Steel, preparation method and application thereof

A manufacturing method and steel technology, applied in the field of alloy steel manufacturing, can solve the problems of resistance to sulfide stress corrosion, resistance to microbial corrosion, and inability to meet high strength at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

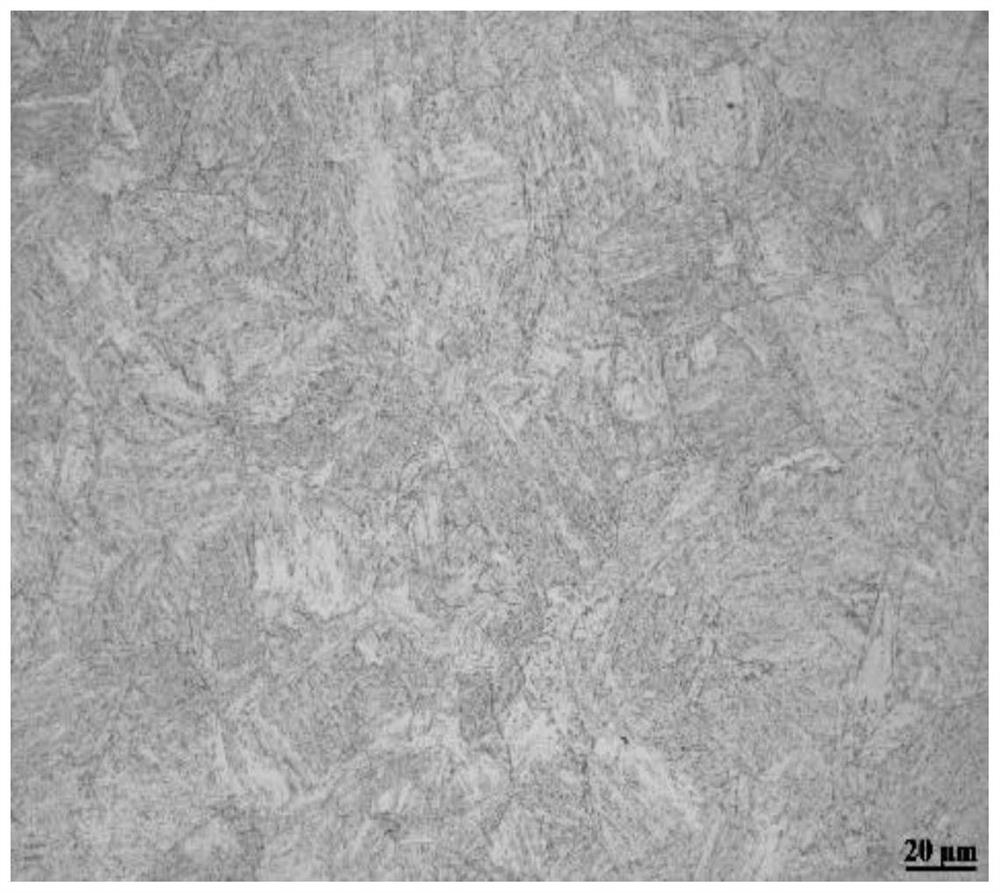

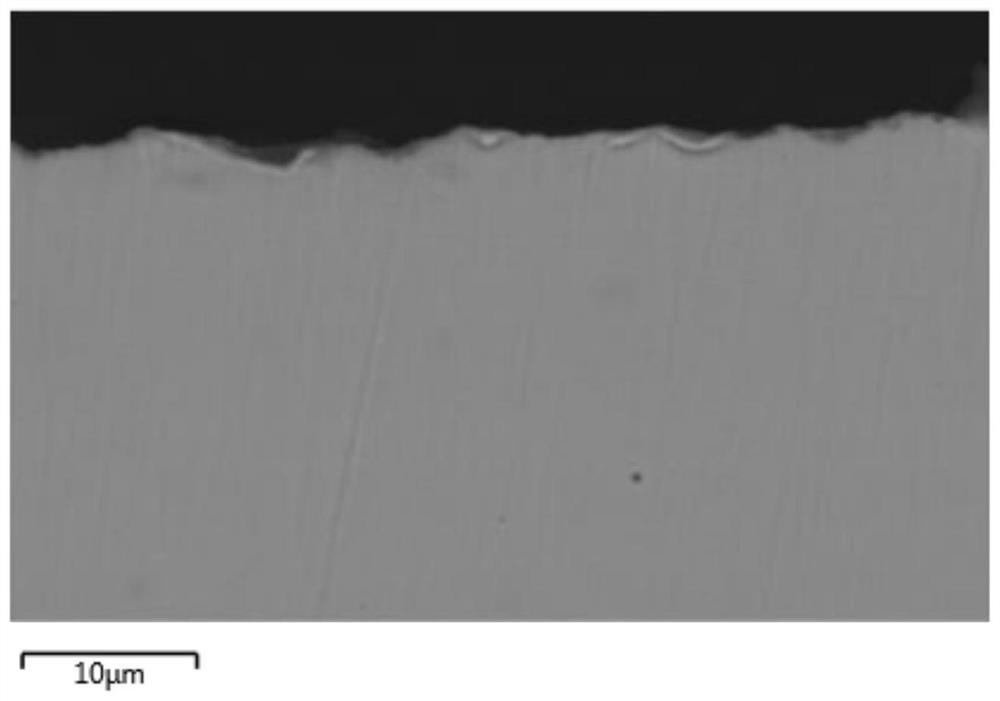

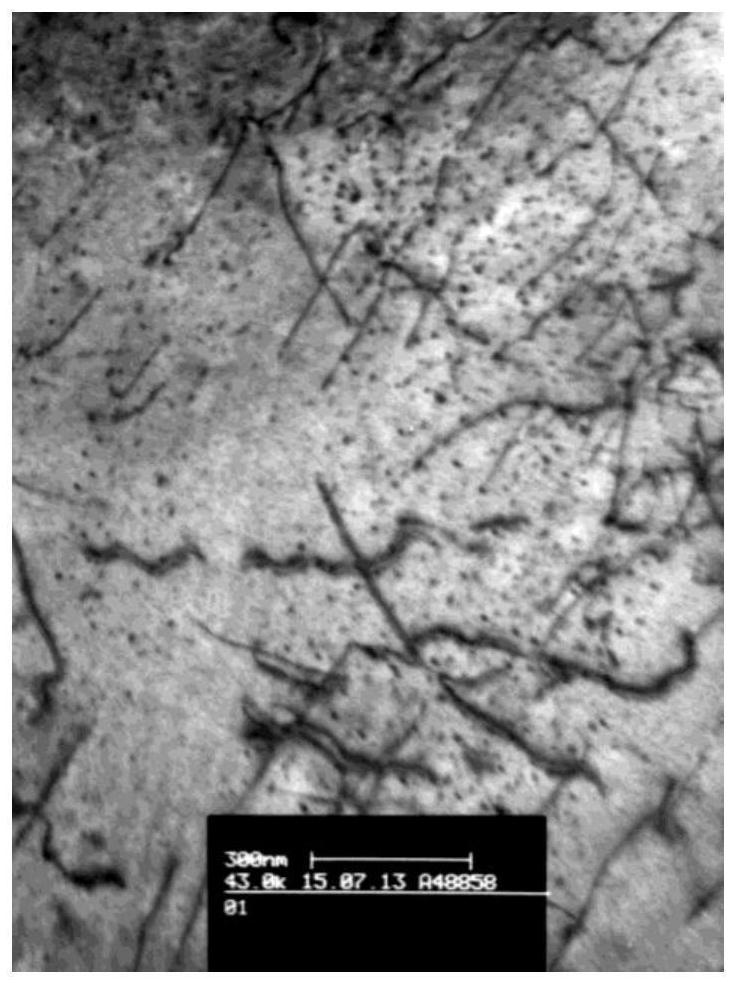

Image

Examples

Embodiment 1

[0046] In terms of weight percentage, the chemical composition of steel is: C 0.091%, Si 0.24%, Mn 0.51%, Cu0.92%, Al 0.32%, Ce 0.12%, Cr 1.0%, Mo 0.82%, Nb 0.004%, V 0.20 %, Ti 0.001%, N 0.003%, S 0.001%, P 0.002%, O 0.002%, Ca 0.005%, and the balance is Fe. Wherein, the sum of the content of Cu element, Al element and Ce element is 1.36%.

Embodiment 2

[0048] In terms of weight percentage, the chemical composition of steel is: C 0.14%, Si 0.21%, Mn 0.50%, Cu 0.93%, Al 0.42%, Ce 0.15%, Cr 1.0%, Mo 0.85%, Nb 0.003%, V 0.005% , Ti 0.002%, N0.005%, S 0.001%, P 0.002%, O 0.004%, B 0.001%, and the balance is Fe. Wherein, the sum of the contents of Cu element, Al element and Ce element is 1.50%.

Embodiment 3

[0050] In terms of weight percentage, the chemical composition of steel is: C 0.097%, Si 0.22%, Mn 0.59%, Cu1.17%, Al 0.22%, Ce 0.13%, Cr 1.02%, Mo 0.80%, V 0.10%, N 0.004 %, S 0.001%, P 0.002%, O 0.003%, B 0.001%, and the balance is Fe. Wherein, the sum of the content of Cu element, Al element and Ce element is 1.52%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com