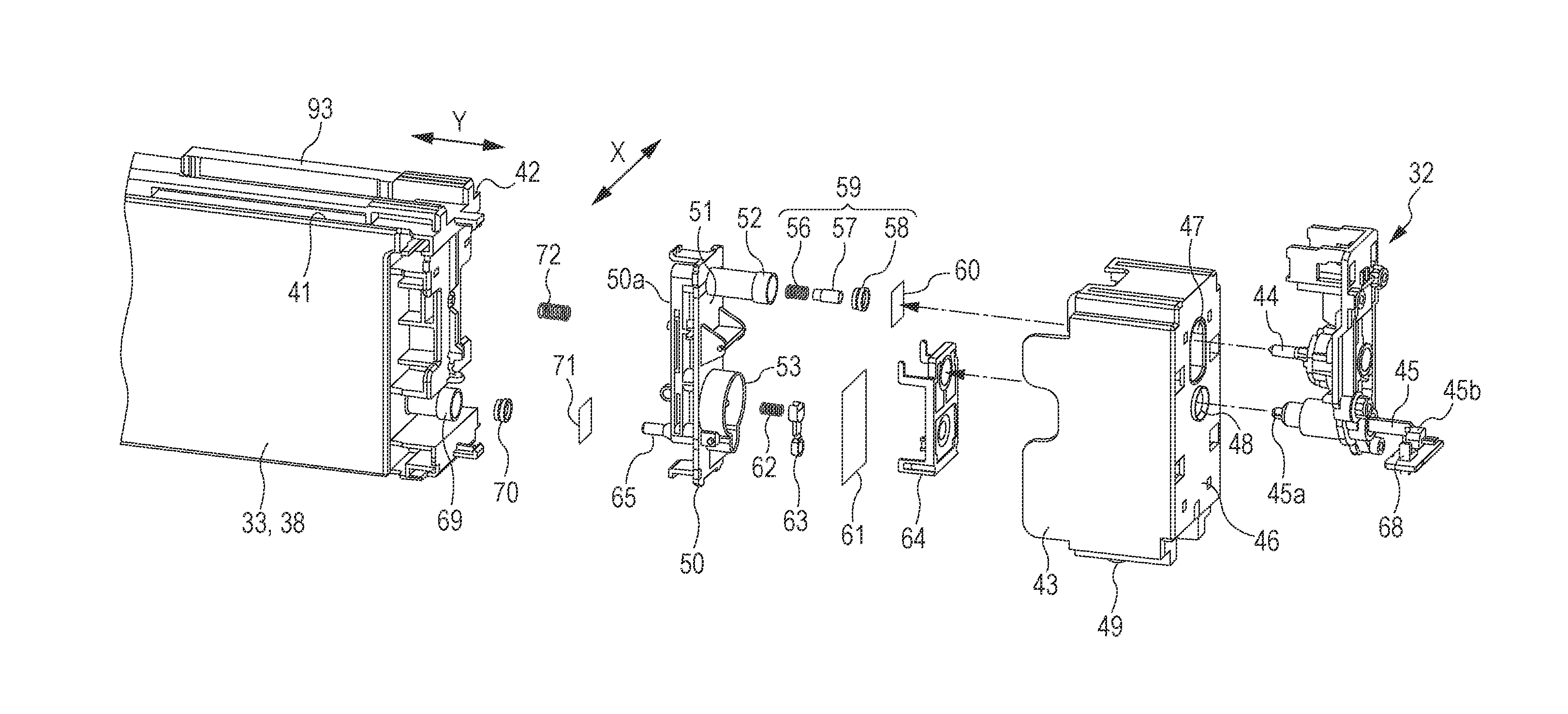

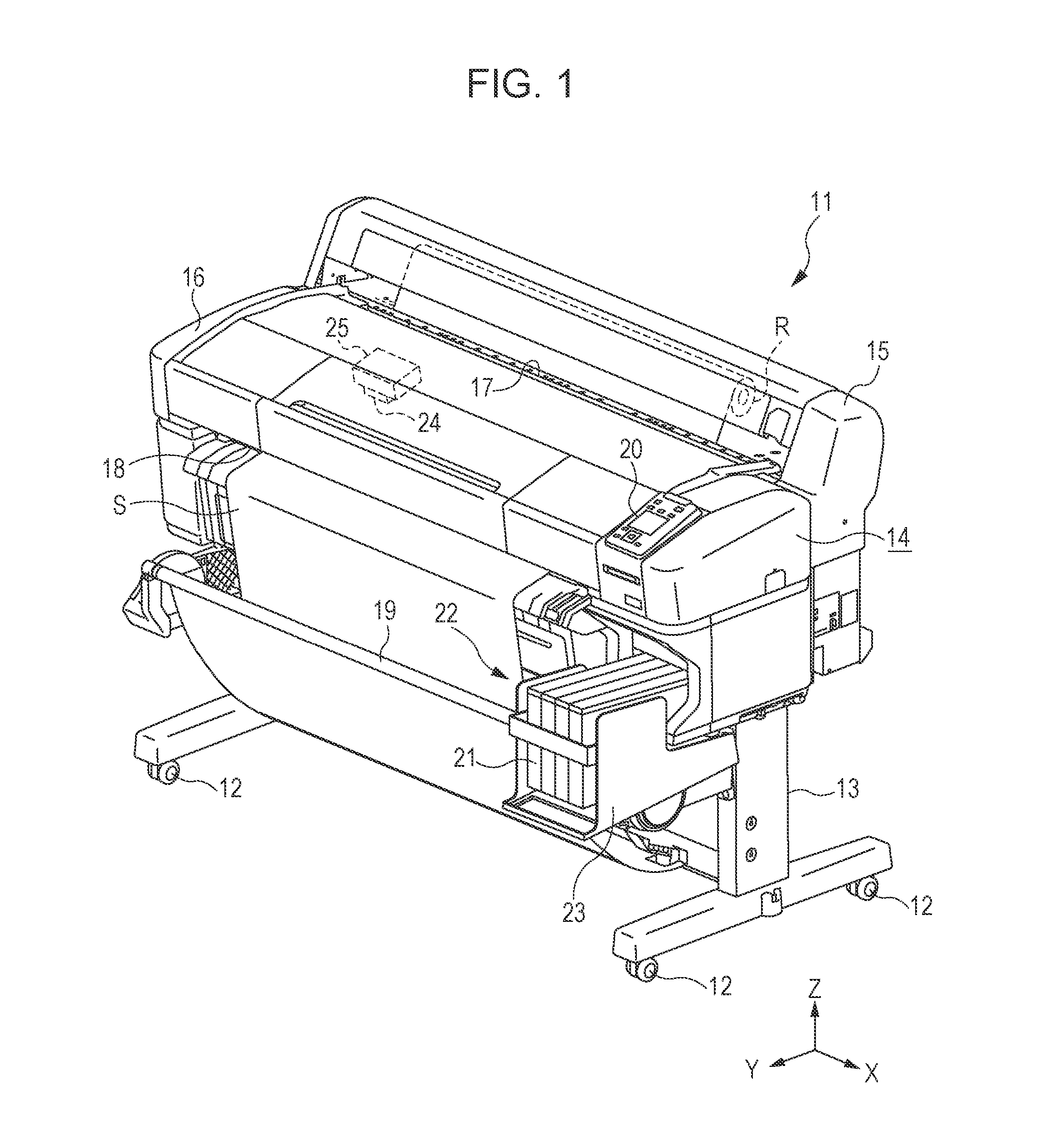

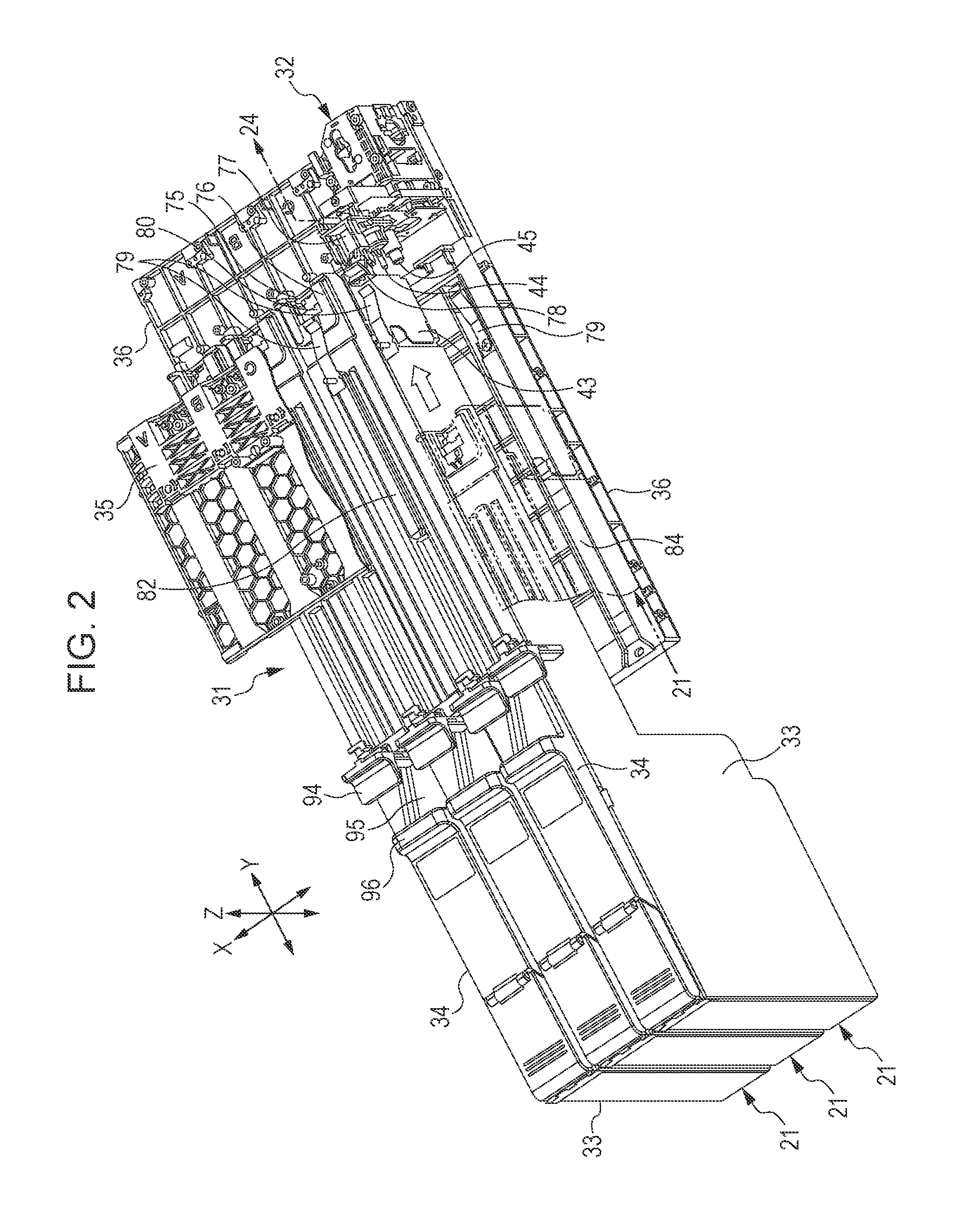

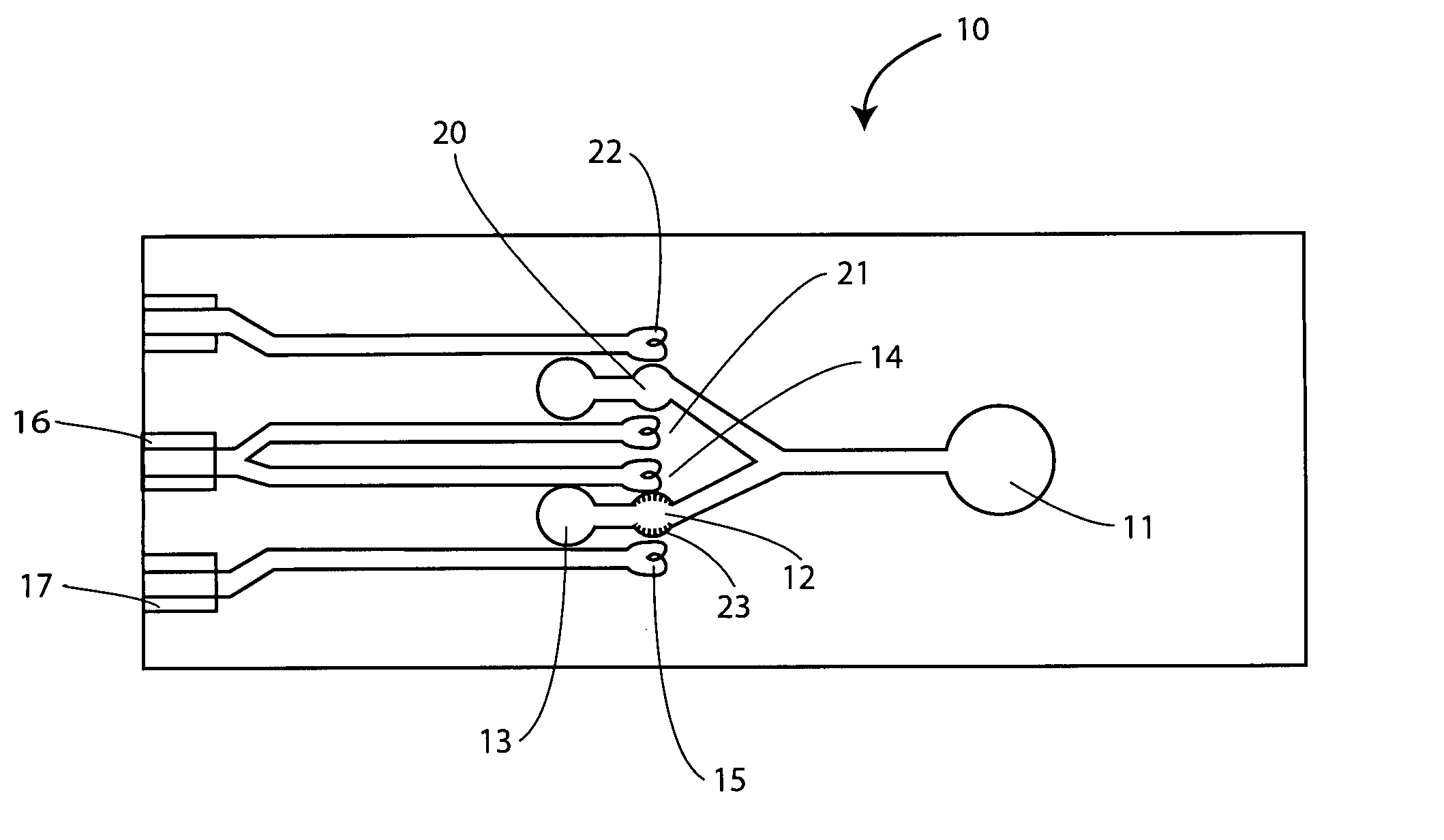

Liquid Storage Container

ActiveUS20140063148A1Difference in pressureReduce differential pressurePrintingEngineeringLiquid storage

A liquid storage container includes a liquid storage body storing ink supplied to a printer consuming the ink. The liquids storage body includes an ink chamber which can store the ink, a filler port through which ink can be poured into the ink chamber, a lead-out port which leads out the ink stored in the ink chamber to the printer side, and a lead-out channel which connects a channel opening formed in the ink chamber and the lead-out port.

Owner:SEIKO EPSON CORP

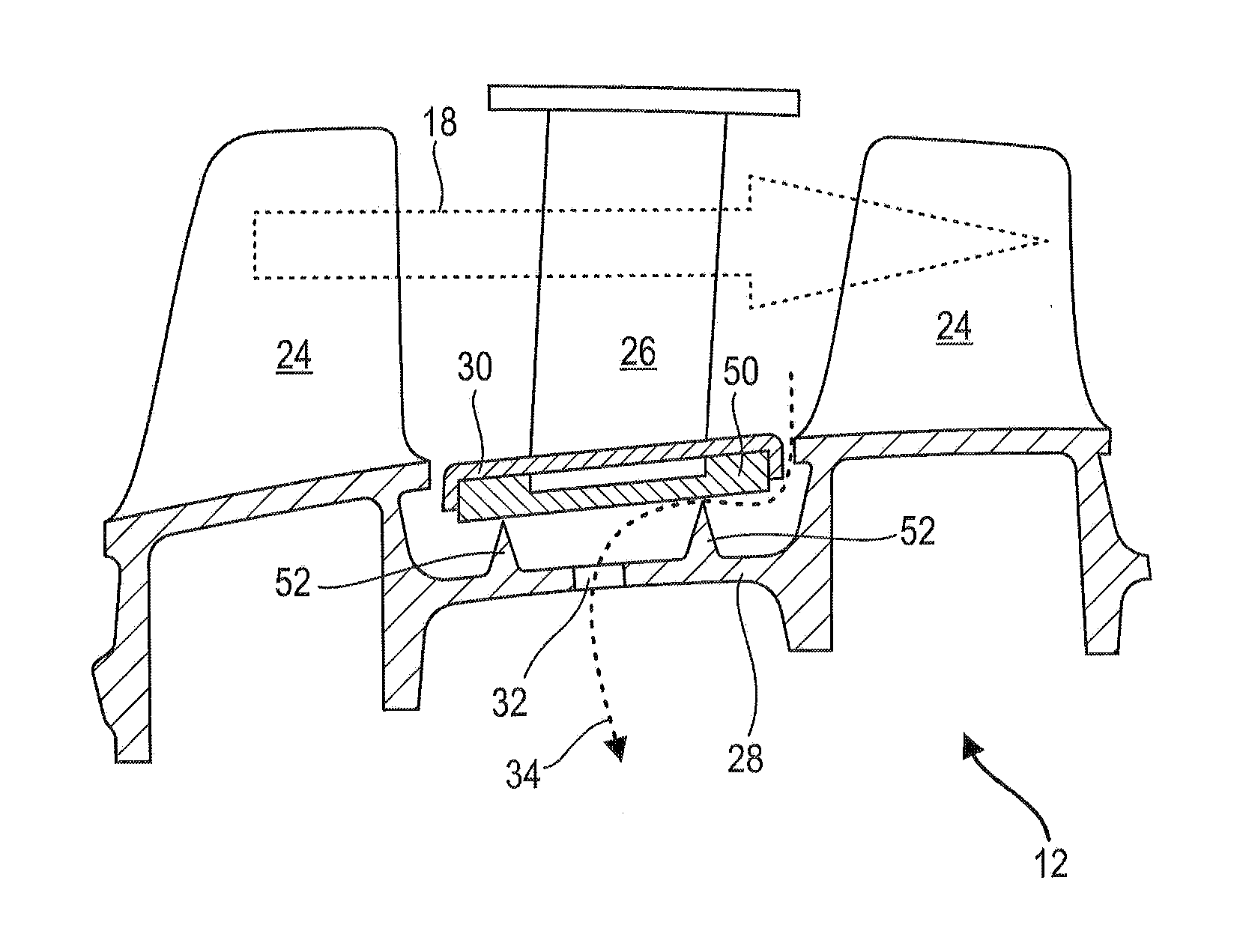

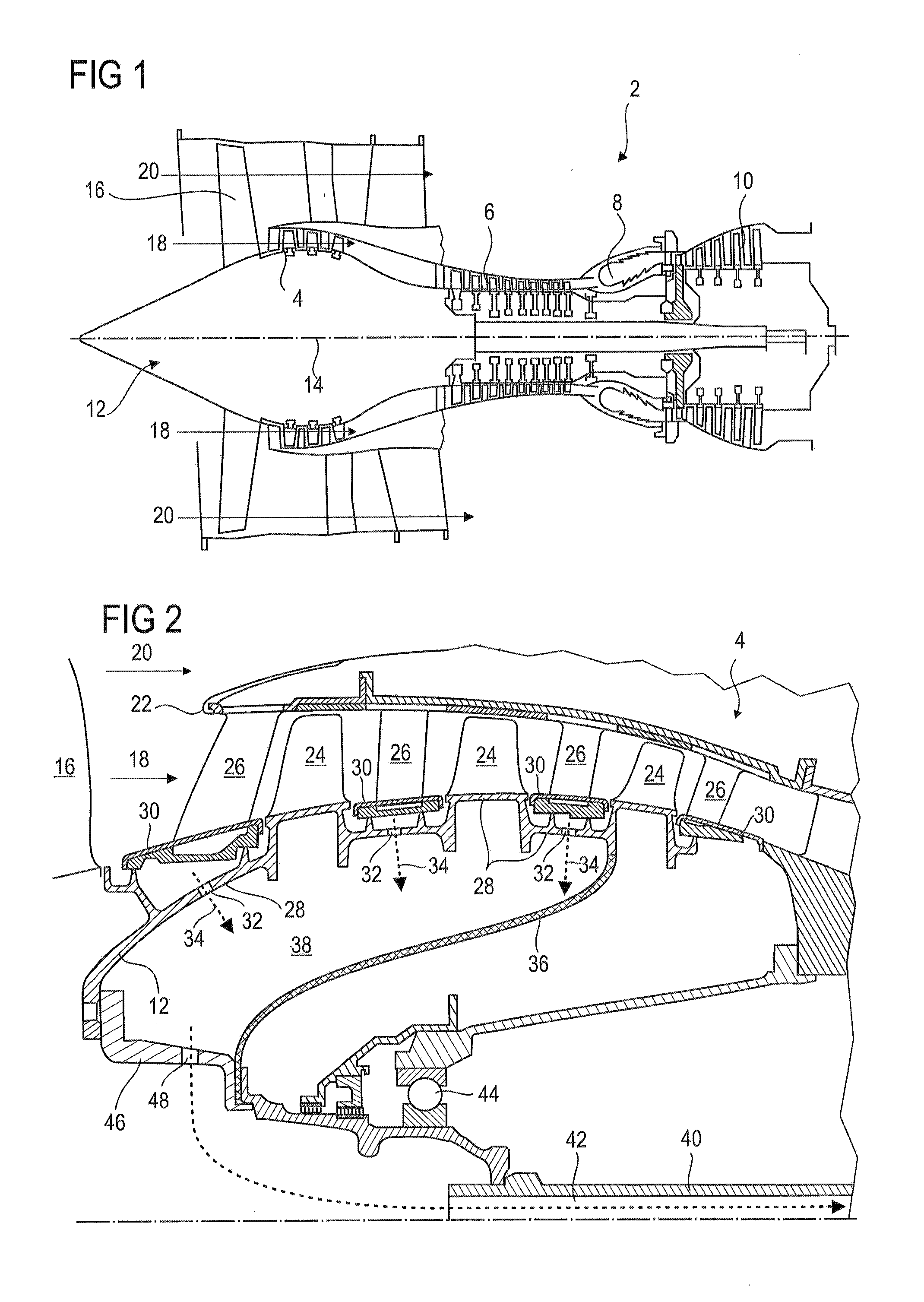

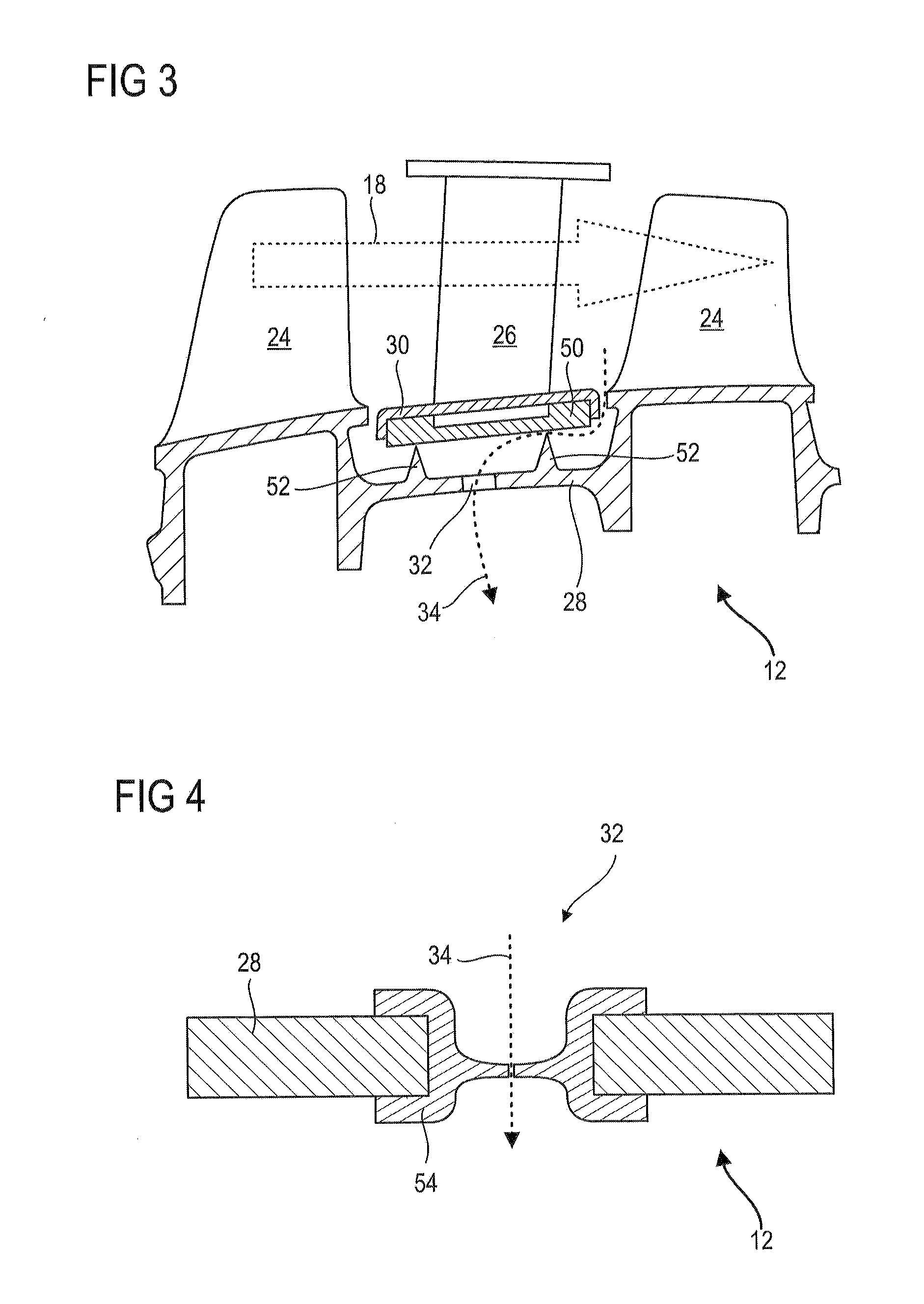

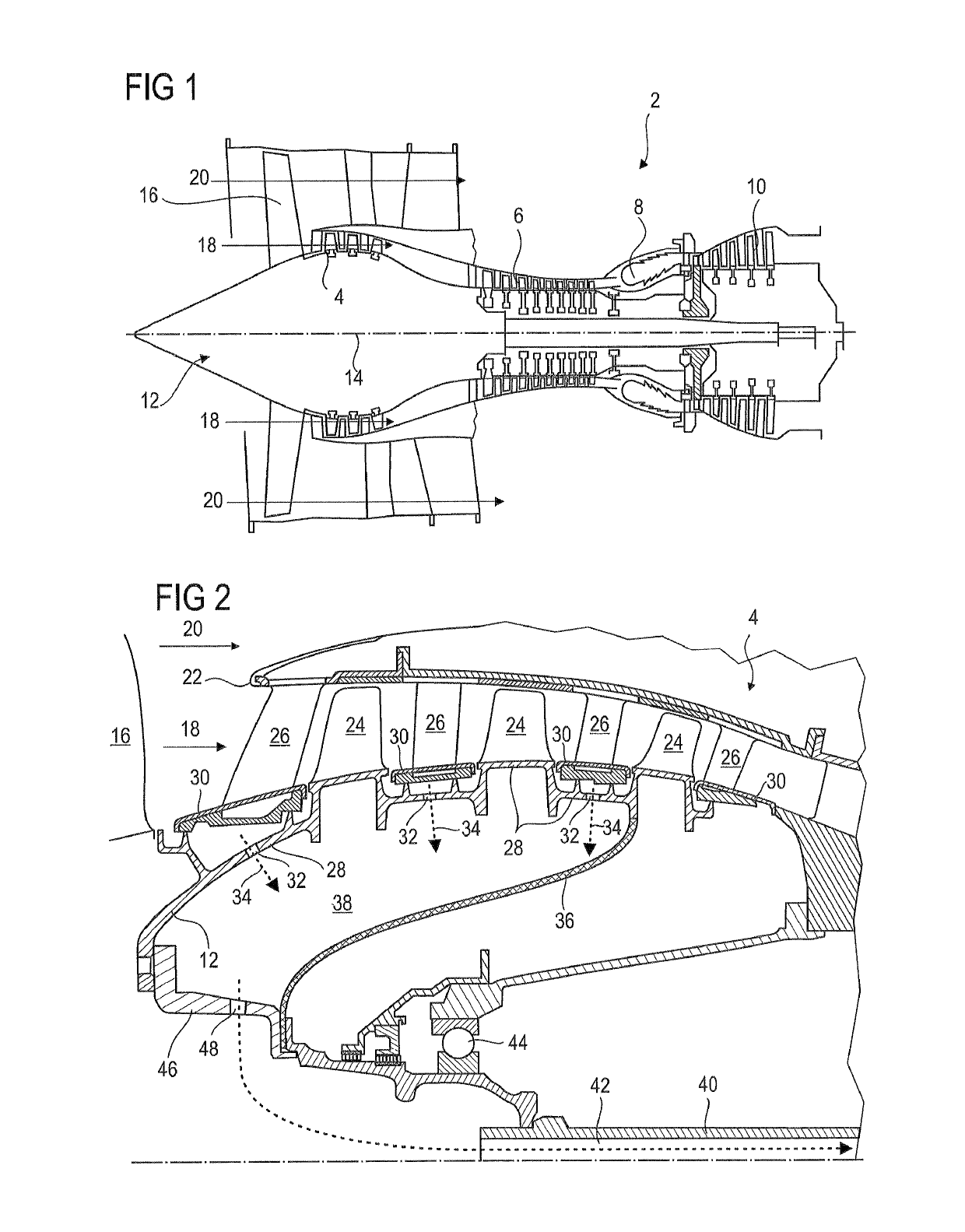

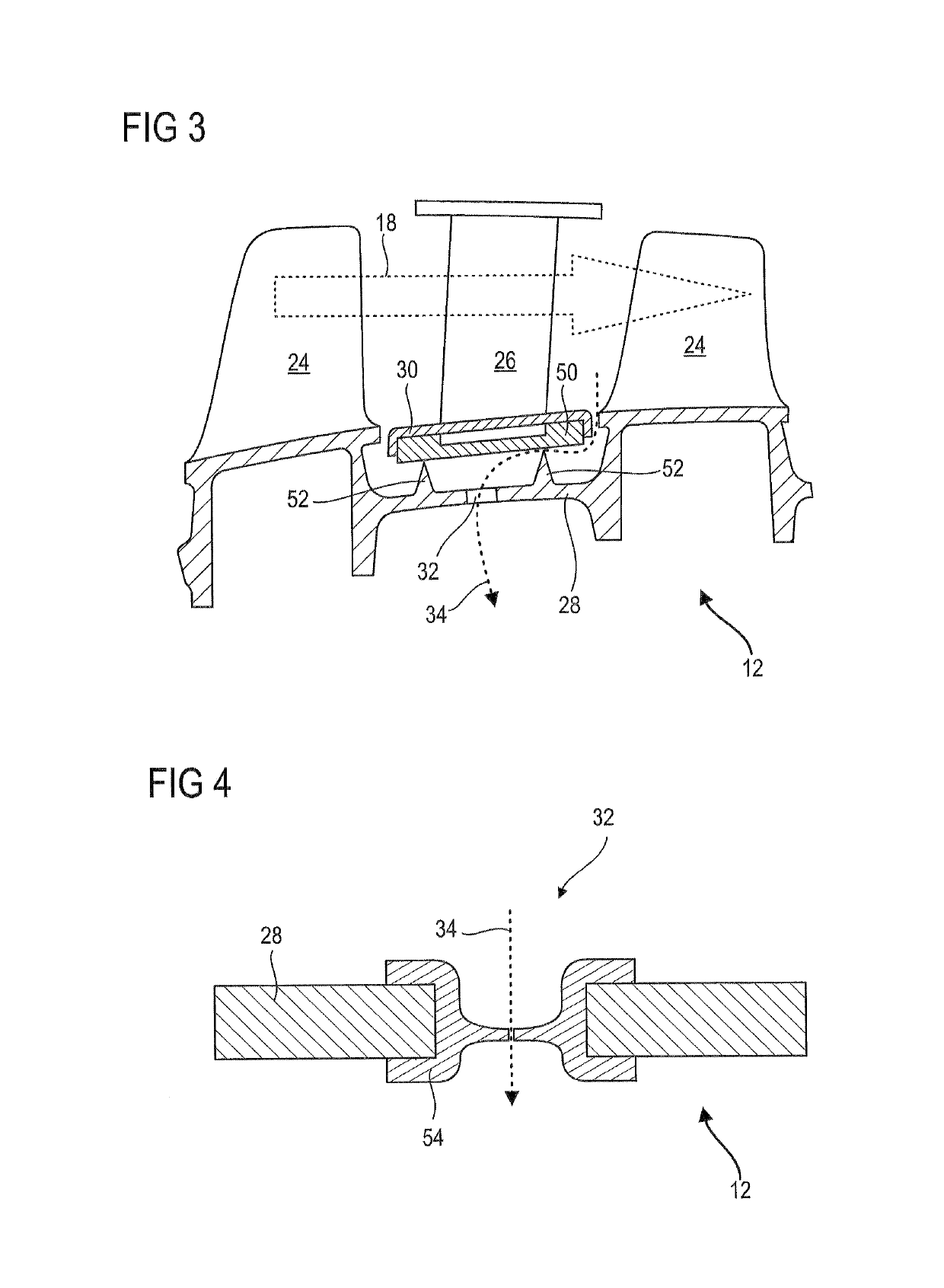

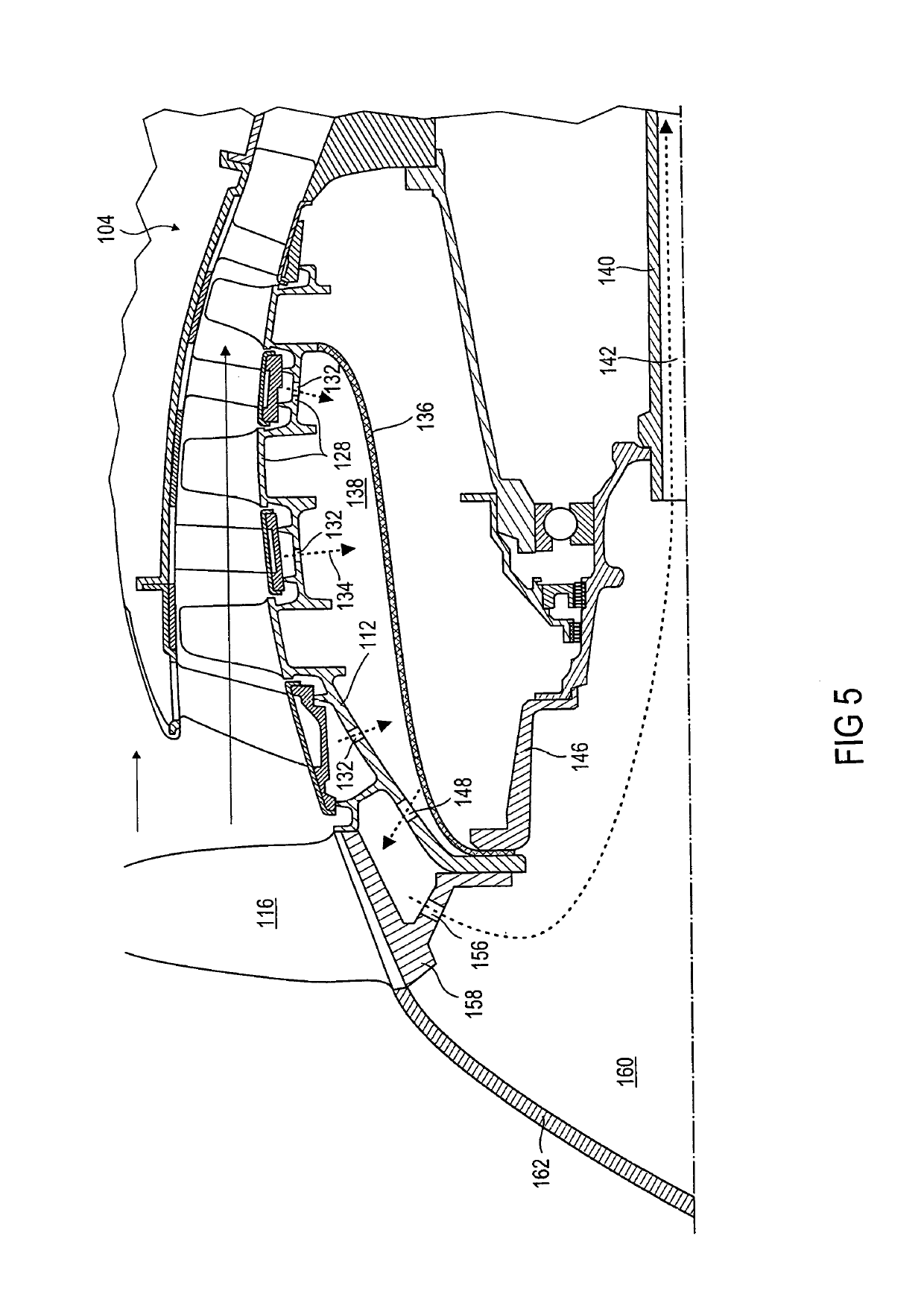

Perforated Drum of a Compressor of an Axial Turbine Engine

ActiveUS20170023023A1Increase spaceReduce in quantityPump componentsEngine fuctionsTurbojetAero engine

A rotor, in particular a drum of a low-pressure compressor of a turbojet aero engine, is disclosed. The rotor includes an outer annular wall delimiting a primary annular flow of the turbine engine, sealing devices with two rubbing strips or annular ribs formed on the wall. The rubbing strips cooperate by abrasion with inner shrouds. In addition, the annular wall includes rows of intake orifices for leakages which are arranged between each pair of rubbing strips in order to aspirate the recirculation leakages there. A plenum for leakages is formed inside the rotor by means of a composite partitioning, then evacuates the parasitic flow downstream of the turbine engine via the central shaft.

Owner:TECHSPACE AERO

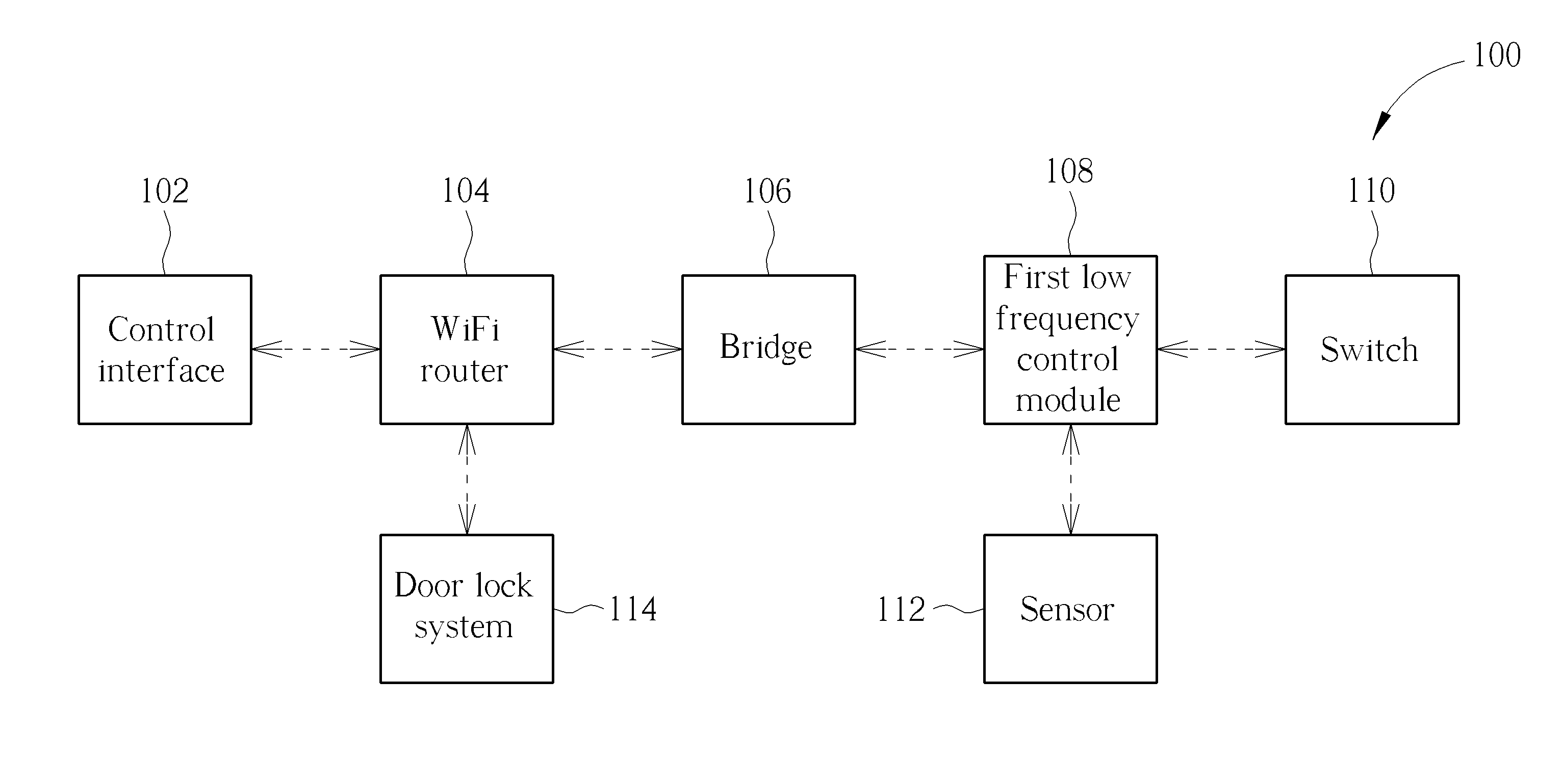

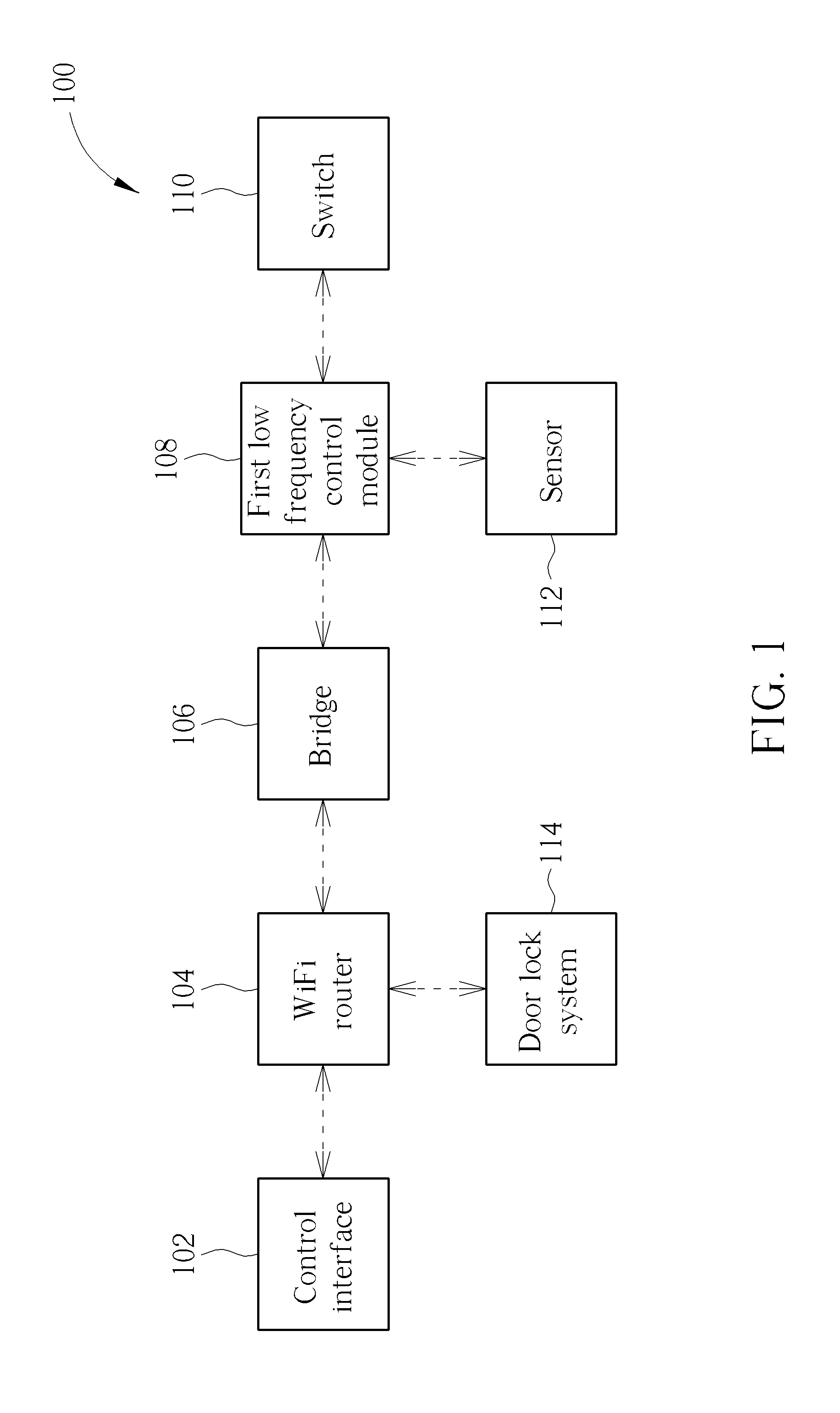

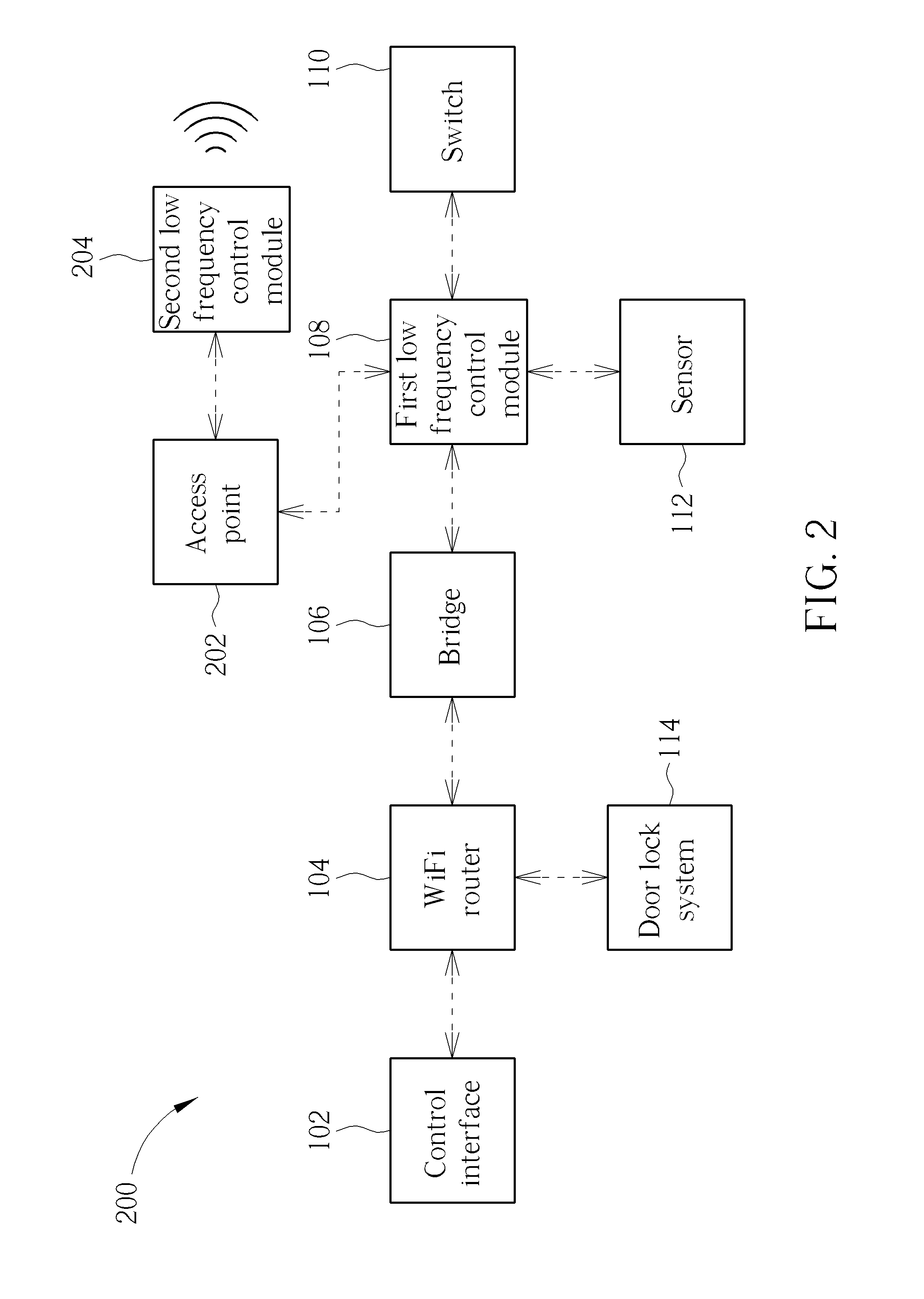

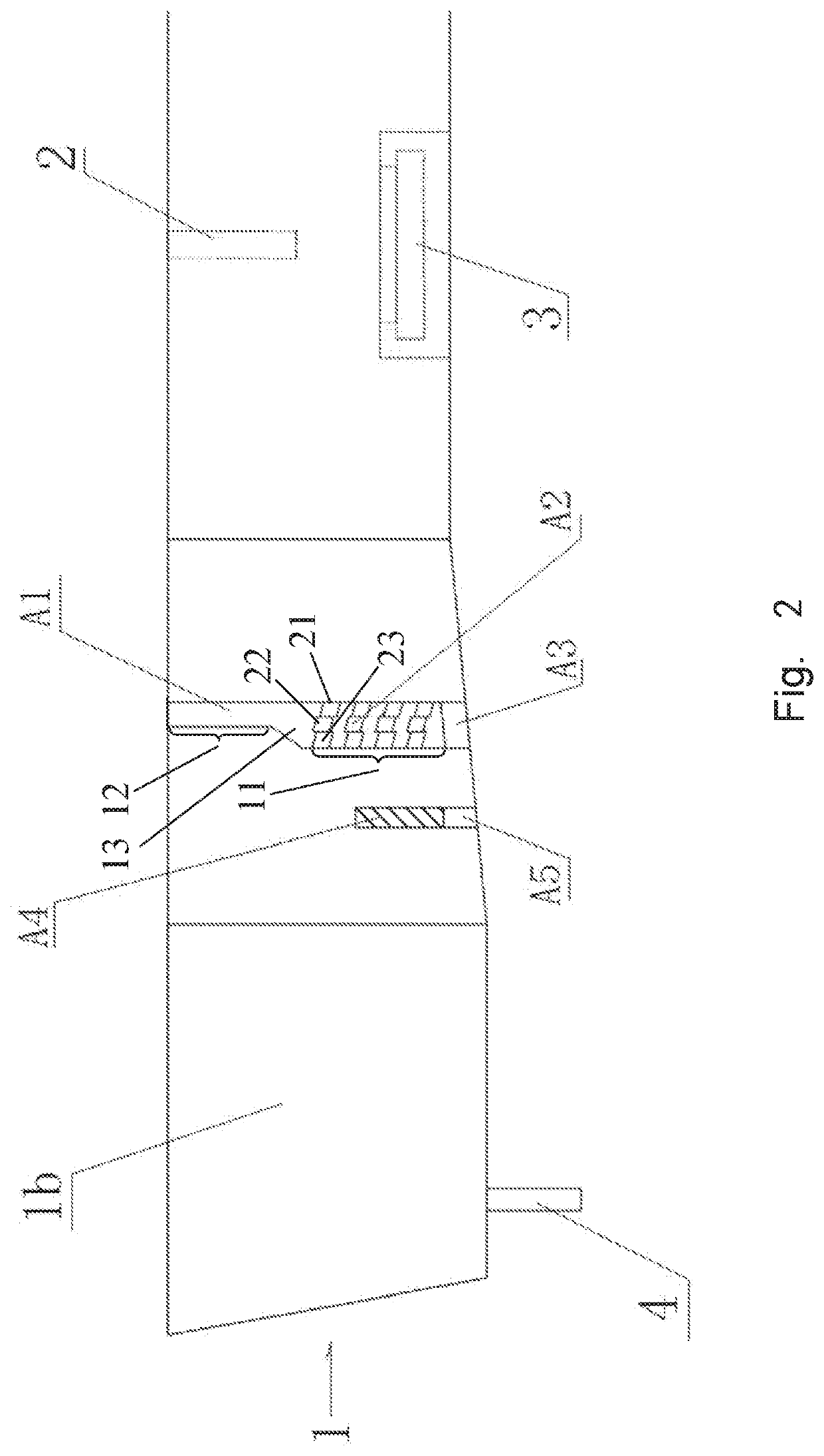

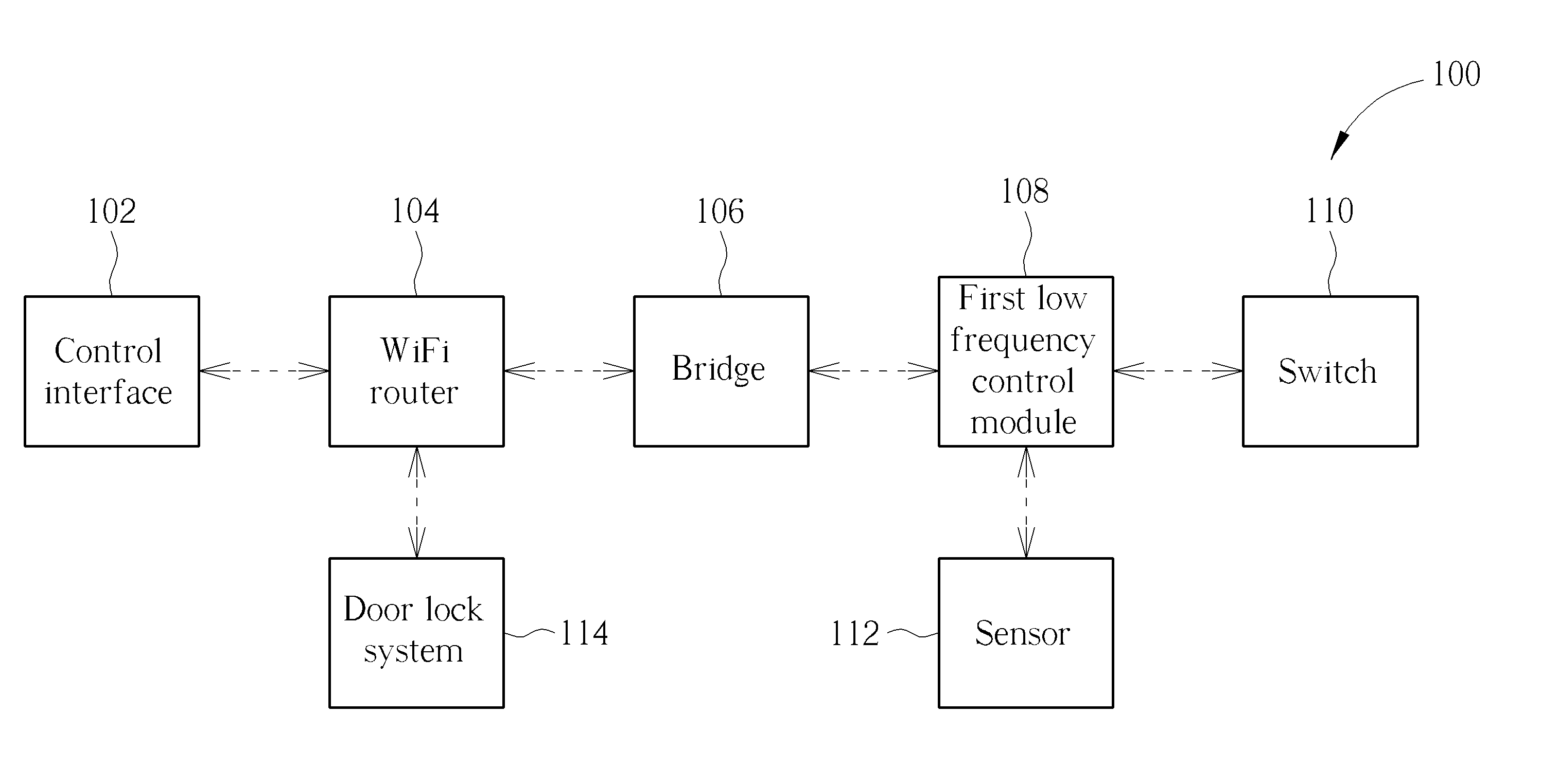

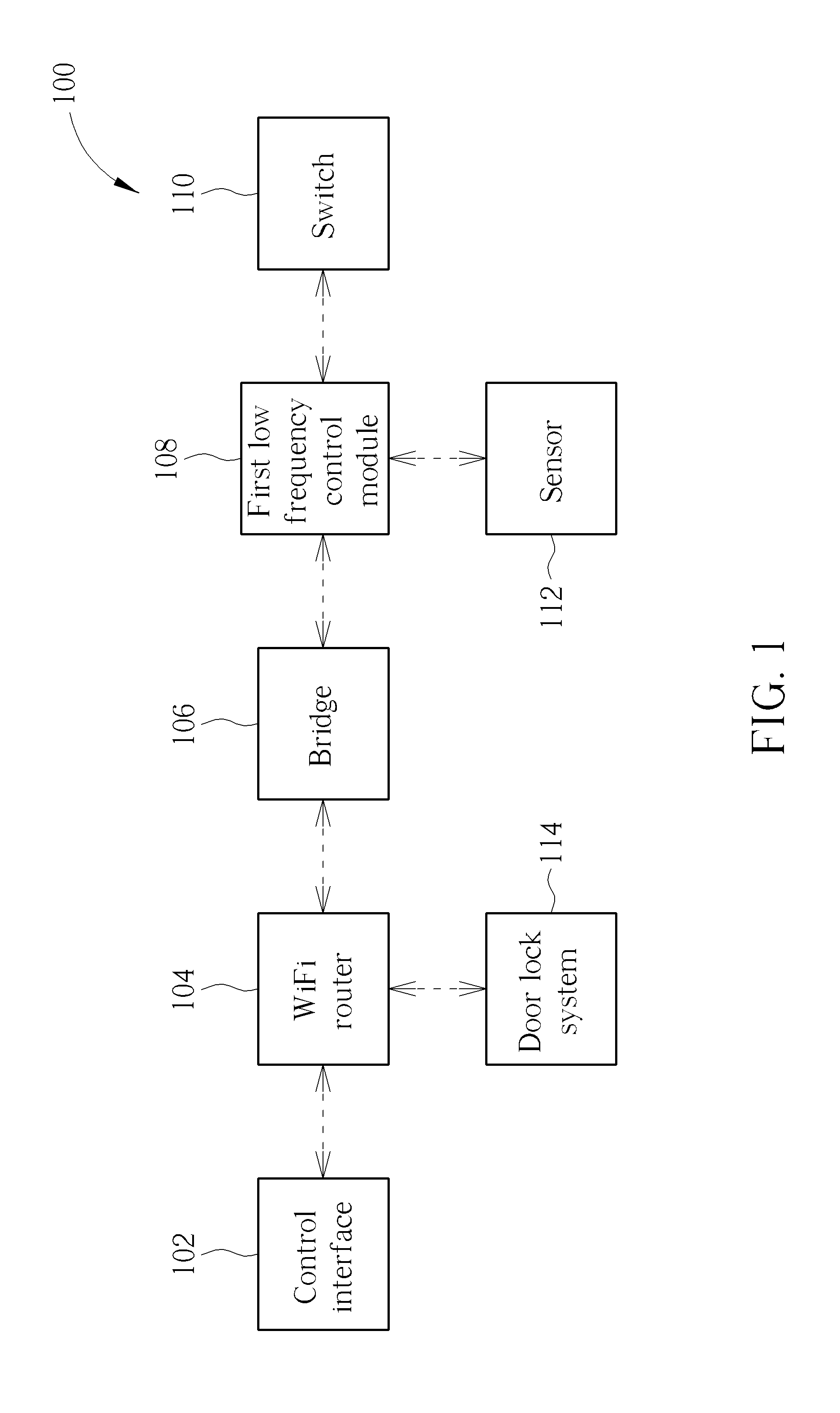

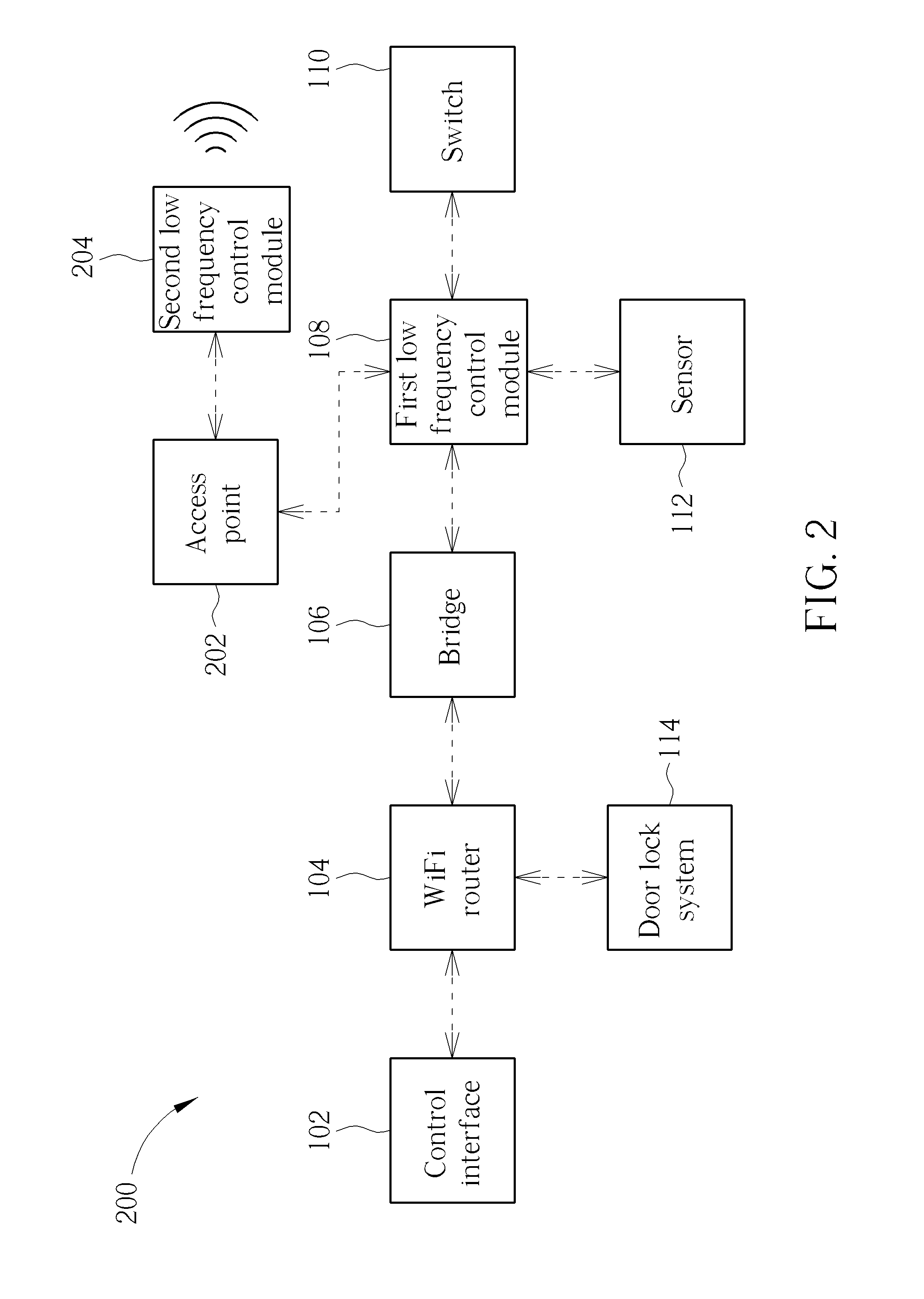

Remote control system having a communication frequency lower than wireless fidelity signals

ActiveUS20140176308A1Short transmission distanceLess blockedElectric signal transmission systemsNetwork topologiesRemote controlControl theory

A remote control system includes a control interface, a WiFi router, a bridge, and a low frequency control module. The WiFi router is linked to the control interface for communicating with the control interface via WiFi signals. The bridge is linked to the WiFi router for down-converting WiFi signals outputted from the WiFi router to low frequency signals and up-converting received low frequency signals to WiFi signals. The low frequency control module is linked to the bridge for communicating with the bridge via the low frequency signals.

Owner:LEADOT INNOVATION

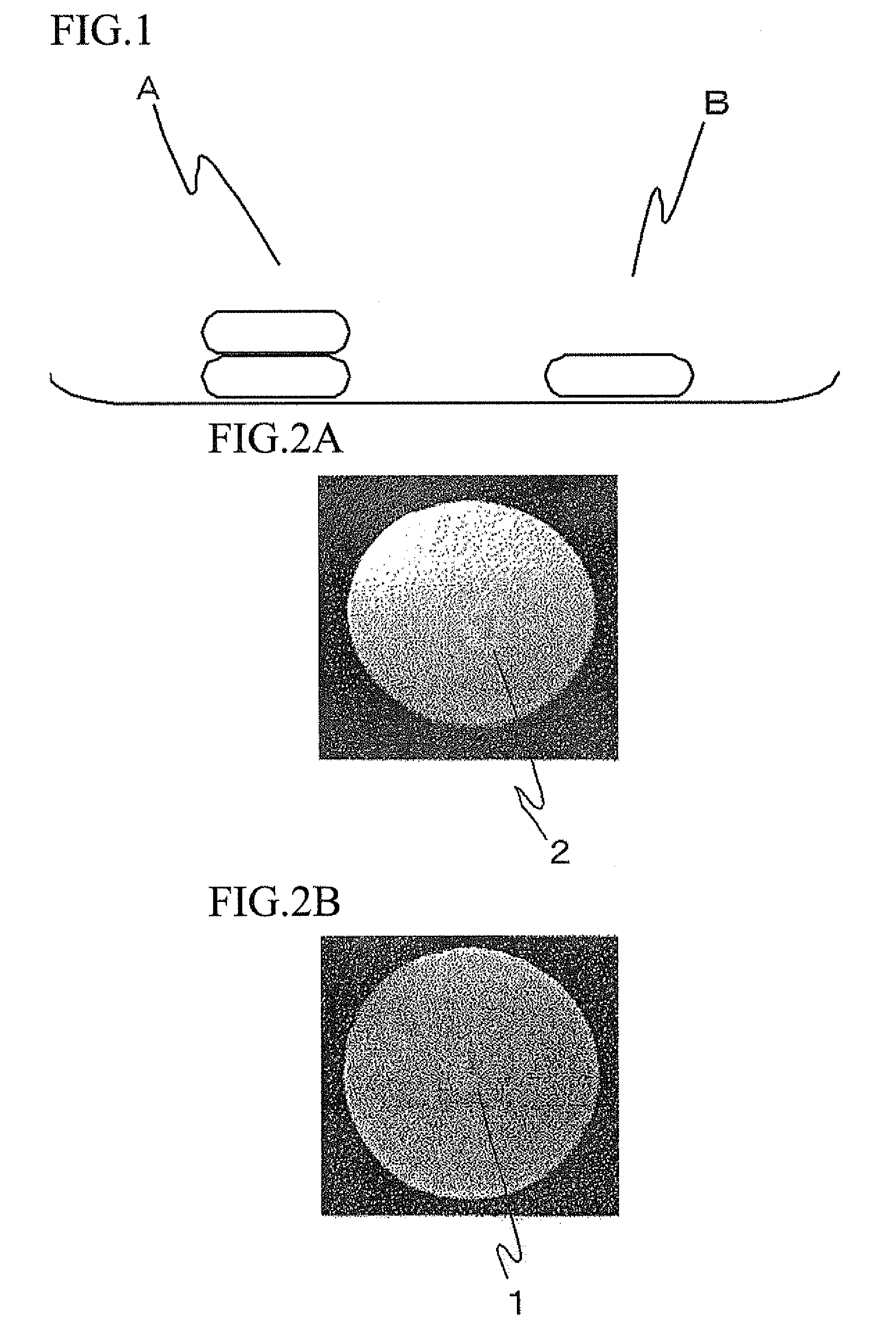

Vented dome

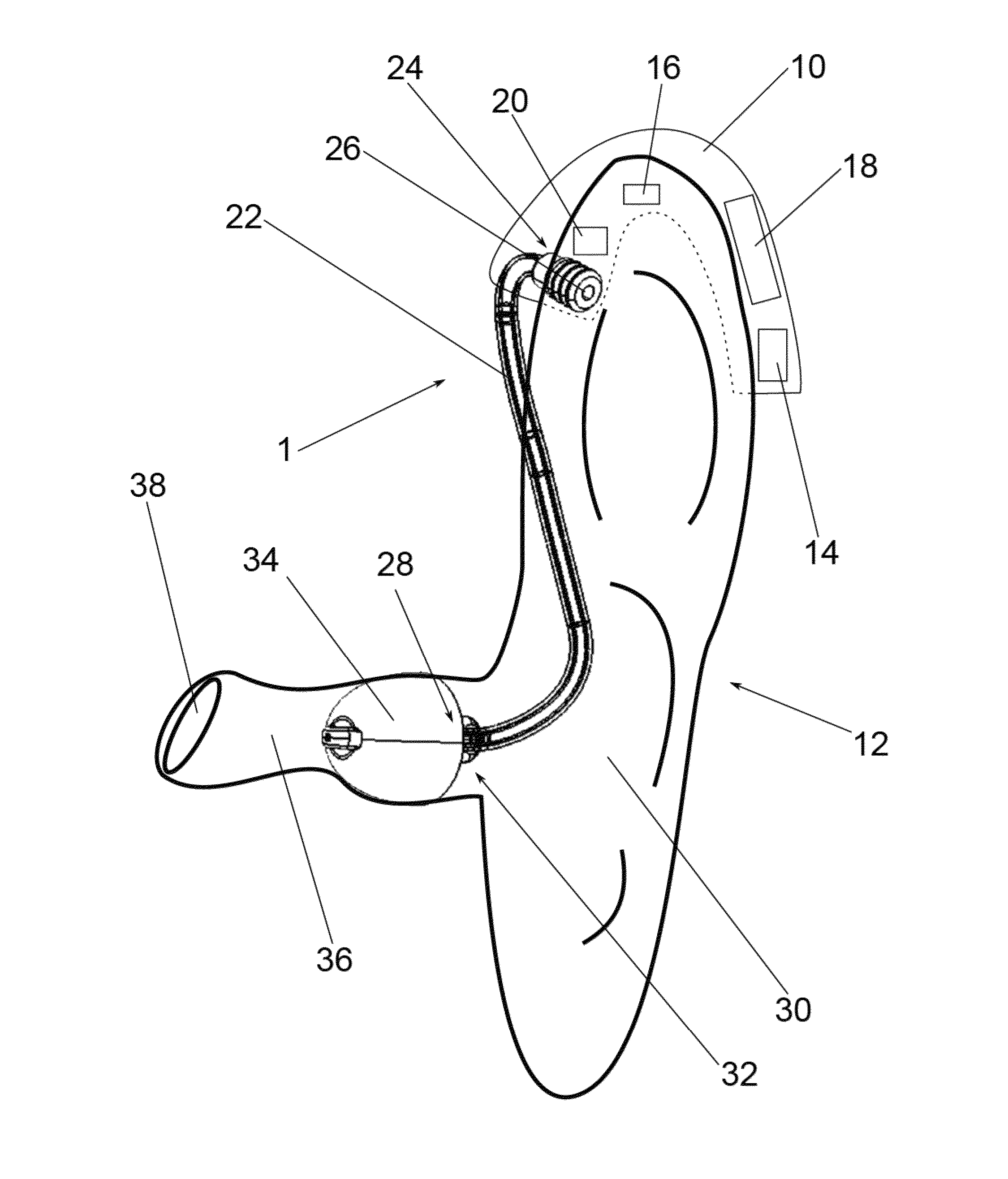

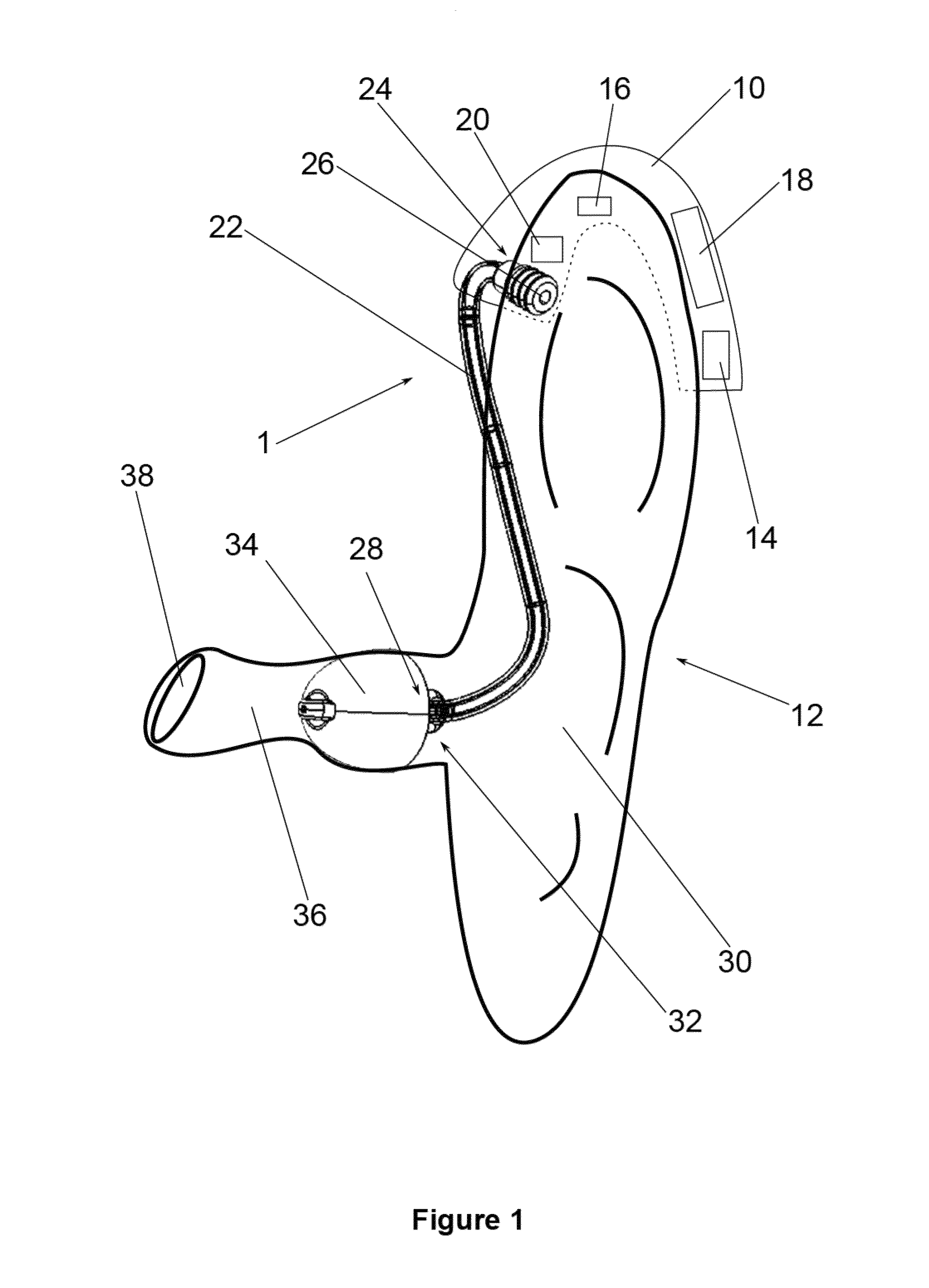

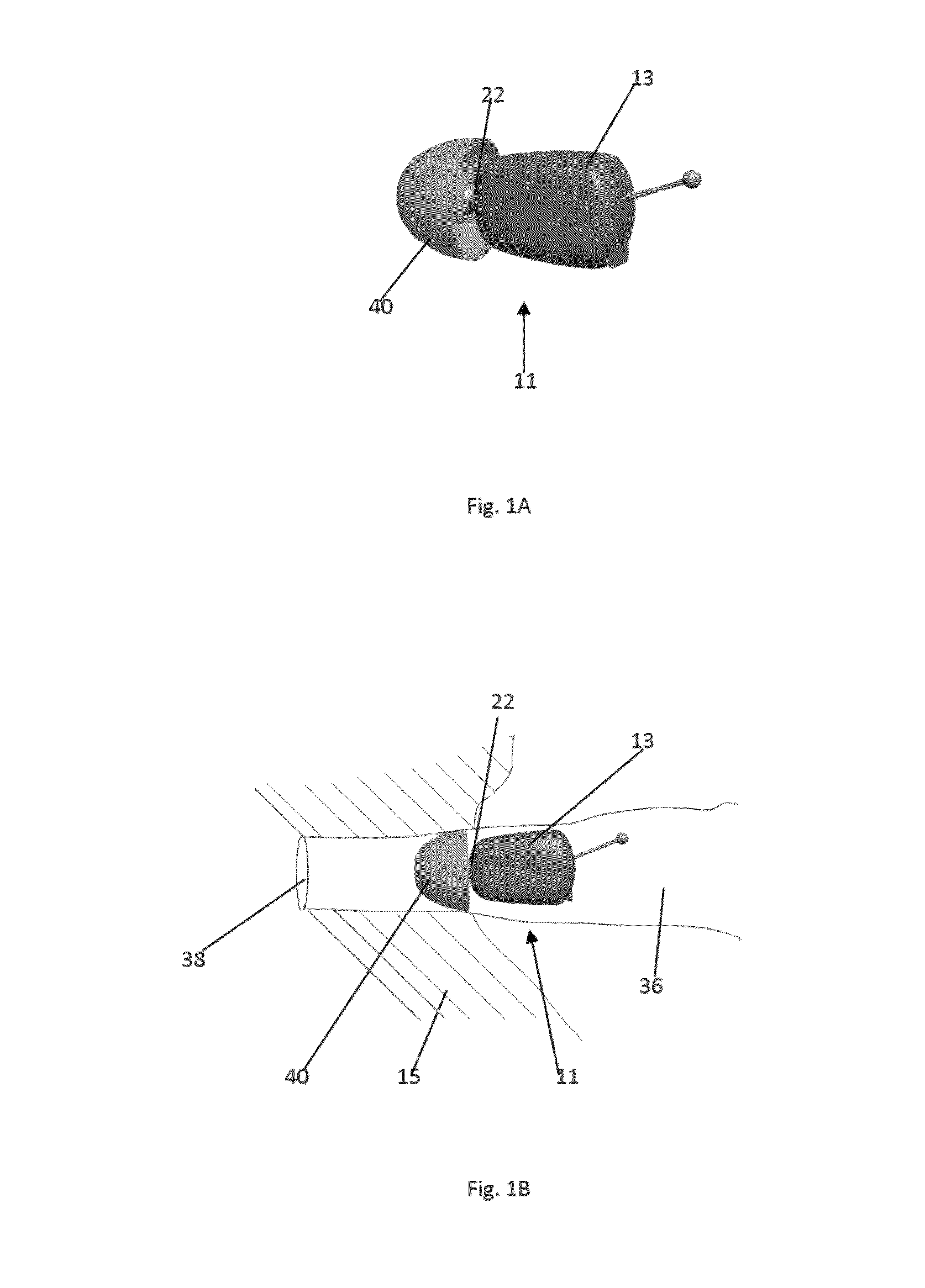

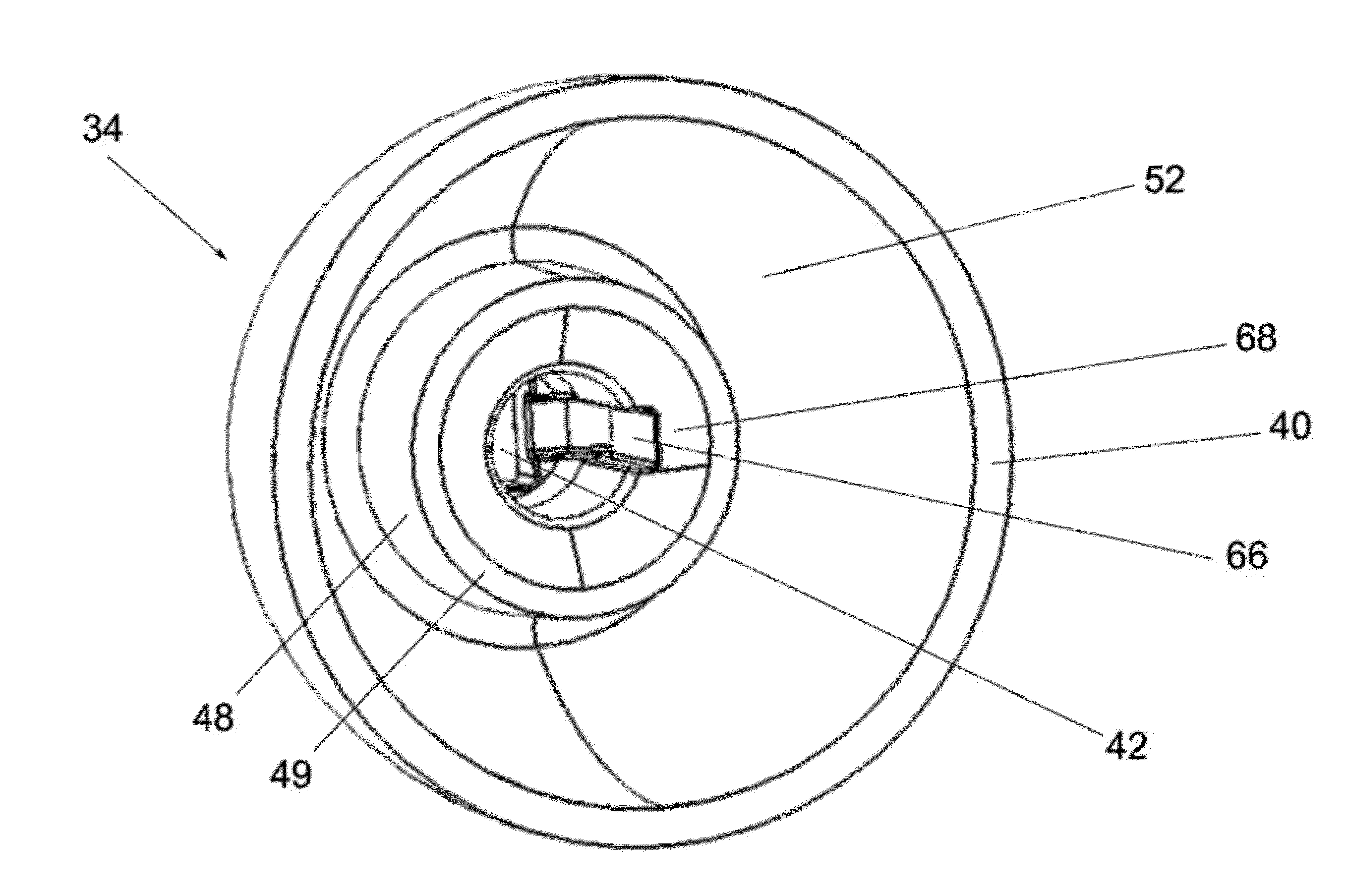

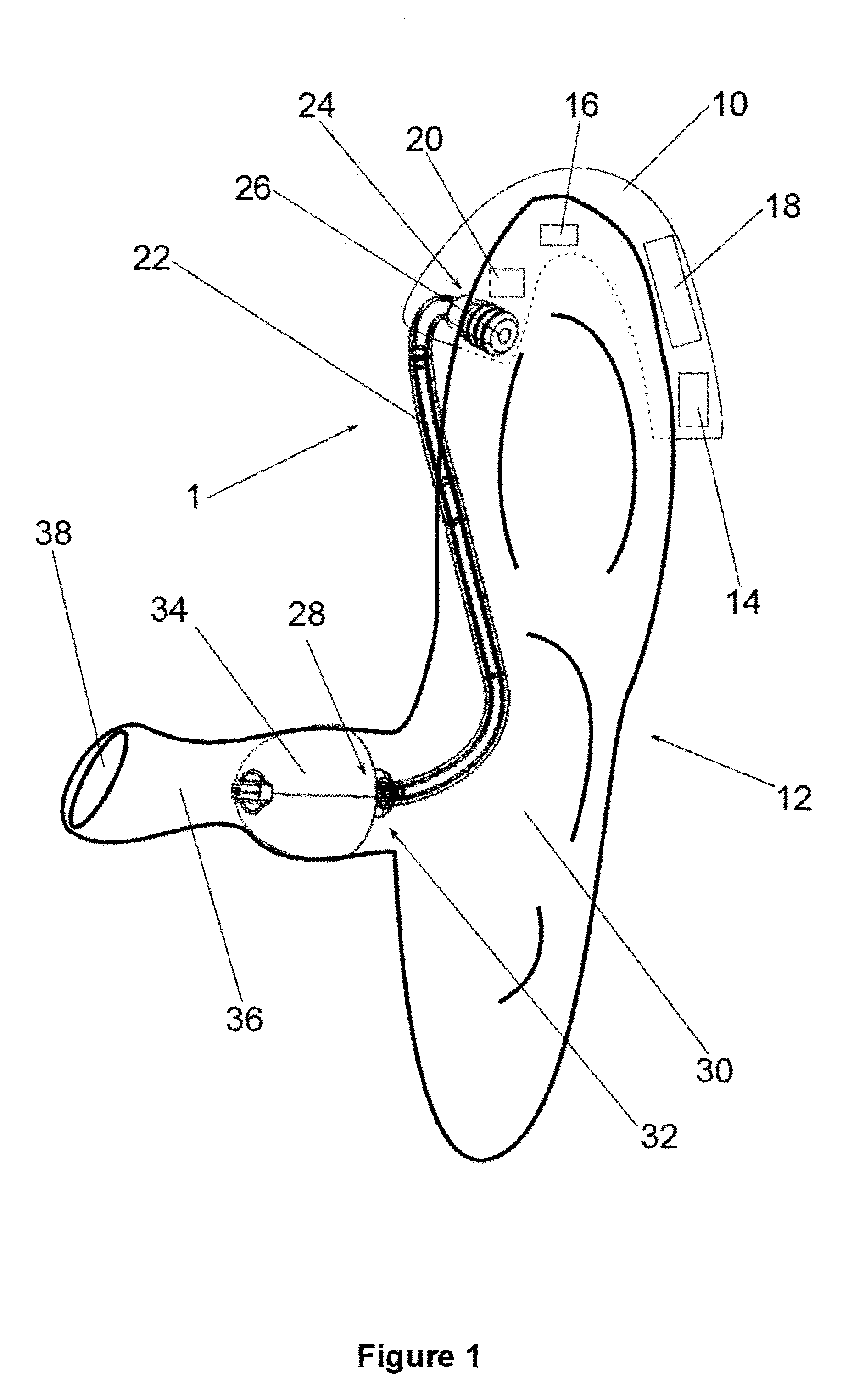

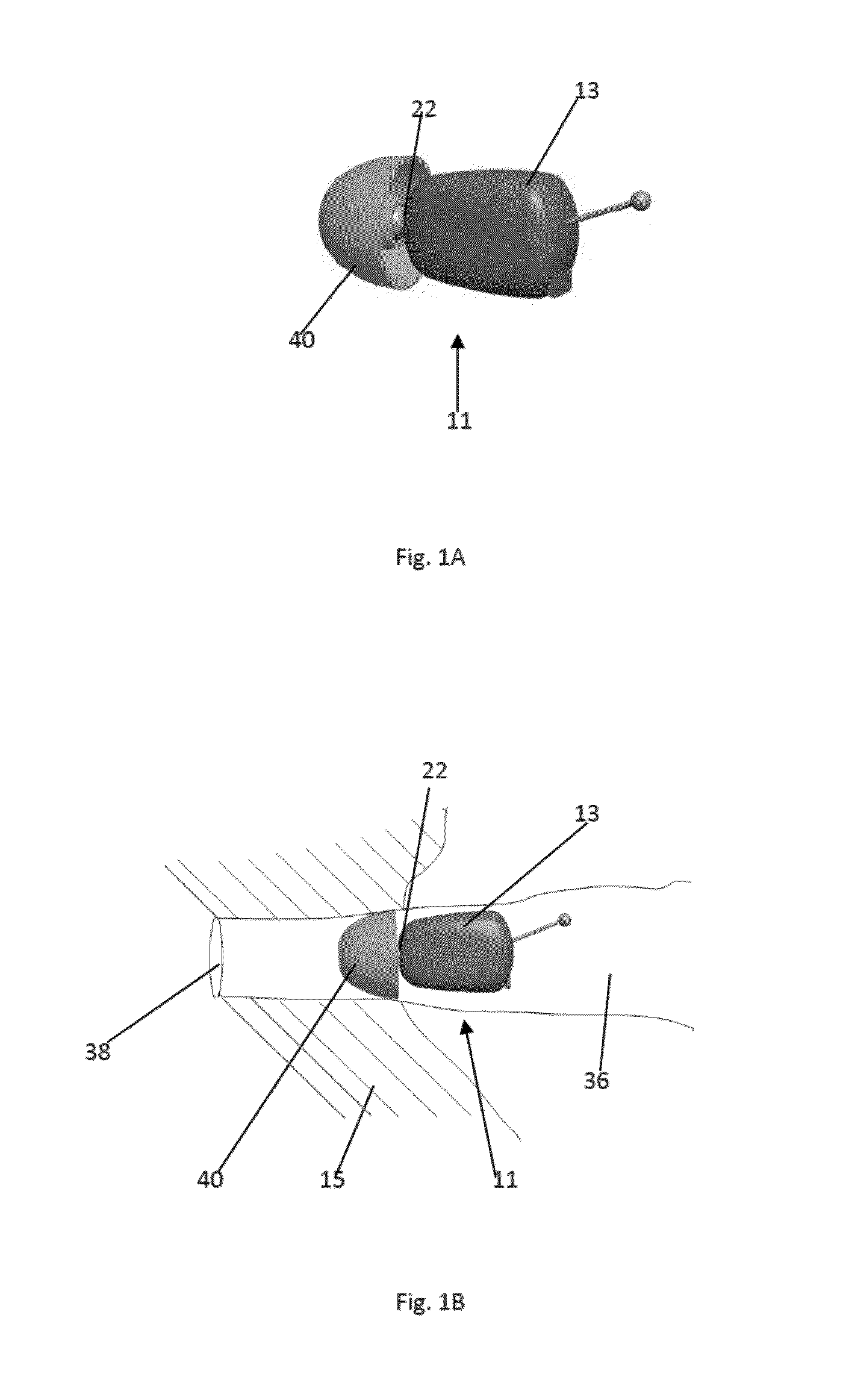

ActiveUS9277336B2Need lessIncreased Design FreedomOcclusion effect electronic compensationBehind the ear hearing aidsProximal pointEngineering

A hearing device includes a BTE unit and a thin acoustic tube. The BTE unit includes a microphone, an amplifier, a power source, and a receiver and is configured to mount behind or on a user's ear. The tube includes a proximal end and a distal end with the proximal end and the distal end being connected to the receiver and to a flexible mounting insert respectively. The insert comprises a dome shape part and at least one core hole permeable for sound transmitted from the tube, which is configured to arrange in a user's ear canal to transmit sound generated by the BTE unit to a tympanic membrane of the user. The inserts diameter is adapted to at least have the same diameter as user's ear canal diameter to close the ear canal of the user and has at least one internal vent pathway located on the circumference of the core hole.

Owner:OTICON

Vented dome

ActiveUS20150003655A1Small sizeReduce sound transmissionOcclusion effect electronic compensationBehind the ear hearing aidsProximal pointEngineering

A hearing device includes a BTE unit and a thin acoustic tube. The BTE unit includes a microphone, an amplifier, a power source, and a receiver and is configured to mount behind or on a user's ear. The tube includes a proximal end and a distal end with the proximal end and the distal end being connected to the receiver and to a flexible mounting insert respectively. The insert comprises a dome shape part and at least one core hole permeable for sound transmitted from the tube, which is configured to arrange in a user's ear canal to transmit sound generated by the BTE unit to a tympanic membrane of the user. The inserts diameter is adapted to at least have the same diameter as user's ear canal diameter to dose the ear canal of the user and has at least one internal vent pathway located on the circumference of the core hole.

Owner:OTICON

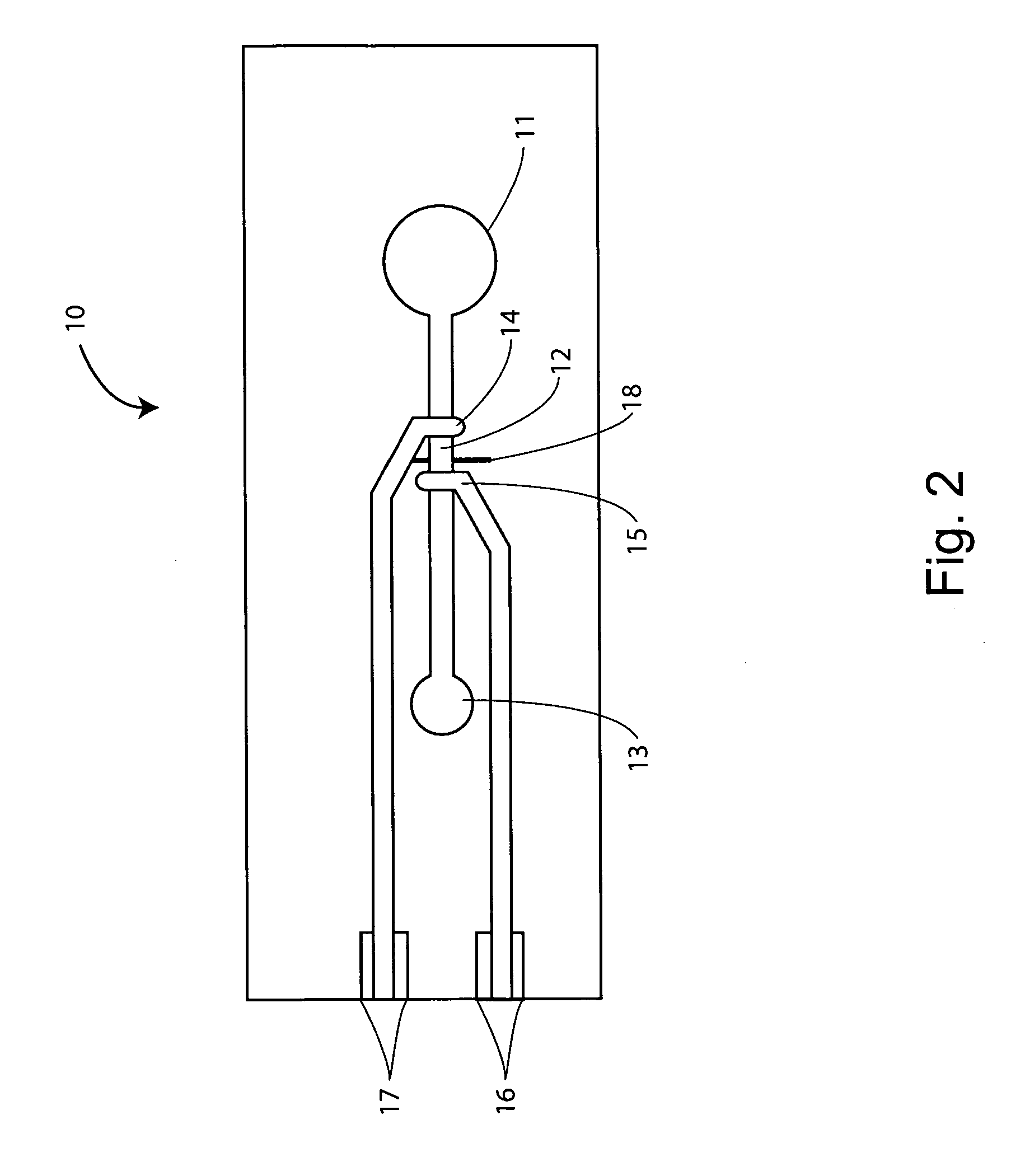

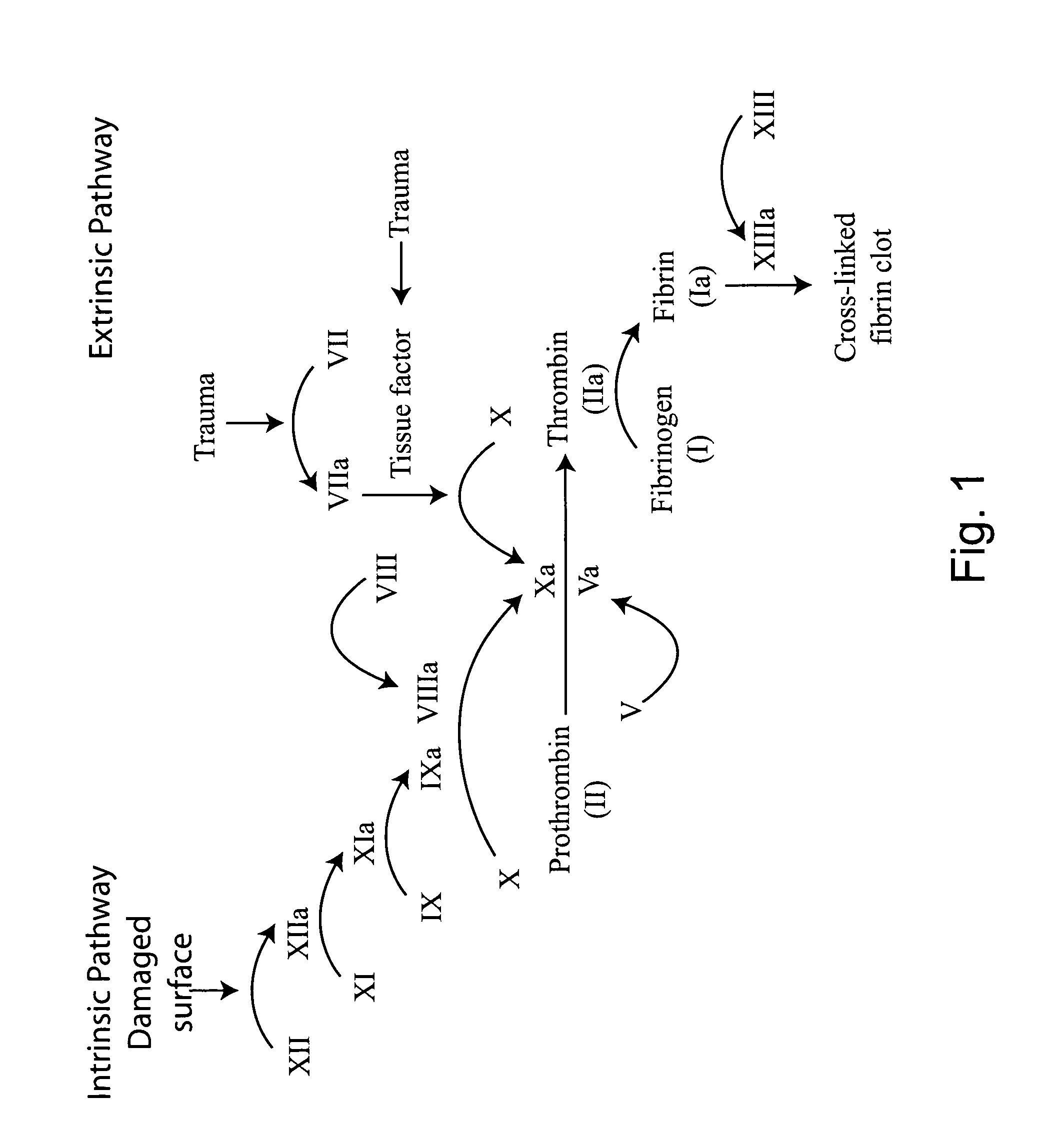

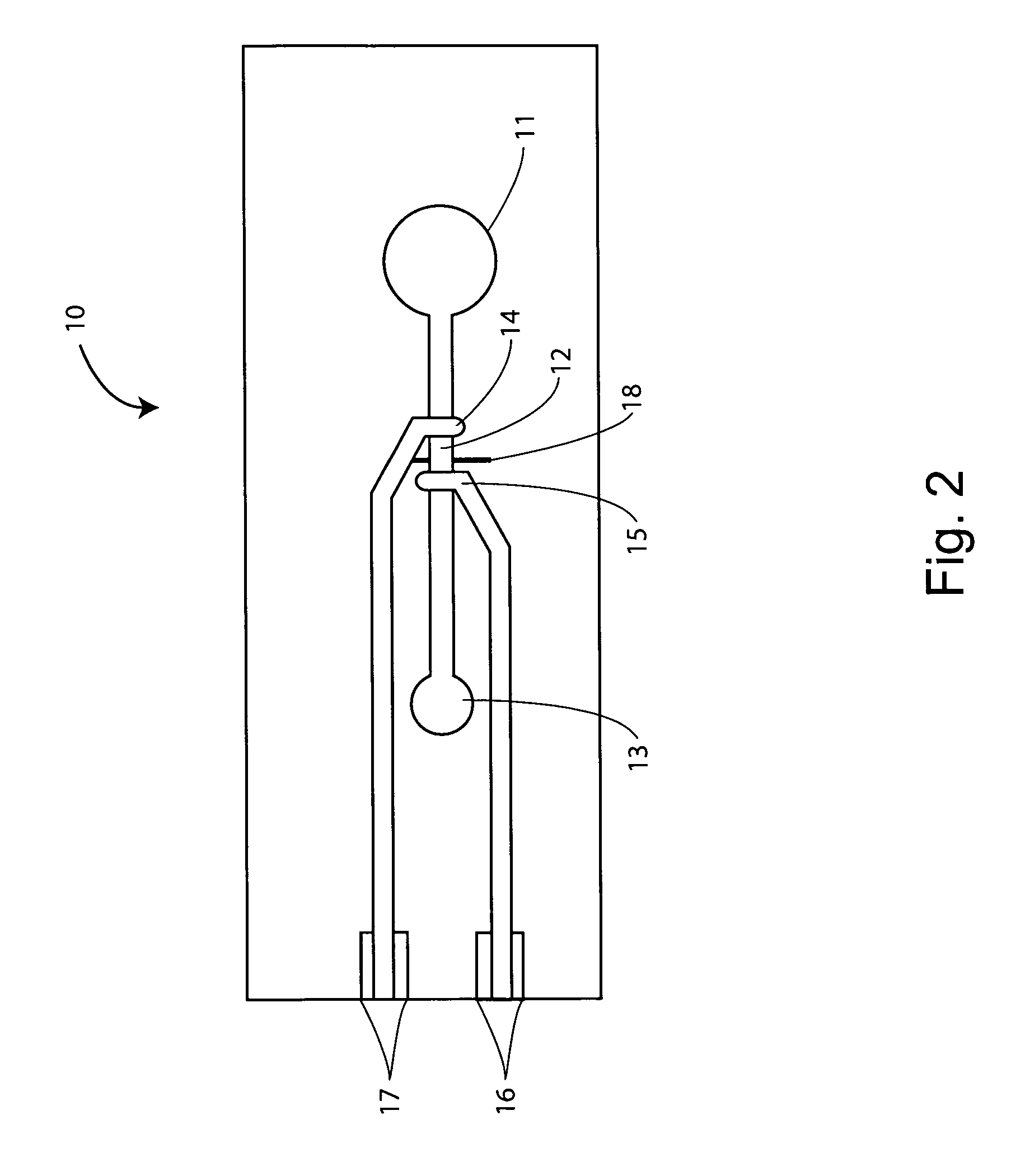

Inductive coagulation sensors and devices

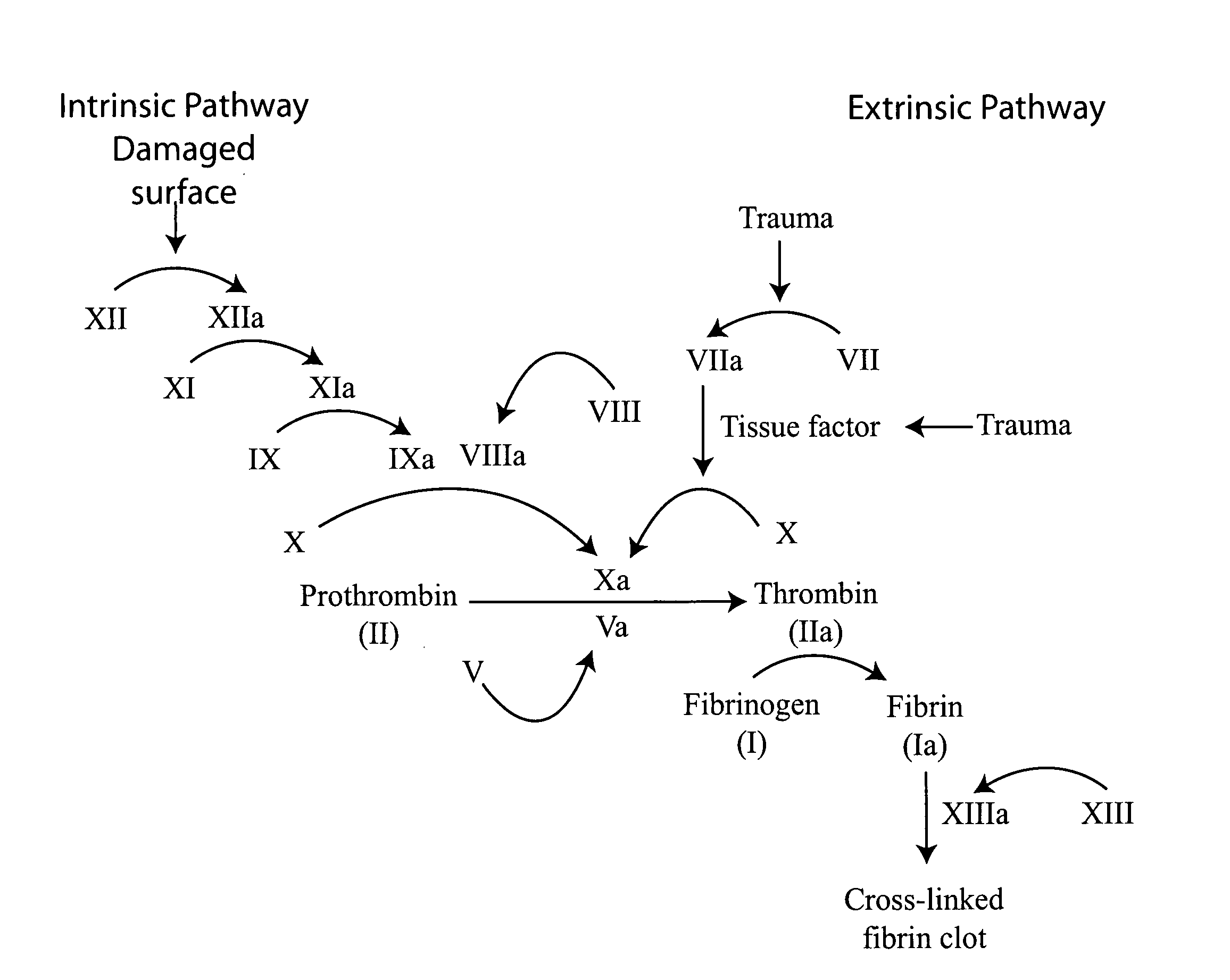

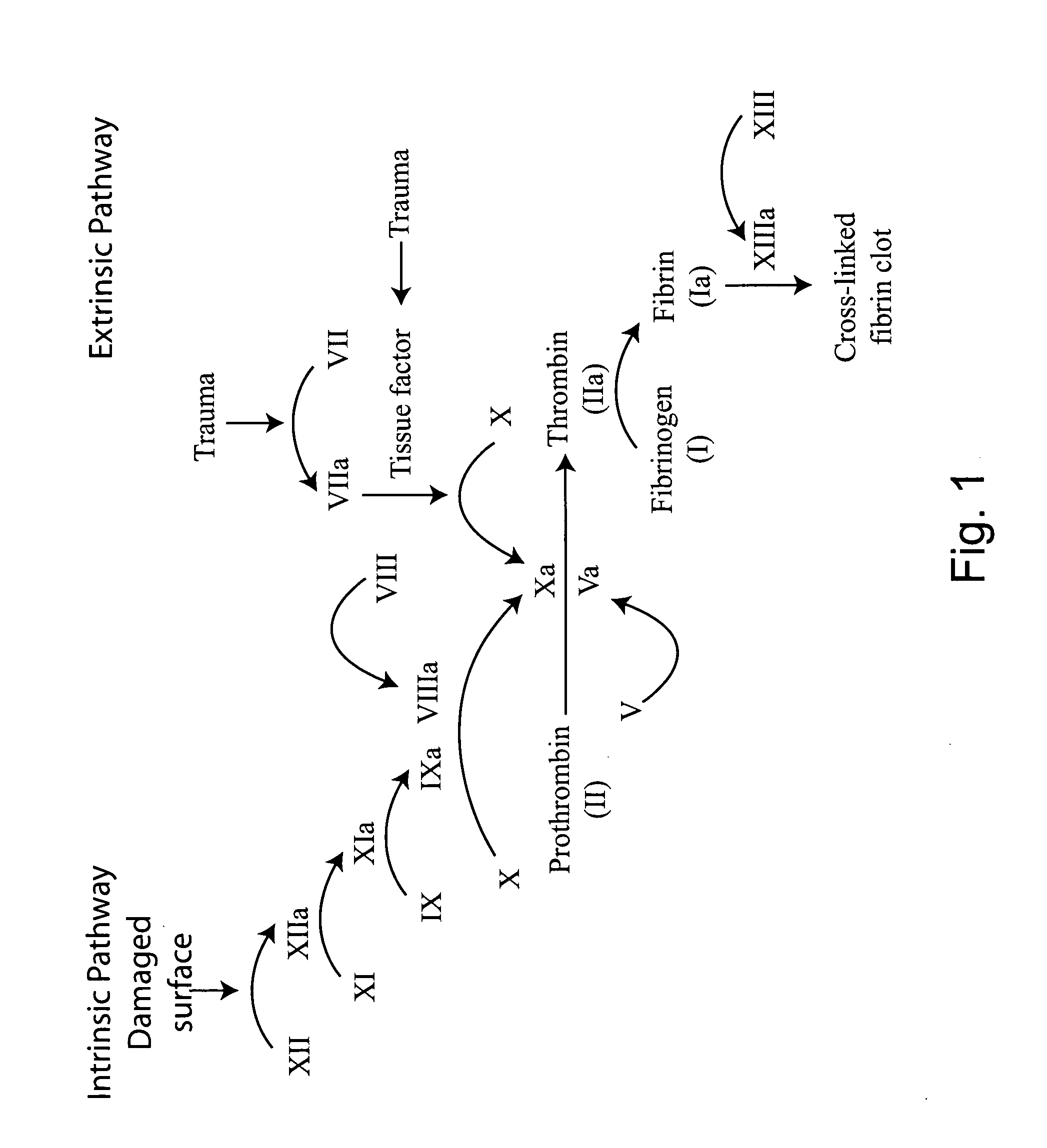

ActiveUS20110109325A1Increase influenceReduces and eliminates phenomenonFlow propertiesInductance measurementsElectricityInductor

This invention provides methods and devices for detecting the viscosity and conductivity of a conductive fluid sample. A sample fluid can be received into a sample chamber between a field inductor and sensor inductor. Electromagnetic fields generated by the field inductor can be modulated due to the counter-emf induced in the sample. The modulations can be detected by the sensor inductor and correlated to electric parameters in the fluid.

Owner:MICROPOINT BIOTECHNOLOGIES CO LTD

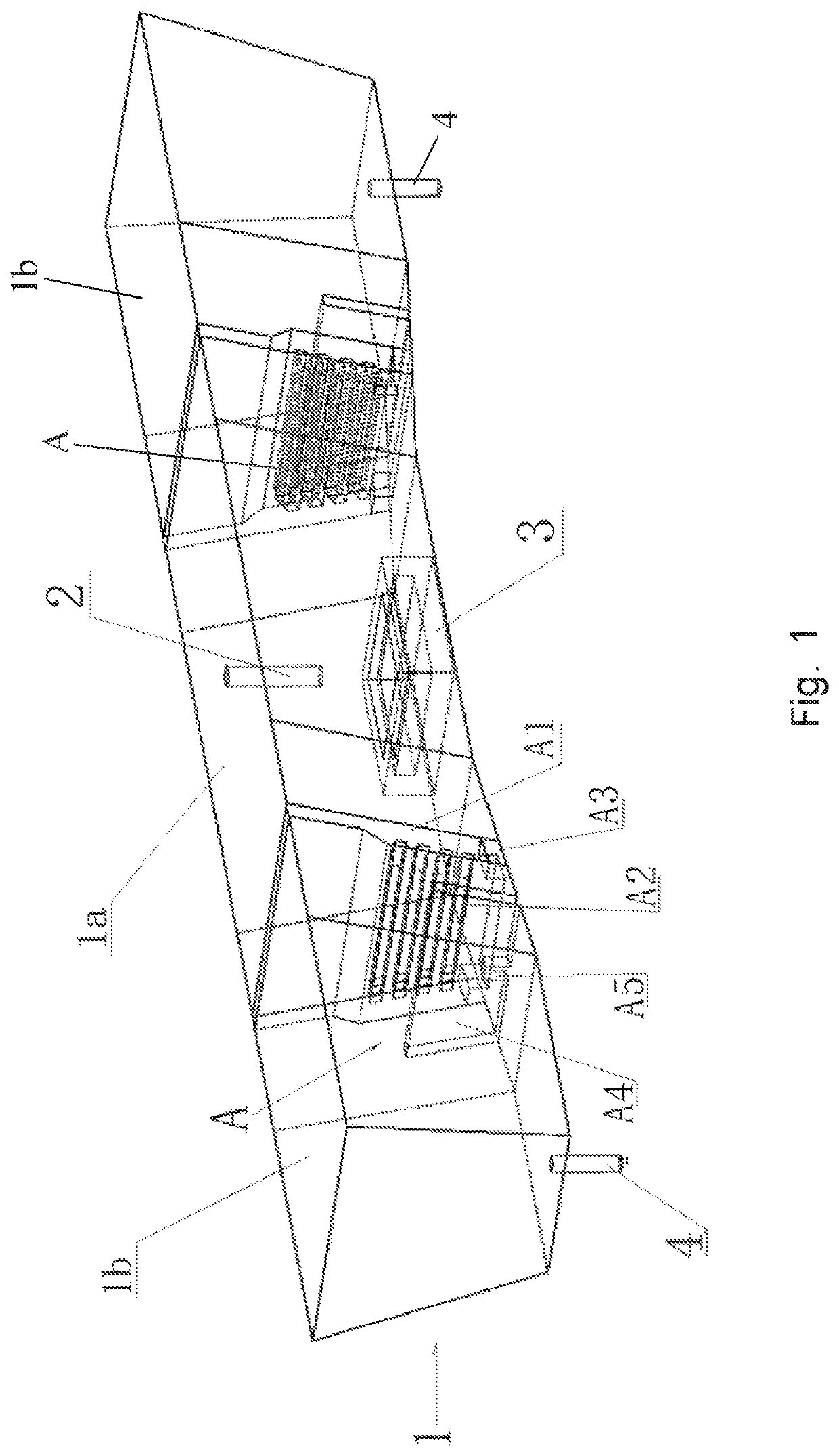

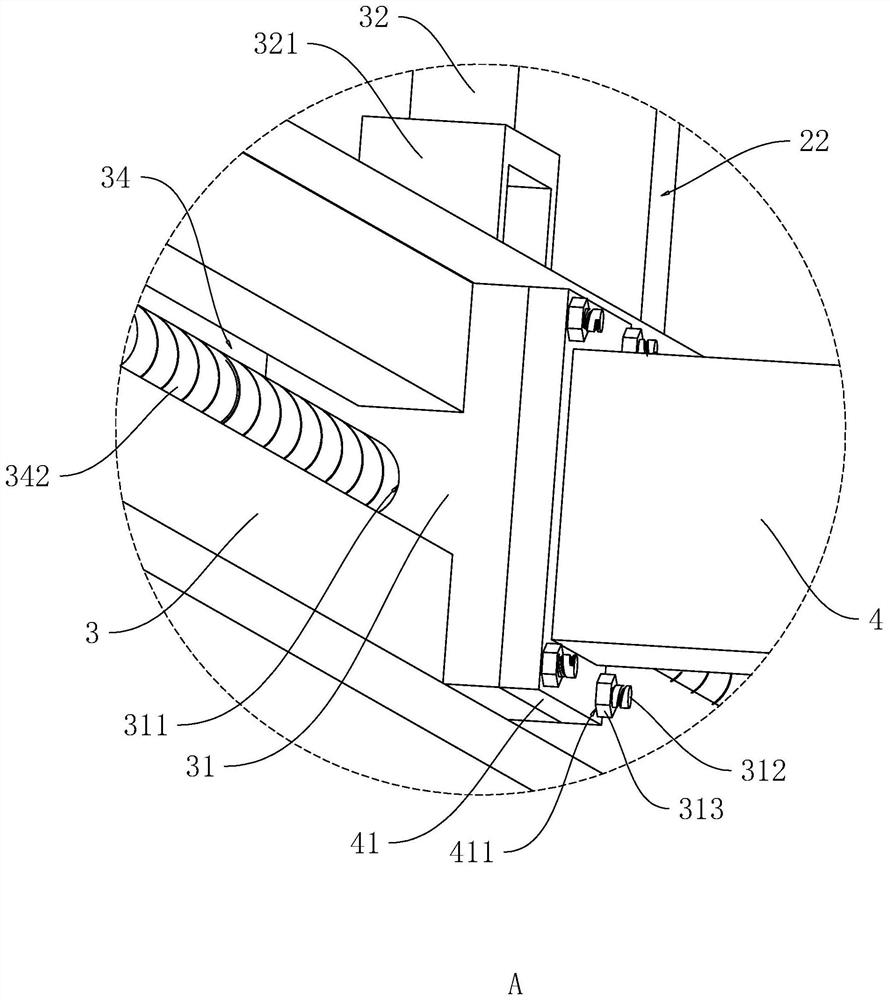

Flow-controllable tundish structure capable of filtering inclusions in molten steel

ActiveUS20210016346A1Reduce in quantityPromote growthMelt-holding vesselsCasting cleaning apparatusLiquid steelMechanics

Disclosed is a flow-controllable tundish structure capable of filtering inclusions in molten steel. The tundish structure comprises a tundish (1), the tundish being divided into three separated cavities which comprise an impact zone cavity (1a) in the middle and pouring zone cavities (1b) at two sides thereof. A long nozzle (2) for pouring is vertically arranged in the center of the impact zone cavity, and molten steel flows down out of the long nozzle for pouring and is injected into the impact zone cavity; and a turbulence suppressor (3) directly facing the long nozzle for pouring is arranged on the cavity bottom under the long nozzle for pouring, and the molten steel flowing down out of the long nozzle for pouring impacts on the turbulence suppressor and is then buffered and mixed. Filter assemblies (A) are respectively arranged between the impact zone cavity and the pouring zone cavities at the two sides, and the buffered and mixed molten steel in the impact zone cavity is filtered by the filter assemblies and is then delivered into the pouring zone cavities at the two sides. Discharge ports (4) are respectively arranged in the bottom of the pouring zone cavities, and the molten steel filtered by the filter assemblies flows into the pouring zone cavities and then flows out from the discharge ports. The flow-controllable tundish structure has the advantages of a simple structure, easy building and lower cost, and has a good liquid steel purification effect.

Owner:BAOSHAN IRON & STEEL CO LTD

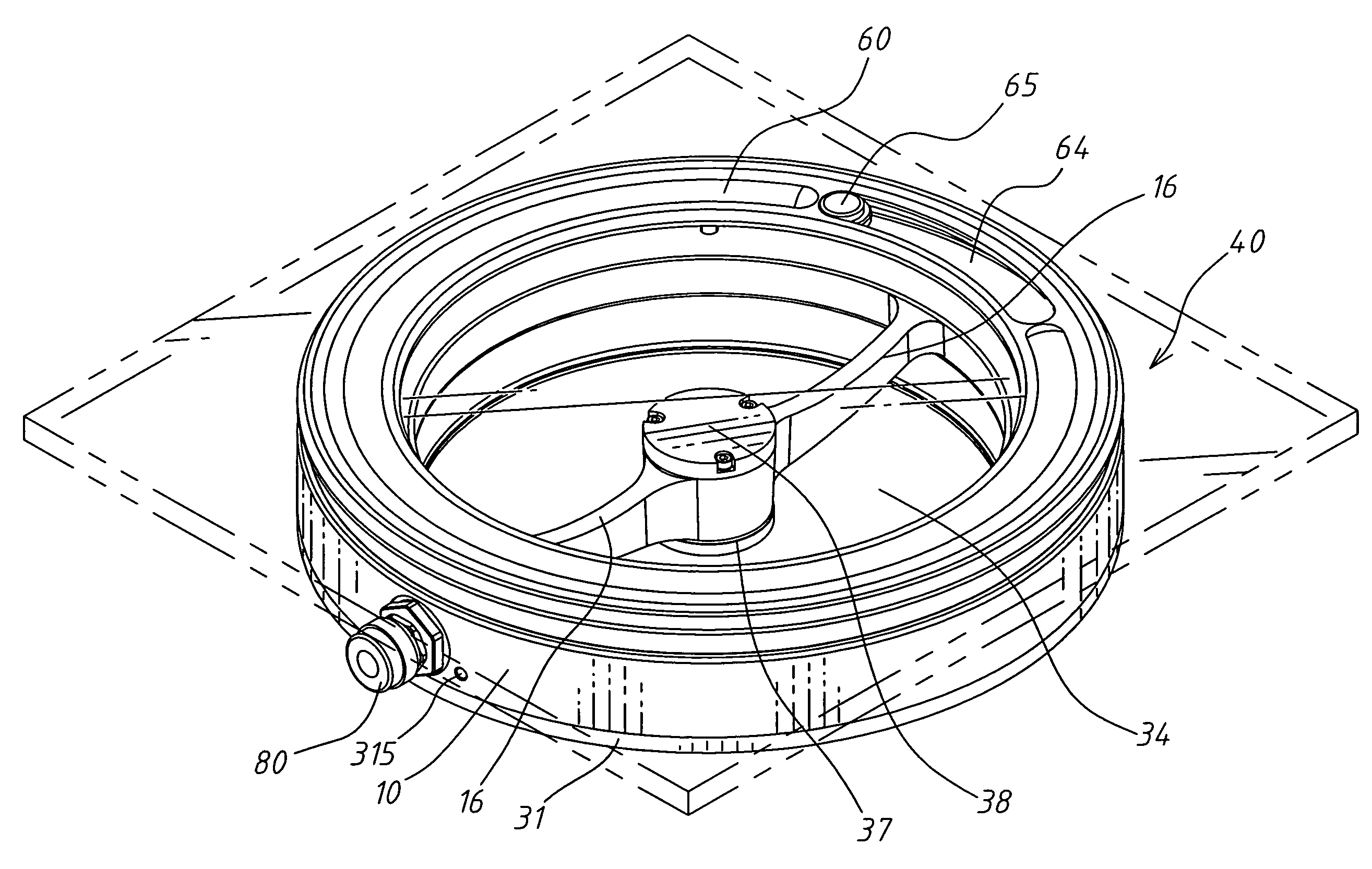

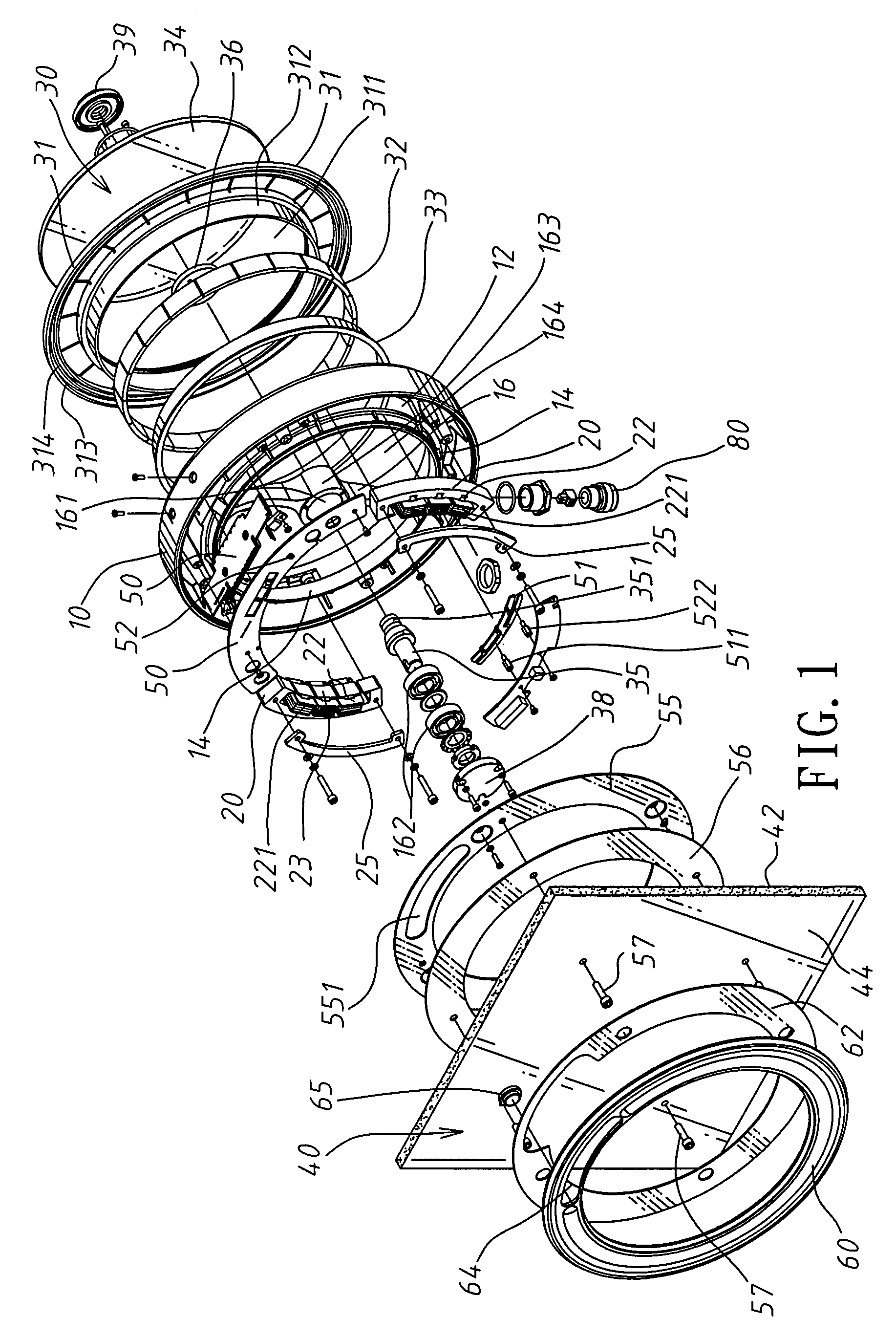

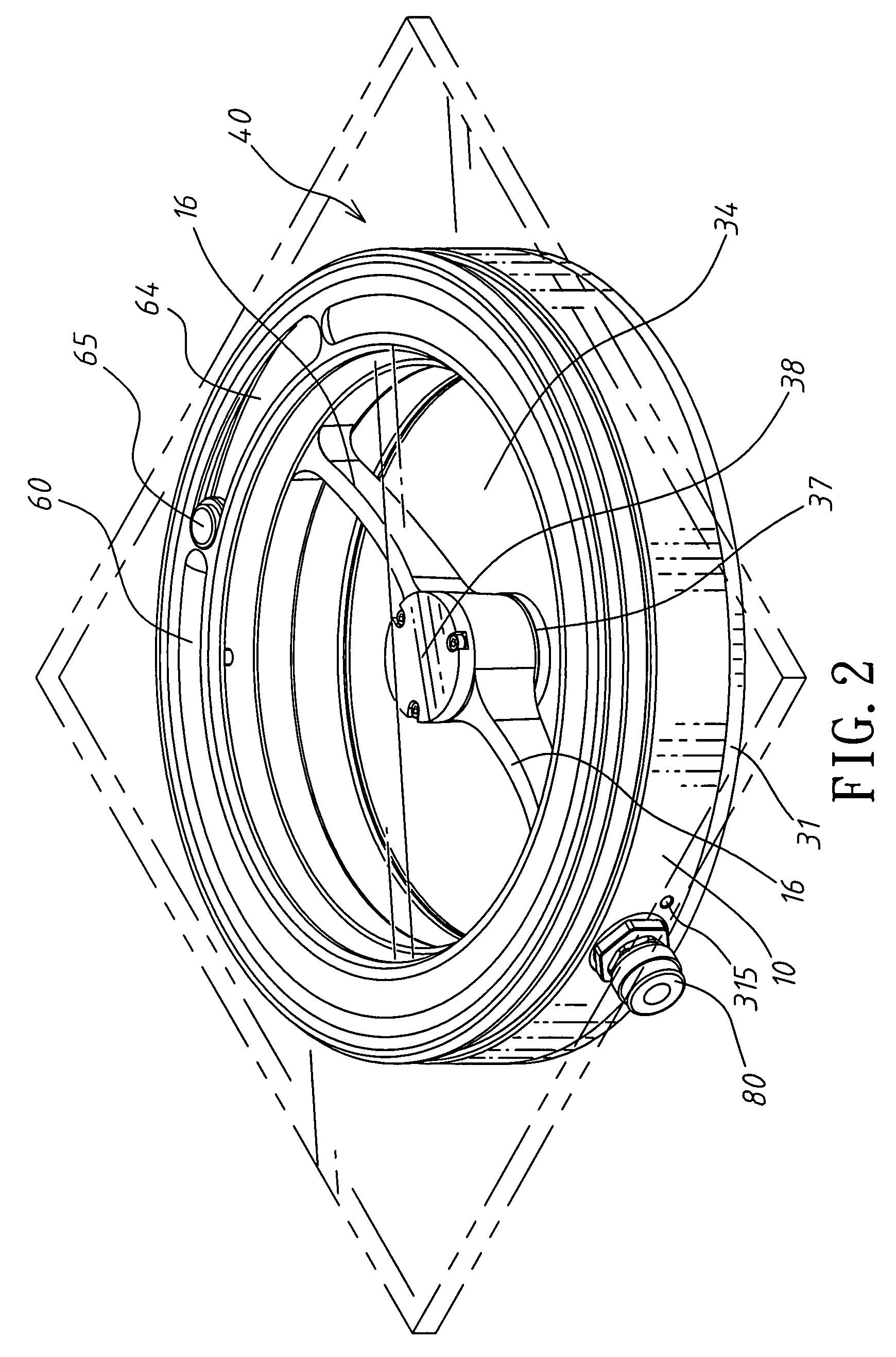

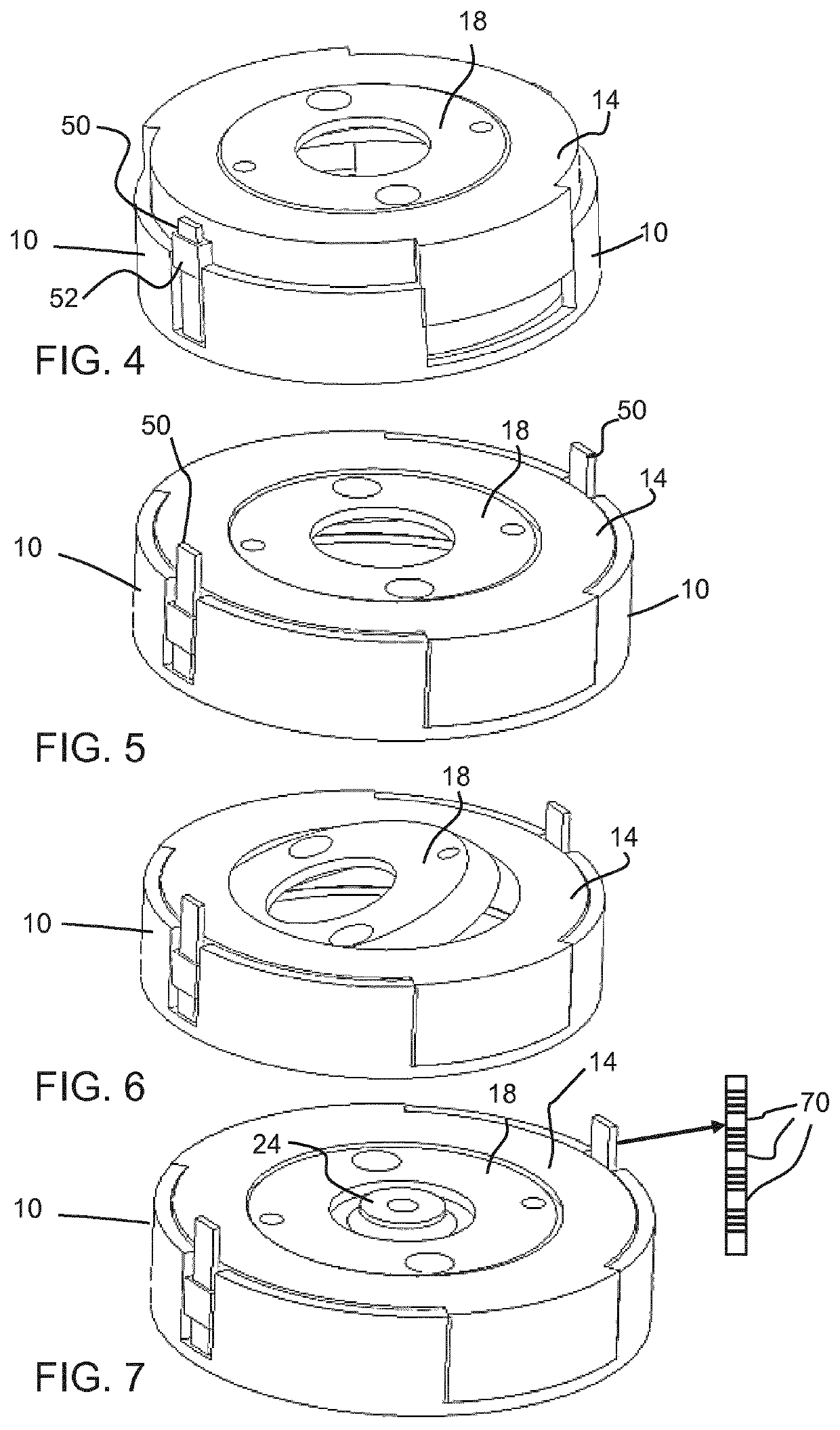

Rotating window

A rotating window includes a circular base member, a transparent window, and a magneto-conductive element, which are assembled into an electric motor device. By this rotating window, area of transparent region of the transparent window is increased, an outer diameter of a central shaft hole is decreased, and a support bracket is designed as an I-shape or a half I-shape, thereby largely decreasing barriers to the transparent window, allowing a user to conveniently see through scenery or objects at one side of the transparent window without a dead angle. In case that the rotating window is hit by objects and rotates eccentrically, an air gap of the motor disappears, and an entire frame of the rotating window will be absorbed magnetically to the magneto-conductive element, thereby improving safety to people and objects.

Owner:YEH TZU YUAN

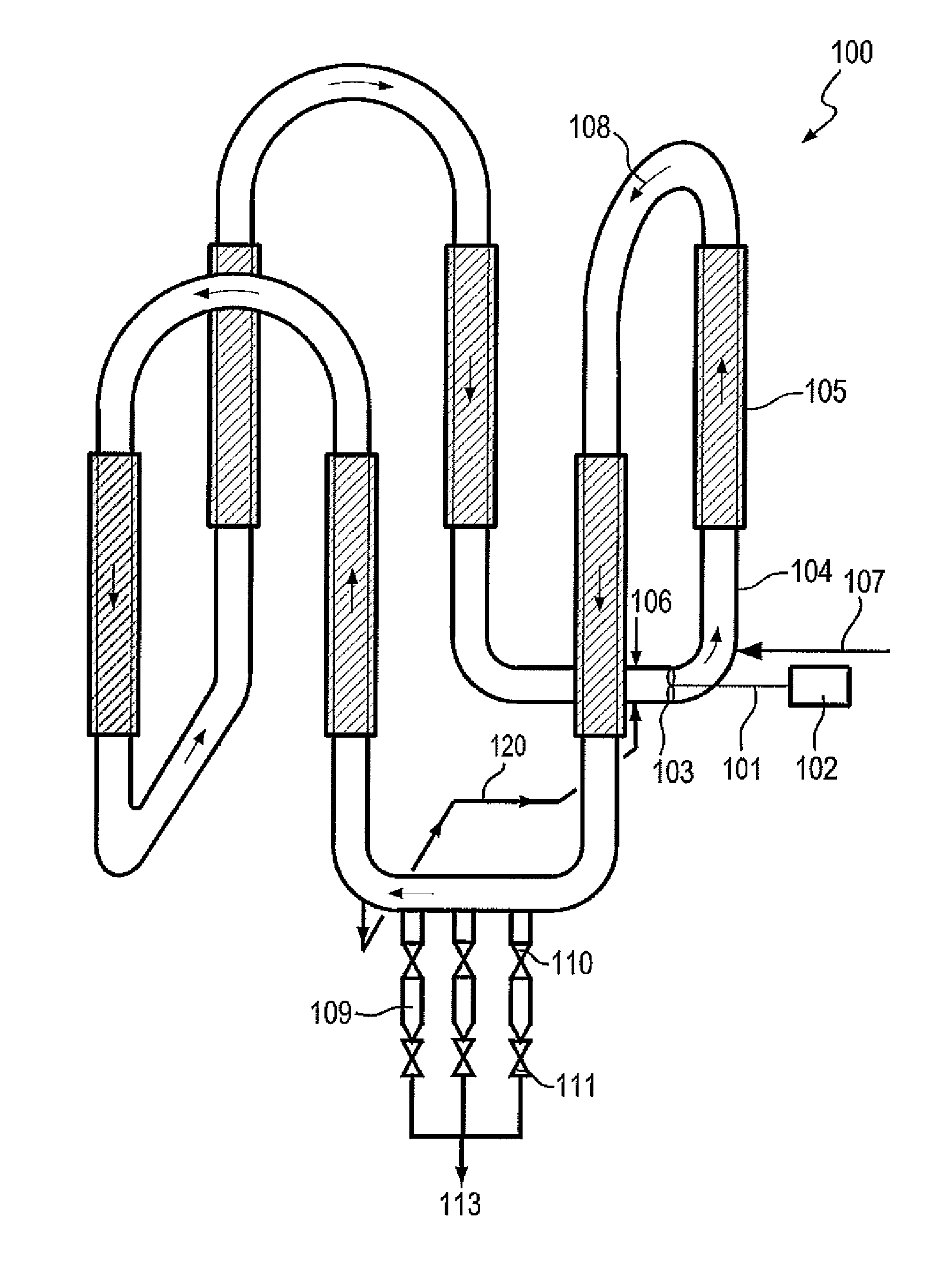

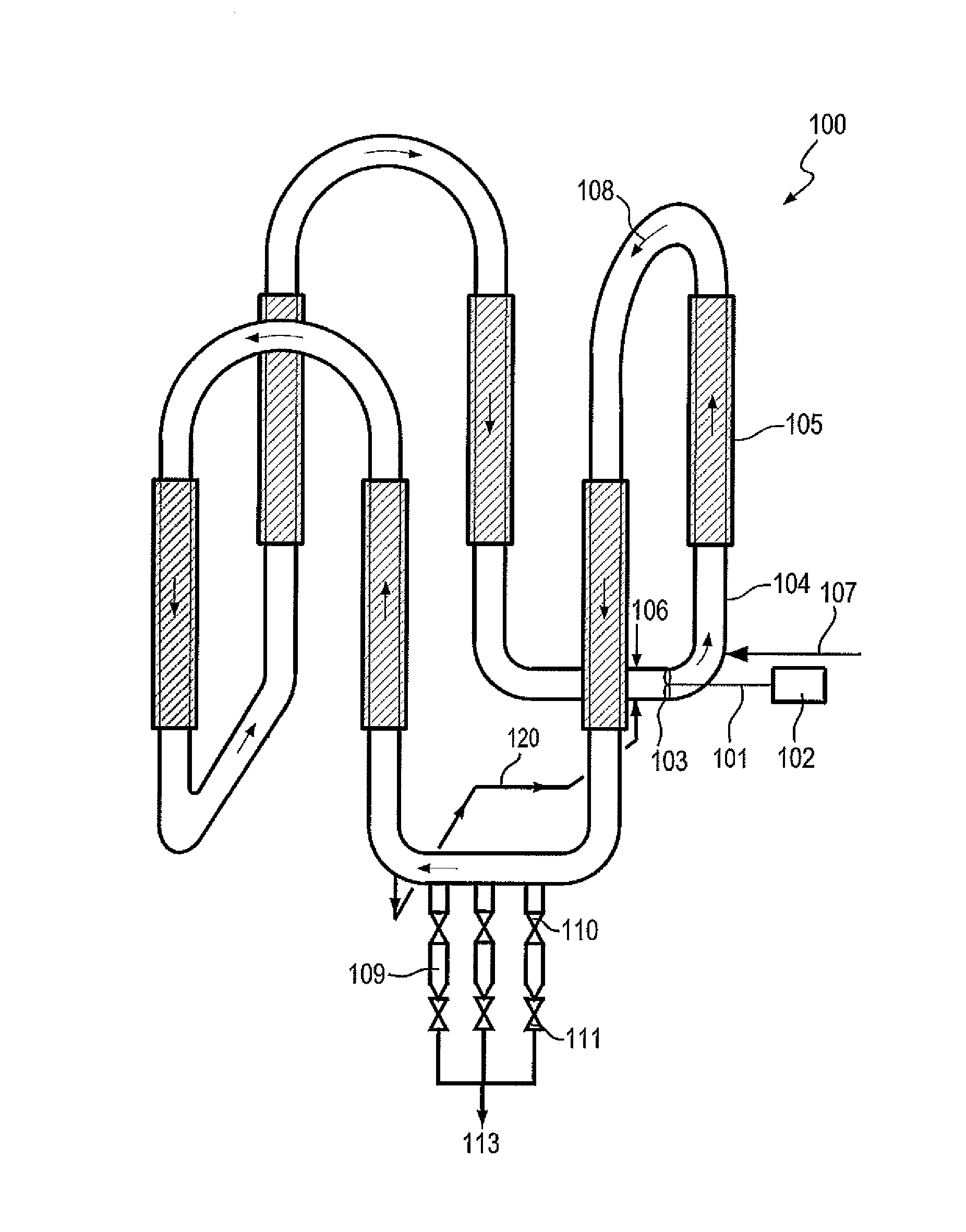

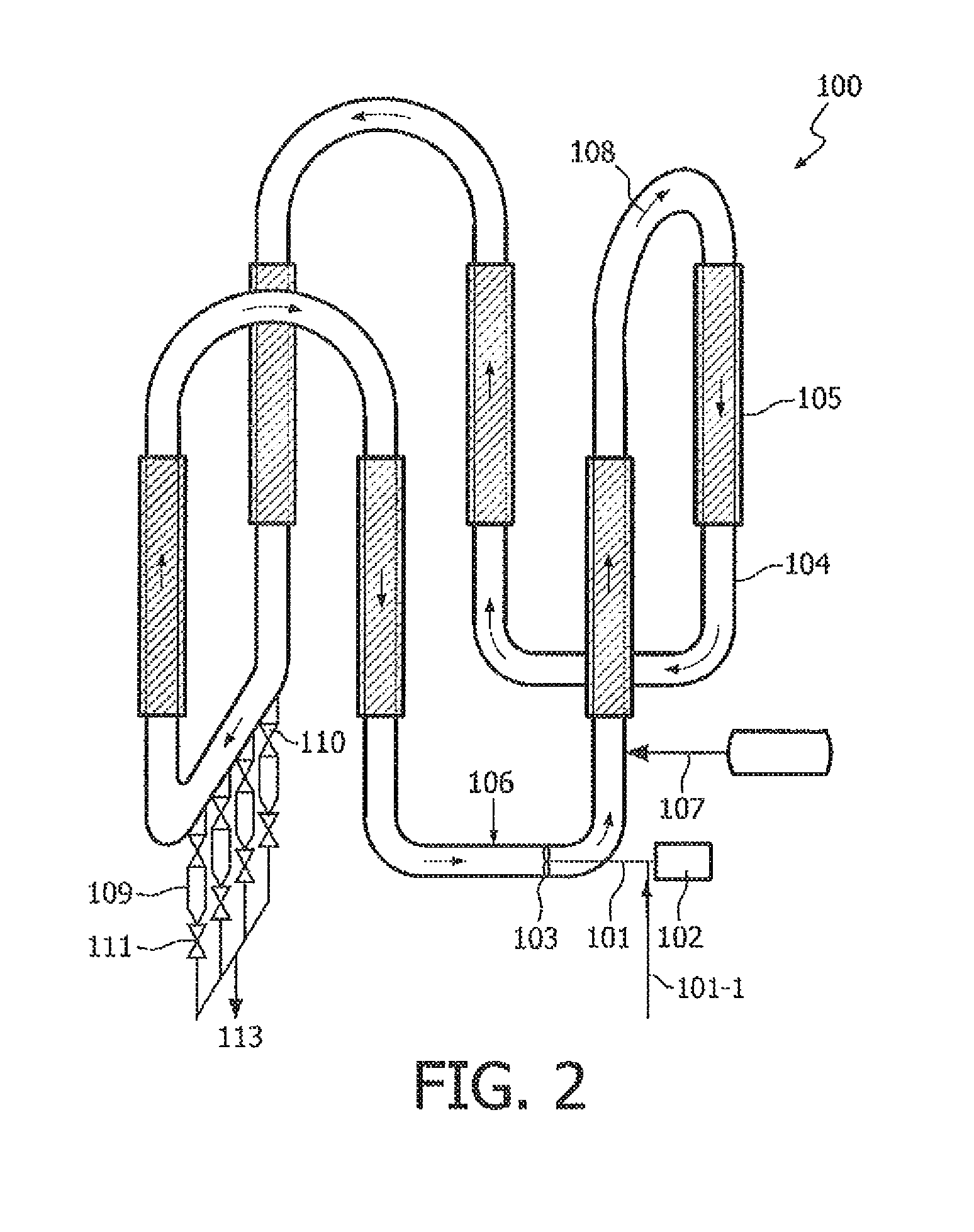

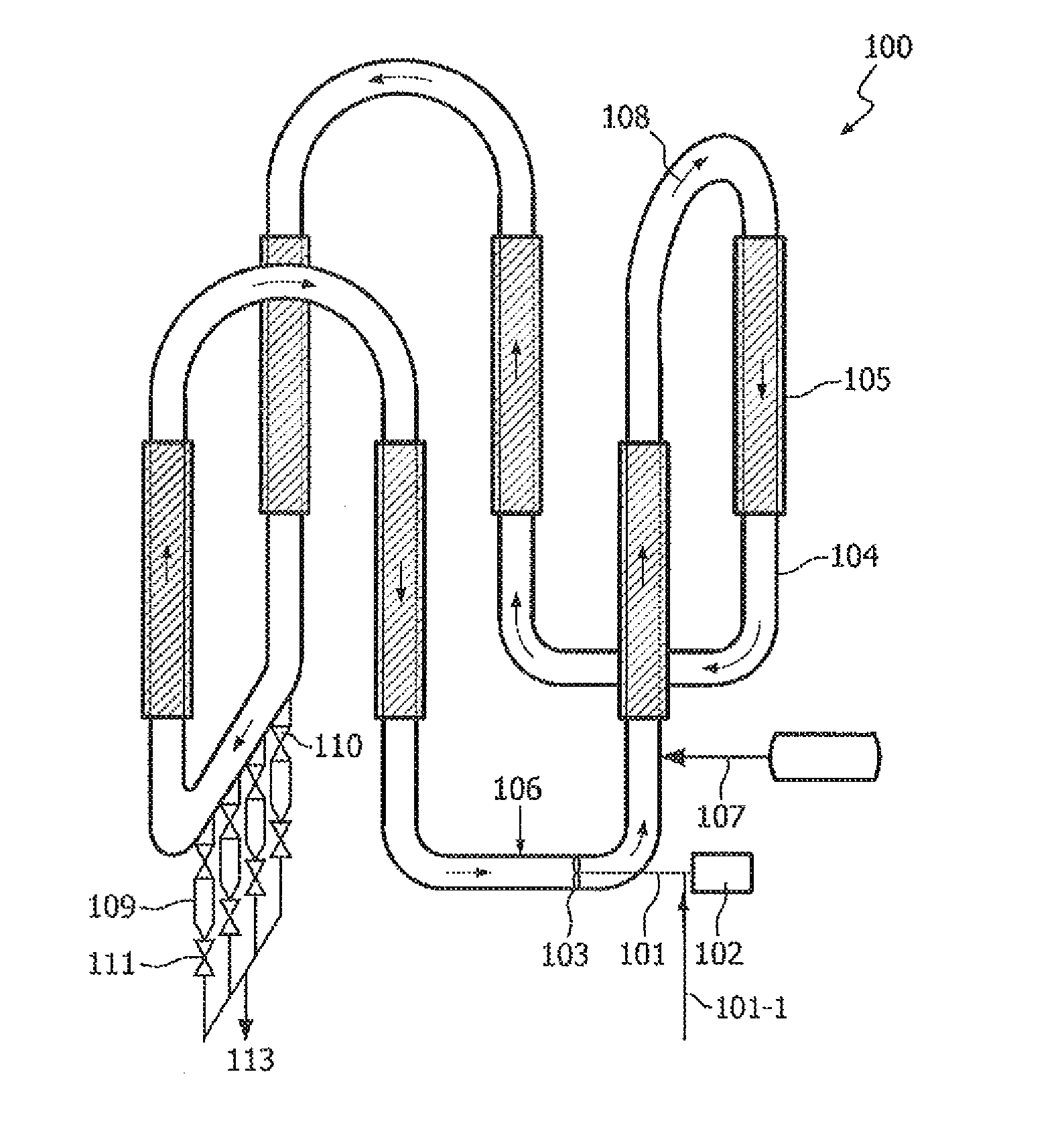

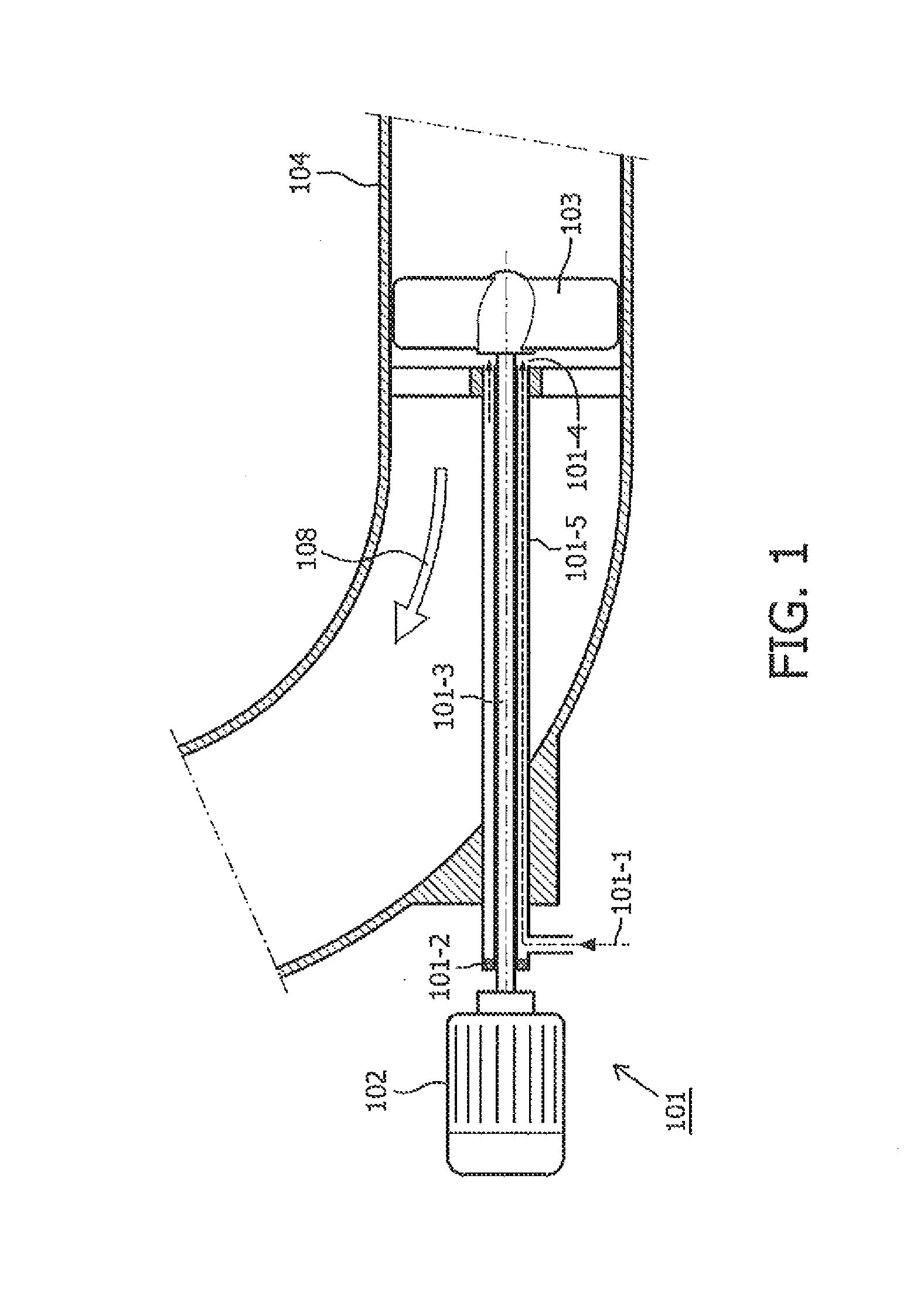

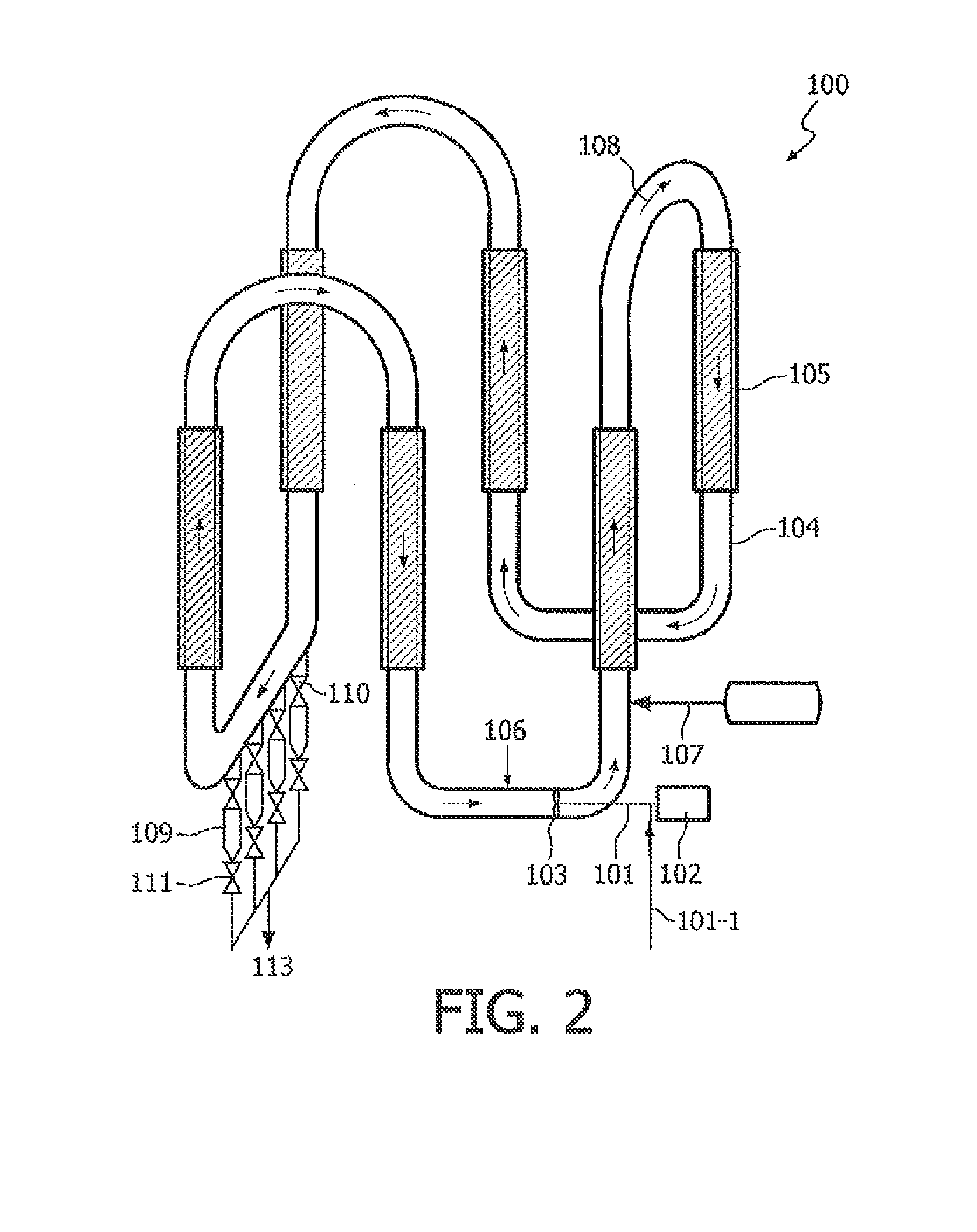

Process for preparing polyolefins

InactiveUS8916657B2Less blockedLow production costChemical/physical/physico-chemical stationary reactorsPolyolefinFouling

The present invention relates to a process of preparing a polyolefin in a loop reactor by introducing anti-fouling agent in by-pass pipes. Also, the invention relates to the use of anti-fouling agent to prevent blockage by feeding the anti-fouling agent into the by-pass pipes of the loop reactor.

Owner:TOTAL RES & TECH FELUY

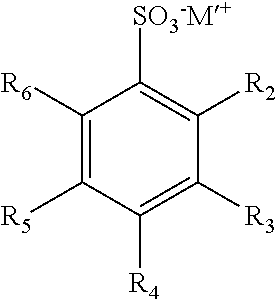

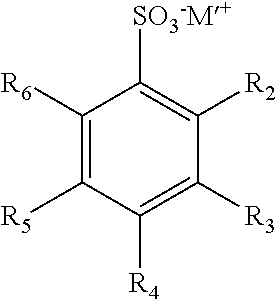

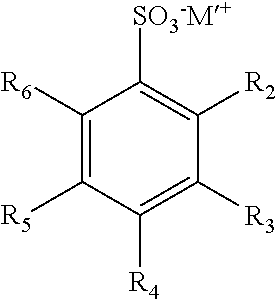

Coating agent comprising hydroxyalkyl cellulose

ActiveUS20120157674A1Low levelLess blockedPharmaceutical non-active ingredientsCoatingsAqueous solutionCellulose

There are provided a coating agent containing a hydroxyalkyl cellulose in which a content of hydroxyalkyl groups within the hydroxyalkyl cellulose is within a range of 40 to 50% by mass, preferably a coating agent containing a hydroxyalkyl cellulose in which the content of hydroxyalkyl groups is within a range of 40 to 50% by mass and also a viscosity of 2% aqueous solution at 20° C. is within a range of 3.0 to 5.9 mPa·s; and a solid preparation coated with the coating agent.

Owner:NIPPON SODA CO LTD

Process for preparing polyolefins

InactiveUS8946359B2Prevent scalingReduce vibrationChemical/physical/physico-chemical stationary reactorsFeed devicesImpellerPolyolefin

The present invention relates to a process of preparing a polyolefin in a loop reactor by introducing anti-fouling agent through a sleeve provided around at least part of the shaft of the pump. Also, the invention relates to the use of anti-fouling agent to prevent or reduce fouling by feeding the anti-fouling agent against the impeller of the pump upon introduction to the loop reactor.

Owner:TOTAL RES & TECH FELUY

Liquid storage container

Owner:SEIKO EPSON CORP

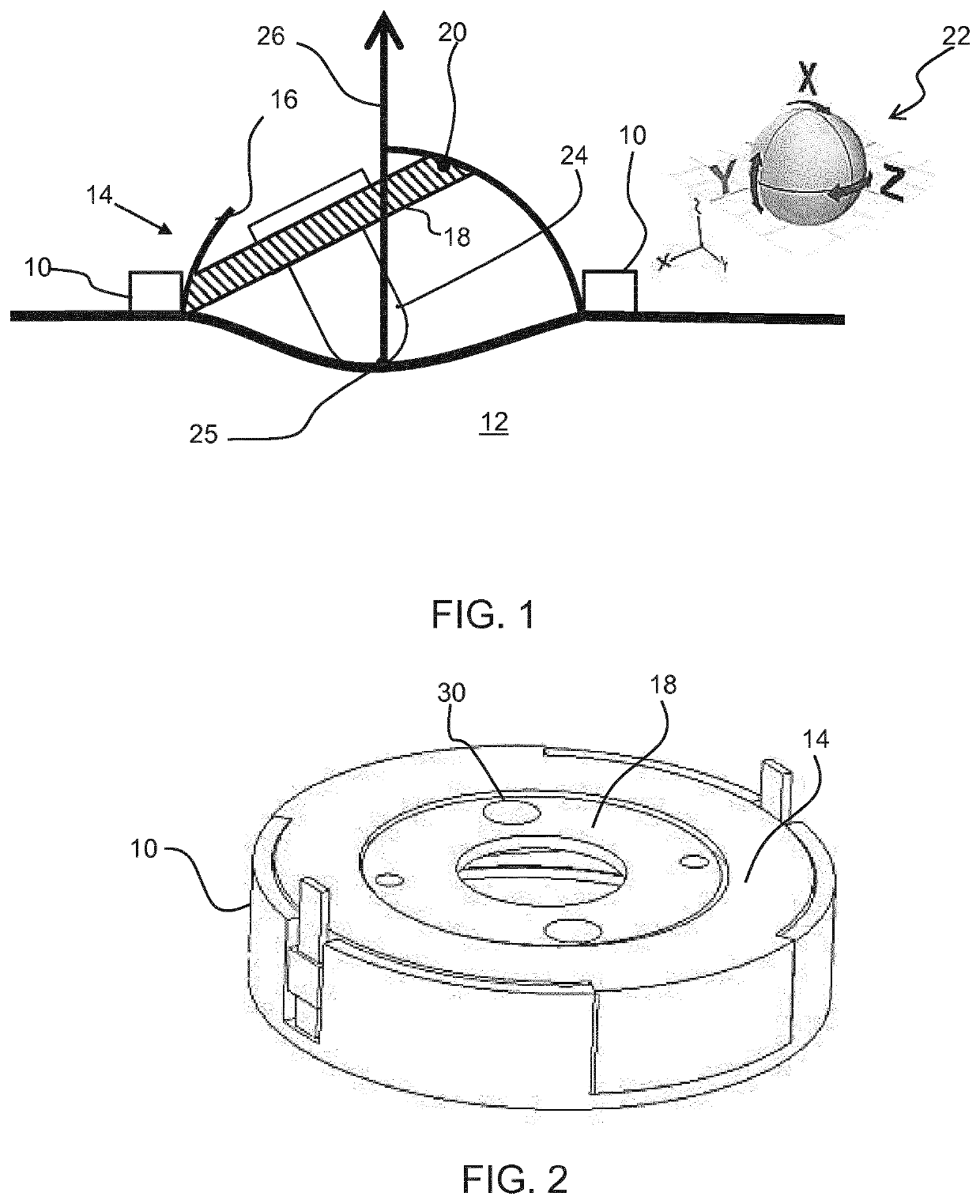

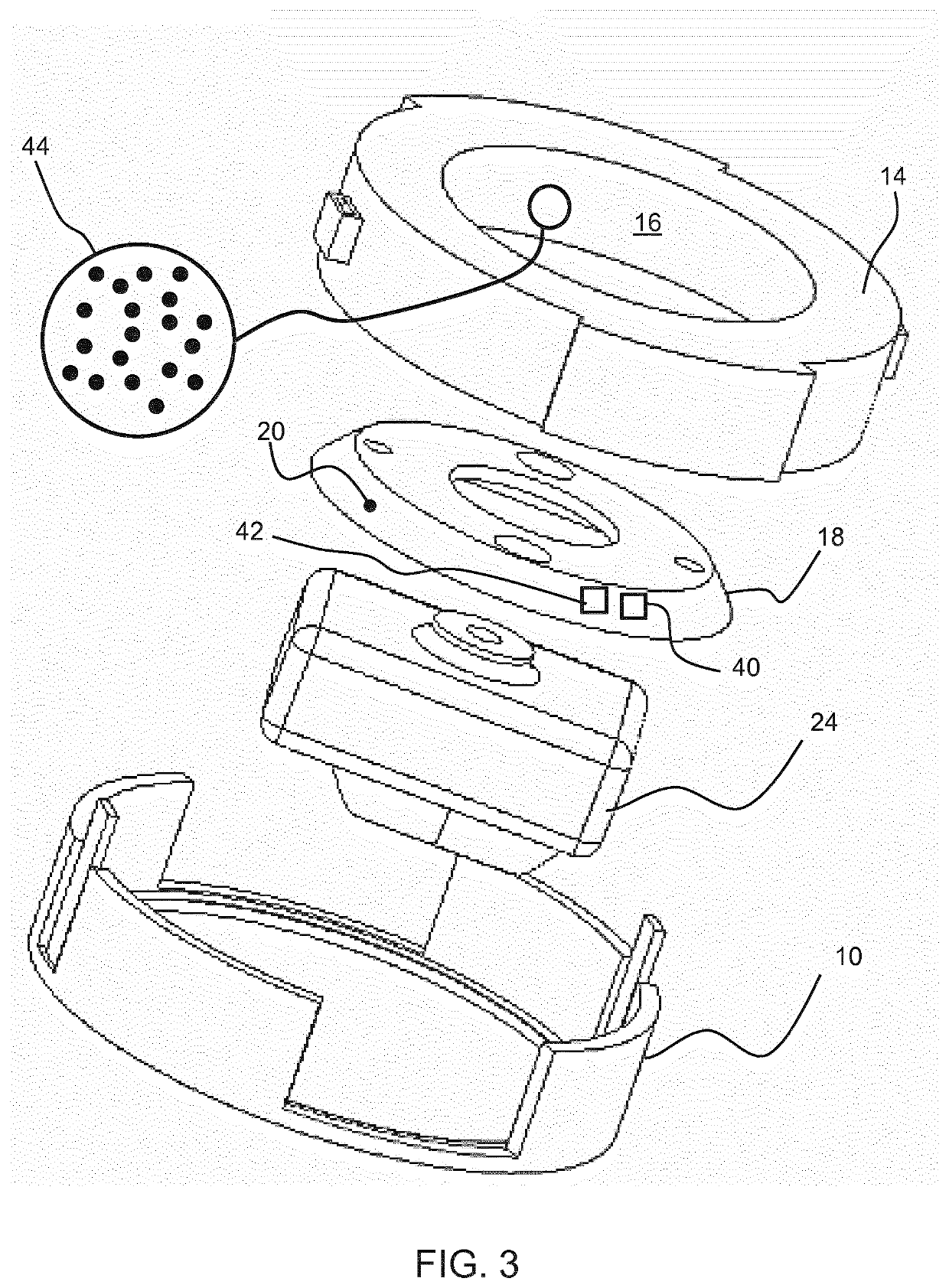

Ultrasound probe arrangement

ActiveUS20200015780A1Large degree of rotational freedomSignificant degreeUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsCircular discEngineering

An ultrasound probe arrangement comprises a holder for application to a surface, a housing mounted over the holder and a probe carrier. The housing has an inner guide surface which comprises a portion of a sphere and the probe carrier comprises a disc having an outer guide surface around the outer rim of the disc which comprises a portion of sphere. The probe carrier is slidable within the housing with the inner and outer guide surfaces in contact. An ultrasound probe is carried by the probe carrier and makes contact with the surface, e.g. skin. This arrangement enables the probe to be held in a desired orientation so that a clinician can work hands-free. The disc design enables different probe designs to be used with the same basic holder and housing design.

Owner:KONINKLJIJKE PHILIPS NV

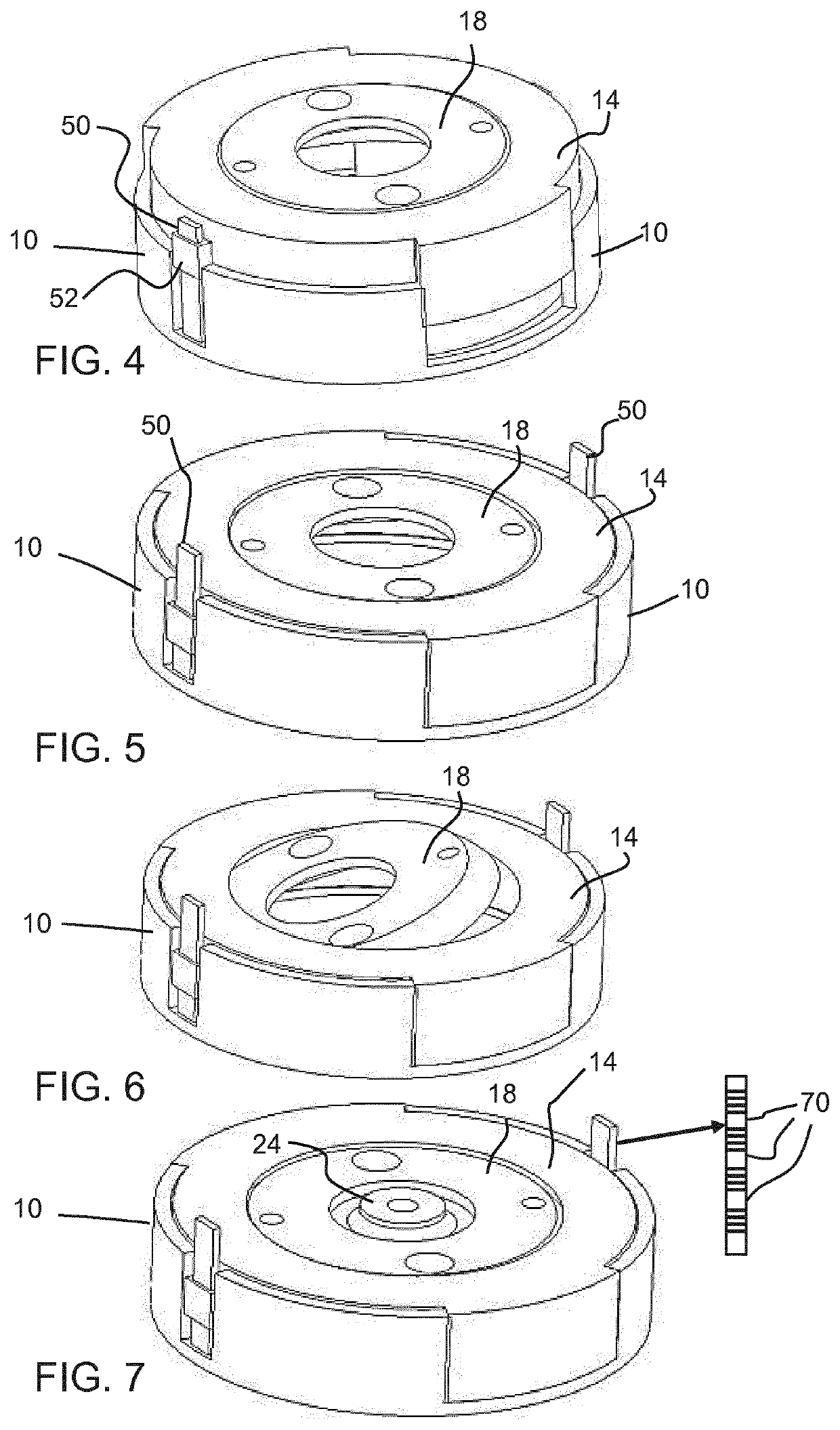

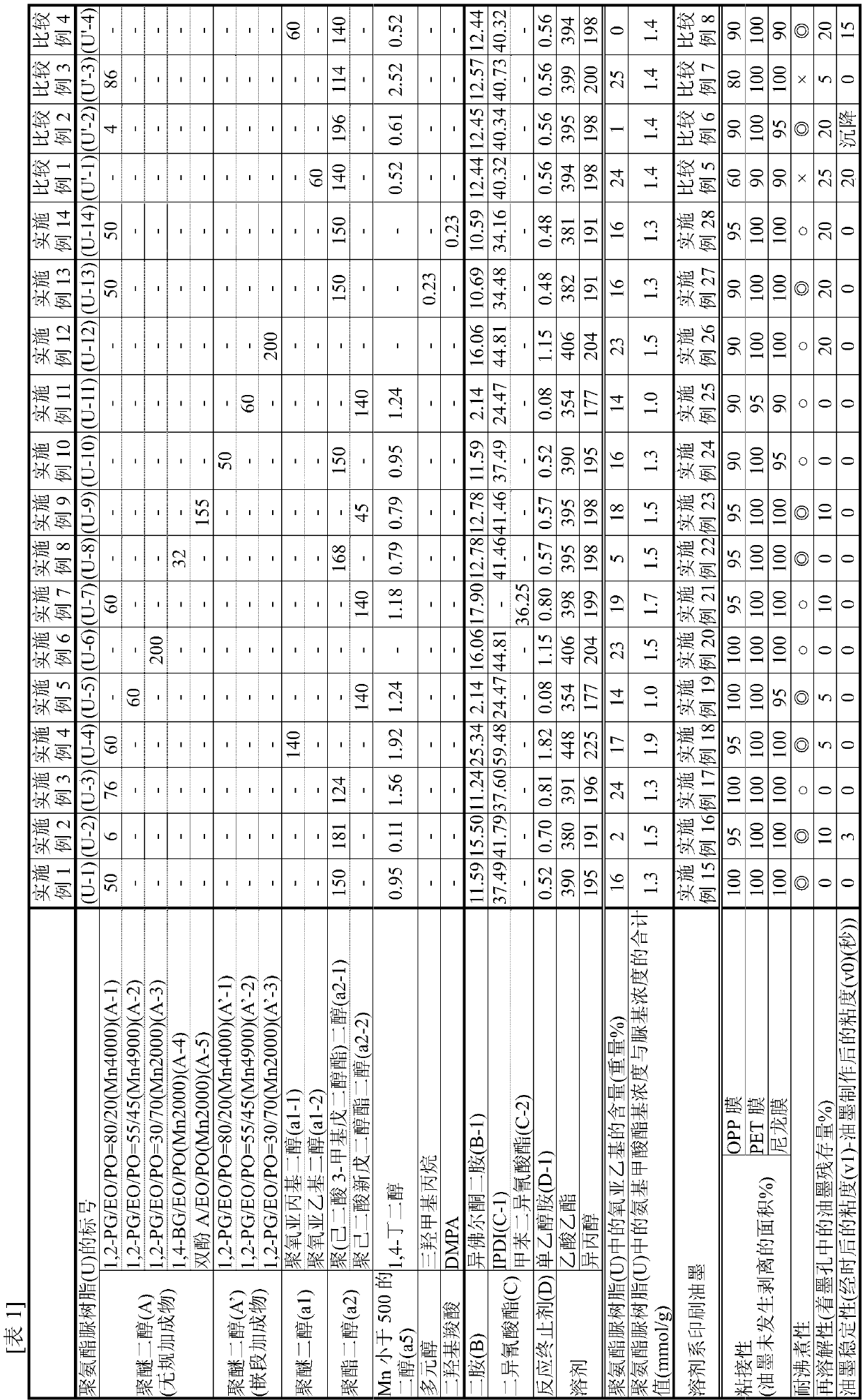

Binder for solvent-based printing ink, and solvent-based printing ink including same

Provided is a binder for solvent-based printing inks which are extensively usable on various plastic films, can be highly easily redissolved in solvents, and rarely cause printing plate clogging during printing, which have excellent ink stability even in case where water has come thereinto, and which have excellent boiling resistance. The binder for solvent-based printing inks according to the present invention comprises a polyurethane-urea resin (U), wherein the polyurethane-urea resin (U) is a resin obtained from, as essential constituent monomers, a polyether diol (A) that is an adduct obtained by causing alkylene oxides comprising ethylene oxide and 1,2-propylene oxide to add to a compound (F) having two active hydrogen atoms, a diamine (B), and a diisocyanate (C), the polyurethane-urea resin (U) having a content of oxyethylene groups of 2-24 wt%.

Owner:SANYO CHEM IND LTD

Process for preparing polyolefins

InactiveUS20130123441A1Prevent scalingLow production costChemical/physical/physico-chemical stationary reactorsFeed devicesImpellerPolyolefin

The present invention relates to a process of preparing a polyolefin in a loop reactor by introducing anti-fouling agent through a sleeve provided around at least part of the shaft of the pump. Also, the invention relates to the use of anti-fouling agent to prevent or reduce fouling by feeding the anti-fouling agent against the impeller of the pump upon introduction to the loop reactor.

Owner:TOTAL RES & TECH FELUY

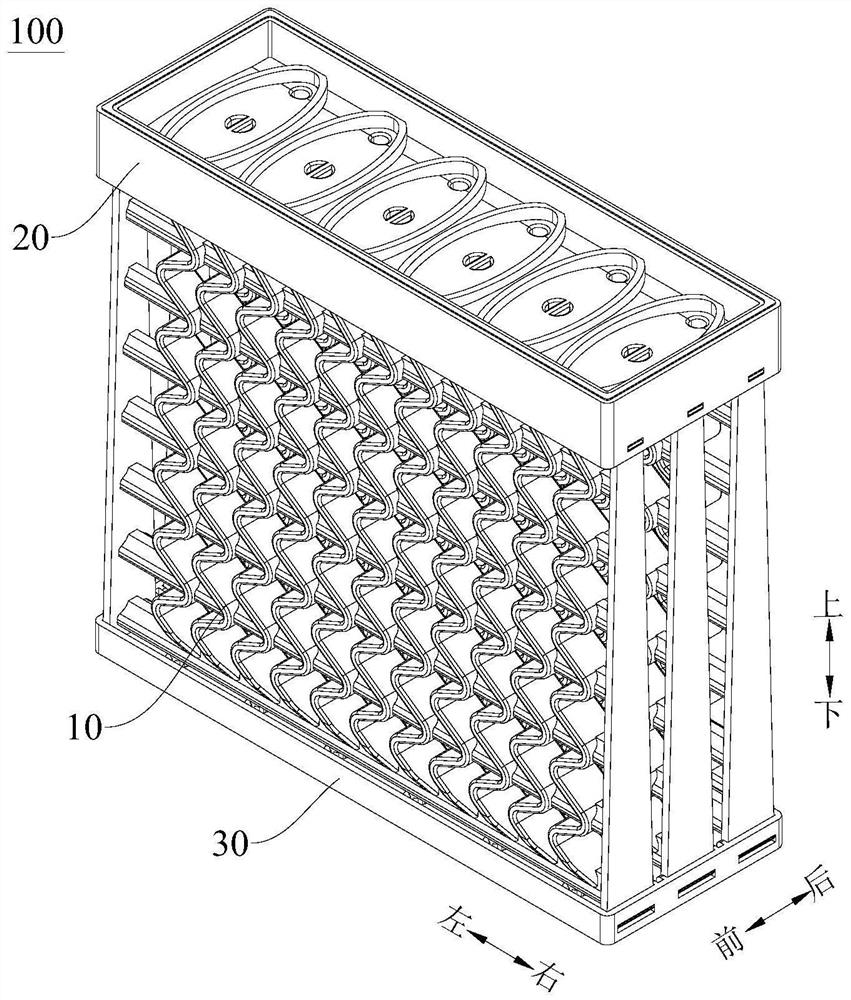

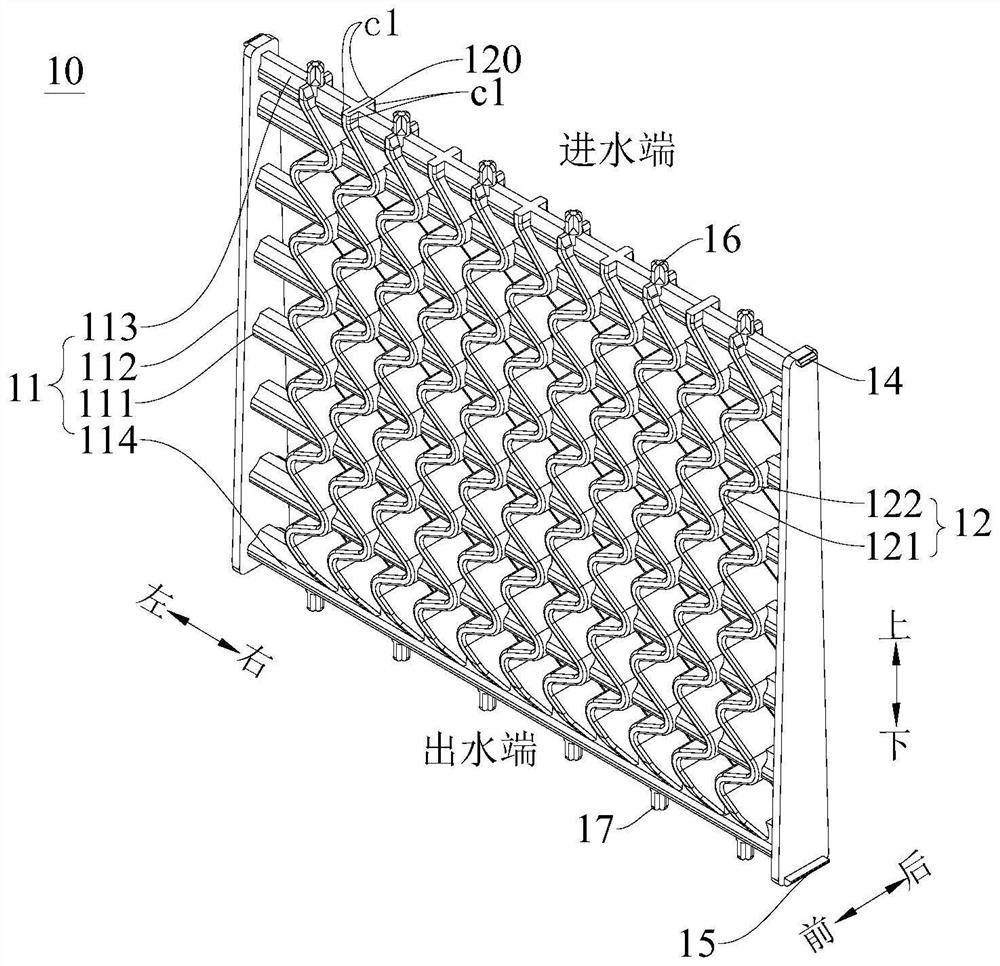

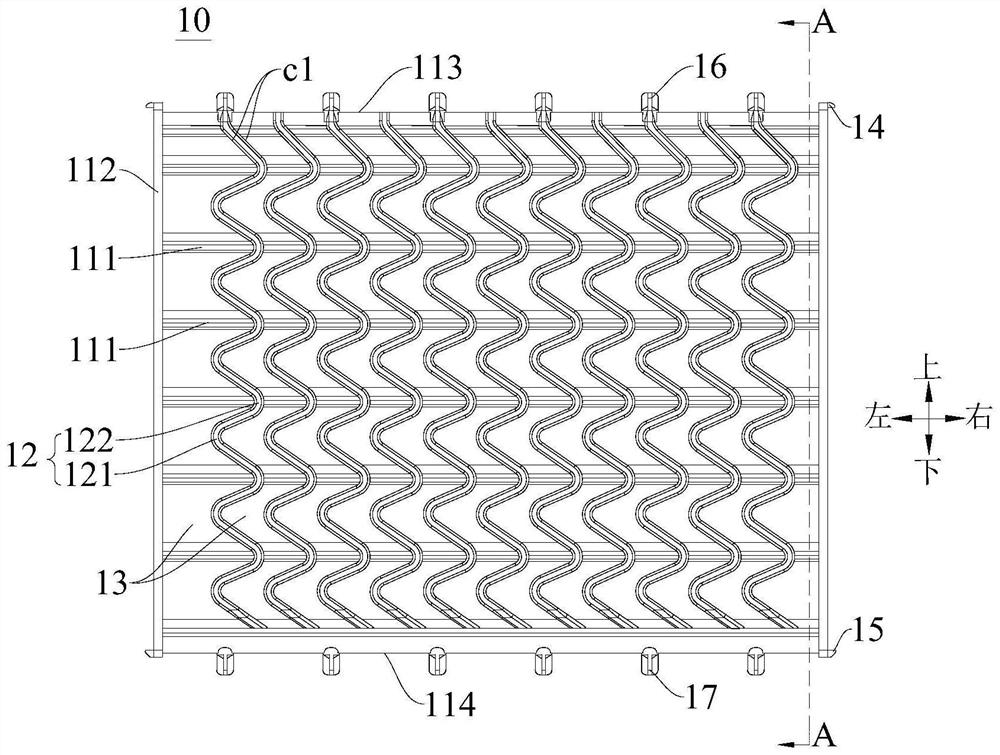

Wet curtain structure of humidifier

PendingCN114576754AImprove the humidification effectReduce energy consumptionLighting and heating apparatusEfficient regulation technologiesWater flowEngineering

The invention discloses a wet curtain structure of a humidifier, which comprises a curtain body, and the curtain body is a non-water-absorbing piece. The upper end and the lower end of the curtain body are a water inlet end and a water outlet end, the curtain body comprises a connecting part and a plurality of flow guide parts, the connecting part and the flow guide parts are integrally formed and connected, the flow guide parts are sequentially arranged in the horizontal direction, and the connecting part is connected with the flow guide parts so that the curtain body can be in a net shape. At least one flow guide part is in a wave shape extending in a winding mode in the vertical direction, and vent holes are defined between the adjacent flow guide parts and used for ventilation in the thickness direction of the curtain body. According to the wet curtain structure, the flow guide part forms the zigzag extending waveform, the flowing area of water flow on the surface of the flow guide part is increased, the flowing time of the water flow is prolonged, and the humidifying effect of the humidifier can be improved. The multiple flow guide parts are connected into a net through the connecting parts, the overall structural strength is enhanced, and noise is reduced. The curtain body serves as a non-water-absorbing piece, the service life is prolonged, the use cost is reduced, and potential health hazards are reduced.

Owner:FOSHAN SHUNDE DEERMA ELECTRIC APPLIANCES CO LTD

Cosmetic shaving stick

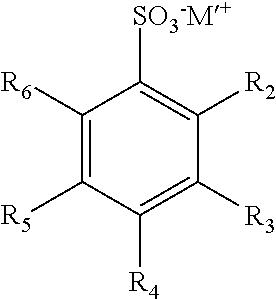

ActiveUS20180325790A1Pleasant application propertyEasily rinsed offCosmetic preparationsHair removalGlycerolFatty acid

Disclosed is a cosmetic product comprising a cosmetic stick composition that comprises one or more fatty acids and / or salts thereof, one or more anionic surfactants selected from alkyl sulfates, alkyl ether sulfates and alkylbenzenesulfonates, and glycerol as well as an application container which contains the stick composition.

Owner:BEIERSDORF AG

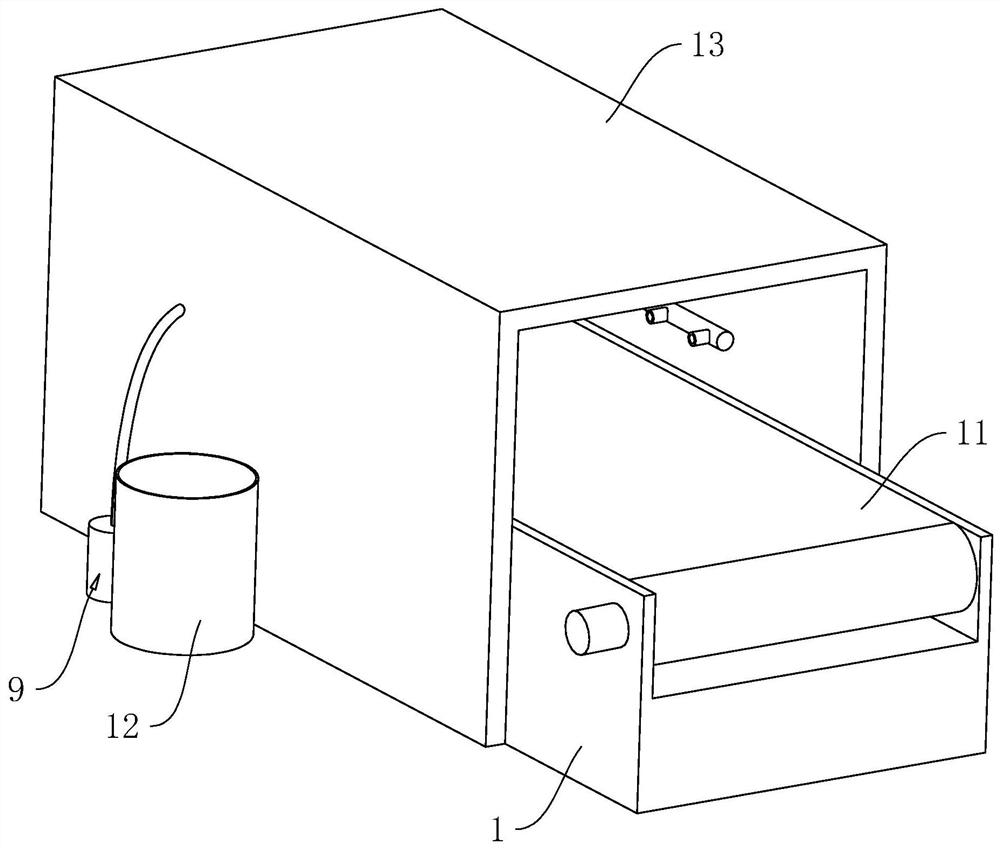

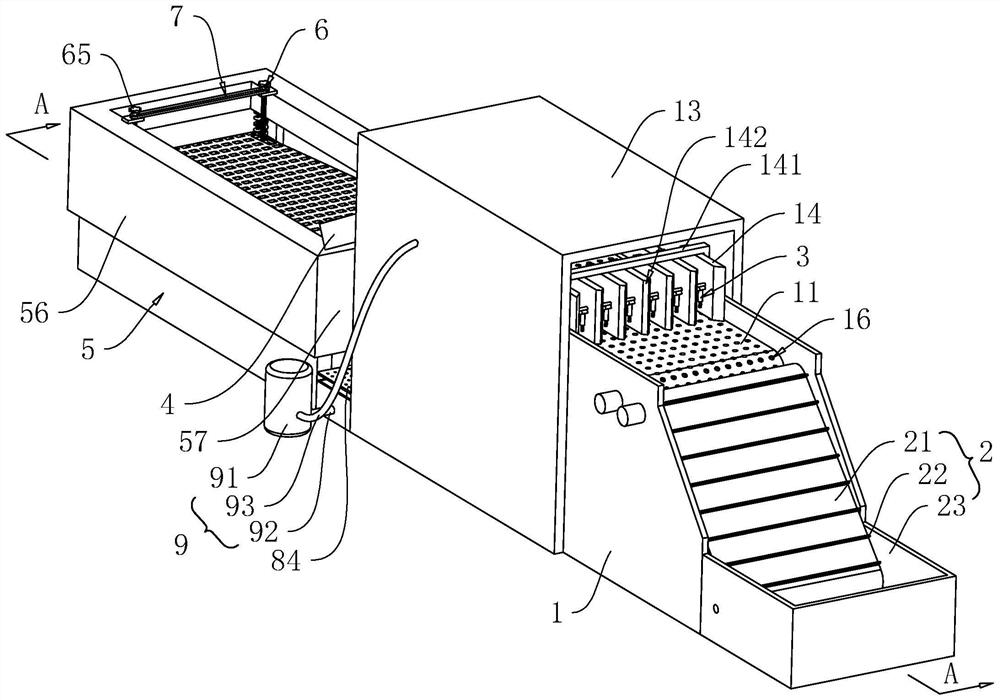

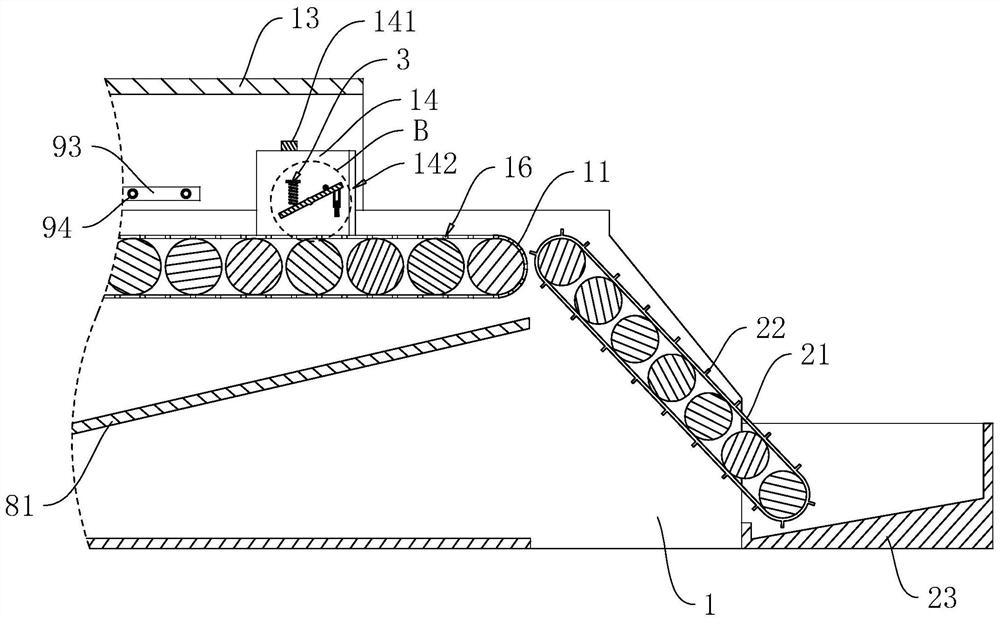

A kind of oiling machine and heat treatment process using the equipment

ActiveCN112934511BReduce standing upLess blockedPretreated surfacesFurnace typesThermodynamicsTransmission belt

The application relates to an oiling machine and a heat treatment process using the equipment, which includes a frame on which an oil storage tank, a first conveyor belt for driving several bearings, and a first conveyor belt for atomizing the oil in the oil storage tank And spray into the atomizing device in the oil storage tank, the frame is provided with a transmission device, the transmission device includes a second conveyor belt, a number of driving plates and a material storage box, the material storage box, the second conveyor belt are arranged in sequence along the transmission direction of the first conveyor belt, The material storage box is located below the first conveyor belt and is arranged on the frame; one end of the second conveyor belt is located in the material storage box, and the other end is located at the first conveyor belt place, and several drive plates are arranged on the second conveyor belt, and the drive plate and the second conveyor belt A space is formed between the bearings for limiting placement, and the distance between the surface of the driving plate away from the second conveyor belt and the second conveyor belt is smaller than the radius of the bearing. The present invention has the effect of reducing the occurrence of the bearing standing up when the bearing is processed.

Owner:新昌沛斯轴承配件有限公司

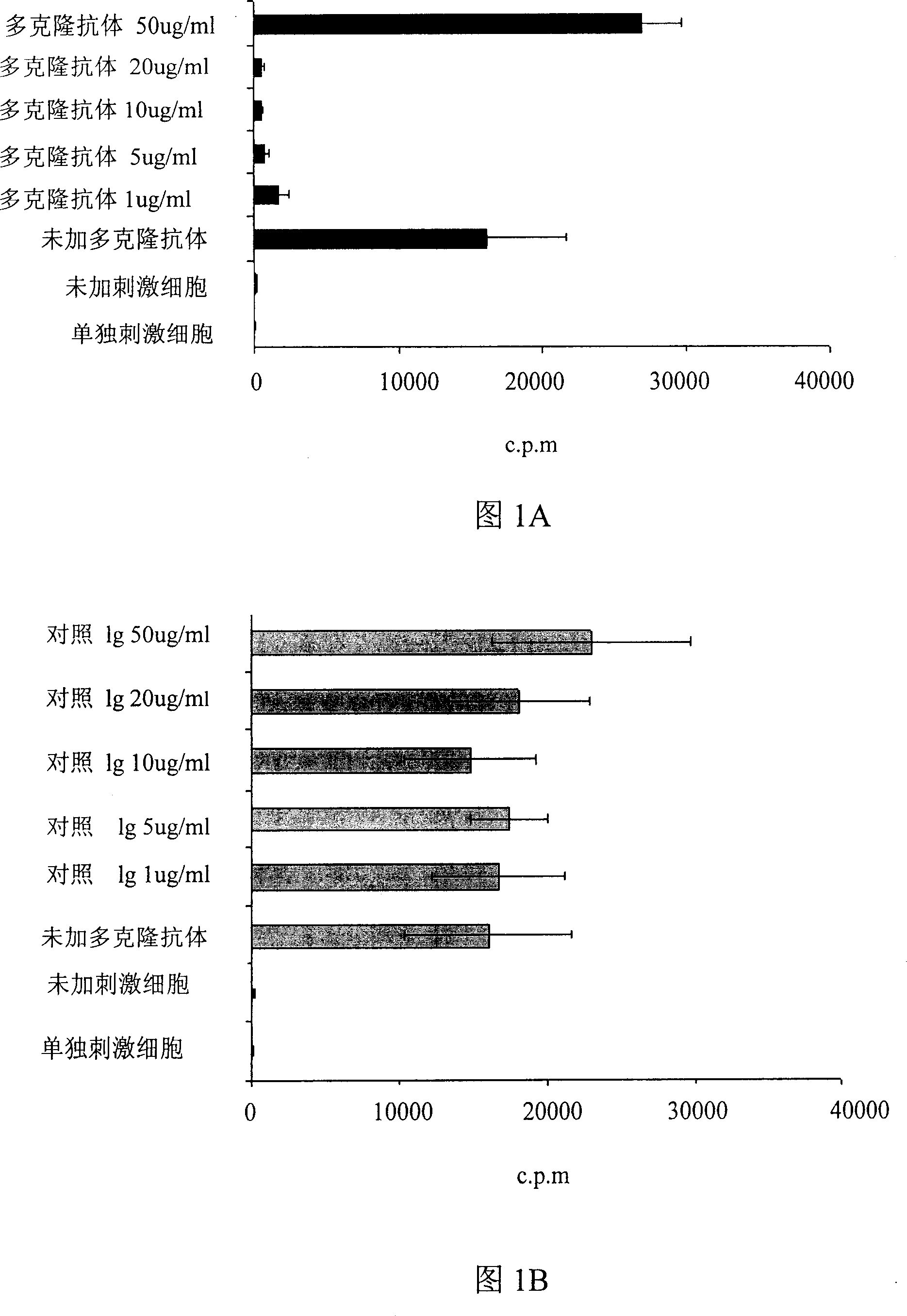

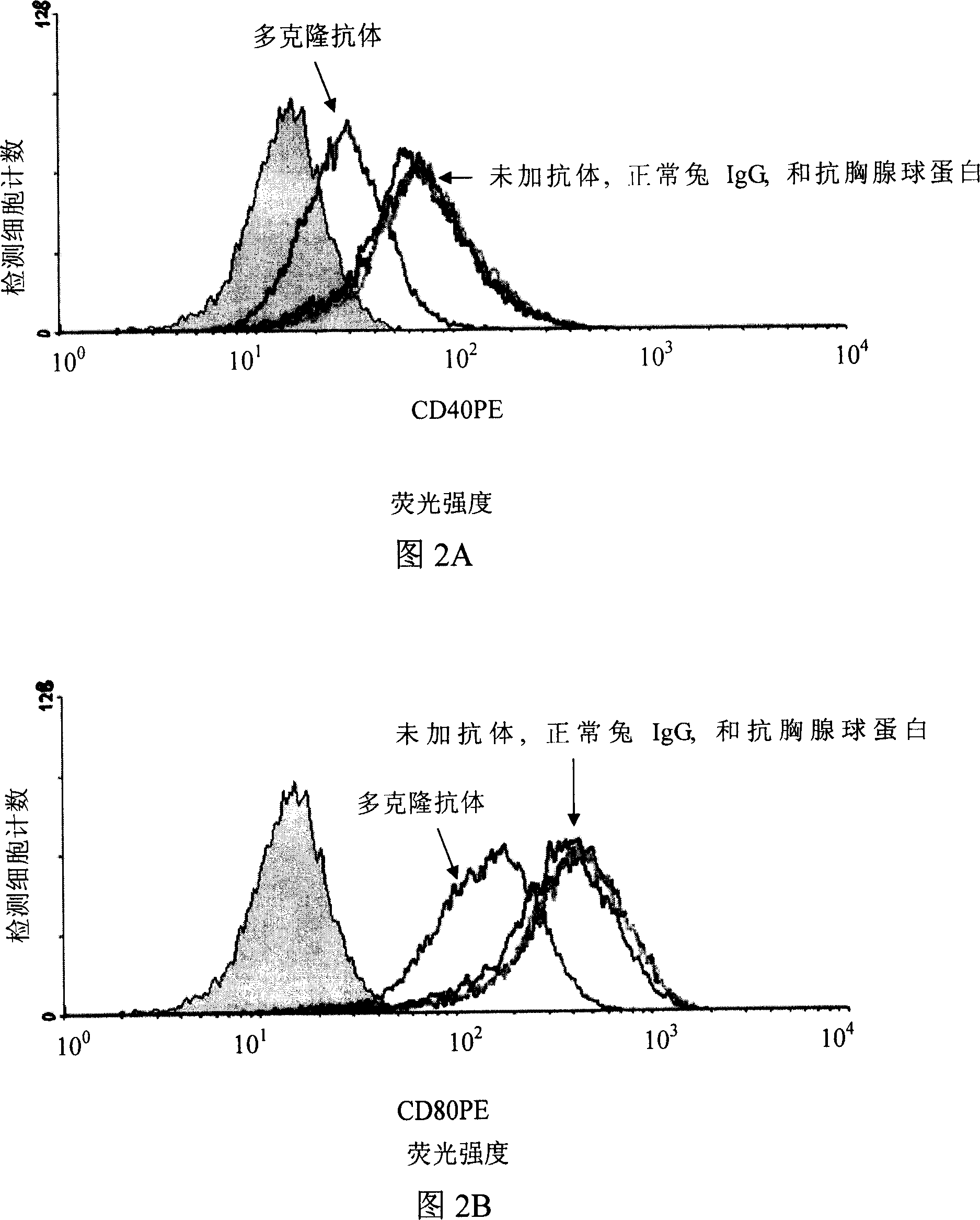

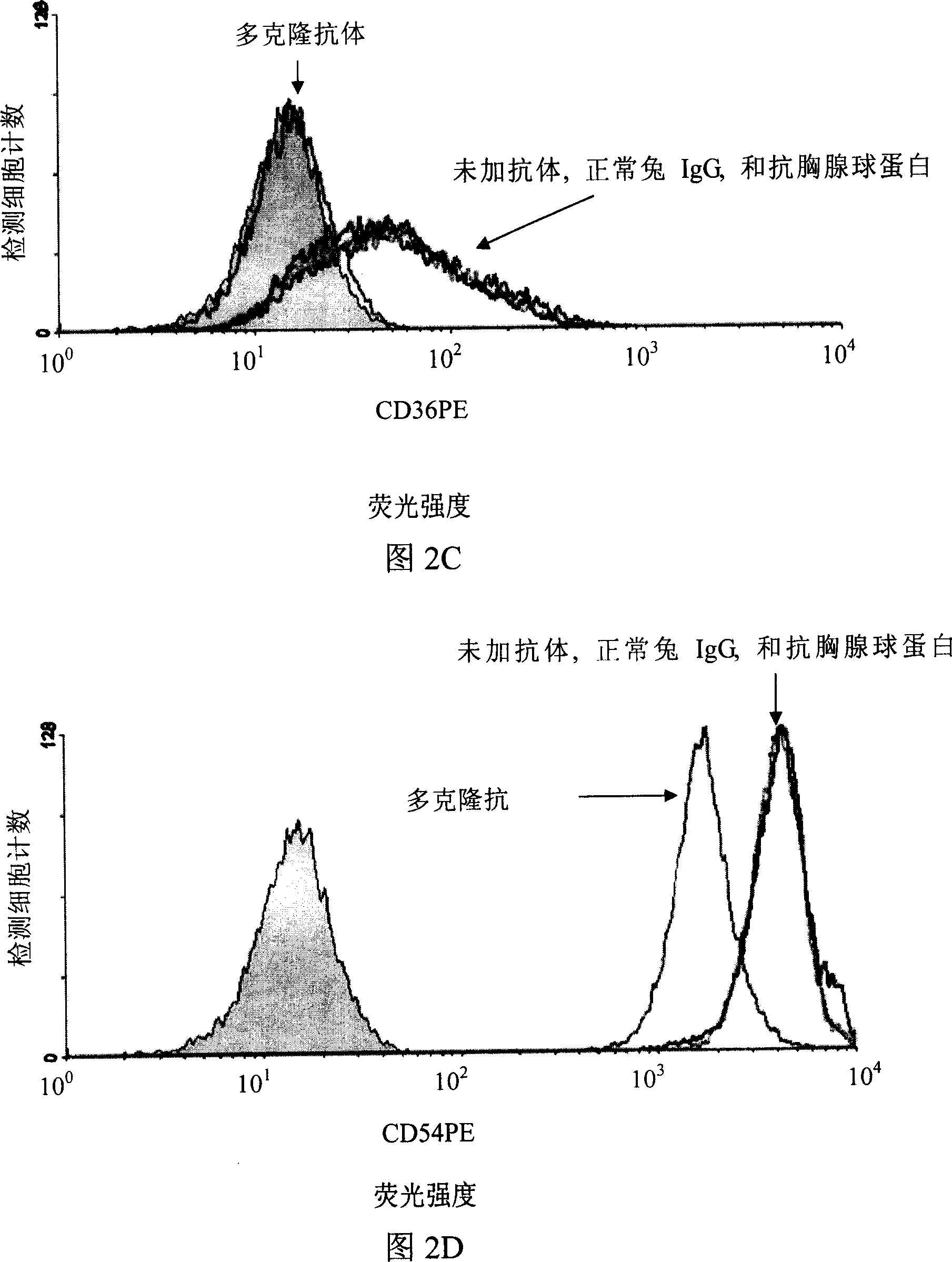

Antigenic composite, multi-clone antibody prepared by it and its application

InactiveCN101088560AExclude lessLess blockedAntibody ingredientsImmunological disordersPolyclonal antibodiesAutoimmune disease

The present invention relates to antigen composition comprising leukocyte and cell line mixture. The antigen composition may be animal immunized to obtain new generation of polyclonal antibody possessing specific abnormal immunity reaction preventing and treating effect. The present invention proposes immunotherapy on abnormal immunity reactions, including autoimmune diseases, implant-anti-host diseases, rejection reaction, etc. The polyclonal antibody the present invention provides acts directly on lymphocyte and monocyte to be determined to participate in the abnormal immunity reaction while having less removal and blocking on static or unactivated lymphocyte.

Owner:徐何 +2

Inductive coagulation sensors and devices

ActiveUS8633711B2Increase influenceReduces and eliminates phenomenonFlow propertiesInductance measurementsElectricityInductor

This invention provides methods and devices for detecting the viscosity and conductivity of a conductive fluid sample. A sample fluid can be received into a sample chamber between a field inductor and sensor inductor. Electromagnetic fields generated by the field inductor can be modulated due to the counter-emf induced in the sample. The modulations can be detected by the sensor inductor and correlated to electric parameters in the fluid.

Owner:MICROPOINT BIOTECHNOLOGIES CO LTD

Remote control system having a communication frequency lower than wireless fidelity signals

ActiveUS8922353B2Short transmission distanceLess blockedElectric signal transmission systemsEqual length code transmitterRemote controlEngineering

A remote control system includes a control interface, a WiFi router, a bridge, and a low frequency control module. The WiFi router is linked to the control interface for communicating with the control interface via WiFi signals. The bridge is linked to the WiFi router for down-converting WiFi signals outputted from the WiFi router to low frequency signals and up-converting received low frequency signals to WiFi signals. The low frequency control module is linked to the bridge for communicating with the bridge via the low frequency signals.

Owner:LEADOT INNOVATION

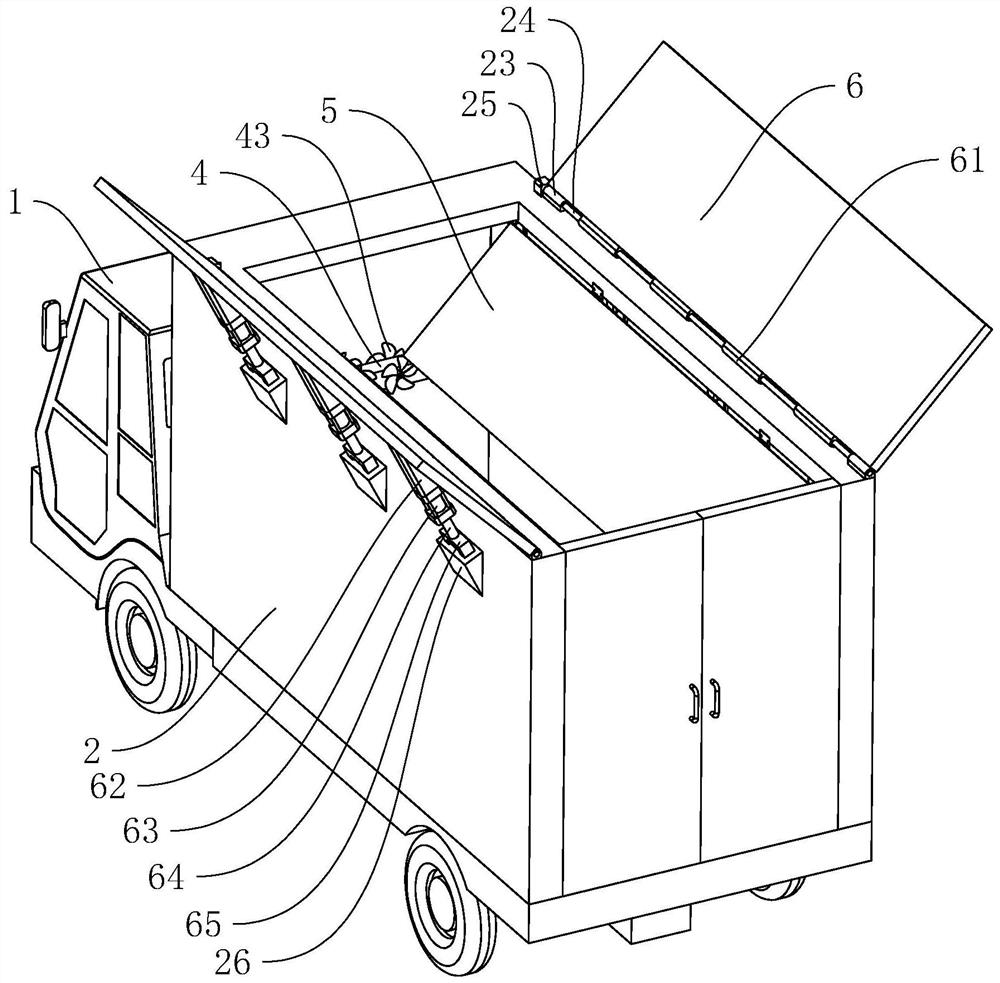

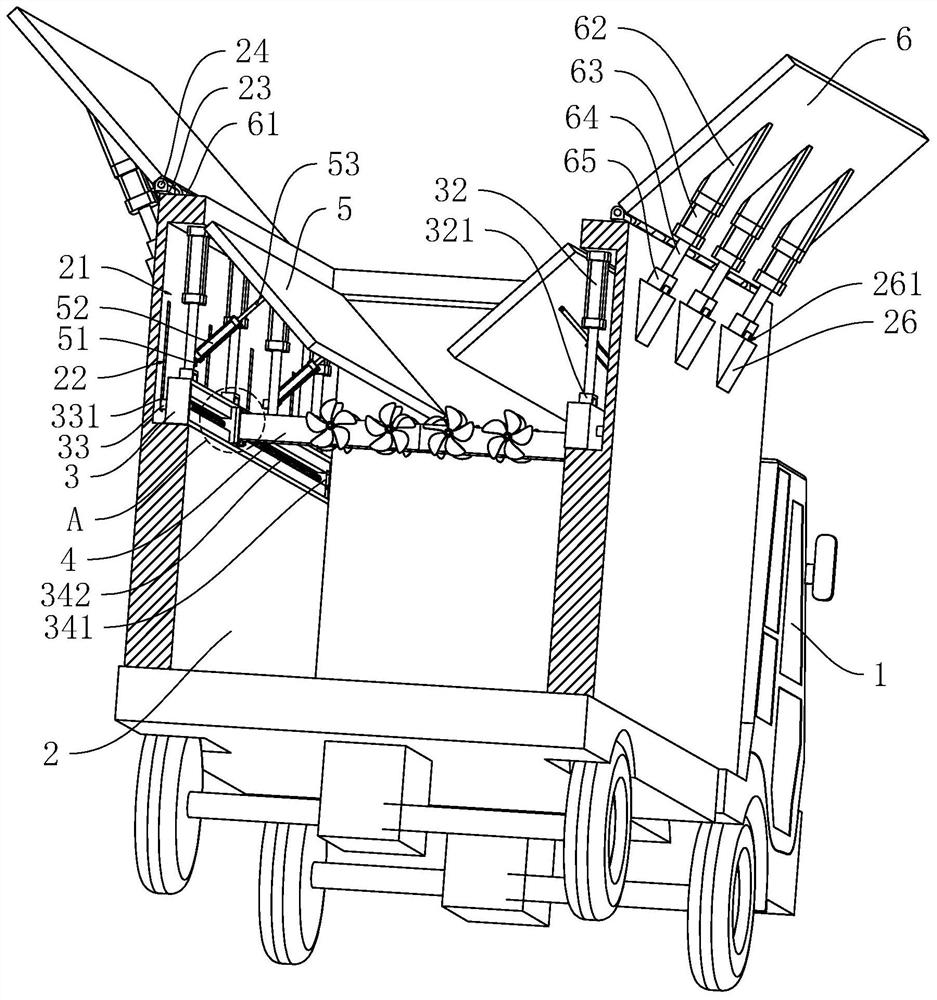

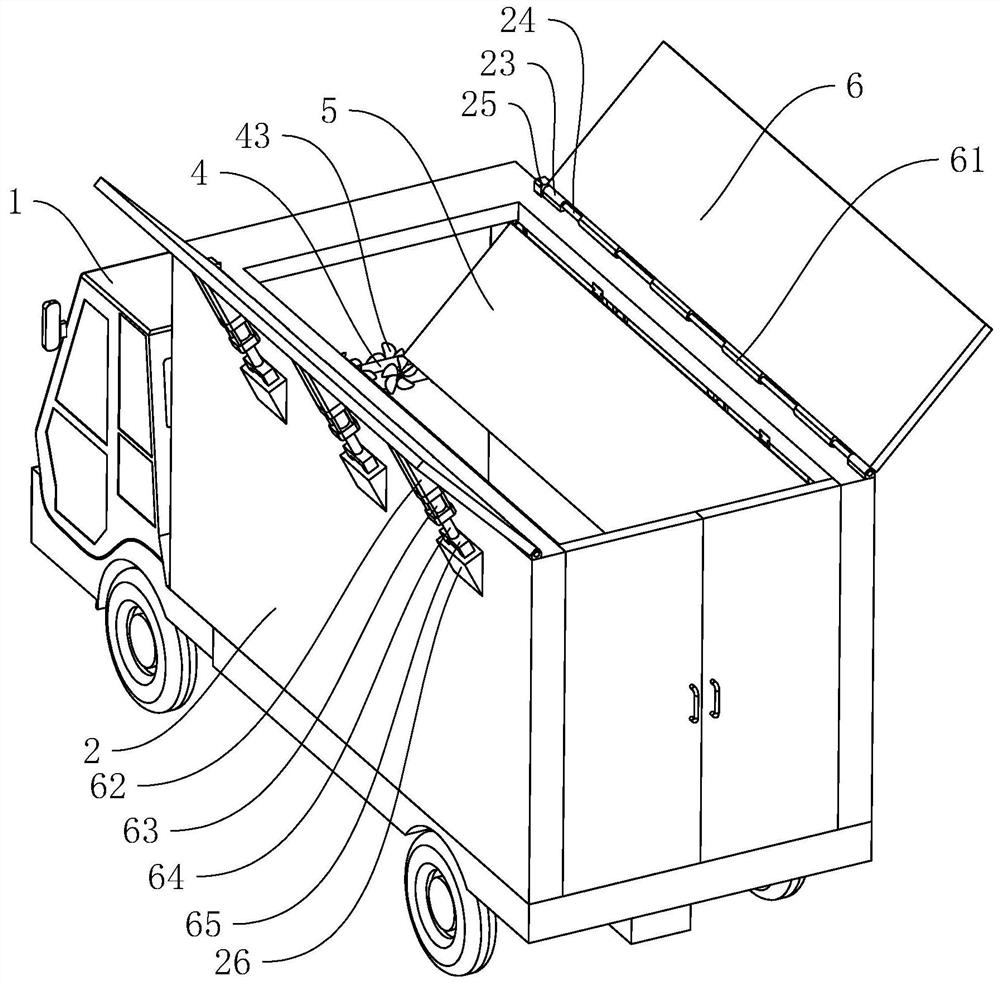

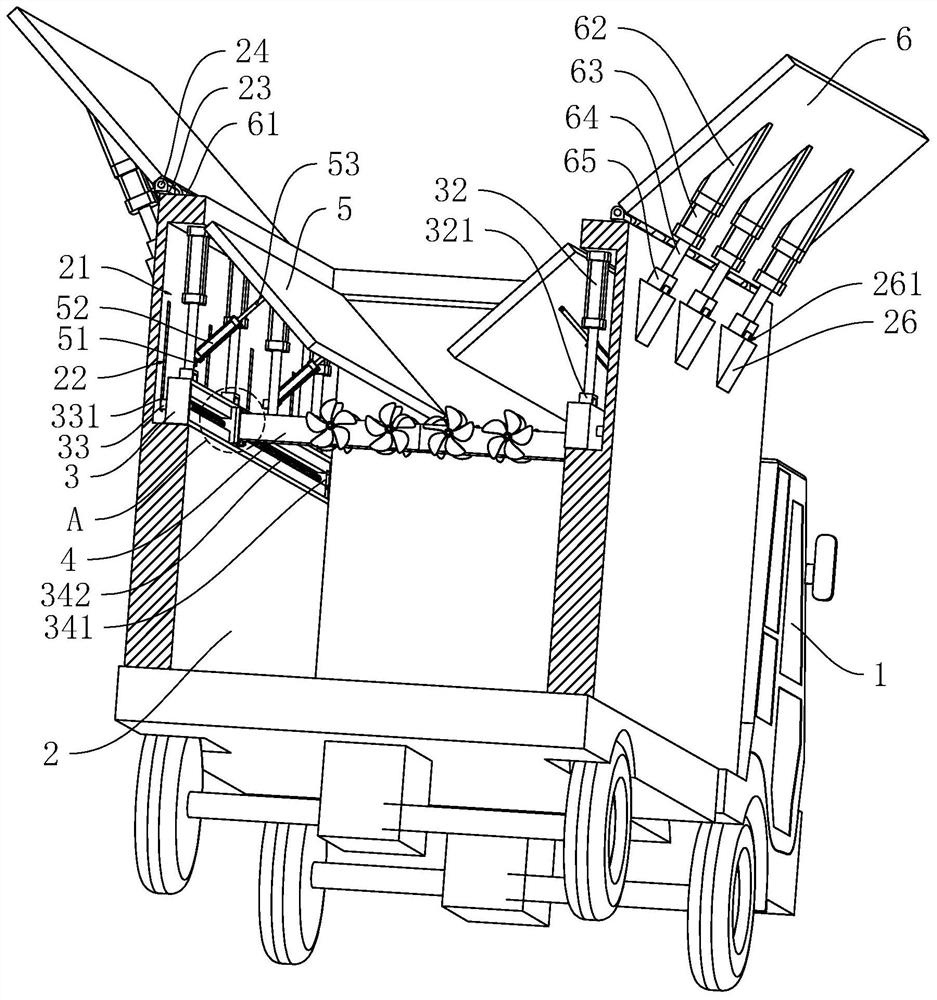

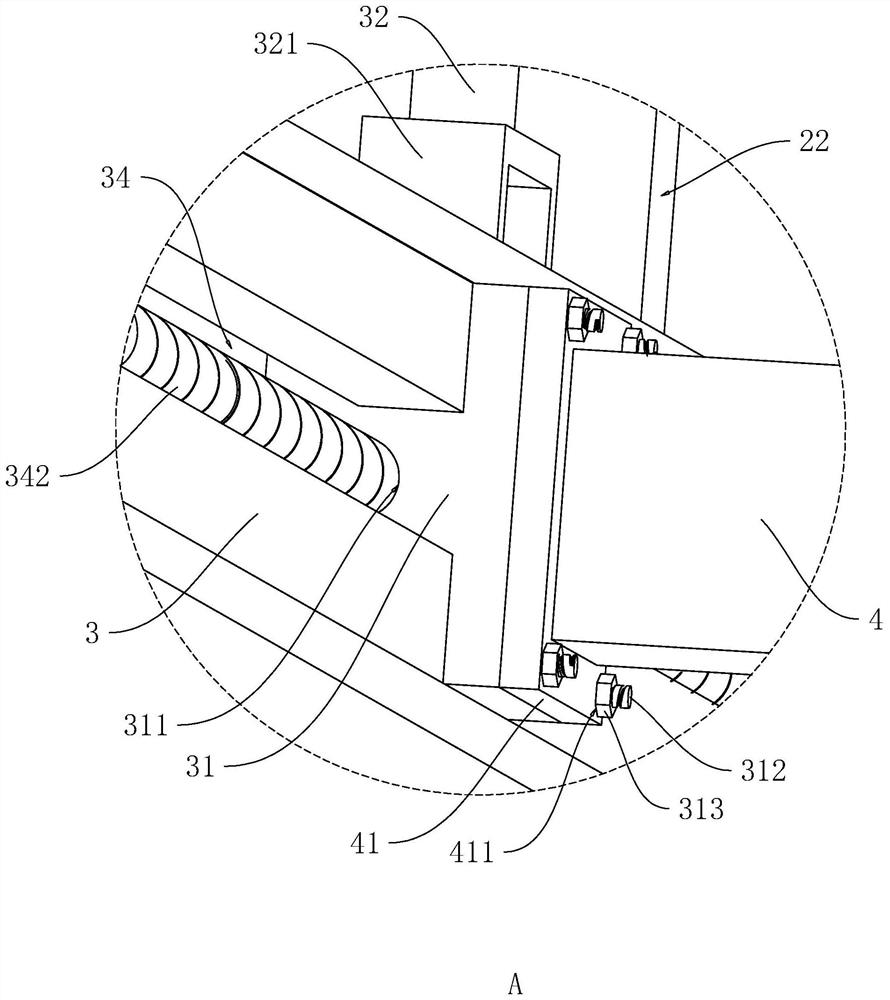

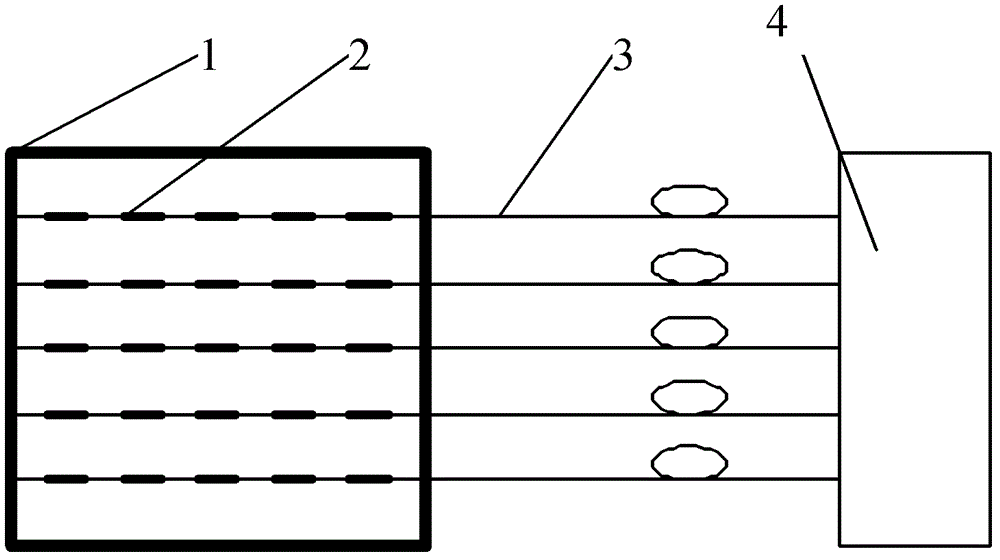

Equipment and method for transporting mud for earthwork excavation

ActiveCN113120097BEasy to stackFlatten evenlyGrain treatmentsLoading-carrying vehicle superstructuresSoil scienceSlide plate

The present application relates to a mud transporting equipment for earthwork excavation, which belongs to the technical field of construction earthwork conveying equipment, and includes a body of an earth moving vehicle and a bucket installed on the body of the dirt moving vehicle. A flattening mechanism for bulldozing the soil is symmetrically arranged, and the flattening mechanism includes a lifting plate arranged on the inner wall of the bucket through a lifting assembly, and a sliding plate is slidably connected to one side of the lifting plate, One side of the sliding plate is provided with a push plate through a locking assembly, and the lifting plate is provided with a driving assembly for driving the sliding plate to move. The application can facilitate the effective accumulation of soil inside the truck body, thereby facilitating the uniform flattening of the soil accumulated inside the truck body, thereby increasing the mud transporting capacity of the earth moving vehicle and speeding up the efficiency of mud transporting .

Owner:上海友海建设工程有限公司

Perforated drum of a compressor of an axial turbine engine

ActiveUS10273977B2Increase spaceReduce in quantityPump componentsEngine fuctionsAero engineAir turborocket

A rotor, in particular a drum of a low-pressure compressor of a turbojet aero engine, is disclosed. The rotor includes an outer annular wall delimiting a primary annular flow of the turbine engine, sealing devices with two rubbing strips or annular ribs formed on the wall. The rubbing strips cooperate by abrasion with inner shrouds. In addition, the annular wall includes rows of intake orifices for leakages which are arranged between each pair of rubbing strips in order to aspirate the recirculation leakages there. A plenum for leakages is formed inside the rotor by means of a composite partitioning, then evacuates the parasitic flow downstream of the turbine engine via the central shaft.

Owner:TECHSPACE AERO

Coating agent comprising hydroxyalkyl cellulose

ActiveUS9040686B2Less blockedLevel of adhesionPharmaceutical non-active ingredientsCoatingsCelluloseAqueous solution

A coating agent containing a hydroxyalkyl cellulose in which a content of hydroxyalkoxy groups within the hydroxyalkyl cellulose is within a range of 40 to 50% by mass, preferably a coating agent containing a hydroxyalkyl cellulose in which the content of hydroxyalkoxy groups is within a range of 40 to 50% by mass and also a viscosity of 2% aqueous solution at 20° C. is within a range of 3.0 to 5.9 mPa·s; and a solid preparation coated with the coating agent.

Owner:NIPPON SODA CO LTD

Mud conveying equipment and method for earth excavation

ActiveCN113120097AEasy to stackFlatten evenlyGrain treatmentsLoading-carrying vehicle superstructuresSlide plateGeotechnical engineering

The invention relates to mud conveying equipment for earth excavation, and belongs to the technical field of building earth conveying equipment. The mud conveying equipment for earth excavation comprises an earth moving vehicle body and a vehicle hopper installed on the earth moving vehicle body, and bulldozing mechanisms used for bulldozing mud are symmetrically arranged in the two inner side walls of the vehicle hopper; the bulldozing mechanism comprises a lifting plate arranged on the inner side wall of the vehicle hopper through a lifting assembly, a sliding plate is slidably connected to one side of the lifting plate, a bulldozing plate is arranged at one side of the sliding plate through a locking assembly, and a driving assembly used for driving the sliding plate to move is arranged on the lifting plate. According to the invention, soil can be effectively accumulated in the vehicle hopper conveniently, so that the effect of uniformly bulldozing the soil accumulated in the vehicle hopper can be achieved conveniently, the soil conveying amount of the earth moving vehicle can be increased, and the soil conveying efficiency can be improved.

Owner:上海友海建设工程有限公司

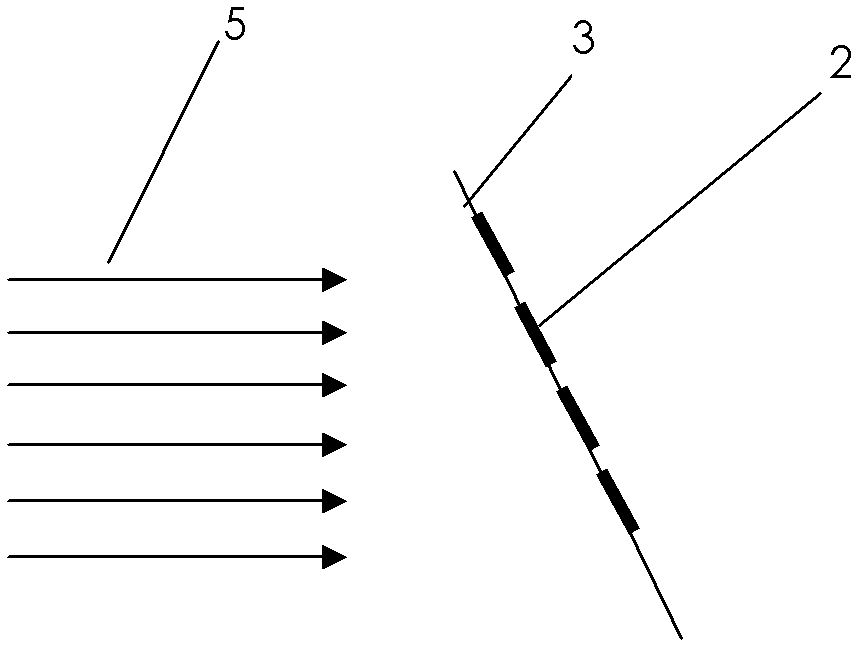

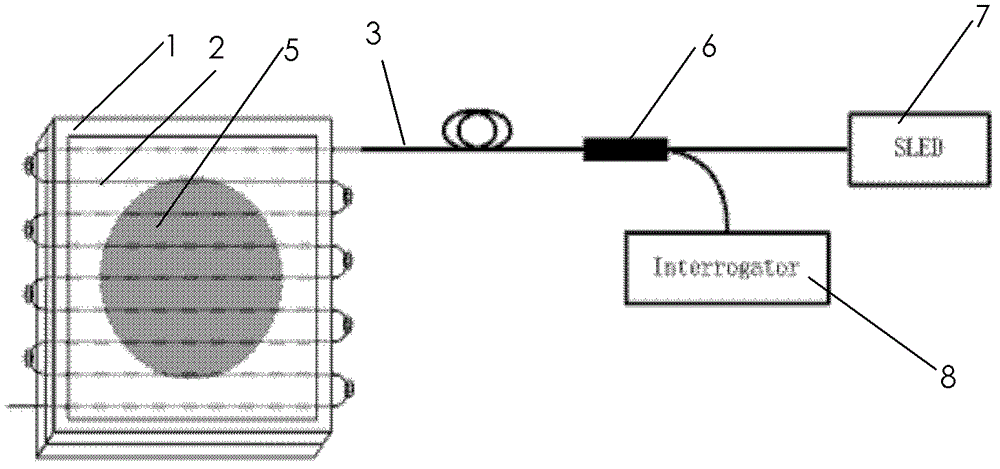

High-energy laser beam parameter diagnosis method based on fiber Bragg grating and diagnosis instrument

Owner:NORTHWEST INST OF NUCLEAR TECH

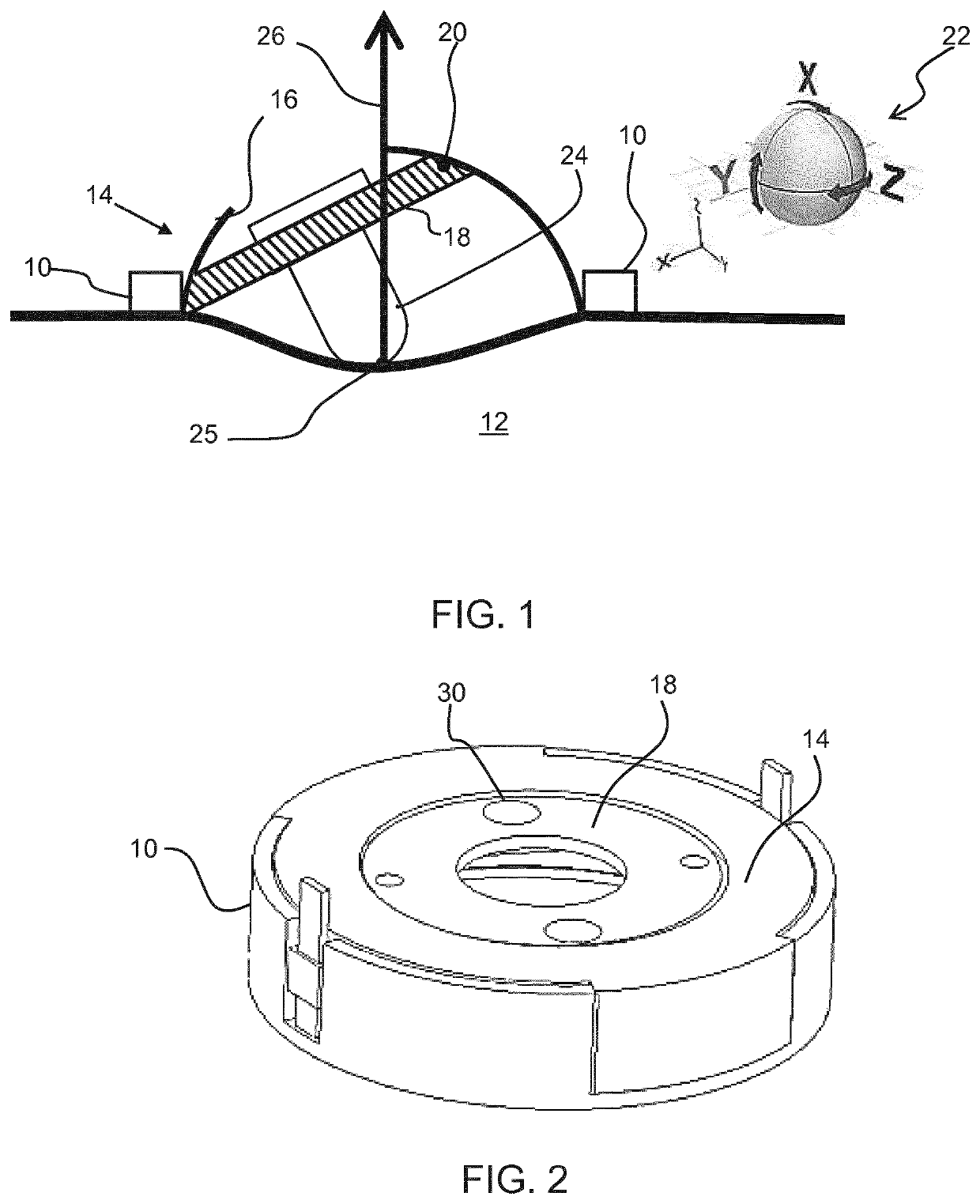

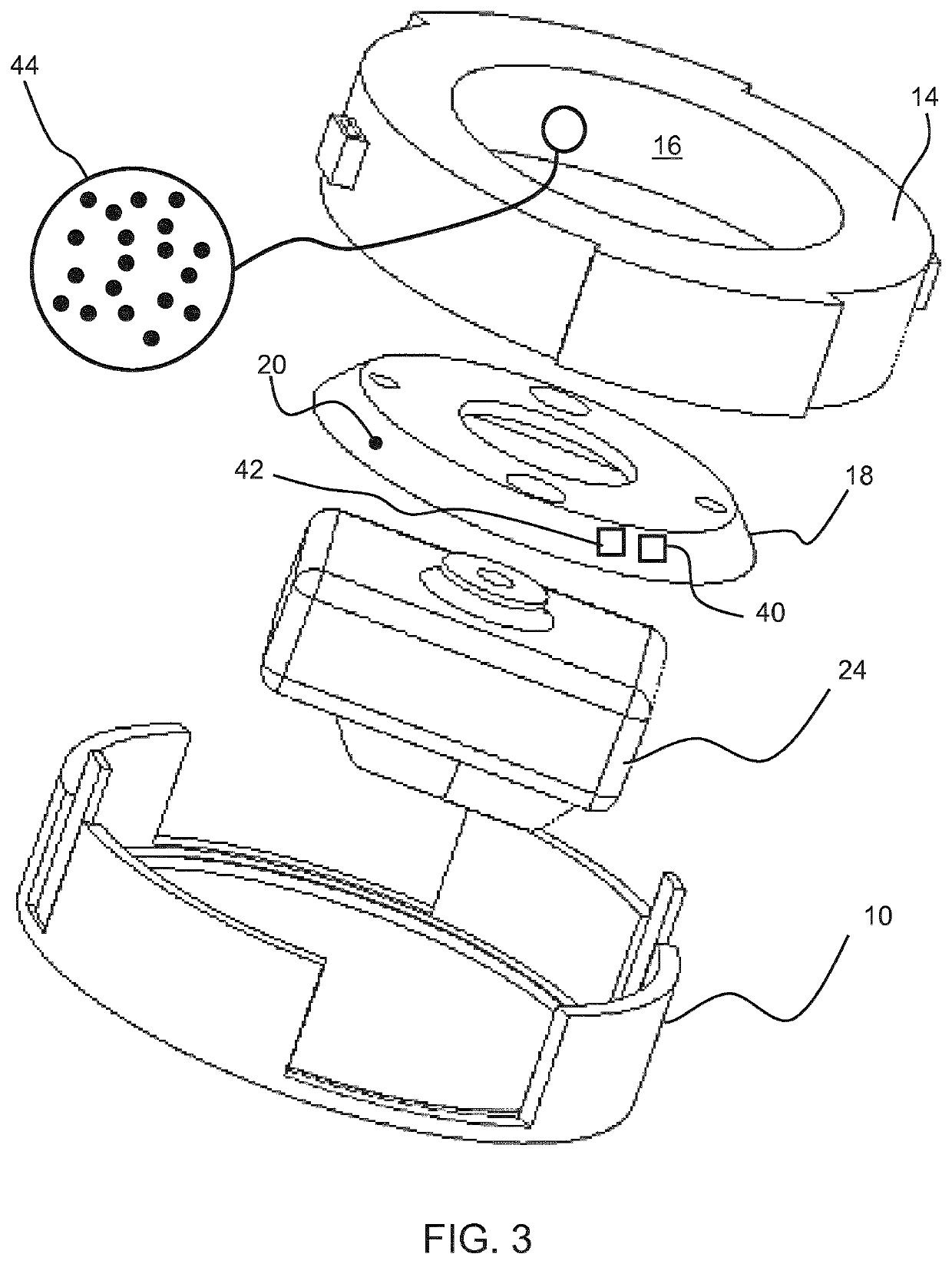

Ultrasound probe holder arrangement using guiding surfaces and pattern recognition

ActiveUS11272902B2Less blockedAvoid equipmentUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsCircular discEngineering

An ultrasound probe arrangement comprises a holder for application to a surface, a housing mounted over the holder and a probe carrier. The housing has an inner guide surface which comprises a portion of a sphere and the probe carrier comprises a disc having an outer guide surface around the outer rim of the disc which comprises a portion of sphere. The probe carrier is slidable within the housing with the inner and outer guide surfaces in contact. An ultrasound probe is carried by the probe carrier and makes contact with the surface, e.g. skin. This arrangement enables the probe to be held in a desired orientation so that a clinician can work hands-free. The disc design enables different probe designs to be used with the same basic holder and housing design.

Owner:KONINKLJIJKE PHILIPS NV

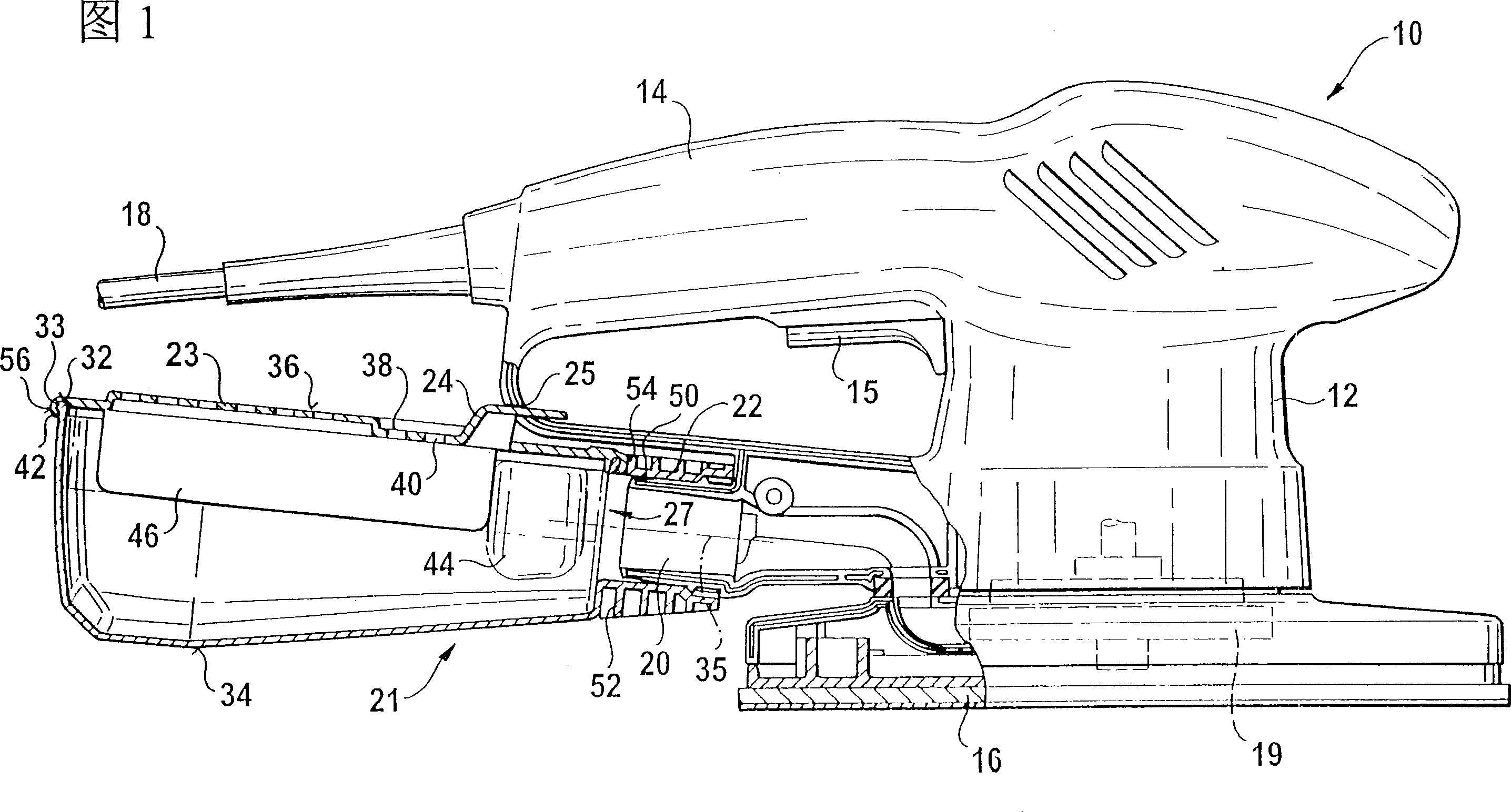

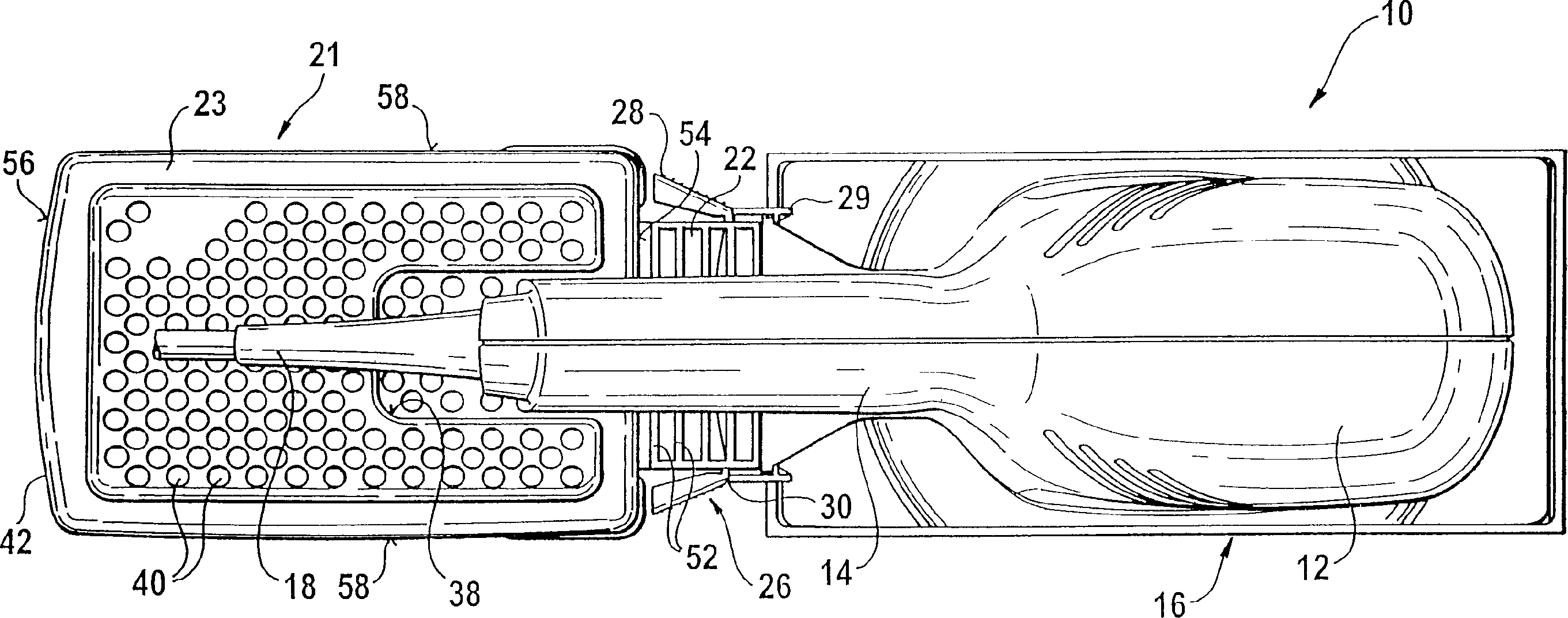

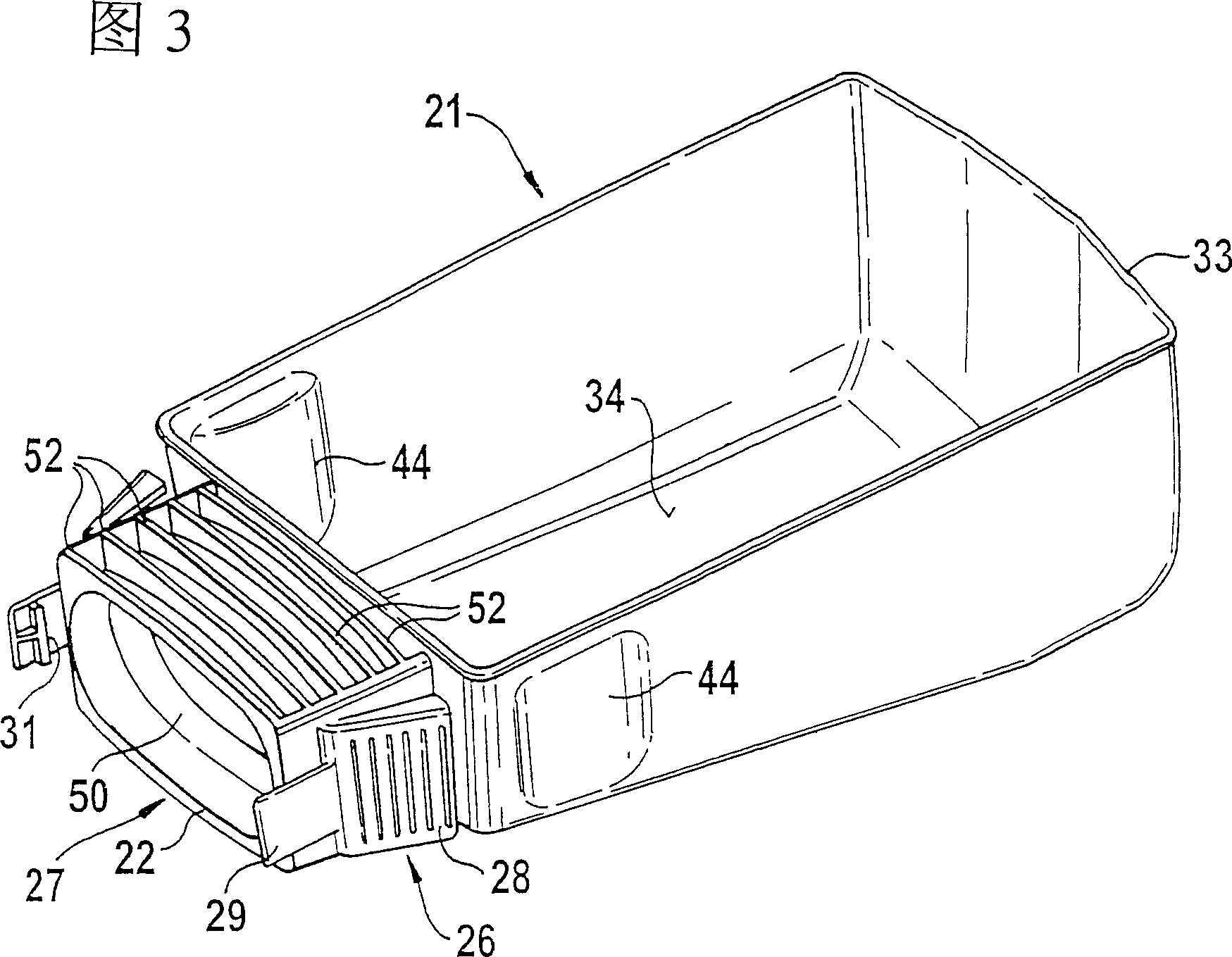

Hand-held tool with dust extractor

InactiveCN1173800CSteady suctionExtend your lifePortable percussive toolsPortable power-driven toolsHand heldEngineering

Owner:ROBERT BOSCH GMBH

Cosmetic shaving stick

ActiveUS10583072B2Easily rinsed offEasy to glideCosmetic preparationsHair removalPolymer scienceActive agent

Owner:BEIERSDORF AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com