Multifunctional multi-stage nanocone array structure coating with multi-band stealth and super-hydrophobic characteristics and preparation method of multifunctional multi-stage nanocone array structure coating

A multi-functional coating and nano-array technology, applied in coatings, radiation-absorbing coatings, camouflage coatings, etc., can solve the problem of inability to effectively achieve multi-band stealth performance and hydrophobic performance, energy sources that do not meet the development trend of energy conservation and environmental protection, coating The layer does not have the self-deicing ability and other problems, and achieves good microwave absorption performance, accelerated deicing efficiency, and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

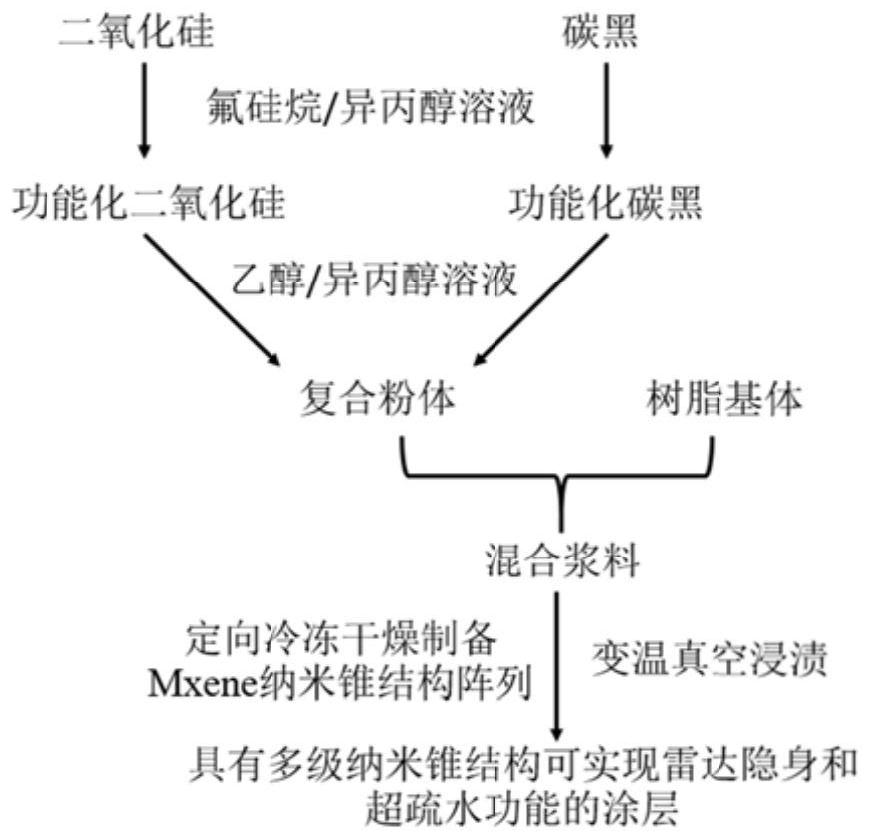

[0039] A multi-functional multi-level nanocone array structure coating with multi-band stealth and super-hydrophobic properties and a preparation method thereof, comprising the following steps:

[0040] (1) Take the metal material as the base material, and cut the base material into a square with a side length of 5cm, and use an alcohol solution with a concentration of 50% to clean the surface of the base material, and dry it for later use;

[0041] (2) Spread the MXene aqueous solution with a monolayer diameter of less than 500 nm with a molar concentration of 5% on the surface of the substrate, use a mold to control the thickness of the aqueous solution, remove water by directional freeze-drying technology, and retain the MXene self-assembly to form a nanocone structure array. Height 30μm;

[0042] (3) The nano-carbon black and nano-silica powder are respectively subjected to surface functionalization treatment in a fluorosilane / isopropanol solution with a molar concentratio...

Embodiment 2

[0047] A multi-functional multi-level nanocone array structure coating with multi-band stealth and super-hydrophobic properties and a preparation method thereof, comprising the following steps:

[0048] (1) Take the polymer material as the base material, and cut the base material into a square with a side length of 5cm, and use an alcohol solution with a molar concentration of 50% to clean the surface of the base material, and dry it for later use;

[0049] (2) Spread the MXene aqueous solution with a monolayer diameter of less than 500 nm with a molar concentration of 10% on the surface of the substrate, control the thickness of the aqueous solution with a mold, remove water by directional freeze-drying technology, and retain the self-assembly of MXene to form a nanocone structure array. Height 30μm;

[0050] (3) The nano-carbon black and nano-silica powder are respectively subjected to surface functionalization treatment in a fluorosilane / isopropanol solution with a molar co...

Embodiment 3

[0055] A multi-functional multi-level nanocone array structure coating with multi-band stealth and super-hydrophobic properties and a preparation method thereof, comprising the following steps:

[0056] (1) Take two materials of metal and polymer as the base material respectively, and cut the base material into a square with a side length of 5cm, and use an alcohol solution with a molar concentration of 50% to clean the surface of the base material, and dry it for later use;

[0057] (2) Spread the MXene aqueous solution with a monolayer diameter of less than 500 nm with a molar concentration of 7% on the surface of the substrate, control the thickness of the aqueous solution with a mold, remove water by directional freeze-drying technology, and retain the MXene self-assembly to form a nanocone structure array. Height 30μm;

[0058] (3) The nano-carbon black and nano-silica powder are respectively subjected to surface functionalization treatment in a fluorosilane / isopropanol s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com