Patents

Literature

30results about How to "Realize the integration of structure and function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

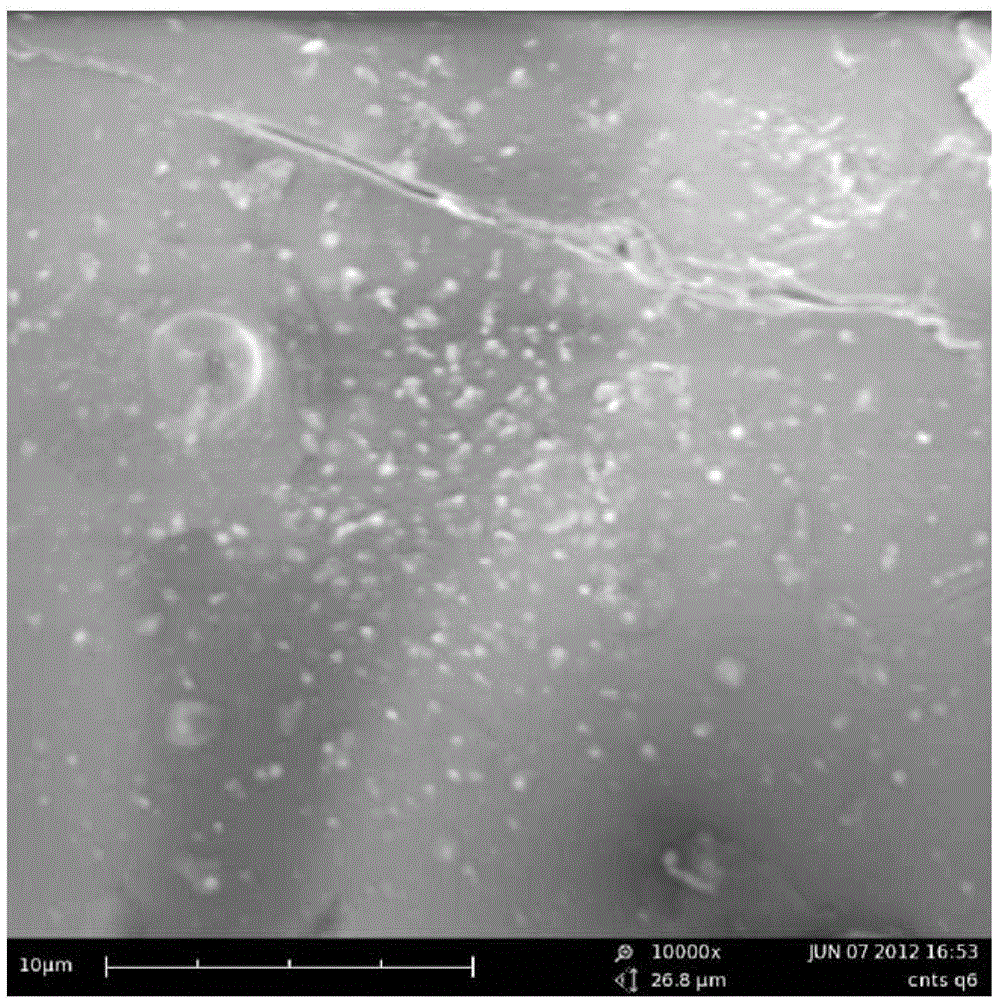

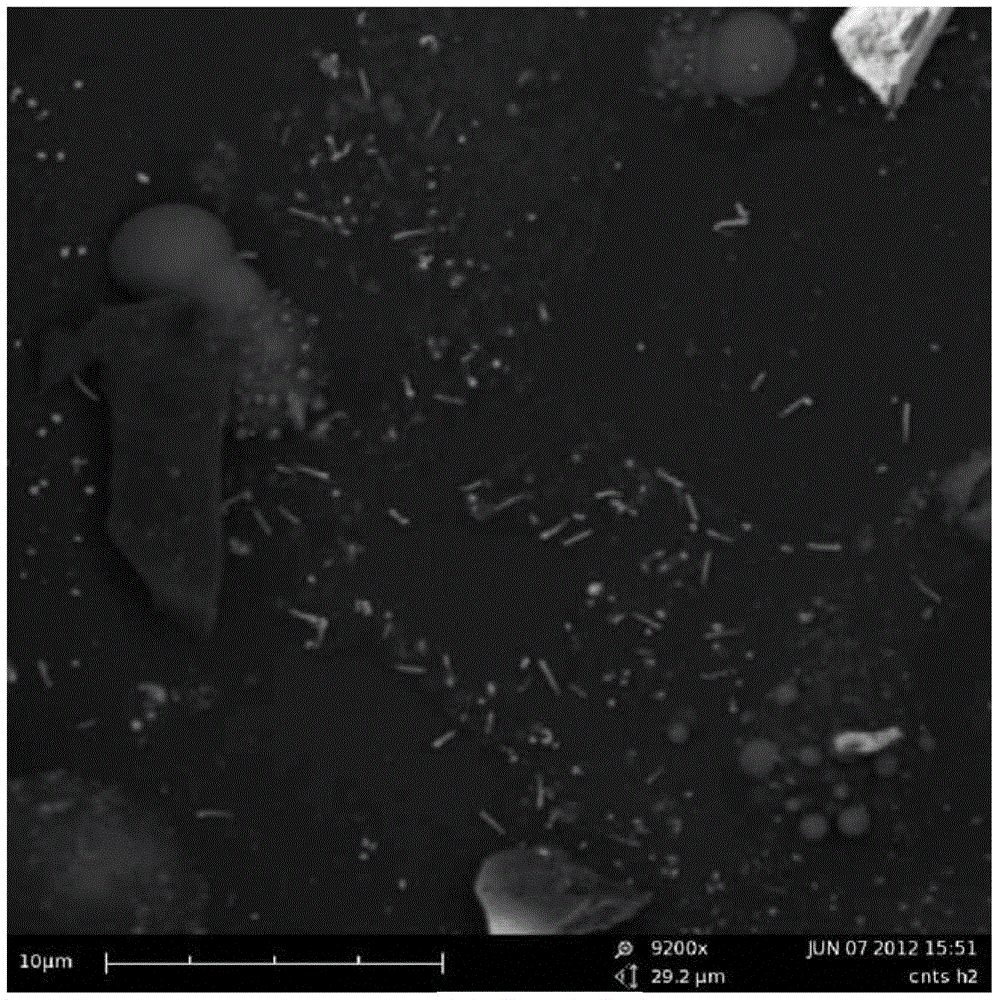

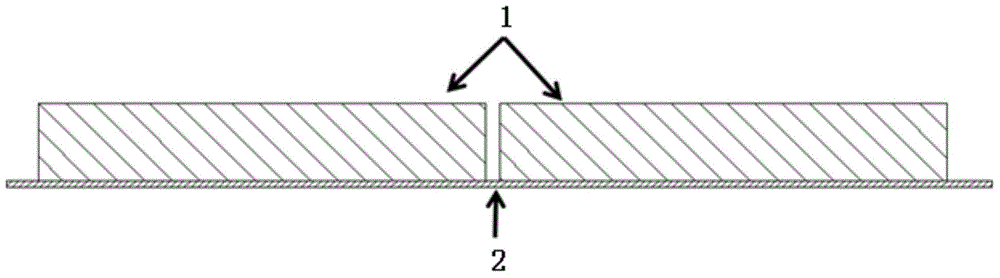

Preparation method of light ablative material

The invention discloses a preparation method of a light ablative material, relates to a preparation method of a thermal protection material, and is aimed at solving the technical problem of high density of the existing carbonization type light ablative material taking phenol-formaldehyde resin as a substrate. The method comprises the following steps of: dissolving boron phenol-formaldehyde resin in acetone to prepare a boron phenol-formaldehyde resin solution; adding the uniformly mixed microsphere filler and carbon nanotube into the boron phenol-formaldehyde resin solution, and mixing uniformly; standing to volatize acetone to obtain mixed paste; putting the phenol-formaldehyde honeycomb cut into a die inner cavity shape into a die, and filling the mixed paste into the phenol-formaldehyde honeycomb to obtain a composite green body; and curing and forming the composite green body to obtain the light ablative material. Through the invention, the density of the prepared light ablative material is as low as 0.2-0.4g / cm<3>, the linear ablativity is 0.035-0.115mm / s, and the mass ablativity is 0.0177-0.0216g / s; and the light ablative material can be used as a thermal protection material of a spacecraft.

Owner:HARBIN INST OF TECH

Preparation method of structure and function integrated neutron absorbing material

InactiveCN109852850AImprove distribution uniformityHigh densityShieldingStructure and functionBoron carbide

The invention relates to a preparation method of a structure and function integrated neutron absorbing material. The method prepares the structure and function integrated neutron absorbing material byadopting a powder metallurgy method through such processes as burdening, ball milling, molding, sealing, compactness, hot rolling and annealing with boron carbide powder, nanometal oxides, aluminum and alloy powder as raw materials. The structure and function integrated neutron absorbing material prepared by the method is excellent in component uniformity, high in compactness, high in heat conductivity and excellent in mechanical performance.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS +2

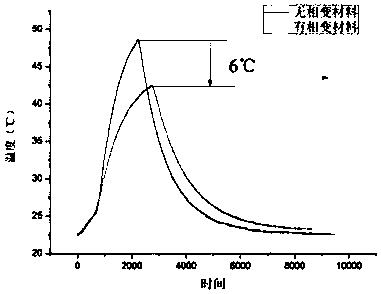

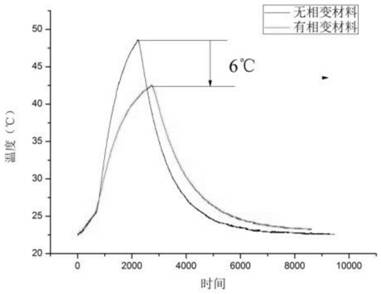

Two-temperature phase-change temperature-variable swelled vermiculite plate and preparation method thereof

ActiveCN109678423ALarge adsorption capacityRealize the integration of structure and functionMass ratioPortland cement

The invention discloses a two-temperature phase-change temperature-variable swelled vermiculite plate and a preparation method thereof. The plate comprises the following raw materials: a kieselguhr phase-change composite material, a swelled vermiculite composite phase-change material, Portland cement and a water reduction agent, wherein the kieselguhr phase-change composite material has a phase-change temperature of 5-15DEG C, and latent heat of phase change is greater than or equal to 30 J / g; the swelled vermiculite composite phase-change material has a phase-change temperature of 25-40 DEG C, and the latent heat of phase change is greater than or equal to 80J / g. The kieselguhr phase-change composite material, the swelled vermiculite composite phase-change material, the Portland cement and the water reduction agent are uniformly stirred with water at a mass ratio of (10-30):(20-40):(30-60):(0.2-0.6):(20-40), and the mixture is cast, molded, maintained for two days and then demoulded to obtain the plate. According to the plate prepared with the method disclosed by the invention, micropore adsorption functions of swelled vermiculite and kieselguhr on phase-change materials are sufficiently taken into play, and structure-function integration of a building material is achieved while temperature adjustment efficiency is ensured; in addition, the plate can be cost in situ and playsroles in both winter and summer, and compared with other plates, the plate has a wider application range.

Owner:SOUTHEAST UNIV

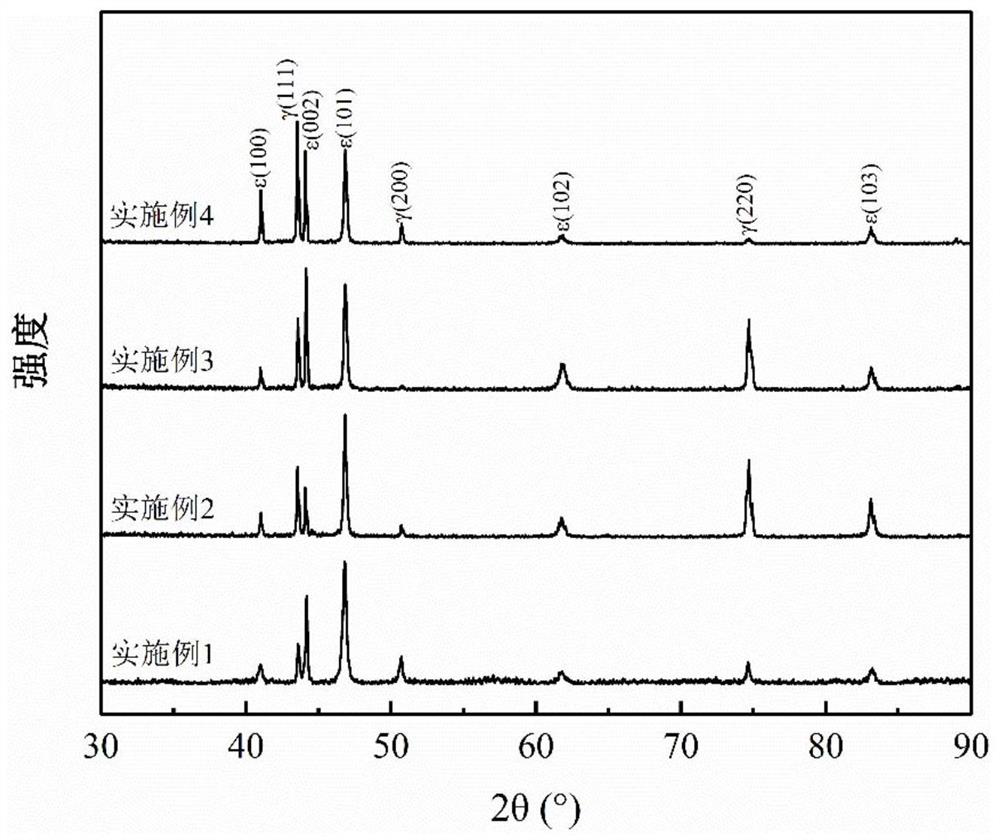

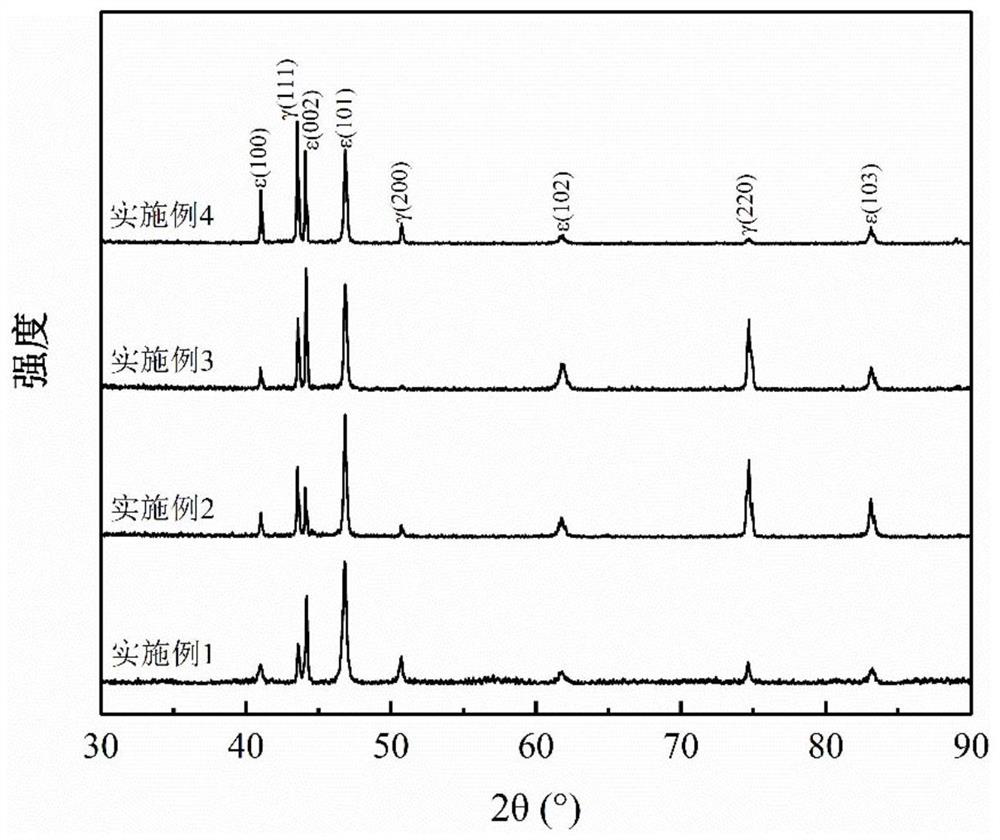

Structure and function integrated high-entropy alloy and preparation method thereof

ActiveCN111778438ARaise the level of yield strengthRealize the integration of structure and functionHigh densityHigh entropy alloys

The invention discloses structure and function integrated high-entropy alloy based on an Al-Nb-Zr-Mo-V-Hf system, and belongs to the field of high-entropy alloy materials. The structure and function integrated high-entropy alloy comprises the components of, by mass, 4-15% of aluminum, 20-30% of niobium, 20-60% of zirconium, 5-15% of molybdenum, 1-5% of vanadium and the balance 0.01-20.0% of hafnium and inevitable impurities. Aiming at the problems that at present, typical high-entropy alloy which is of a BCC structure and difficult to melt, such as TaNbMoW, TaNbMoWV and other elements comprising a lot of high-density metal is high in density, high in cost, poor in plasticity at the room temperature and cannot serve as a structure material for application, meanwhile, full attention is givento study on high-entropy alloy having neutron absorptivity, according to the high-entropy alloy based on the Al-Nb-Zr-Mo-V-Hf system provided by the invention, the special effect of the Hf element issufficiently considered, and accordingly, structure and function integration of the high-entropy alloy is achieved.

Owner:NORTHEASTERN UNIV +1

Steel, preparation method and application thereof

The invention provides steel, a preparation method and application thereof. The preparation method comprises the following steps: batching according to the following chemical compositions to obtain araw material, wherein the raw material comprises the following chemical compositions in percentage by weight: 0.08-0.30% of C, equal to or less than 0.5% of Si, equal to or less than 1.0% of Mn, 0.5-2.0% of Cu, equal to or less than 1.0% of Al, 0.01-0.2% of Ce, 0.5-1.5% of Cr, 0.5-1.5% of Mo, equal to or less than 0.3% of V, equal to or less than 0.005% of N, equal to or less than 0.005% of O, equal to or less than 0.005% of S, equal to or less than 0.005% of P and the balance of Fe; sequentially carrying out smelting, pouring and aftertreatment on the raw material to obtain steel; and when the content of each of O and S in a reaction product system is equal to or less than 0.005wt%, adding the element Ce in the reaction product system. The prepared steel has the advantages of being high in strength and toughness and resisting sulfide stress corrosion and microbiological corrosion and realizes integration of structure and function.

Owner:HENGYANG VALIN STEEL TUBE +1

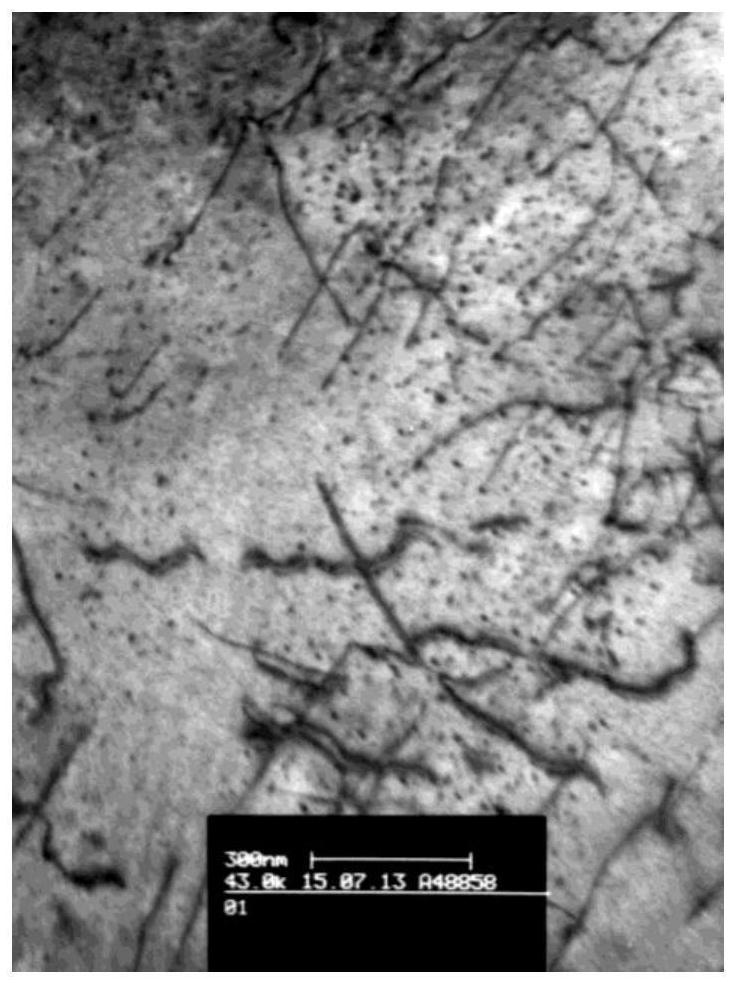

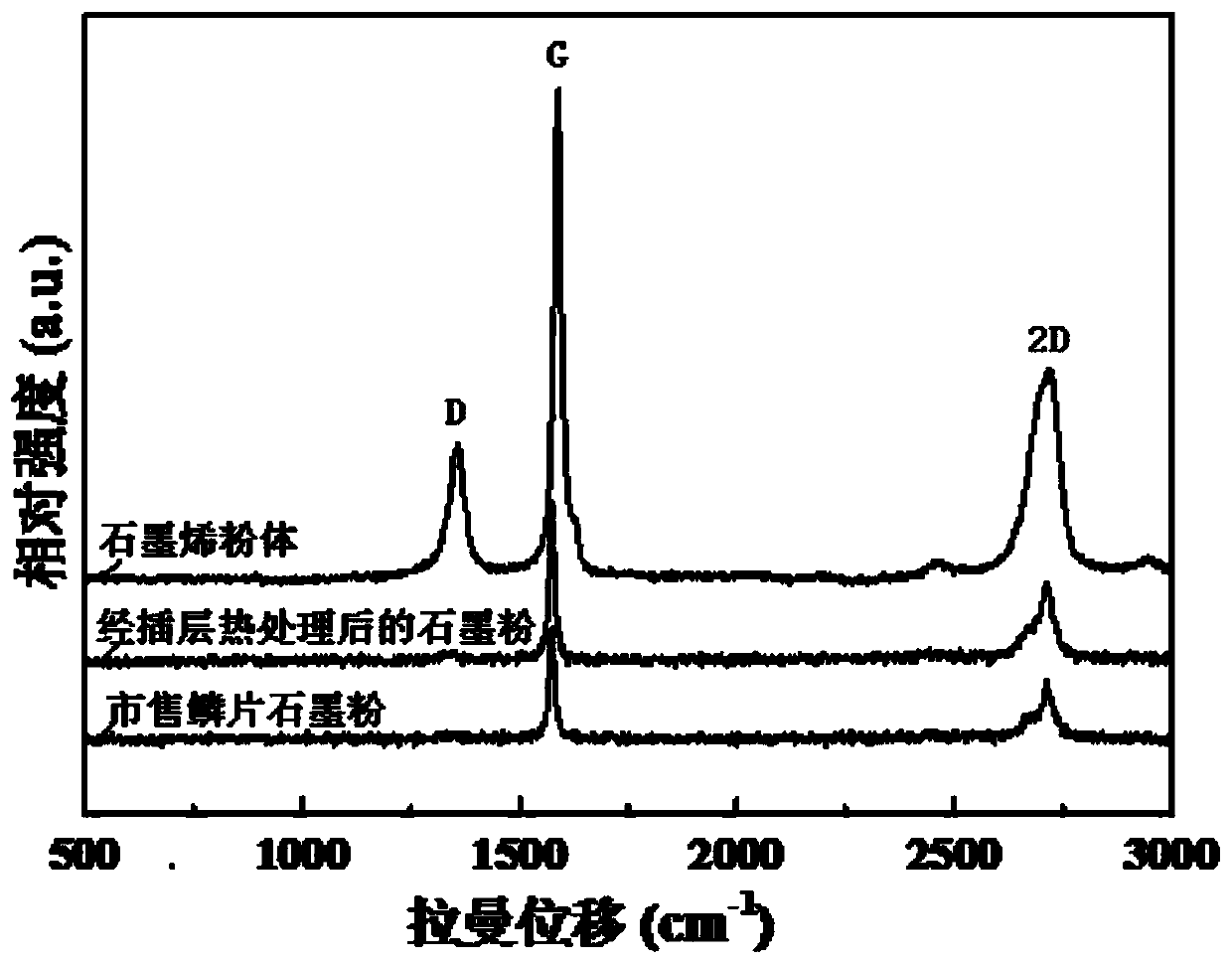

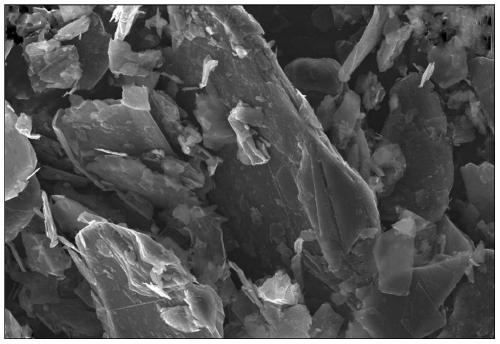

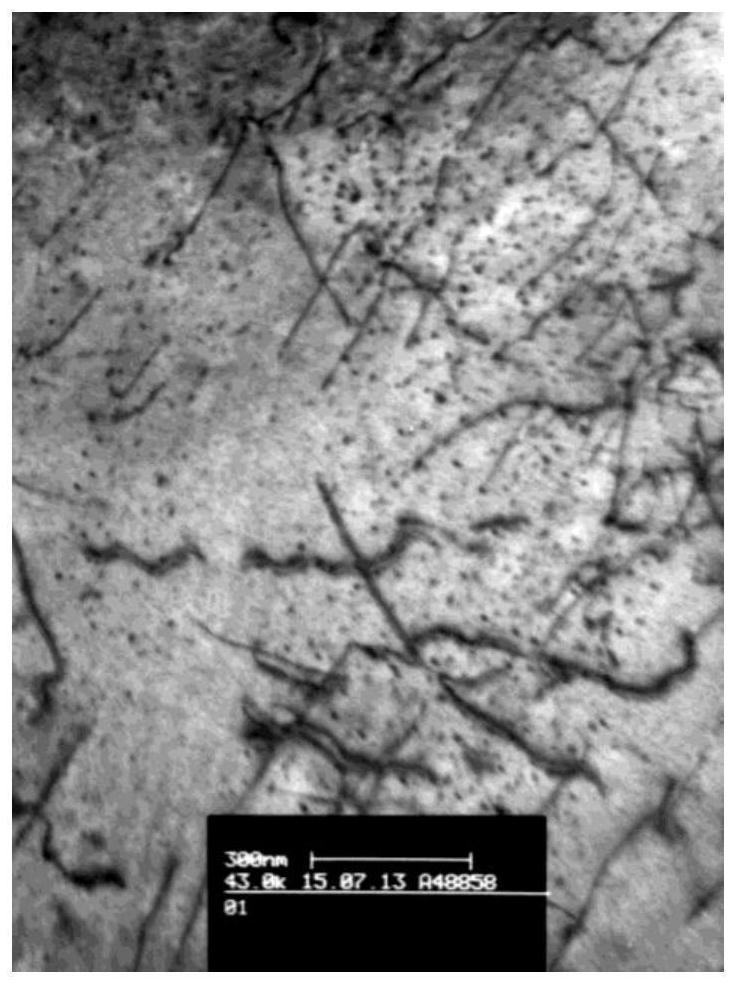

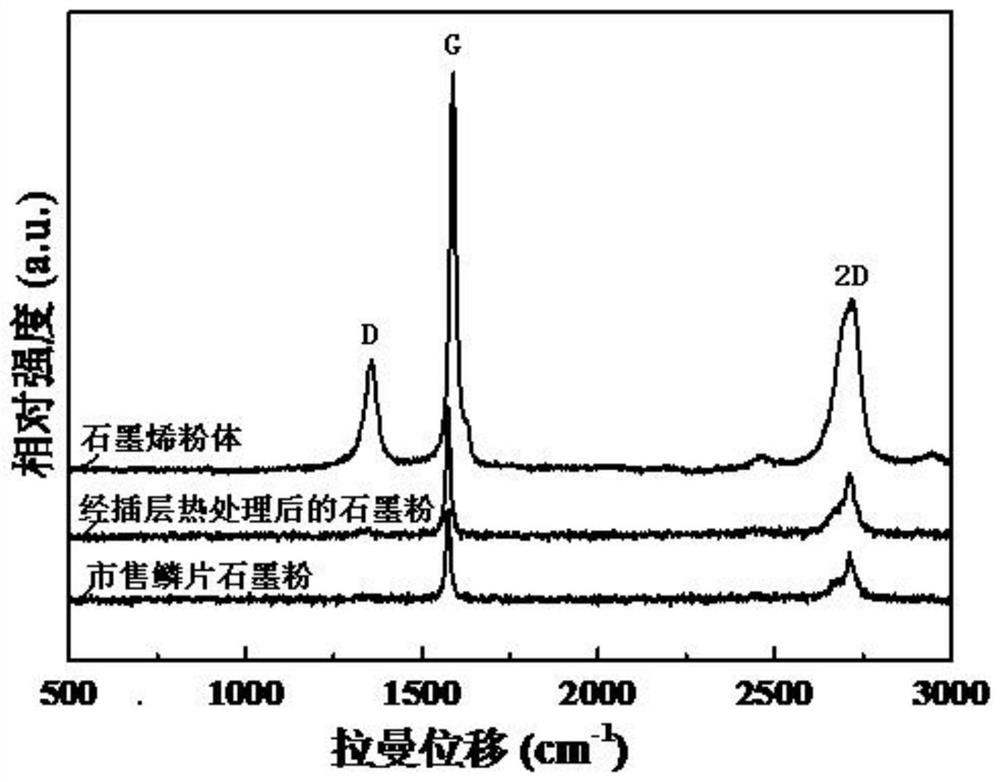

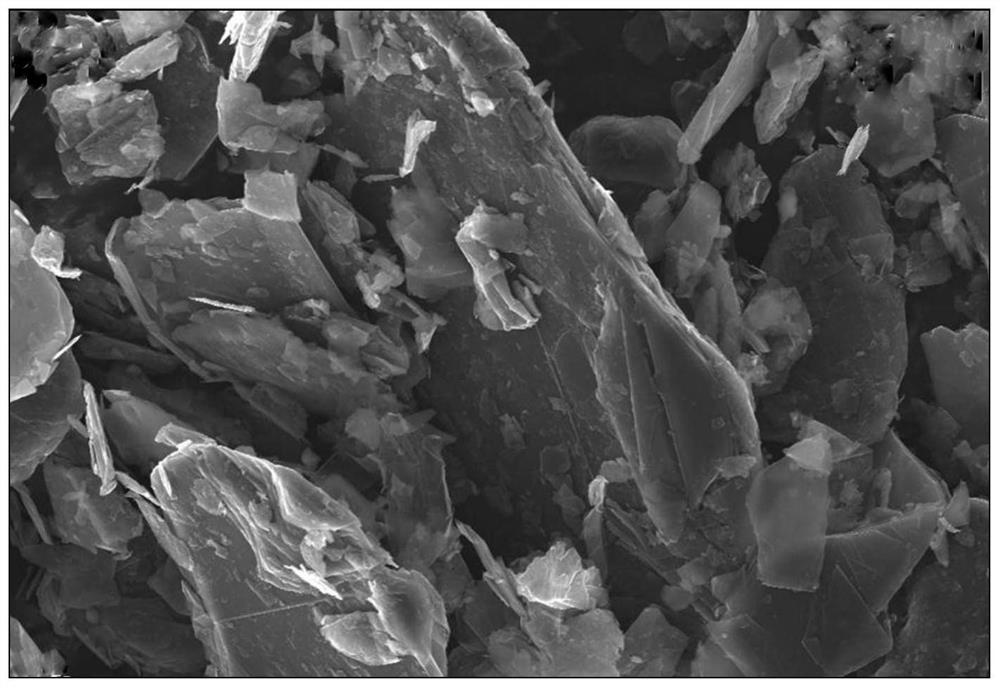

Preparation method and application of graphene powder

The invention discloses a preparation method of graphene powder. The method comprises the following steps: 1, carrying out ultrasonic cleaning on graphite powder, and carrying out vacuum freeze dryingto obtain pretreated graphite powder; 2, carrying out intercalation heat treatment on the pretreated graphite powder under atmosphere protection; and 3, performing ball-milling stripping of high-speed vibration shearing on the graphite powder subjected to intercalation heat treatment under a low-temperature liquid nitrogen condition to obtain the graphene powder. The invention also discloses an application of the graphene powder as a reinforcement material in a metal composite material. Vacuum freeze drying, intercalation heat treatment and ball-milling stripping under the low-temperature liquid nitrogen condition are combined, the bonding force between graphite flake layers of the graphite powder is gradually weakened, the spacing between the graphite flake layers is increased, the graphene powder with low-density defects and multi-stage distribution is obtained through layer-by-layer stripping, pollution to the environment is avoided, the requirement for equipment is low, the yieldis high, and the method is suitable for large-scale industrial production of the graphene powder; and the application of the invention improves the performance of the metal composite material.

Owner:西安稀有金属材料研究院有限公司 +1

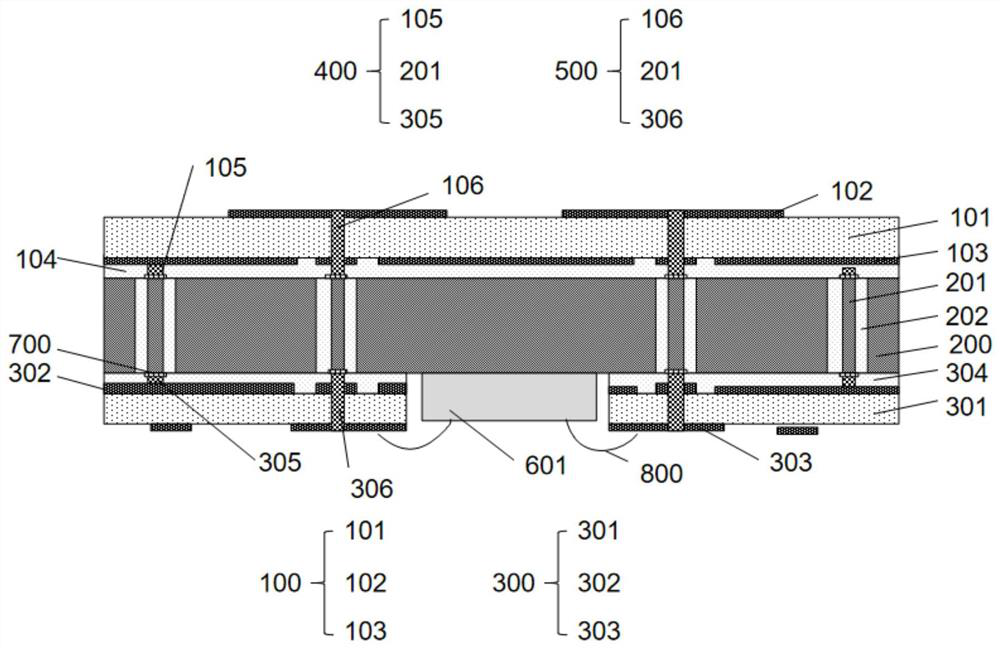

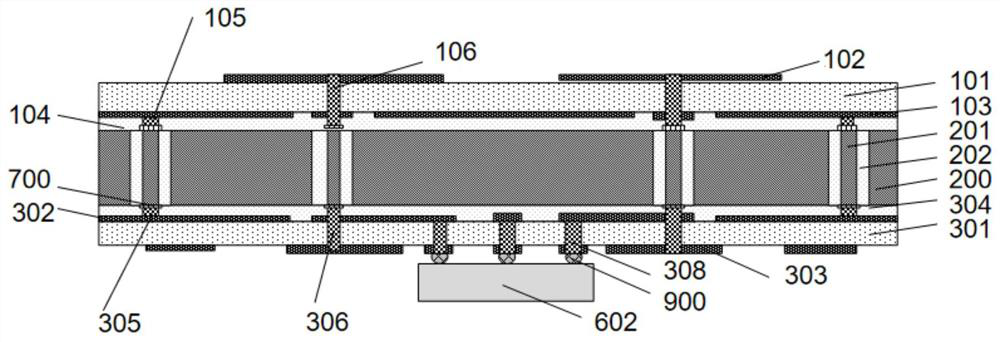

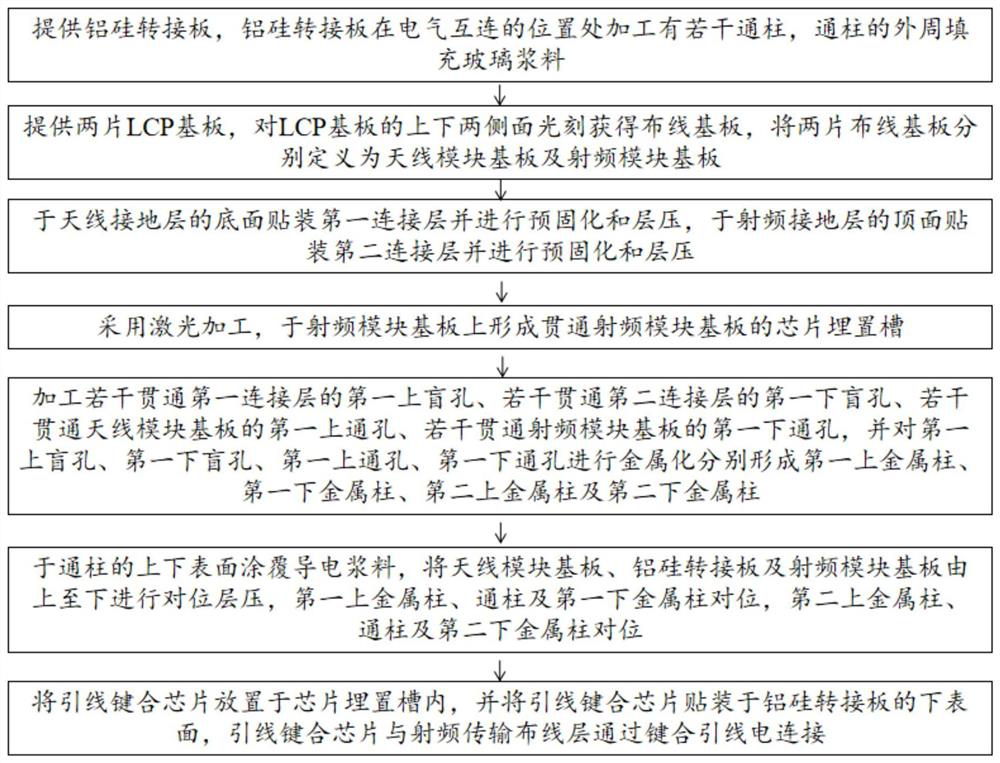

Integrated packaging antenna and packaging method thereof

ActiveCN112820721ALow dielectric constantLow moisture absorptionSemiconductor/solid-state device detailsAntenna supports/mountingsComputer networkSemiconductor chip

The invention discloses an integrated packaging antenna comprising at least one semiconductor chip, an antenna module substrate, an aluminum-silicon adapter plate and a radio frequency module substrate, the antenna module substrate, the aluminum-silicon adapter plate and the radio frequency module substrate are sequentially laminated from top to bottom, and the antenna module substrate comprises an antenna layer LCP substrate, an antenna pattern layer and an antenna grounding layer, wherein the antenna pattern layer and the antenna grounding layer are arranged on the top surface and the bottom surface of the antenna layer LCP substrate. the radio frequency module substrate comprises a radio frequency layer LCP substrate, a radio frequency grounding layer and a radio frequency transmission wiring layer, and the radio frequency grounding layer and the radio frequency transmission wiring layer are arranged on the top face and the bottom face of the radio frequency layer LCP substrate respectively. The problem that a common adapter plate is relatively poor in heat dissipation and cannot serve as a mechanical support is solved; compared with a traditional silicon adapter plate or an LTCC substrate, the cost can be reduced, and heat dissipation can be improved; meanwhile, integration of the substrate and the shell is completed, structural function integration of the substrate and the shell is achieved, and integration, miniaturization and light-weight packaging of an antenna module and a radio frequency module are achieved.

Owner:SHANGHAI SPACEFLIGHT ELECTRONICS & COMM EQUIP RES INST

Carbon fiber reinforced ultra-temperature vacuum insulated composite material

The invention discloses a carbon fiber reinforced ultra-temperature vacuum insulated composite material. The carbon fiber reinforced ultra-temperature vacuum insulated composite material is characterized by comprising a seal carbon fiber reinforced ceramic-based composite shell and an inner cavity. The composite shell is composed of a carbon fiber reinforced C / C composite material without through air holes, and a silicon carbide coating is arranged on the inner surface of the shell, a silicon carbide coating and a zirconium carbide coating are arranged on the outer surface, and the pressure of air in the inner cavity is lower than 1000 Pa. The material can be used in the environment with the temperature of 1500 DEG C or above, has an extremely low thermal conductivity coefficient and is high in strength and capable of being used as a structural material, and the structure and function integration is achieved.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

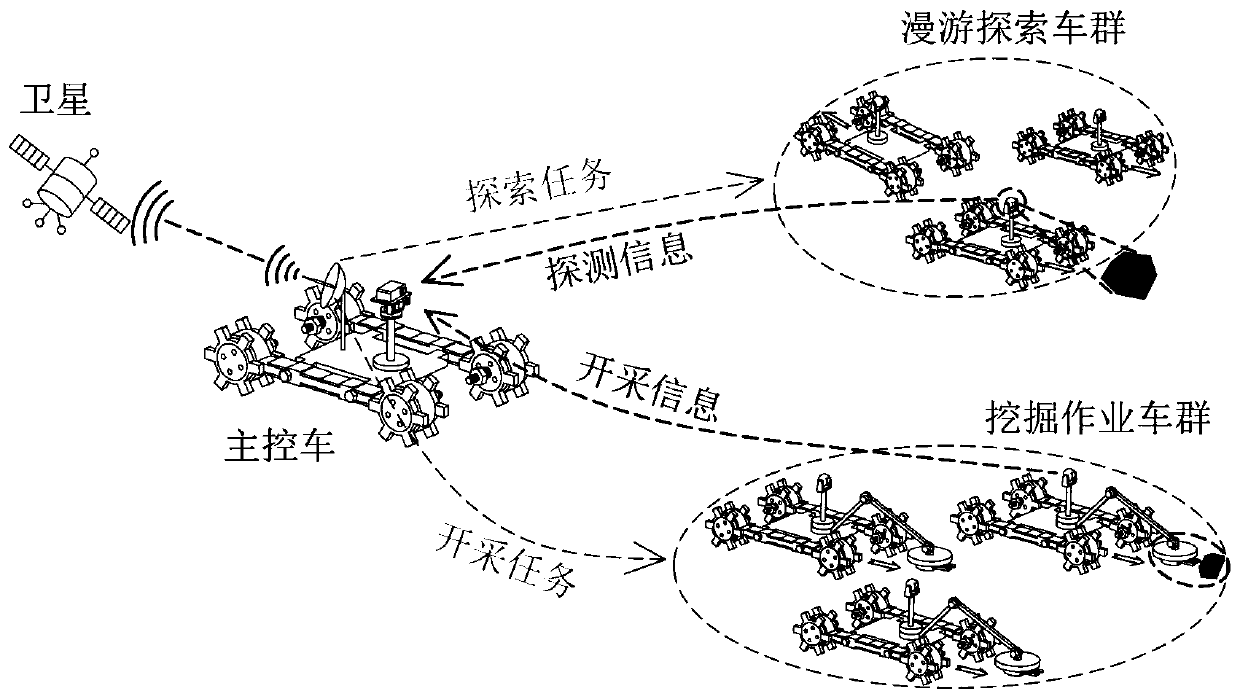

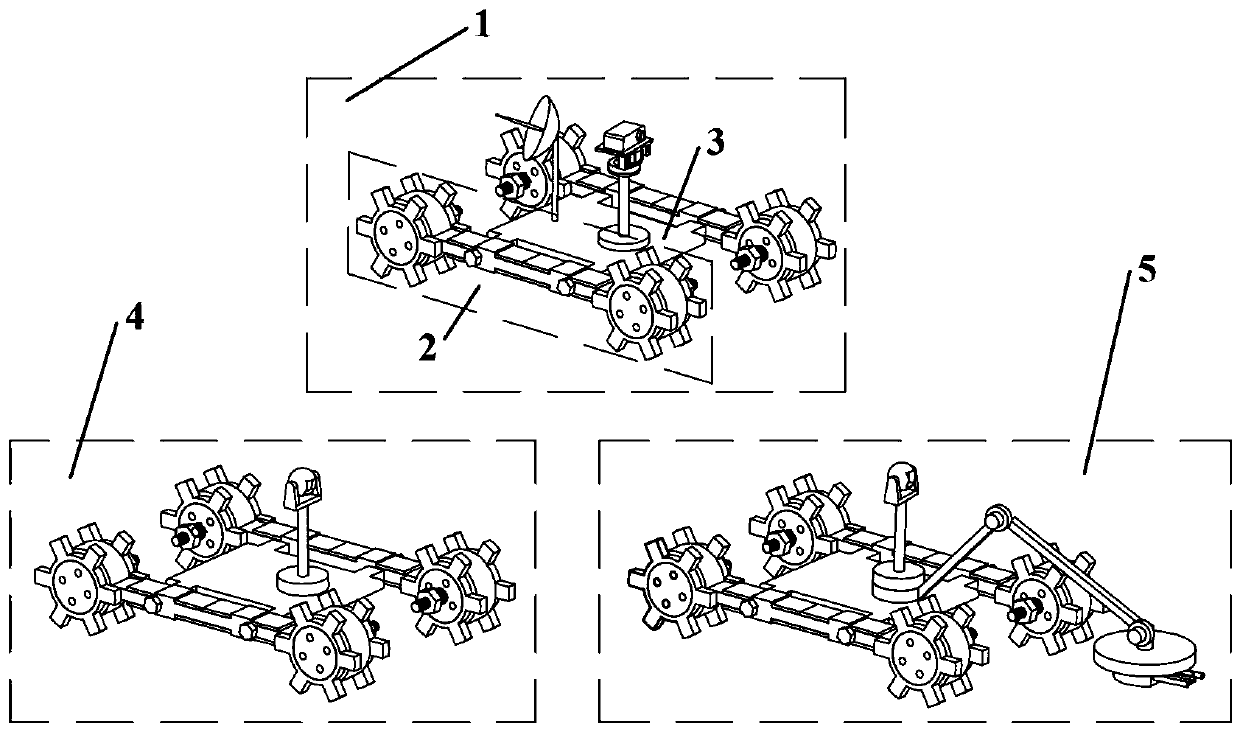

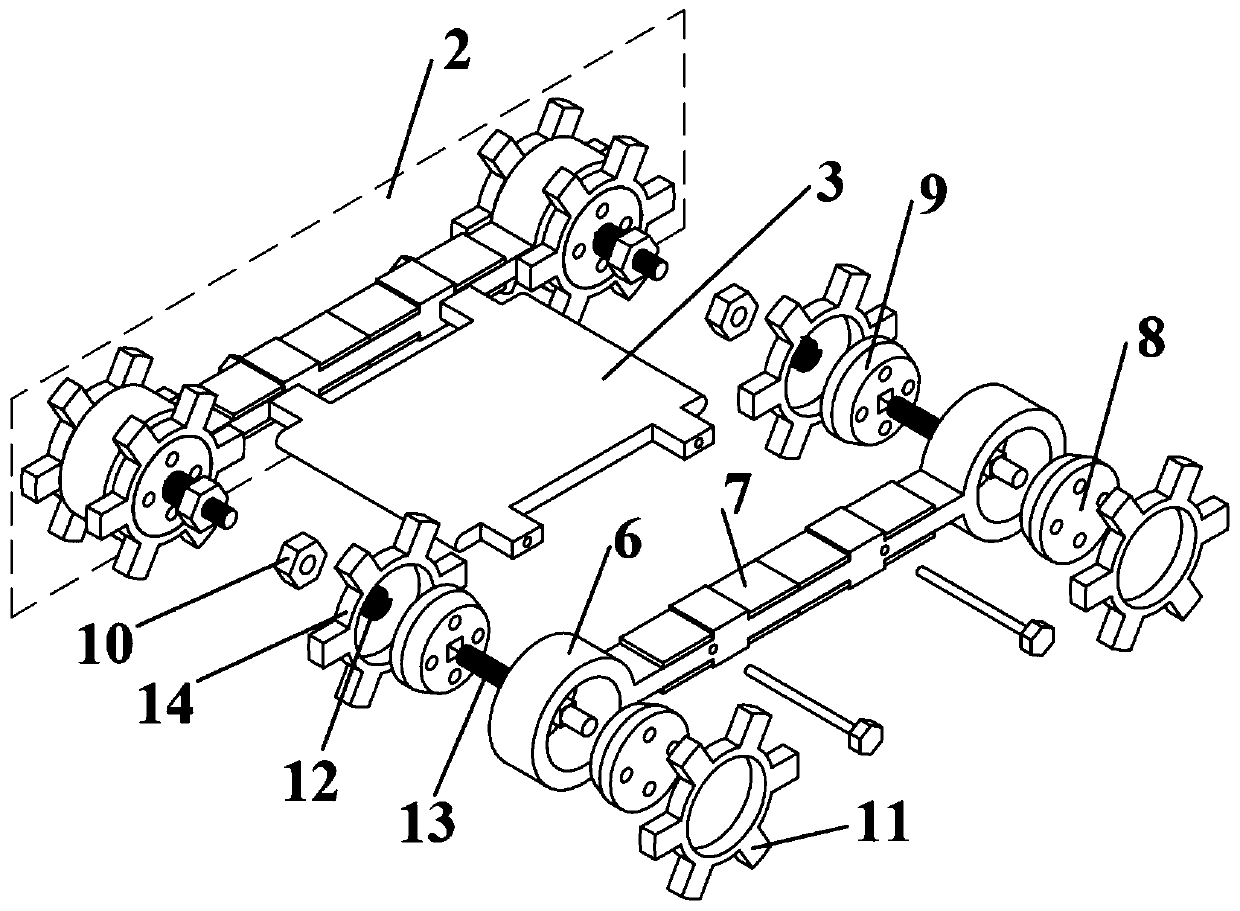

Cluster intelligent control piezoelectric driving moon detection system and method thereof

PendingCN111591467AAvoid the disadvantages of heavy weight and complex structureAddress reliabilityPiezoelectric/electrostriction/magnetostriction machinesExtraterrestrial carsPiezoelectric actuatorsControl engineering

The invention discloses a cluster intelligent control piezoelectric driving moon detection system and a method thereof. The system comprises a main control vehicle, an exploration vehicle group and anoperation vehicle group. The main control vehicle is used for determining exploration and operation targets and paths and respectively distributing the exploration and operation targets and paths tothe exploration vehicle group and the operation vehicle group. The exploration vehicle group and the operation vehicle group respectively complete a lunar surface exploration task and a sample collection task. All mobile systems in the system are driven by a patch type piezoelectric actuator, so that the miniaturization design of the lunar surface detector is realized, and the problem of load increase caused by a plurality of detectors in a cluster form is eliminated. According to the detection system, the reliability and the detection efficiency of the lunar rover are improved by using an intelligent cluster control method.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Preparation method of light ablative material

The invention discloses a preparation method of a light ablative material, relates to a preparation method of a thermal protection material, and is aimed at solving the technical problem of high density of the existing carbonization type light ablative material taking phenol-formaldehyde resin as a substrate. The method comprises the following steps of: dissolving boron phenol-formaldehyde resin in acetone to prepare a boron phenol-formaldehyde resin solution; adding the uniformly mixed microsphere filler and carbon nanotube into the boron phenol-formaldehyde resin solution, and mixing uniformly; standing to volatize acetone to obtain mixed paste; putting the phenol-formaldehyde honeycomb cut into a die inner cavity shape into a die, and filling the mixed paste into the phenol-formaldehyde honeycomb to obtain a composite green body; and curing and forming the composite green body to obtain the light ablative material. Through the invention, the density of the prepared light ablative material is as low as 0.2-0.4g / cm<3>, the linear ablativity is 0.035-0.115mm / s, and the mass ablativity is 0.0177-0.0216g / s; and the light ablative material can be used as a thermal protection material of a spacecraft.

Owner:HARBIN INST OF TECH

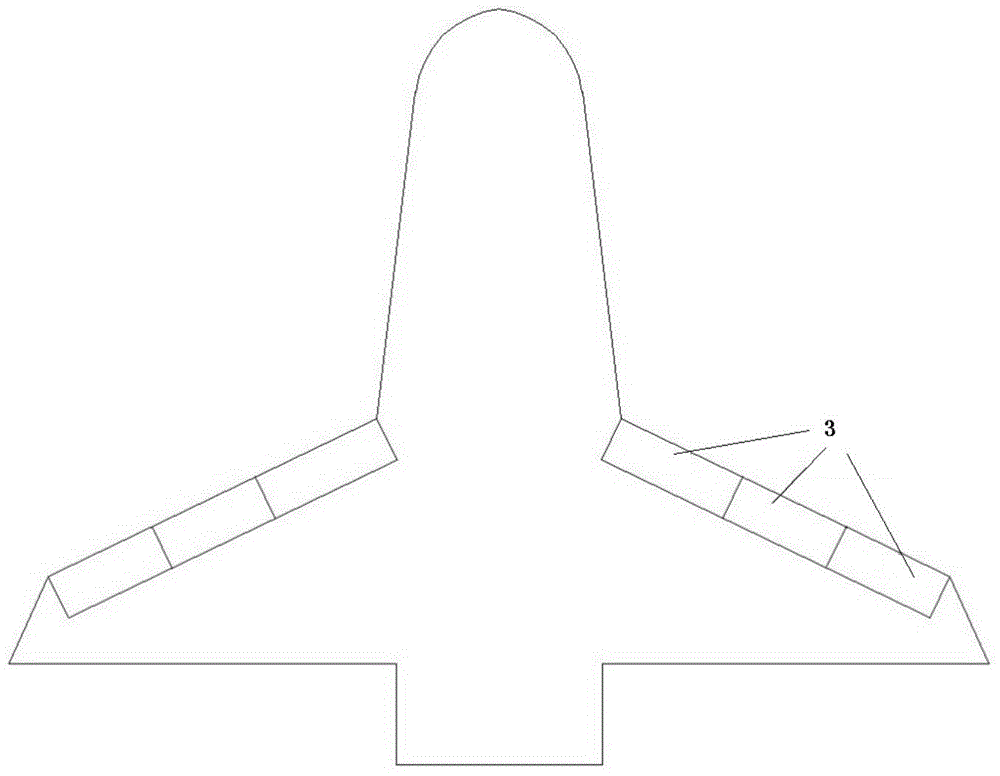

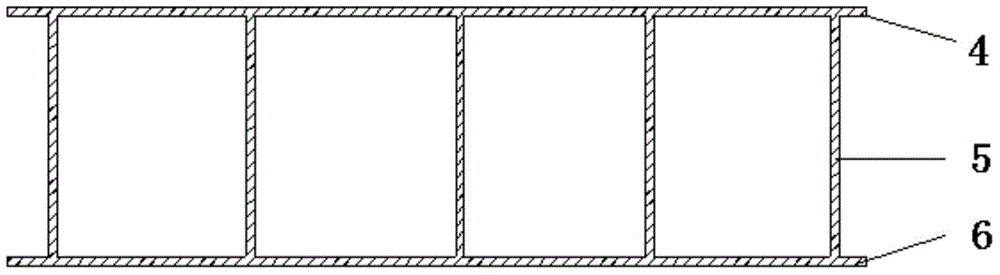

Heat insulation structure used for high-mach-number air vehicle

InactiveCN105000166AGuaranteed insulation effectSimplify the assembly processFuselage insulationEngineering

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

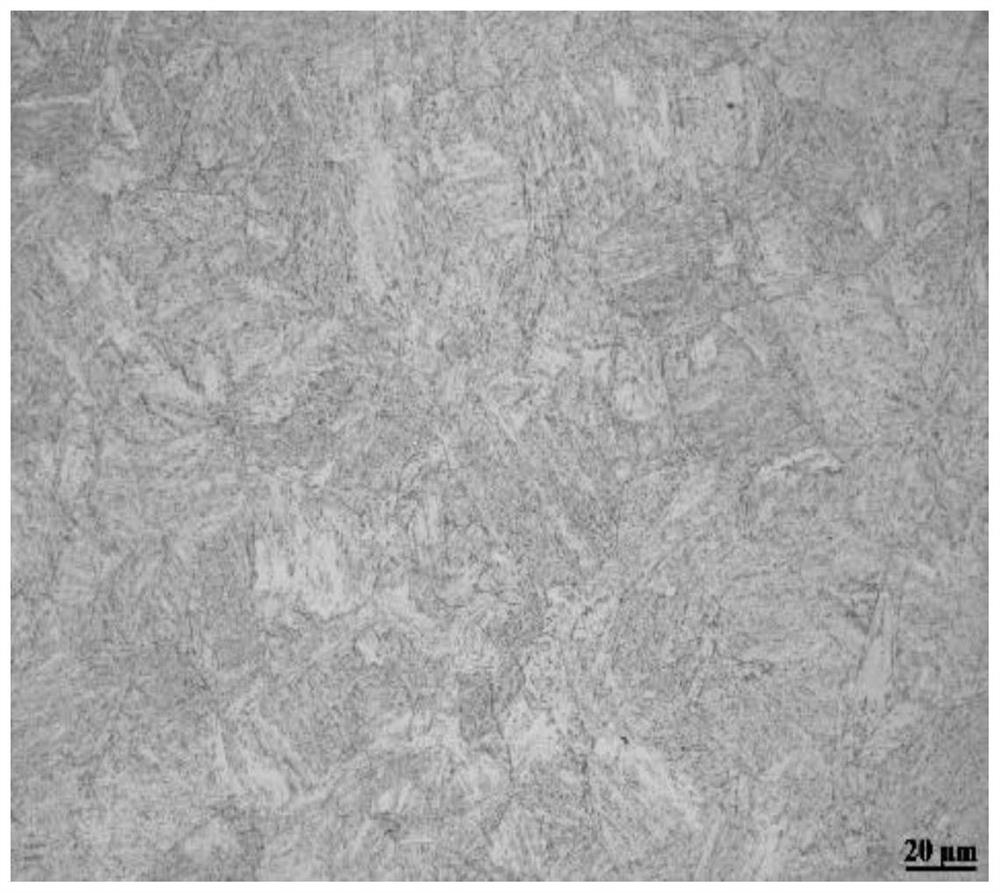

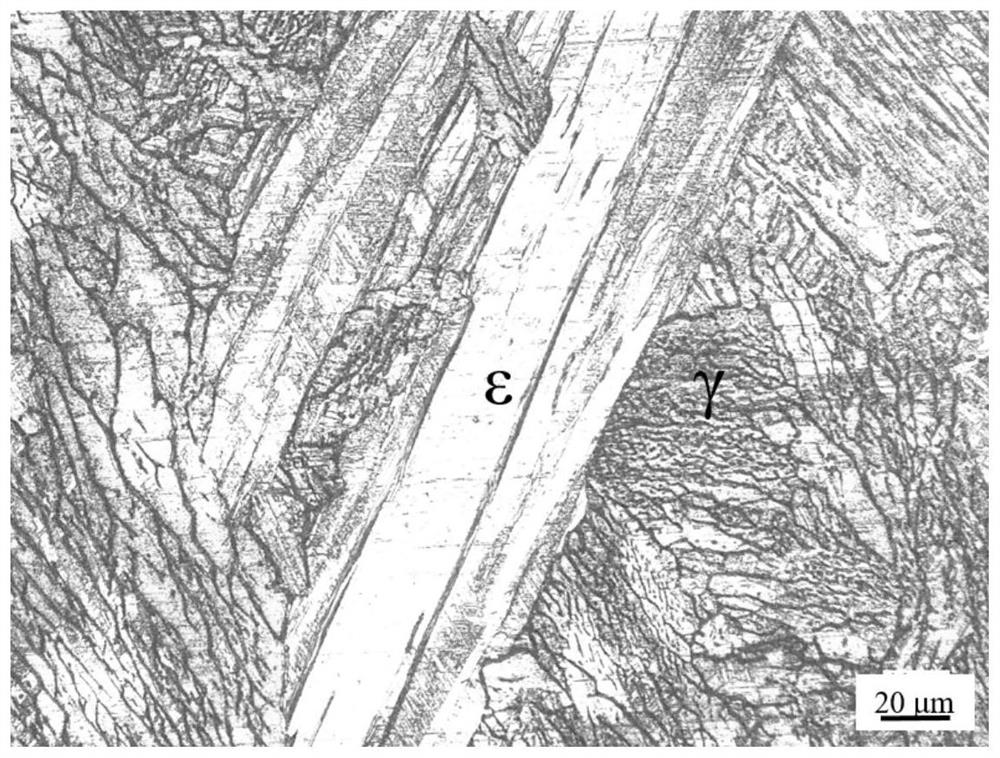

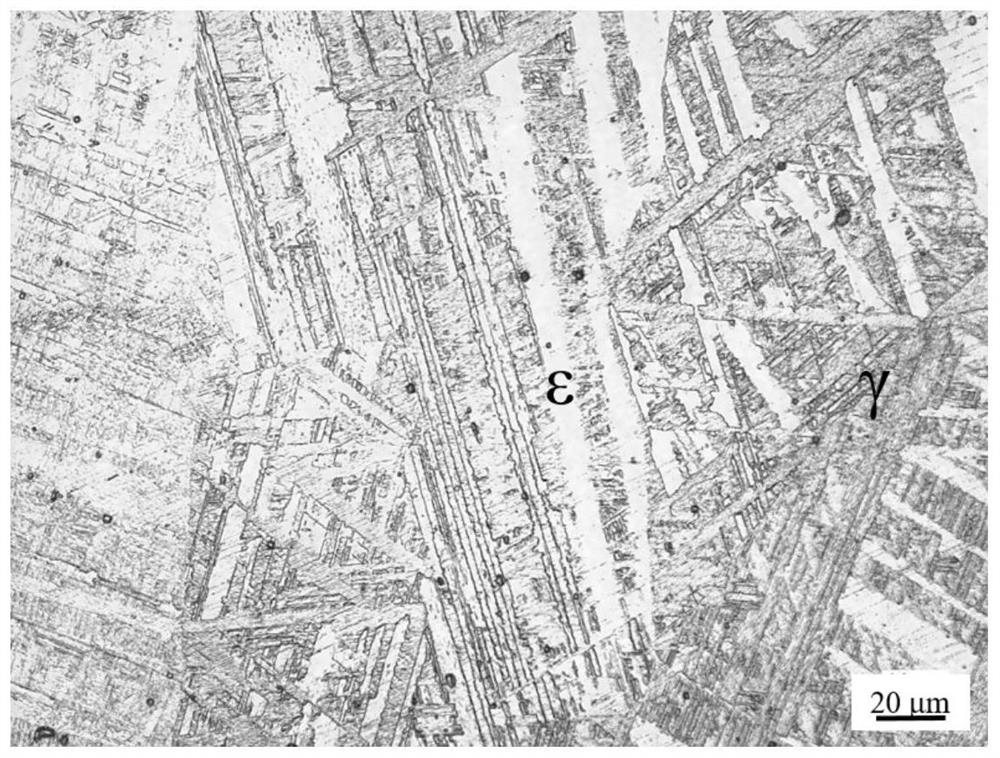

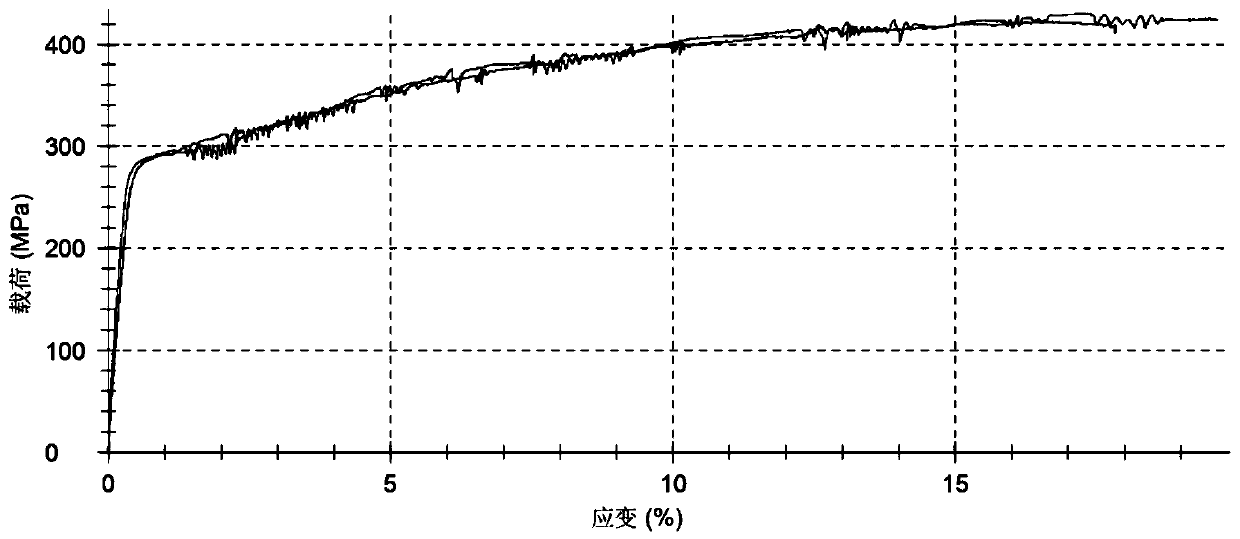

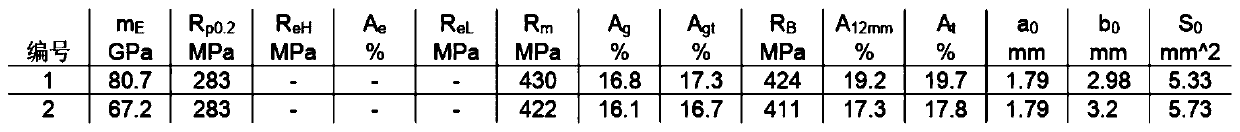

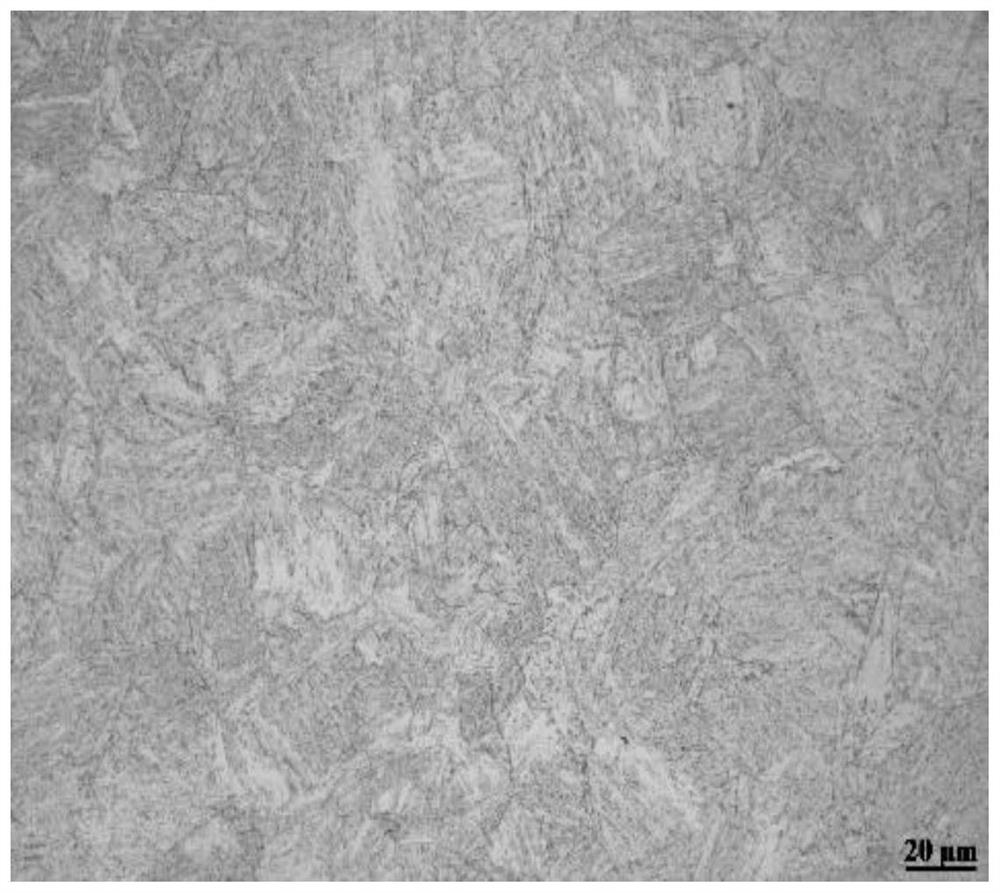

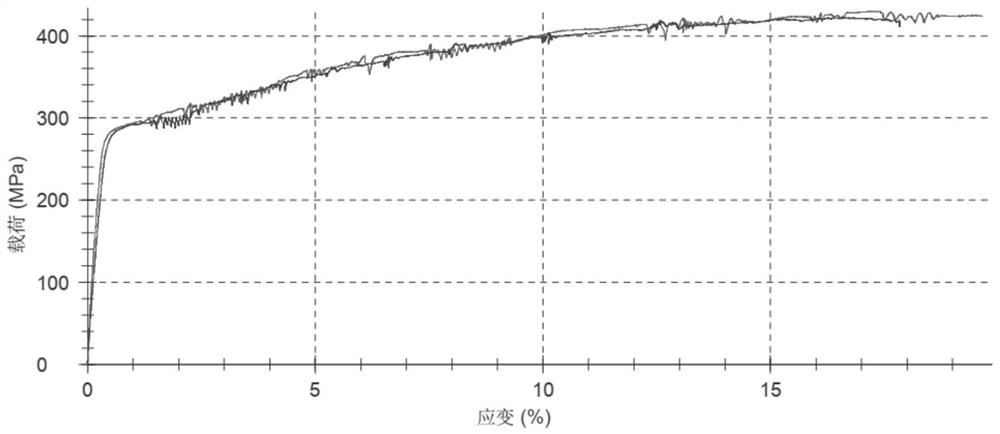

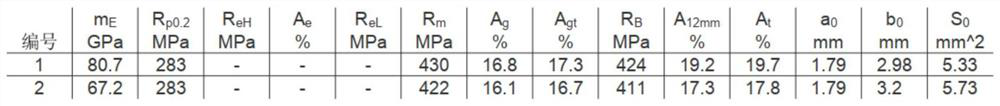

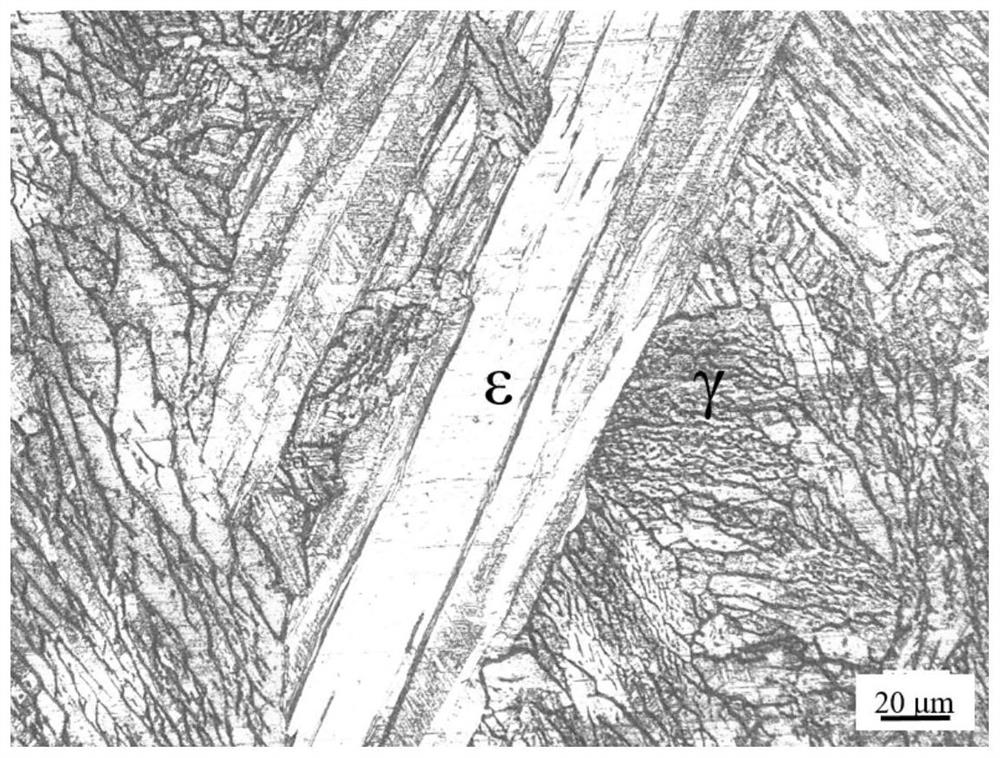

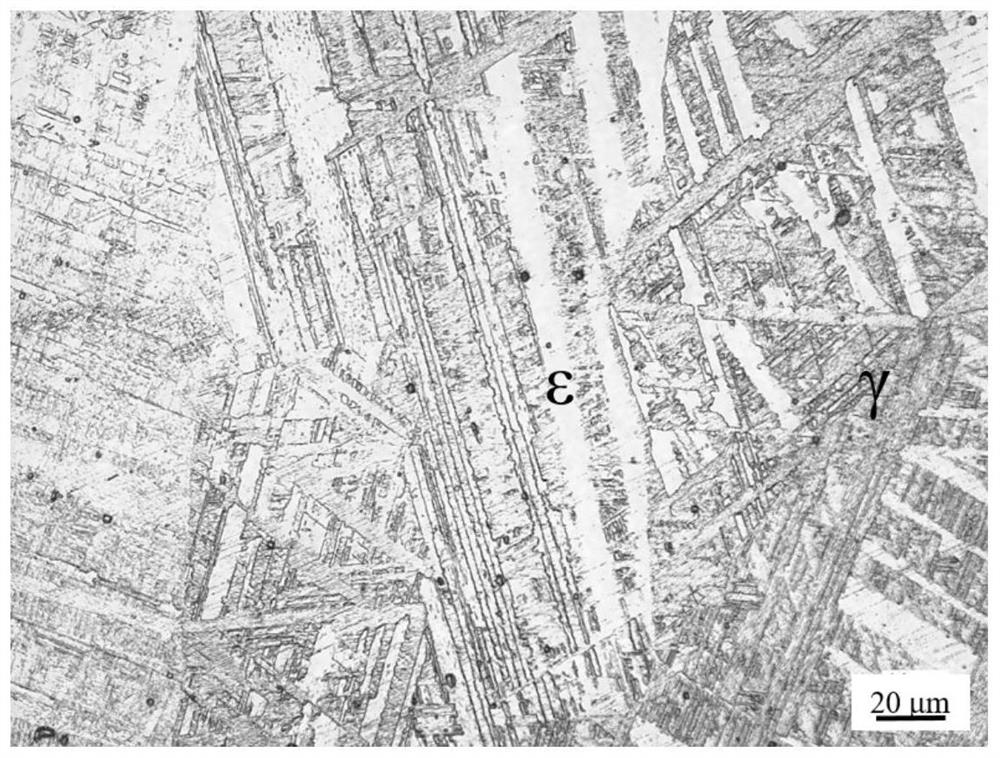

High-damping high-strength high-entropy alloy material with high corrosion resistance and preparation method of high-damping high-strength high-entropy alloy material

The invention provides a high-damping high-strength high-entropy alloy material with high corrosion resistance and a preparation method of the high-damping high-strength high-entropy alloy material. The high-entropy alloy material is prepared from the following metal raw materials in percentage by atomic number: 20% of manganese, 15% of chromium, 5-20% of cobalt and the balance of iron. The preparation method of the high-entropy alloy material comprises the following steps that manganese particles, chromium particles, cobalt particles and iron particles are weighted according to the atomic percentage content of manganese, chromium, cobalt and iron in the metal raw materials of the high-entropy alloy material; the weighed manganese particles, chromium particles, cobalt particles and iron particles are put into a vacuum induction furnace, the vacuum induction furnace is vacuumized, repeated overturning smelting is conducted under protective gas, and alloy liquid is obtained; the obtained alloy liquid is subjected to heat preservation treatment in the vacuum induction furnace; and the alloy liquid subjected to heat preservation is cast to obtain an alloy ingot. The high-entropy alloy material has excellent damping property, mechanical property and corrosion resistance at the same time.

Owner:SOUTHWEST JIAOTONG UNIV

Aluminum-based titanium diboride composite material for neutron shielding and preparation method thereof

ActiveCN111394622AImprove mechanical propertiesRealize the integration of structure and functionMetallic materialsIngot

The invention discloses an aluminum-based titanium diboride composite material for neutron shielding and a preparation method thereof, and relates to the technical field of metal materials. The aluminum-based titanium diboride composite material comprises the following composite materials of, in percentage by mass fraction interval, 1%-20% of magnesium, 0.1%-20% of Gd, 1-20 wt% of TiB2, and the balance aluminum. The preparation method comprises the following steps of A, smelting Al-Mg-Gd (TiB2) raw material to obtain a cast ingot; B, atomizing and spraying powder on the cast ingot to obtain powder; C, performing spark plasma sintering on the powder to obtain a sintered sample; and D, performing hot extrusion on the sintered sample to obtain the aluminum-based titanium diboride composite material for neutron shielding. Through rapid solidification and other processes, a nano-phase which is dispersively distributed and has high neutron absorption capacity is formed in the composite material, and the preparation method greatly improves the neutron shielding performance, guarantees the excellent mechanical performance of the material, and realizes the structural function integration ofthe material.

Owner:SHANGHAI JIAO TONG UNIV

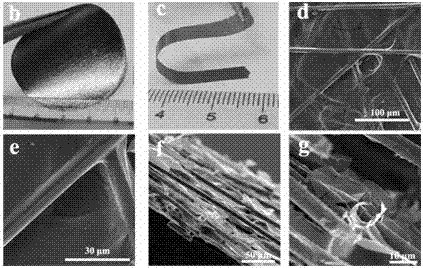

A method for preparing carbon fiber and graphene composite paper

ActiveCN103482996BRealize the integration of structure and functionEliminate local hot spotsSynthetic cellulose/non-cellulose material pulp/paperFiberOxide composite

The invention relates to a method for preparing carbon fibre and graphene composite paper. The method comprises the following steps: performing ultrasonic treatment on graphite oxide in deionized water for 5-100 minutes at the ultrasonic power of 50-300W, thus obtaining a graphene oxide solution with the concentration being 0.1-10mg / mL; performing sedimentation compounding on the graphene oxide solution and a carbon fibre precursor substrate at the mass ratio of the graphene oxide solution to the carbon fibre precursor substrate being (0.01-100):1, thus obtaining carbon fibre and graphene oxide composite paper; and performing high-temperature processing under a protective atmosphere or vacuum protective condition for 0.1-10 hours at the temperature of 300-3,000 DEG C, thus obtaining the carbon fibre and graphene composite paper. The method has the advantages of high thermal conductivity, high conductivity, good mechanical property, and easiness in realizing large-scale production.

Owner:山东热坤新材料有限公司

Steel, its preparation method and its application

The invention provides a steel material, a preparation method and an application thereof. Including: dosing according to the following chemical composition to obtain raw materials: by weight percentage, the raw materials include C 0.08-0.30%, Si≤0.5%, Mn≤1.0%, Cu 0.5-2.0%, Al≤1.0%, Ce 0.01- 0.2%, Cr 0.5~1.5%, Mo 0.5~1.5%, V≤0.3%, N≤0.005%, O≤0.005%, S≤0.005%, P≤0.005%, the balance is Fe; the raw materials are smelted in sequence , pouring and post-treatment to obtain steel, and when the content of O and S elements in the reaction product system is not more than 0.005wt%, Ce is added to the reaction product system. The obtained steel has the advantages of high strength, high toughness, sulfide stress corrosion resistance and microbial corrosion resistance, and realizes the integration of structure and function.

Owner:HENGYANG VALIN STEEL TUBE +1

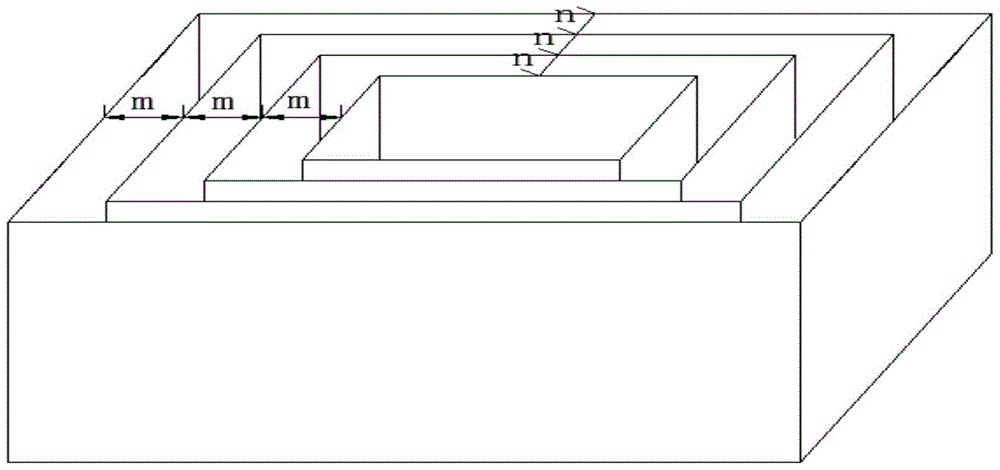

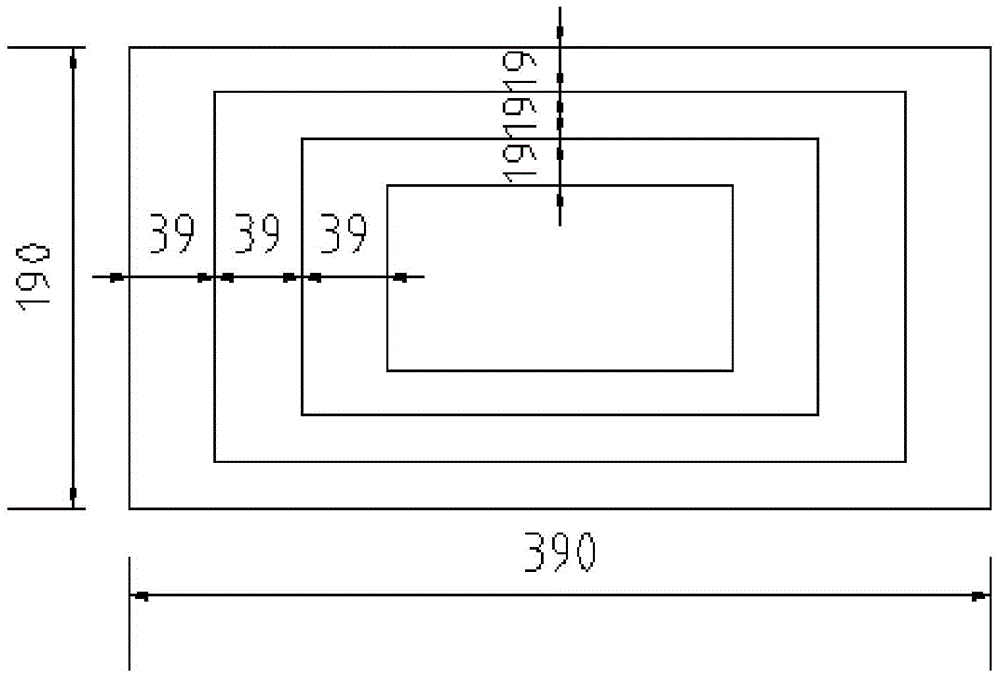

Preparation method of a gradient structure composite functional raw soil block

InactiveCN105174851BHigh quality compositeHigh strengthConstruction materialClimate change adaptationCompression moldingAdobe

The invention discloses a preparation method of a compound functional raw soil building block having a gradient structure. The preparation method comprises the following steps: preparing a die composed of N regions and gradient cement-modified raw soil slurry, wherein the use amount of raw soil in the gradient cement-modified raw soil slurry for casting is progressively decreased in sequence, and the use amount of cement is progressively increased in sequence correspondingly, and the progressive increment of the cement of two adjacent groups is 1 to 5%; filling and casting the slurry to outside regions from middle regions in sequence, pulling clapboards out after the filling is finished, carrying out vibration or compression molding and then curing for 48 hours under room-temperature and dark conditions, dismantling the die, and continuing to cure in a sealing manner for 26 days under the same environment to obtain a building block product. The compound functional raw soil building block having the gradient structure, which is prepared by using the preparation method, not only reserves the advantages of a conventional raw soil building material, but also has relatively high strength and stability, has the characteristics of light weight, heat insulation, high strength, good water resistance and the like and is thus a high-performance building material.

Owner:TIANJIN CHENGJIAN UNIV

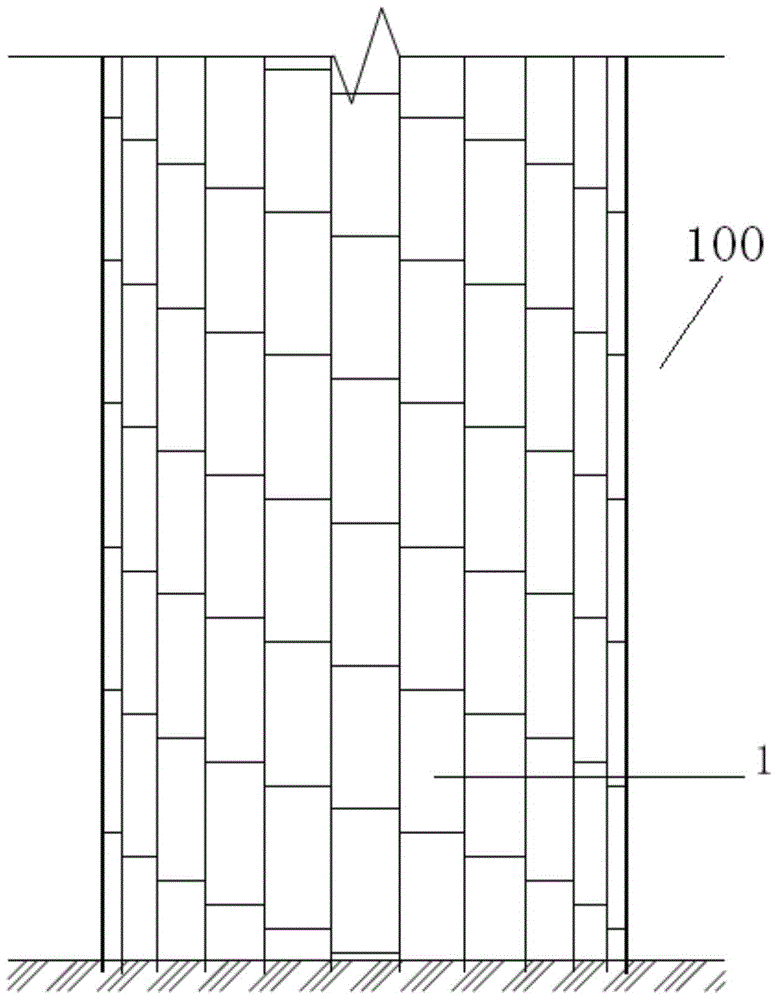

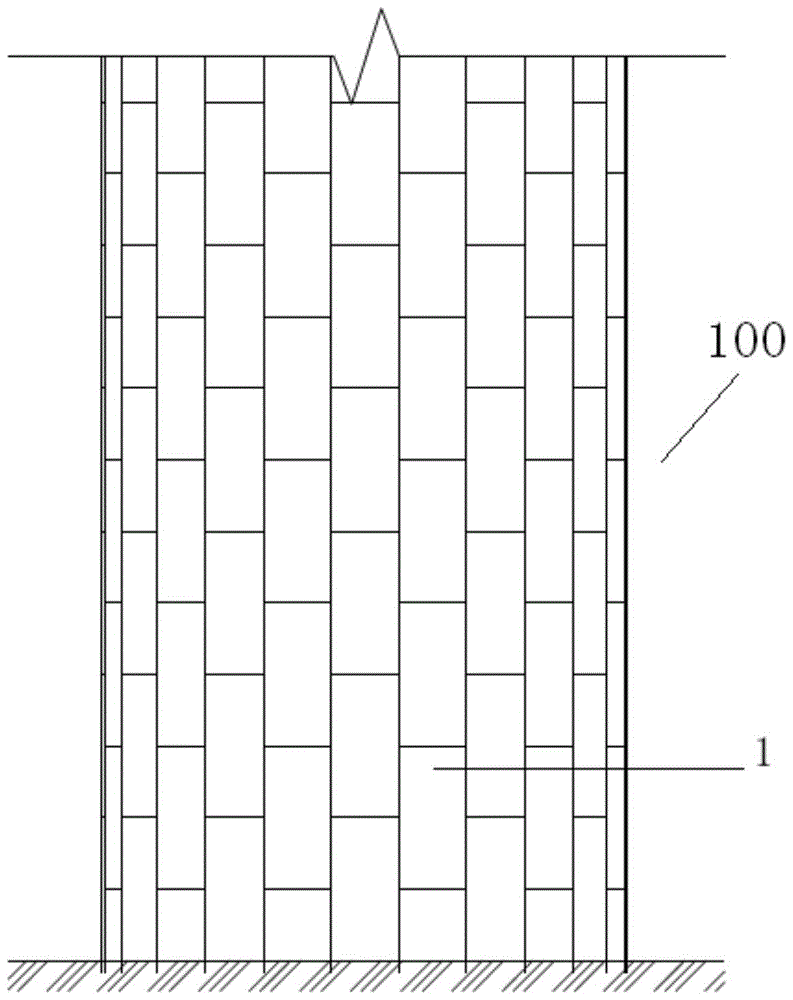

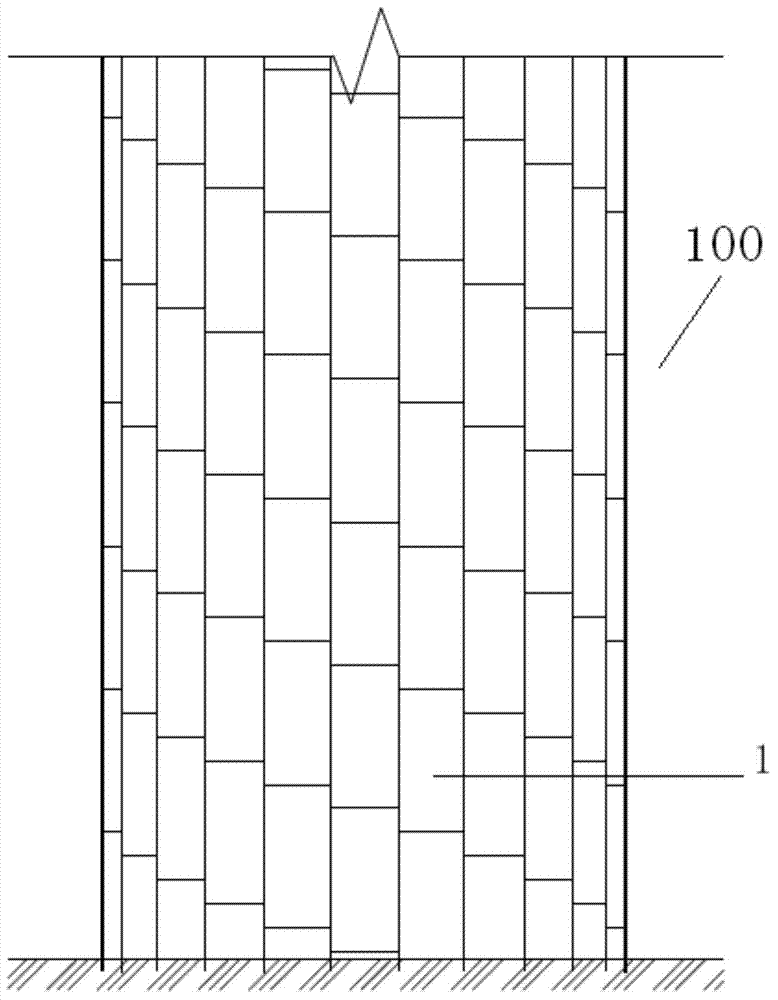

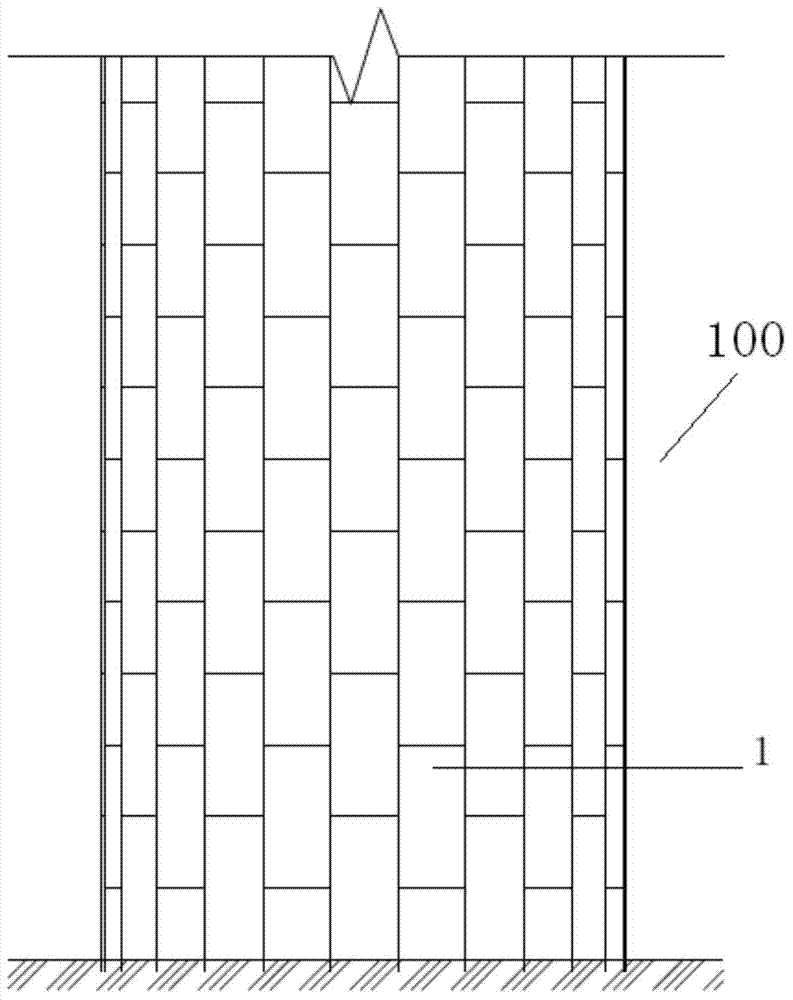

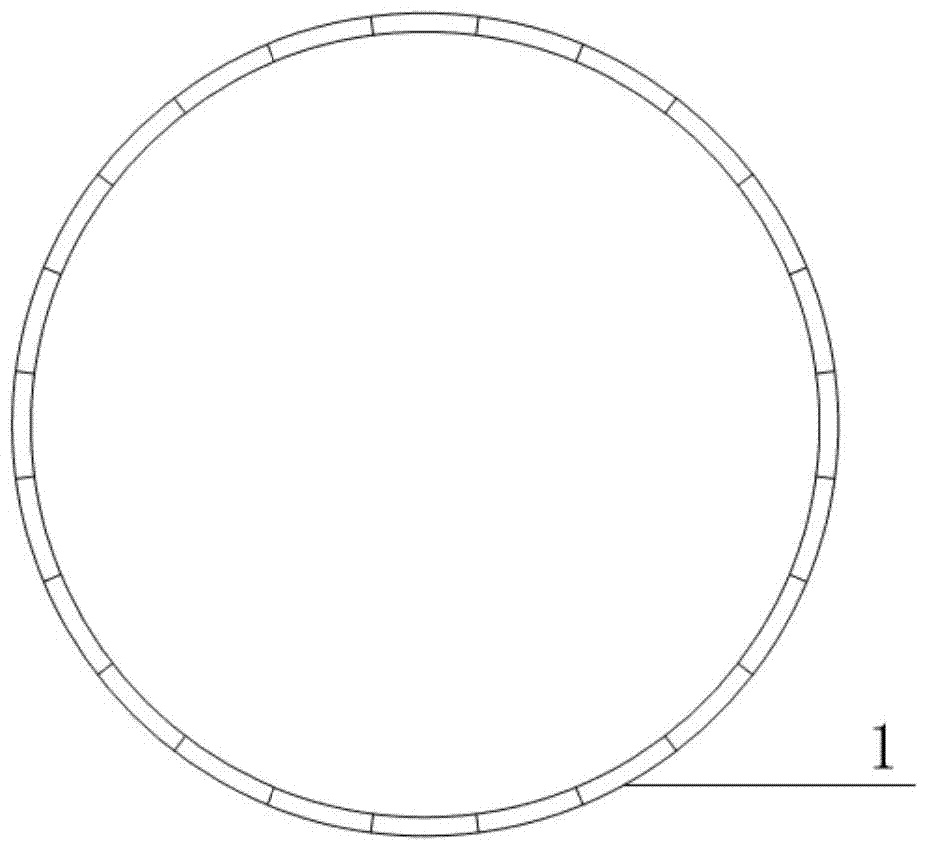

Chimney constructed of novel corrosion-resistant material, construction method thereof, sleeve chimney

ActiveCN104763210BIncreased durabilityIntegration of structure and functionTowersBuilding insulationsFiberEngineering

The invention discloses a chimney constructed by novel corrosion-resistant materials and a construction method thereof and a sleeve chimney with the chimney. The chimney comprises multiple fiber reinforced resin profiles, the fiber reinforced resin profiles are mutually connected in the longitudinal direction to form a column, and the multiple columns are mutually connected in the transverse direction to form to be in a hollow cylinder shape; a cavity of which the upper end and the lower end are open is limited in each fiber reinforced resin profile, filler is arranged in each cavity, and any two fiber reinforced resin profiles which are adjacently arranged in the transverse direction are staggered in the longitudinal direction. According to the embodiment of the chimney, the design thought similar to a fiber reinforced resin sandwich plate is adopted, the fiber reinforced resin profiles and the filler are used in a matched mode, the structural function integration of the chimney is achieved, the corrosion protection problem of the chimney is thoroughly solved, the structural strength of the chimney is high, the manufacture cost is lowered, and the construction is easy.

Owner:TSINGHUA UNIV

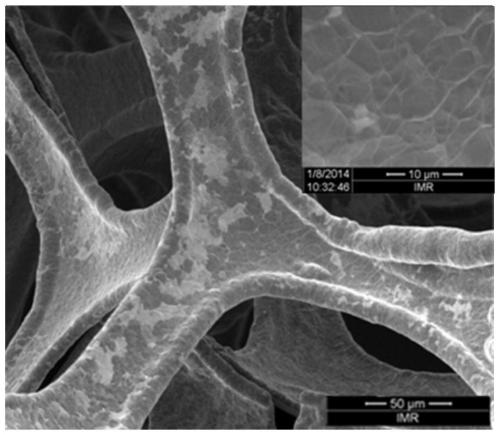

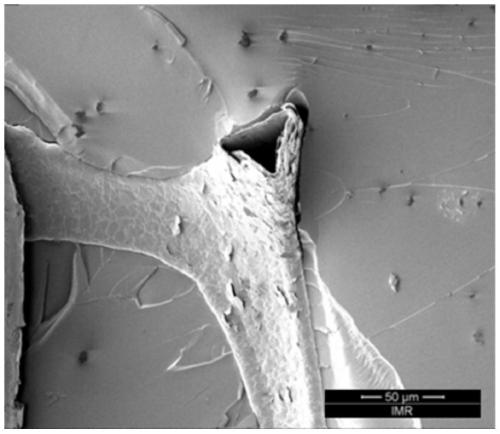

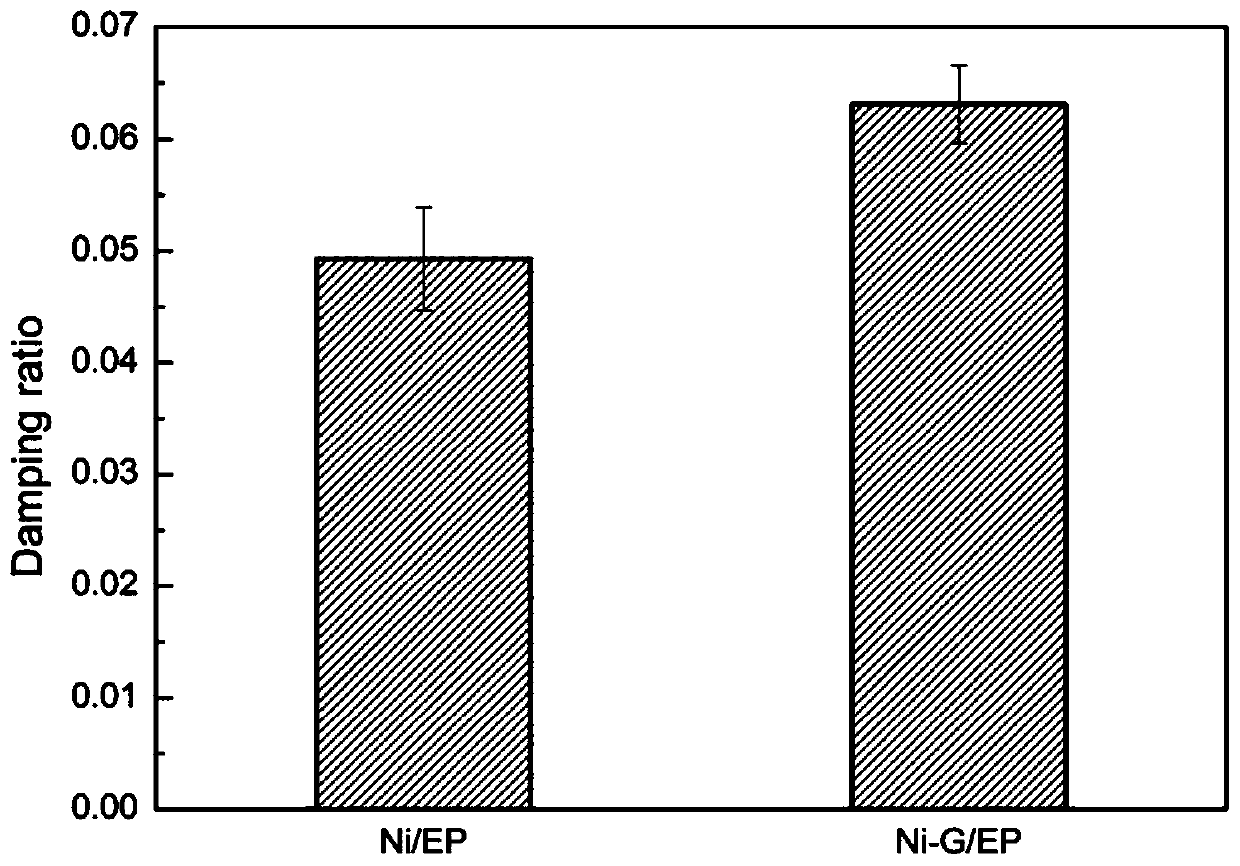

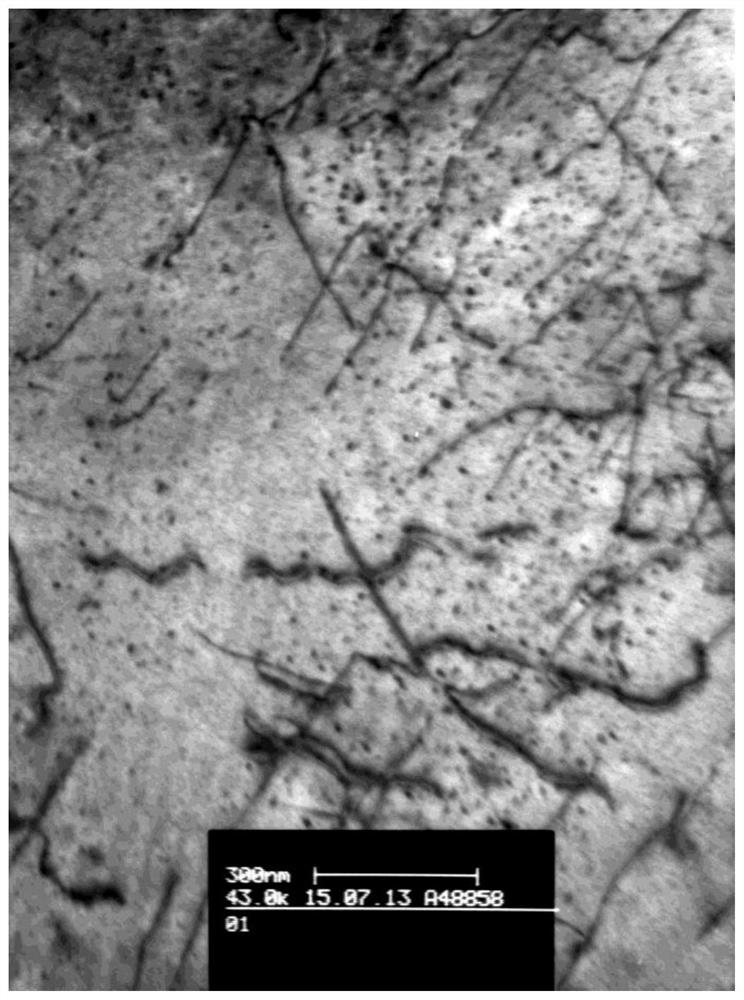

A kind of preparation method of graphene damping composite material

ActiveCN108117719BHigh mechanical strengthMulti-dissipativeChemical vapor deposition coatingMetal frameworkPolymer composites

The invention specifically relates to a preparation method for a graphene damping composite material, belonging to the field of application of graphene composite materials. With graphene or graphene oxide as a raw material, graphene coats a foam metal framework in the manner of chemical vapor deposition or chemical coating, and resin is injected into the foam metal framework coated with a thin graphene layer so as to obtain the graphene / foam metal / polymer composite material. Thus, the damping performance of foam metal can be significantly improved by coating the foam metal framework with the graphene, and after compounding of the foam metal framework with the resin, the graphene / foam metal / polymer composite material with significantly improved mechanical performance and good damping performance can be obtained. The preparation method for the graphene damping composite material has the technical characteristics of simple process, good repeatability, remarkable application effect and thelike.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Steel pipe, its preparation method and application

ActiveCN112063922BHigh strengthImprove toughnessFurnace typesHeat treatment furnacesChemical compositionMicrobial corrosion

The application provides a steel pipe, its preparation method and application. It includes: dosing according to the following chemical composition to obtain raw materials: by weight percentage, the raw materials include C 0.08-0.30%, Si≤0.5%, Mn≤1.0%, Cu 0.5-2.0%, Al≤1.0%, Ce 0.01 ~0.2%, Cr 0.5~1.5%, Mo 0.5~1.5%, V≤0.3%, N≤0.005%, O≤0.005%, S≤0.005%, P≤0.005%, the balance is Fe; Melting, pouring, electroslag remelting, rolling and heat treatment to obtain steel pipes, when the contents of O and S in the reaction product system are not greater than 0.005wt%, Ce is added. The steel pipe prepared by the above method has the advantages of high strength, high toughness, resistance to sulfide stress corrosion and microbial corrosion, and realizes the integration of structure and function.

Owner:HENGYANG VALIN STEEL TUBE +1

Steel pipe and preparation method and application thereof

ActiveCN112063922AHigh strengthImprove toughnessFurnace typesHeat treatment furnacesChemical compositionMicrobial corrosion

The invention provides a steel pipe and a preparation method and application thereof. The preparation method comprises the steps that raw materials are obtained through burdening according to the following chemical components, specifically, the raw materials comprise, by weight, 0.08-0.30% of C, less than or equal to 0.5% of Si, less than or equal to 1.0% of Mn, 0.5-2.0% of Cu, less than or equalto 1.0% of Al, 0.01-0.2% of Ce, 0.5-1.5% of Cr, 0.5-1.5% of Mo, less than or equal to 0.3% of V, less than or equal to 0.005% of N, less than or equal to 0.005% of O, less than or equal to 0.005% of S, less than or equal to 0.005% of P and the balance Fe; and the raw materials are sequentially subjected to smelting, pouring, electroslag remelting, rolling and heat treatment, the steel pipe is obtained, and when the content of O and the content of S in a reaction product system are not larger than 0.005wt%, Ce is added. The steel pipe prepared through the method has the advantages of being highin strength and toughness, resistant to sulfide stress corrosion and microbial corrosion and the like, and structural function integration is achieved.

Owner:HENGYANG VALIN STEEL TUBE +1

An aluminum-based titanium diboride composite material for neutron shielding and its preparation method

ActiveCN111394622BImprove mechanical propertiesRealize the integration of structure and functionMetallic materialsIngot

The invention discloses an aluminum-based titanium diboride composite material for neutron shielding and a preparation method thereof, and relates to the technical field of metal materials; the mass fraction range of magnesium in the composite material is 1-20wt%, and the mass fraction range of Gd 0.1-20wt%, the mass fraction range of TiB2 is 1-20wt%, and the balance is aluminum. The preparation method comprises the following steps: A, melting the Al-Mg-Gd (TiB2) raw material to obtain an ingot; B, atomizing the ingot and spraying powder to obtain a powder; C, sintering the powder by discharge plasma to obtain a sintered sample; D 1. The sintered sample is hot-extruded to obtain an aluminum-based titanium diboride composite material for neutron shielding. Through rapid solidification and other processes, nano-phases with dispersed distribution and strong neutron absorption capacity are formed in the composite material. This preparation method not only greatly improves the neutron shielding performance, but also ensures the excellent mechanical properties of the material, and realizes the material. Structural and functional integration.

Owner:SHANGHAI JIAO TONG UNIV

A high-entropy alloy with integrated structure and function and its preparation method

ActiveCN111778438BRaise the level of yield strengthRealize the integration of structure and functionHigh densityHigh entropy alloys

The invention discloses a high-entropy alloy based on Al-Nb-Zr-Mo-V-Hf system with integrated structure and function, which belongs to the field of high-entropy alloy materials, and its components are: aluminum: 4-15%; Niobium: 20-30%; Zirconium: 20-60%; Molybdenum: 5-15%; Vanadium: 1-5%, the balance is hafnium (0.01-20.0%) and unavoidable impurities; for the current typical BCC structure Refractory high-entropy alloys such as TaNbMoW, TaNbMoWV, etc. contain a large amount of high-density metal elements, the alloy has high density, high cost, poor room temperature plasticity, and is difficult to be used as a bottleneck problem for structural materials. Alloy research has not given sufficient attention. The present invention proposes a high-entropy alloy based on the Al-Nb-Zr-Mo-V-Hf system, and fully considers the special effect of the Hf element, thereby realizing the structural and functional integration of the high-entropy alloy .

Owner:NORTHEASTERN UNIV LIAONING +1

Chimney constructed by novel corrosion-resistant materials and construction method thereof and sleeve chimney

ActiveCN104763210AIncreased durabilityIntegration of structure and functionTowersBuilding insulationsEngineeringUltimate tensile strength

The invention discloses a chimney constructed by novel corrosion-resistant materials and a construction method thereof and a sleeve chimney with the chimney. The chimney comprises multiple fiber reinforced resin profiles, the fiber reinforced resin profiles are mutually connected in the longitudinal direction to form a column, and the multiple columns are mutually connected in the transverse direction to form to be in a hollow cylinder shape; a cavity of which the upper end and the lower end are open is limited in each fiber reinforced resin profile, filler is arranged in each cavity, and any two fiber reinforced resin profiles which are adjacently arranged in the transverse direction are staggered in the longitudinal direction. According to the embodiment of the chimney, the design thought similar to a fiber reinforced resin sandwich plate is adopted, the fiber reinforced resin profiles and the filler are used in a matched mode, the structural function integration of the chimney is achieved, the corrosion protection problem of the chimney is thoroughly solved, the structural strength of the chimney is high, the manufacture cost is lowered, and the construction is easy.

Owner:TSINGHUA UNIV

A kind of corrosion-resistant fast extrusion magnesium alloy and preparation method thereof

The invention belongs to the technical field of metal materials, and discloses a corrosion-resistant fast-extrusion magnesium alloy and a preparation method thereof; the composition mass percentage of the magnesium alloy is: aluminum: 0.1-2.0%, calcium: 0.05-0.5%, tin: 0.01‑0.5%, yttrium: 0.01‑0.45%, and the rest are magnesium, additive elements and unavoidable impurities. The additive elements are one or any combination of cerium, neodymium, and lanthanum, and the addition amount is: cerium: 0 ‑0.45%, Neodymium: 0‑0.45%, Lanthanum: 0‑0.45%. The preparation method includes: forming an atomic-scale microstructure in the magnesium alloy after alloy smelting, pouring, rapid extrusion after homogenization heat treatment, solution heat treatment and artificial aging treatment. The interaction of rare earth elements with Al, Ca and Sn atoms can regulate the size, shape, quantity and distribution of the microstructure, reduce the microgalvanic corrosion of the microstructure and the magnesium matrix, and significantly improve the corrosion resistance.

Owner:JILIN UNIV

A high-damping high-strength high-entropy alloy material with strong corrosion resistance and its preparation method

Owner:SOUTHWEST JIAOTONG UNIV

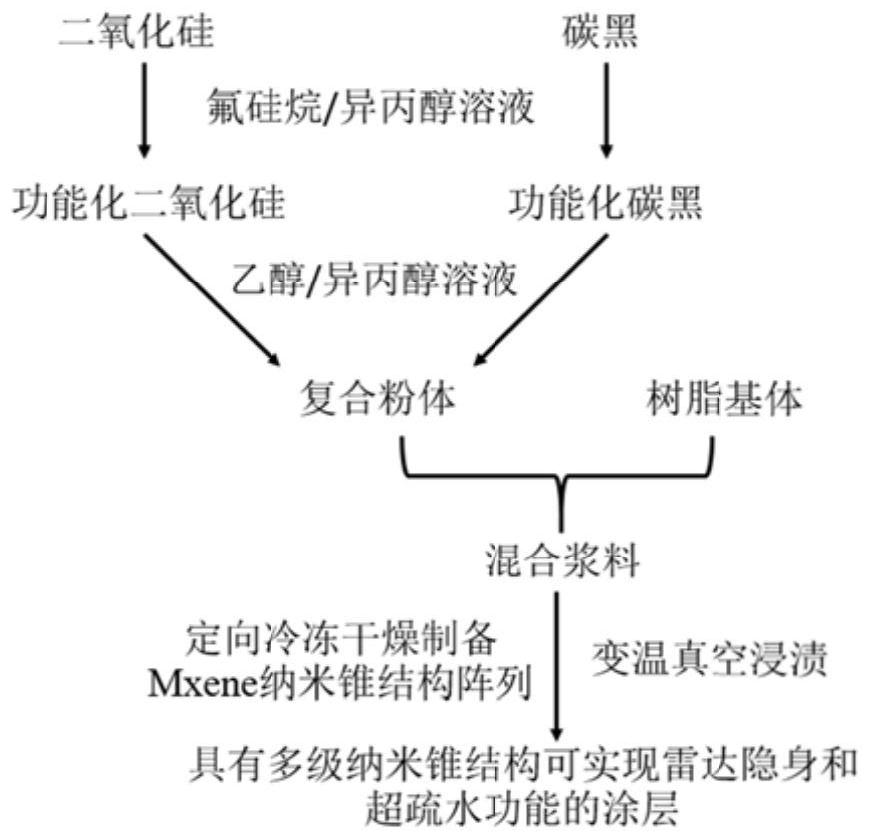

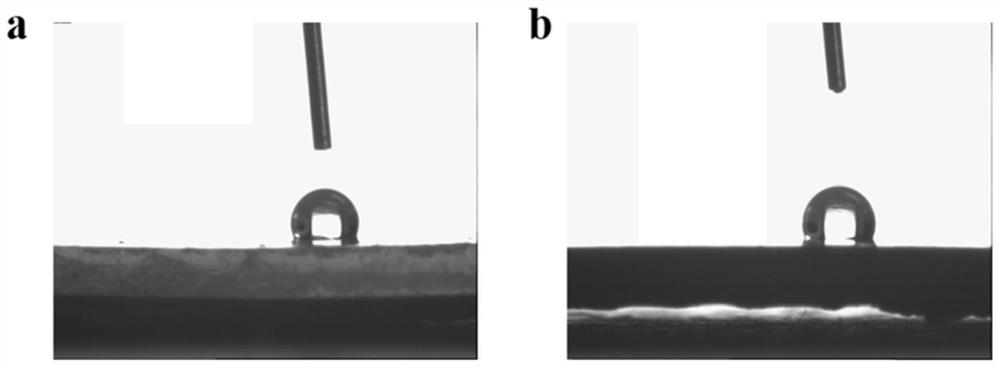

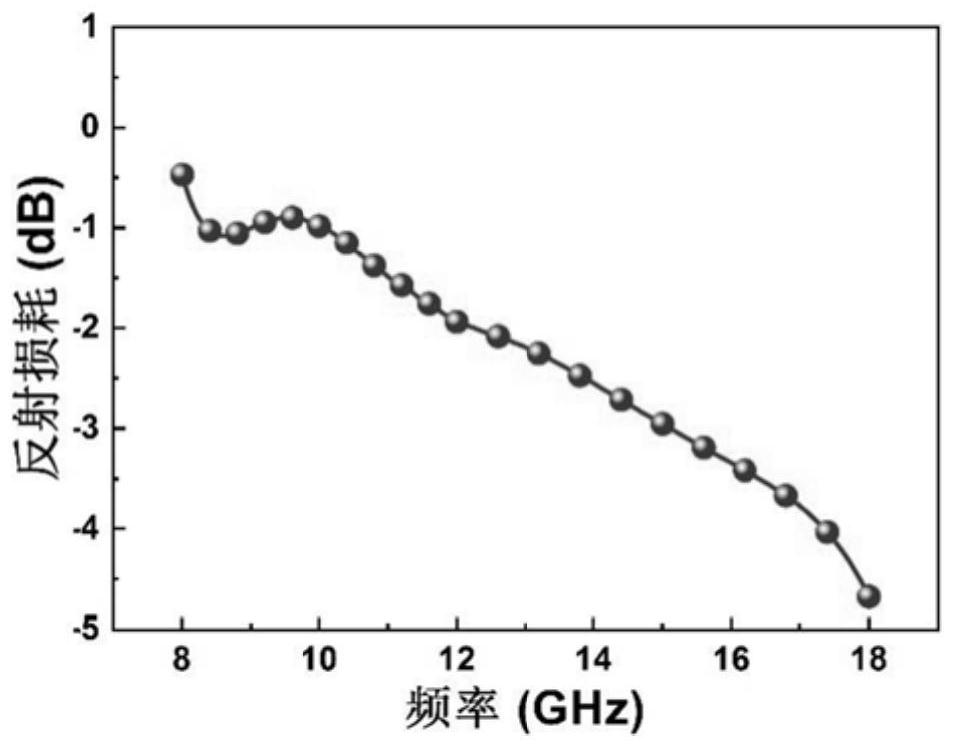

Multifunctional multi-stage nanocone array structure coating with multi-band stealth and super-hydrophobic characteristics and preparation method of multifunctional multi-stage nanocone array structure coating

PendingCN114854310AGood microwave absorption performanceReduce additional energy consumptionRadiation-absorbing paintsWind energy generationSurface-active agentsNanostructured carbon

The invention discloses a multifunctional multi-stage nanocone array structure coating with multi-band compatible stealth and super-hydrophobic characteristics and a preparation method of the multifunctional multi-stage nanocone array structure coating. A nanocone array formed by self-assembly of MXene is constructed by using a directional freeze drying technology, and nano carbon black and nano silicon dioxide are subjected to surface functionalization treatment by using a surfactant; the preparation method comprises the following steps: uniformly mixing treated powder in a solvent to realize self-assembly of a two-stage nanostructure, uniformly mixing the composite powder with a resin matrix by adopting a mechanical stirring process, and compounding prepared slurry with an MXene nanocone array by adopting a variable-temperature vacuum impregnation method to obtain the coating with the multi-stage nanocone structure. The preparation method is easy to operate, low in cost and high in preparation efficiency, and compatibility of multiple functions such as super-hydrophobicity, ice prevention and removal, multi-band stealth, ultraviolet radiation resistance, flexibility, impact resistance and wear resistance can be achieved at the same time. The problems that an existing hydrophobic coating is low in anti-icing and deicing efficiency, incompatible in multi-band stealth and durable in outdoor environment can be solved.

Owner:DALIAN UNIV OF TECH

A kind of preparation method and application of graphene powder

The invention discloses a preparation method of graphene powder. The method comprises: 1. Ultrasonic cleaning of graphite powder and vacuum freeze-drying to obtain pretreated graphite powder; 2. Pretreated graphite powder in an atmosphere Carry out intercalation heat treatment under protection; 3. Exfoliate the graphite powder after intercalation heat treatment under low-temperature liquid nitrogen conditions by performing high-speed vibratory shearing ball milling to obtain graphene powder; the invention also discloses a graphene powder Application as reinforcement material in metal composites. The present invention combines vacuum freeze-drying, intercalation heat treatment and ball milling exfoliation under the condition of low-temperature liquid nitrogen, gradually weakens the bonding force between graphite flakes of graphite powder and increases the distance between graphite flakes, and obtains multiple layers of low-density defects by exfoliating layer by layer. The graphene powder distributed in grades avoids environmental pollution, has low equipment requirements and high output, and is suitable for large-scale industrial production of graphene powder; the application of the present invention improves the performance of metal composite materials.

Owner:西安稀有金属材料研究院有限公司 +1

A dual-temperature phase-change temperature-regulating expanded vermiculite board and its preparation method

ActiveCN109678423BLarge adsorption capacityRealize the integration of structure and functionThermal dilatationPortland cement

The invention discloses a dual-temperature phase change temperature-regulating expanded vermiculite board and a preparation method thereof. The raw materials of the plate include diatomite phase change composite material, expanded vermiculite composite phase change material, portland cement and water reducer. The phase change temperature of the diatomite phase change composite material is 5-15°C, and the latent heat of phase change is ≥30J / g; the phase change temperature of the expanded vermiculite composite phase change material is 25-40°C, and the latent heat of phase change is ≥80J / g. Stir the diatomite phase change composite material, expanded vermiculite composite phase change material, portland cement, water reducer and water according to the mass ratio of 10~30:20~40:30~60:0.2~0.6:20~40 After uniform pouring, it can be demoulded after 2 days of curing. The plate prepared by the invention fully utilizes the micropore adsorption effect of expanded vermiculite and diatomite on phase change materials, and realizes the structural and functional integration of building materials while ensuring the temperature adjustment efficiency; in addition, the plate can be poured on site It works in both winter and summer, and has a wider range of applications than other boards.

Owner:SOUTHEAST UNIV

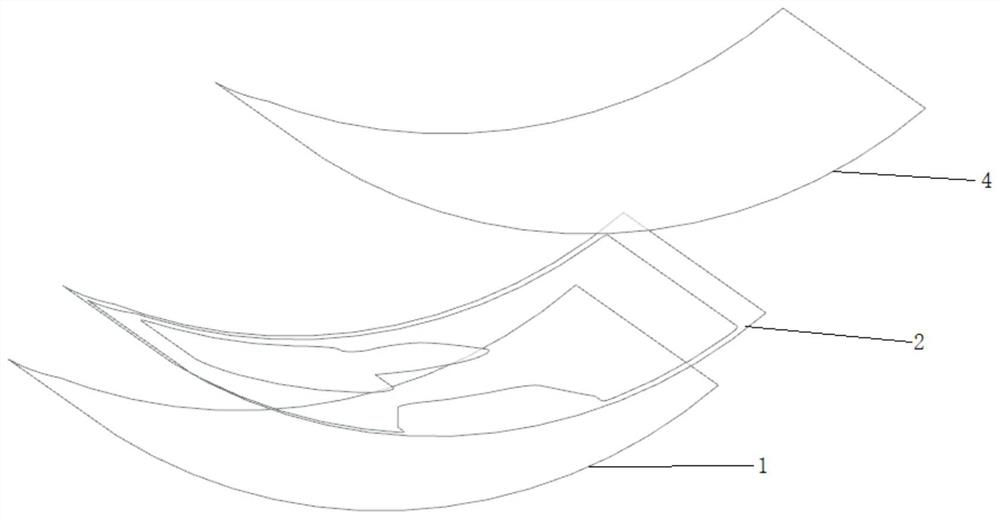

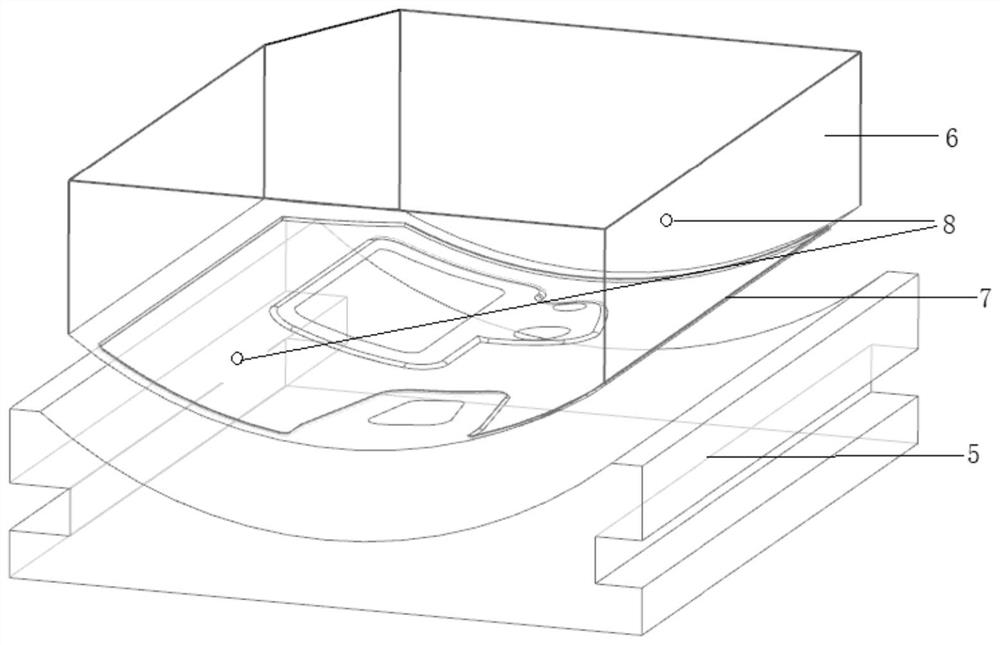

Variable-thickness titanium alloy skin integrated forming method

ActiveCN113997015ARealize the integration of structure and functionHigh material utilizationSandwich constructionsThin walledPolluted environment

The invention relates to a variable-thickness titanium alloy skin integrated forming method, which belongs to the technical field of titanium alloy precision forming, and solves the problems that in the prior art, the material utilization rate is low, the machining efficiency is low, and an existing chemical milling forming process pollutes the environment. Thevariable-thickness titanium alloy skin integrated forming method is characterized in that an outer skin, a gradient reinforcing plate and an inner skin are integrally formed through a high-temperature diffusion bonding technology, and the gradient reinforcing plate is used for adjusting the thickness of the formed skin and is clamped between the outer skin and the inner skin. According to the method, a traditional chemical milling technology is abandoned, environmental pollution is reduced, the requirement for the assembly thickness of the periphery and the framework of the skin part and the requirement for internal thin wall light weight are met, the production efficiency is improved by 30%, the material utilization rate is improved by 60%, and the product percent of pass is improved by 10%.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

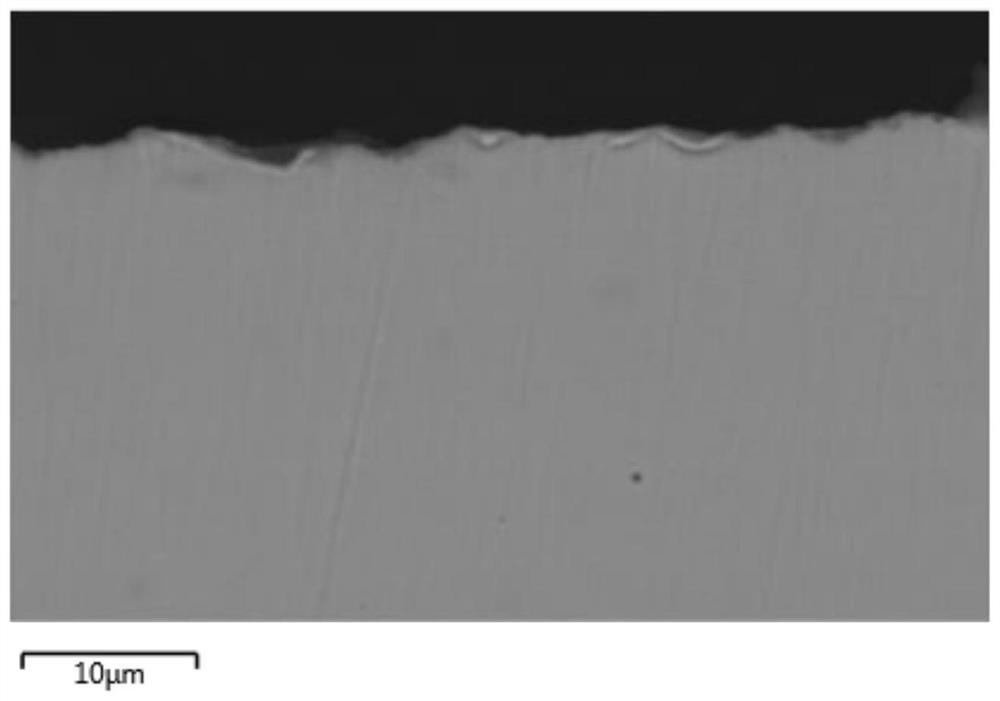

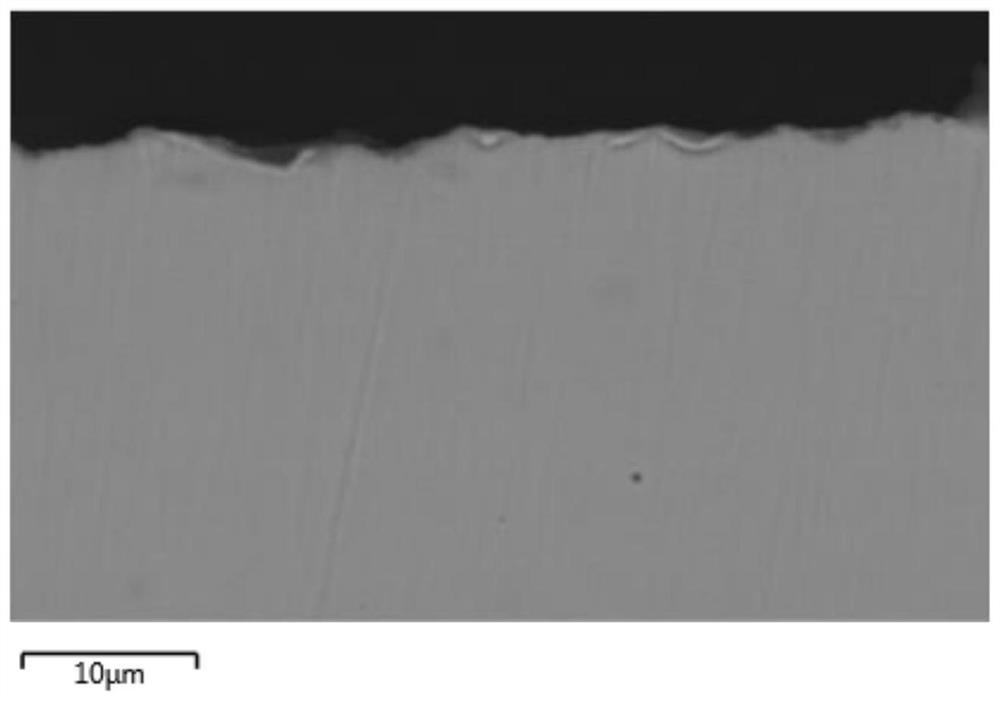

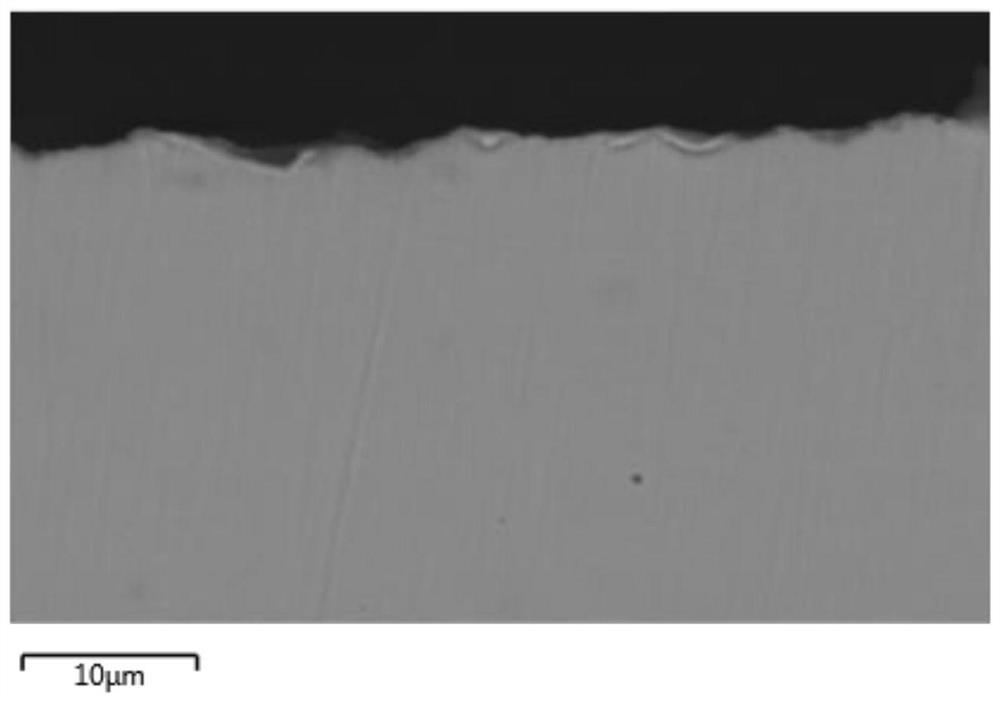

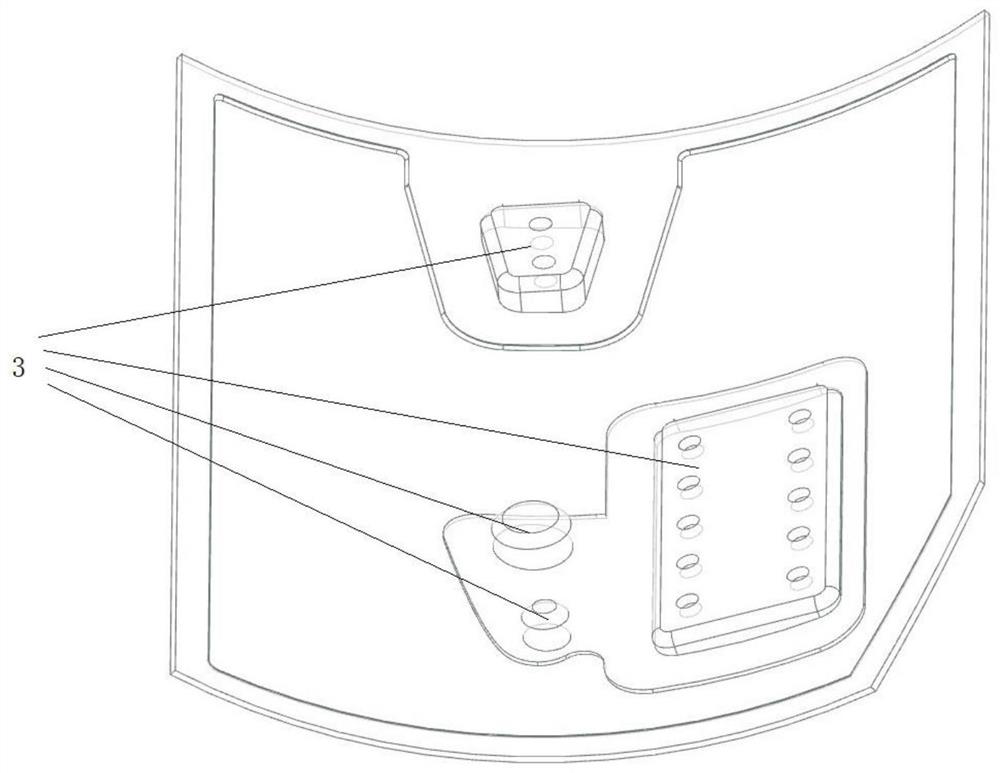

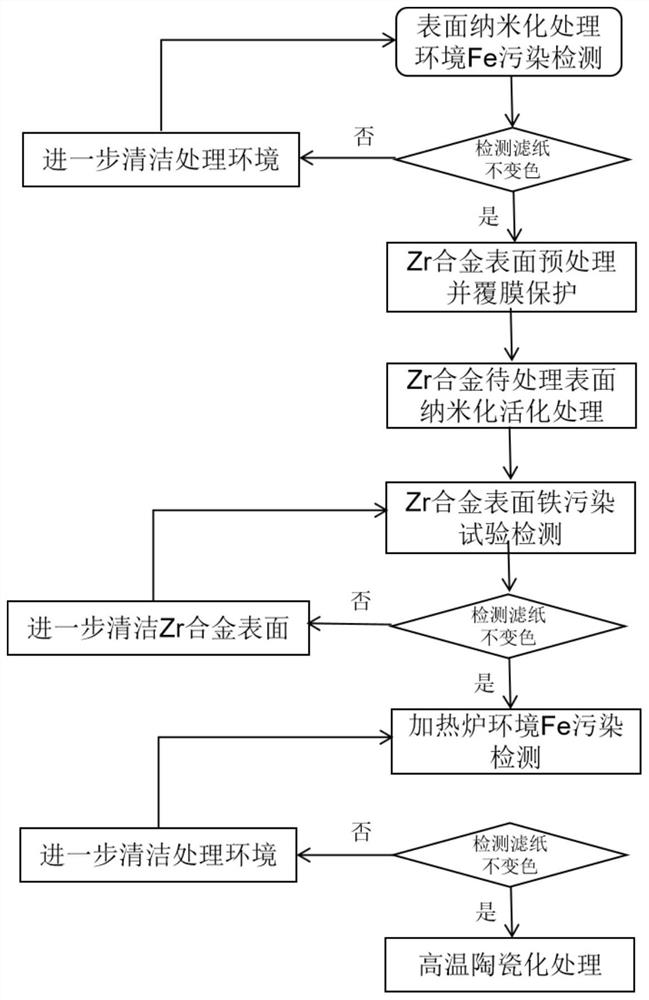

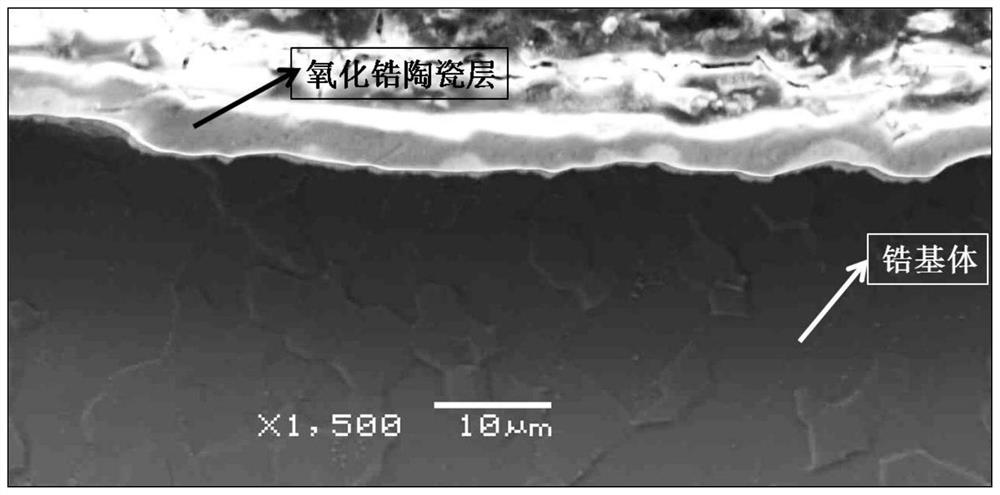

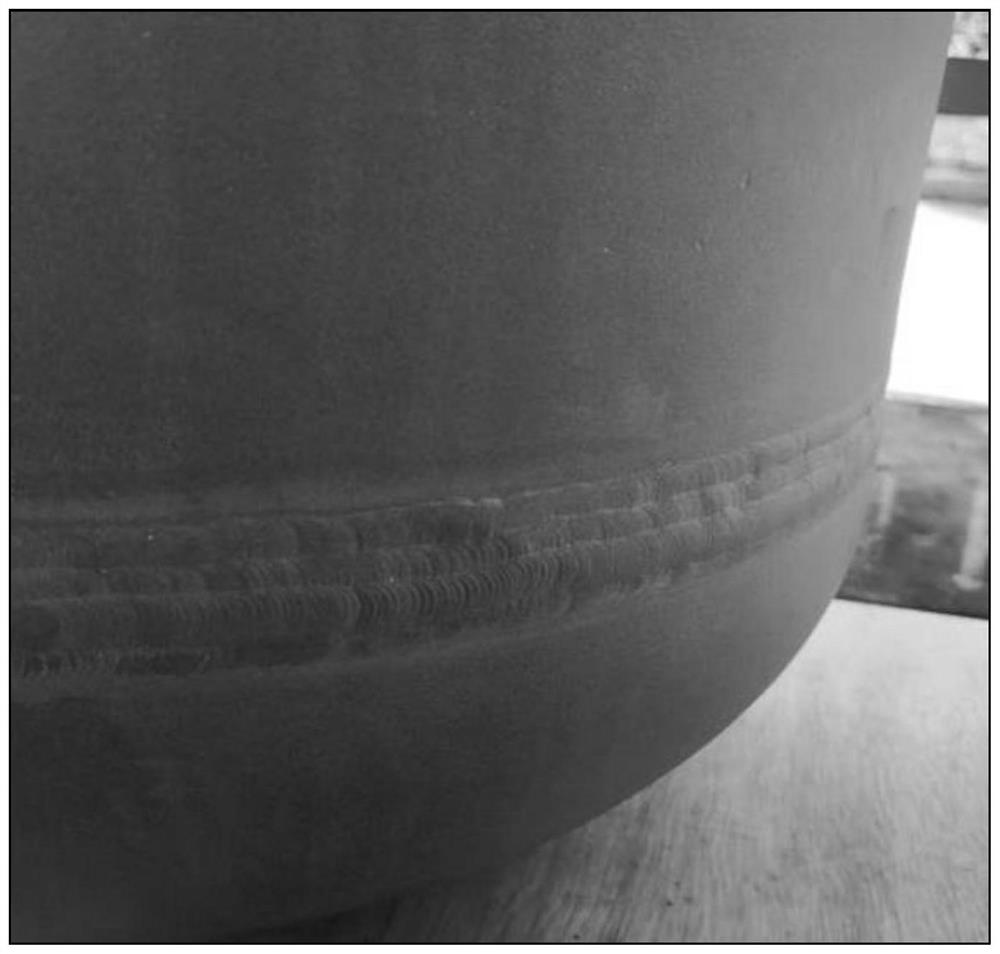

Zirconium-based material surface in-situ ceramization composite treatment method

PendingCN112853255AImprove stress distributionPromotes grain refinementSolid state diffusion coatingCeramic compositeMetallic materials

The invention discloses a zirconium-based material surface in-situ ceramization composite treatment method. The method comprises the following steps: 1, detecting Fe pollution in a surface nanocrystallization treatment environment; 2, pretreating the surface of a zirconium-based material; 3, carrying out surface nanocrystallization treatment on the zirconium-based material; 4, detecting Fe pollution of the zirconium-based material subjected to nanocrystallization treatment; 5, detecting Fe pollution in a heating equipment environment; and 6, performing high-temperature ceramic treatment. The smooth and uniform zirconium-based material processing surface is obtained through nanocrystallization treatment, the stress distribution state of the surface of the zirconium-based material is improved, grain refinement of the surface of the zirconium-based material is promoted, then a complete and compact in-situ ceramic composite treatment layer is formed in combination with high-temperature ceramic treatment, the corrosion resistance and the wear resistance of the surface of the zirconium-based material are improved, the comprehensive service performance of the metal material is greatly improved, and structural function integration of the metal material is effectively achieved.

Owner:XIAN UNITED PRESSURE VESSEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com