Preparation method of a gradient structure composite functional raw soil block

A gradient structure and functional technology, applied in climate change adaptation, building materials, etc., can solve the problems of earthquake resistance, water resistance, poor volume stability, low strength, large deformation, etc., to improve resource utilization efficiency and good thermal insulation The effect of performance, high strength and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

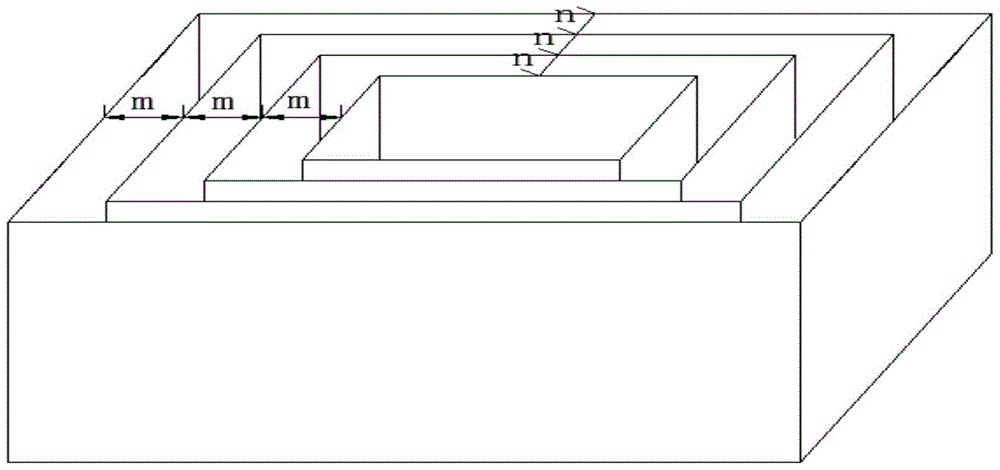

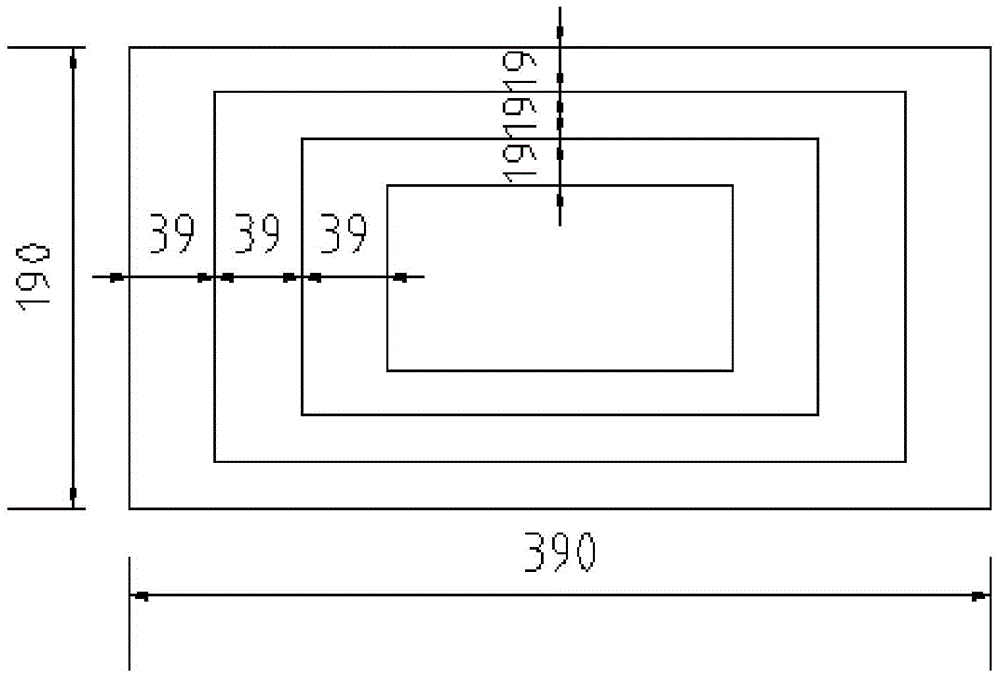

[0022] Apply a release agent such as lubricating oil evenly on each surface of the prepared cast iron mold. The interior of the cast iron mold is divided into 4 grids with extractable annular partitions. In the direction of the long side, the distance between adjacent partitions is 39mm. direction, the distance between adjacent partitions is 19mm, and the release agent is applied on both sides of the partitions. Such as figure 2 shown.

[0023] Take cement and raw soil after drying and grinding, and prepare four groups of cement-modified raw soil material slurries numbered 1, 2, 3, and 4: from group 1 to group 4, the cement content is raw soil and 0%, 5%, 10%, 15% of the total mass of cement; the mixing process is to fully mix the cement and raw soil first, and then add water. The water-cement ratio is 0.3. Take the slurry according to the order of the group number from small to large, and fill the inner compartment from the middle area to the outside in turn. During the f...

Embodiment 2

[0025] Apply a release agent such as lubricating oil evenly on each surface of the prepared cast iron mold. The interior of the cast iron mold is divided into 5 grids by the annular partitions that can be pulled out. In the long side direction, the distance between adjacent partitions is 39mm. In the edge direction, the distance between adjacent partitions is 19mm, and the release agent is also applied on both sides of the partitions.

[0026] Take cement and raw soil after drying and grinding, and prepare five groups of cement-modified raw soil material slurries numbered 1, 2, 3, 4, and 5: from group 1 to group 5, the cement content is The total mass of soil and cement is 0%, 4%, 8%, 12%, and 16%. The mixing process is to fully mix the cement and raw soil before adding water. The water-cement ratio is 0.3.

[0027] All the other operations are the same as in Example 1 to obtain the product of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com