Building blocks with integrated assembling design

a technology of building blocks and assembling designs, applied in the direction of building components, construction materials, walls, etc., can solve the problems of limited commercial value of building with straw bales and concrete, and achieve the effects of less cement, less cement, and increased density of blocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The building material is made of straw chopped in lengths of between 5 cm and 10 cm substantially (These are ideal lengths but it can be shorter or longer.) mixed with Portland cement, mortar cement or lime and a polymer emulsion diluted in water which acts as a bonding agent. These different ingredients are well mixed together and then pressed into blocks of different sizes and shapes. The density of the blocks depends on the proportions by which the different ingredients are combined together as well as on the pressure exerted to compress the blocks. The density of the blocks also determines the structural value and the insulation value. Increased density provides more structural value while decreased density provides more insulation value.

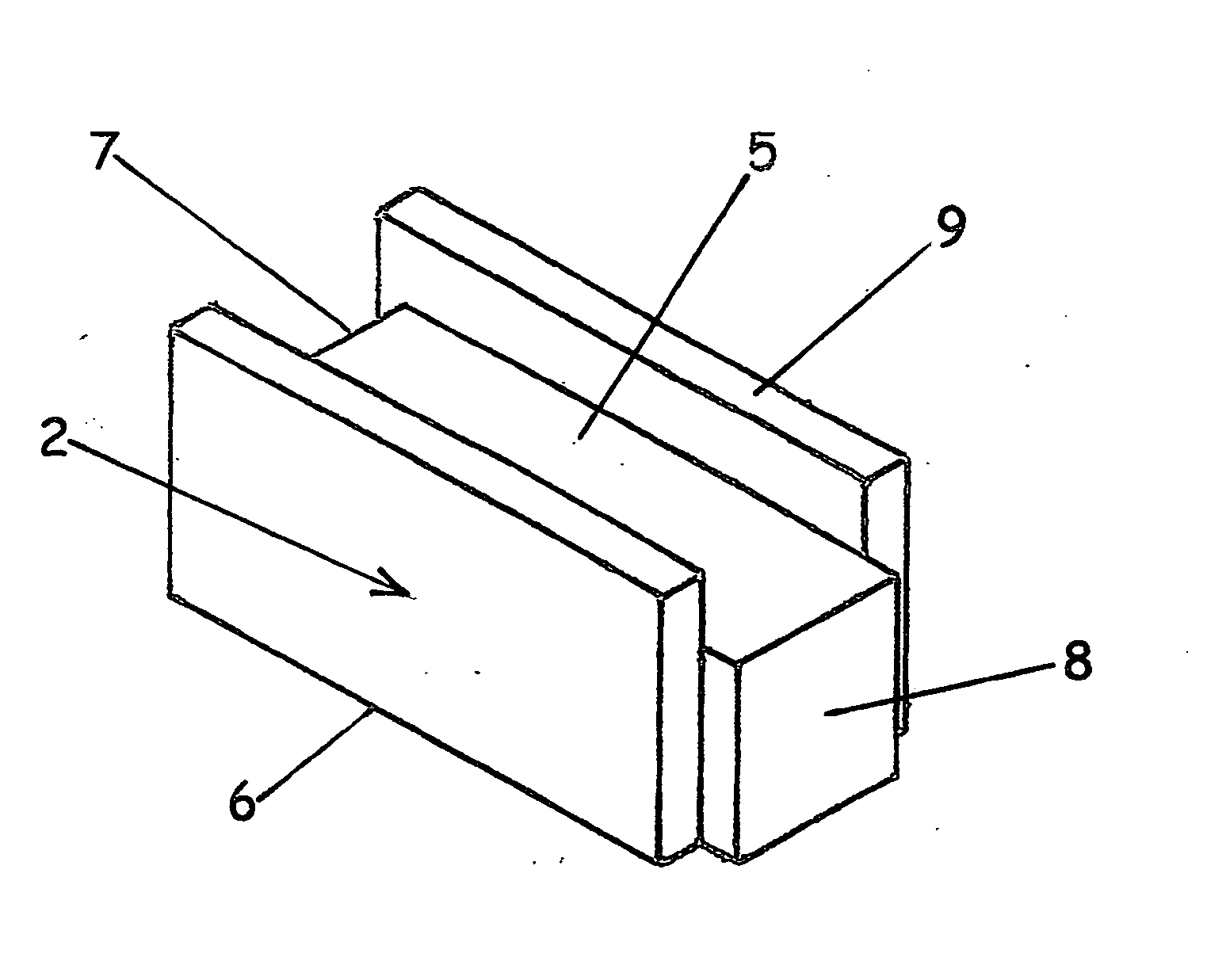

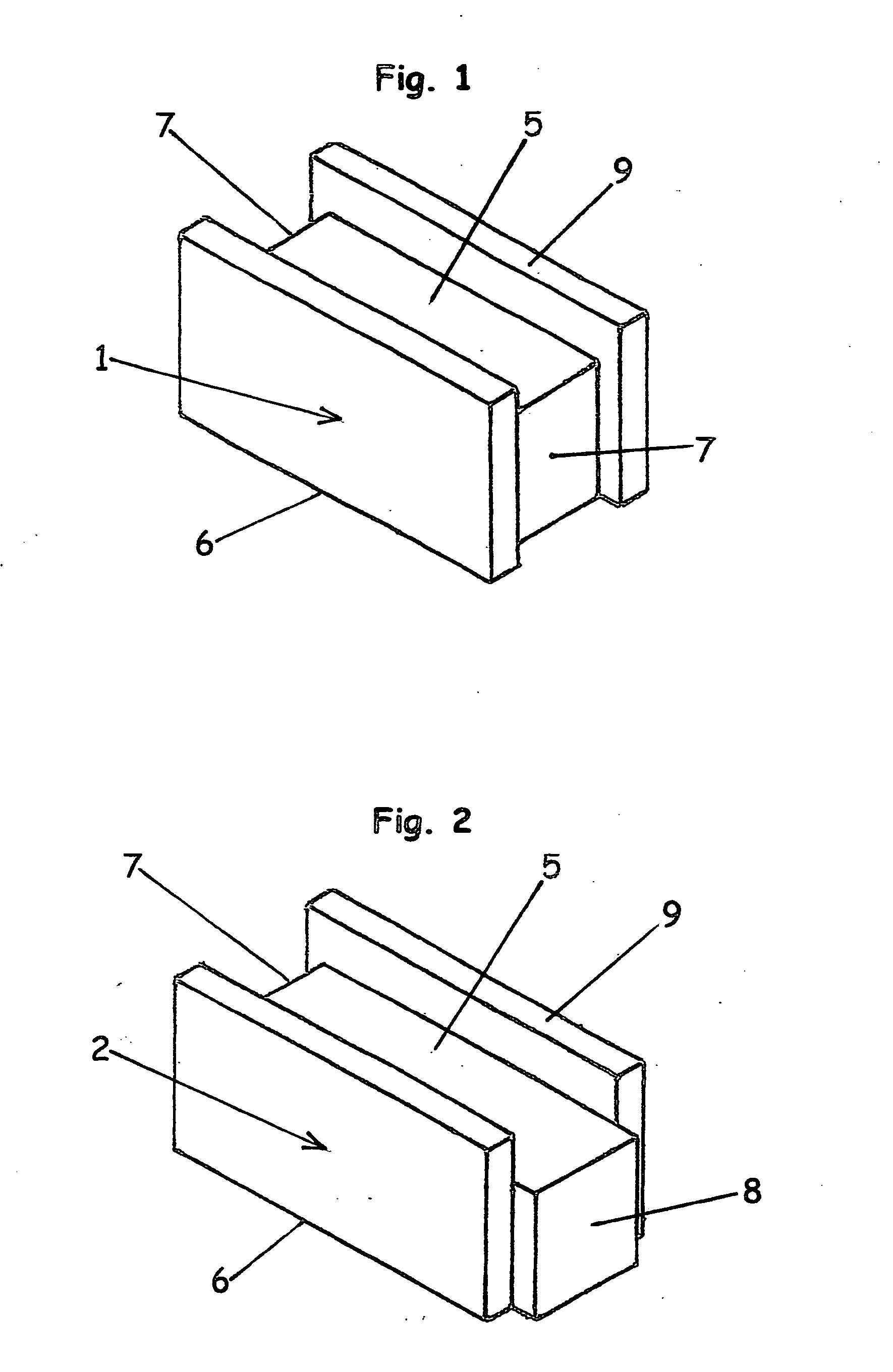

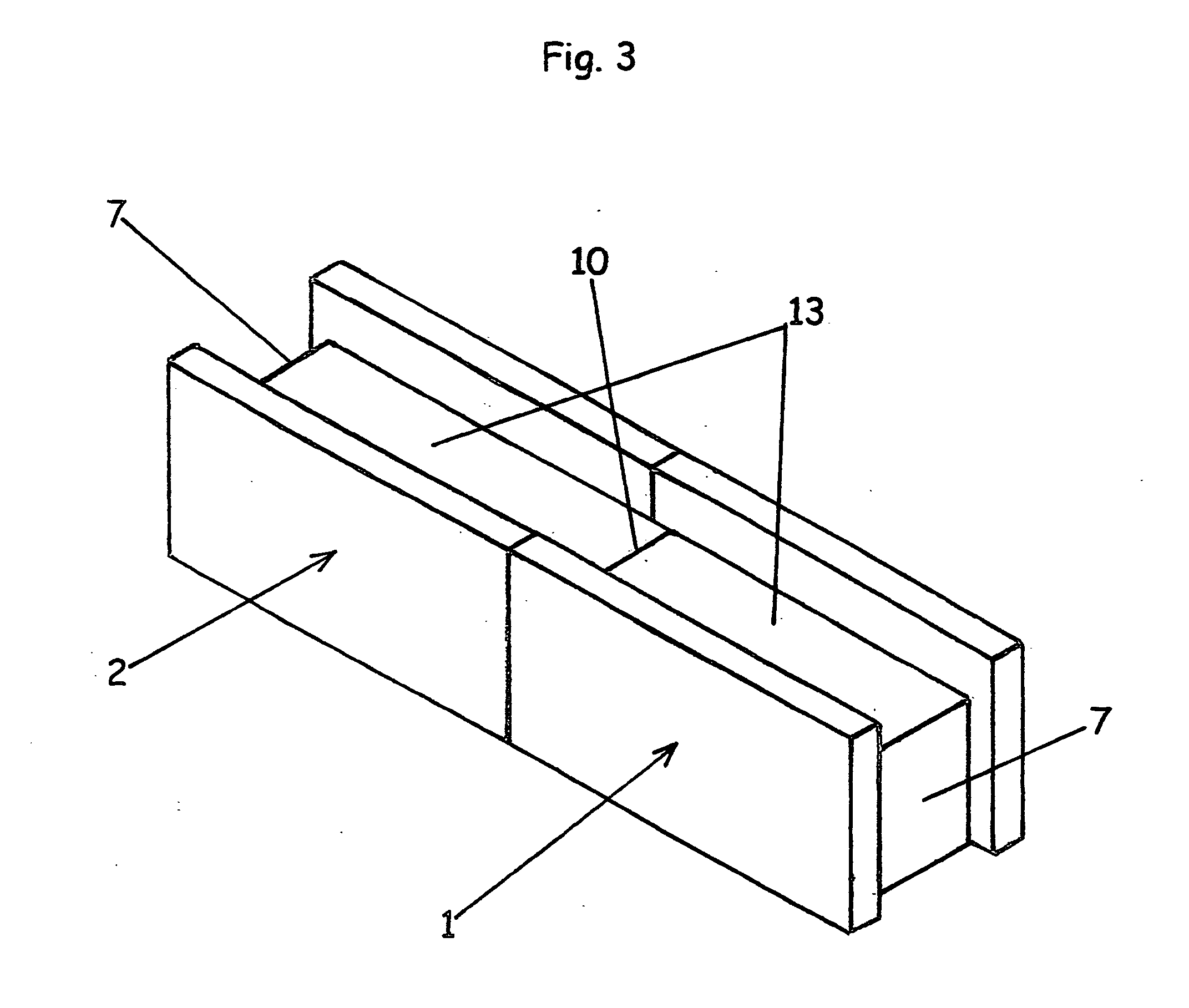

[0056] The blocks are fabricated in four different shapes that can be used in a building system and method to be either stacked and interlocked or assembled to allow for concrete structural reinforcement.

[0057] In an embodiment of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com