A method for preparing carbon fiber and graphene composite paper

A graphene composite and carbon fiber technology, which is applied in the direction of synthetic cellulose/non-cellulose material pulp/paper, fiber raw material processing, papermaking, etc., can solve the problem of toughness and cleanliness requirements of thermal interface materials, graphene paper, etc. Poor mechanical strength, high economic cost, etc., to achieve the effect of abundant raw material sources, elimination of local hot spots, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

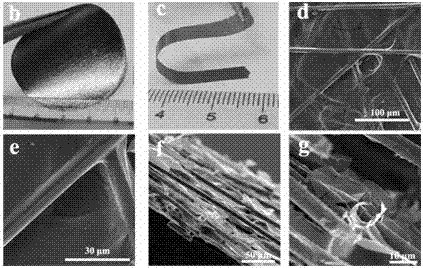

Image

Examples

Embodiment 1

[0025] (1) Polyacrylonitrile-based carbon fiber with a length of 10mm is used as the skeleton matrix, mixed with polyvinyl alcohol and deionized water to prepare a suspension, carbon fiber: polyvinyl alcohol = 1:1 (mass ratio), (carbon fiber + polyvinyl alcohol) Vinyl alcohol): deionized water = 1:4000 (mass ratio), and then wet-processed to prepare the carbon fiber precursor matrix;

[0026] (2) Ultrasonicate the graphite oxide prepared by the Hummers method in water, the ultrasonic time is 30min, the ultrasonic power is 100W, and a graphene oxide solution with a concentration of 4mg / mL is prepared, and the graphene oxide: carbon fiber precursor matrix = 8 : 1 (mass ratio), the graphene oxide solution and the carbon fiber precursor matrix are subjected to vacuum filtration deposition and compounding to obtain carbon fiber and graphene oxide composite paper;

[0027] (3) Treat carbon fiber and graphene oxide composite paper at 1000°C for 3 hours under hydrogen protection to ob...

Embodiment 2

[0030] (1) The pitch-based carbon fiber with a length of 0.1 mm is used as the skeleton matrix, mixed with water-soluble phenolic resin and deionized water to form a suspension, carbon fiber: phenolic resin = 10:1 (mass ratio), (carbon fiber + Phenolic resin): deionized water = 1:8000 (mass ratio), and then wet-processed to prepare the carbon fiber precursor matrix;

[0031] (2) Ultrasonicate the graphite oxide produced by the electrochemical oxidation method in deionized water, the ultrasonic time is 60min, and the ultrasonic power is 120W, to obtain a graphene oxide solution with a concentration of 0.1mg / mL, and follow the graphene oxide: carbon fiber Precursor matrix = 5:1 ratio (mass ratio), the graphene oxide solution and the carbon fiber precursor matrix are coated and compounded to obtain carbon fiber and graphene oxide composite paper;

[0032] (3) Carbon fiber and graphene oxide composite paper was treated at 2000°C under argon protection for 7 hours to obtain carbon ...

Embodiment 3

[0035] (1) Use viscose-based carbon fiber with a length of 20mm as the skeleton matrix, mix it with pulp and deionized water to make a suspension, carbon fiber: pulp = 1:10 (mass ratio), (carbon fiber + pulp): go Ionized water = 1:1000 (mass ratio), and then wet-processed to prepare the carbon fiber precursor matrix;

[0036](2) Ultrasonicate the graphite oxide produced by the electrochemical oxidation method in deionized water, the ultrasonic time is 10min, and the ultrasonic power is 300W, to obtain a graphene oxide solution with a concentration of 10mg / mL, and follow the graphene oxide: carbon fiber precursor Body matrix = 1:20 (mass ratio), the graphene oxide solution and the carbon fiber precursor matrix are coated and compounded, and the number of coatings is 5 times to obtain a carbon fiber and graphene oxide composite paper;

[0037] (3) Treat carbon fiber and graphene oxide composite paper at 2500°C for 10 hours under vacuum protection to obtain carbon fiber and graph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com