Patents

Literature

315results about "Sandwich constructions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

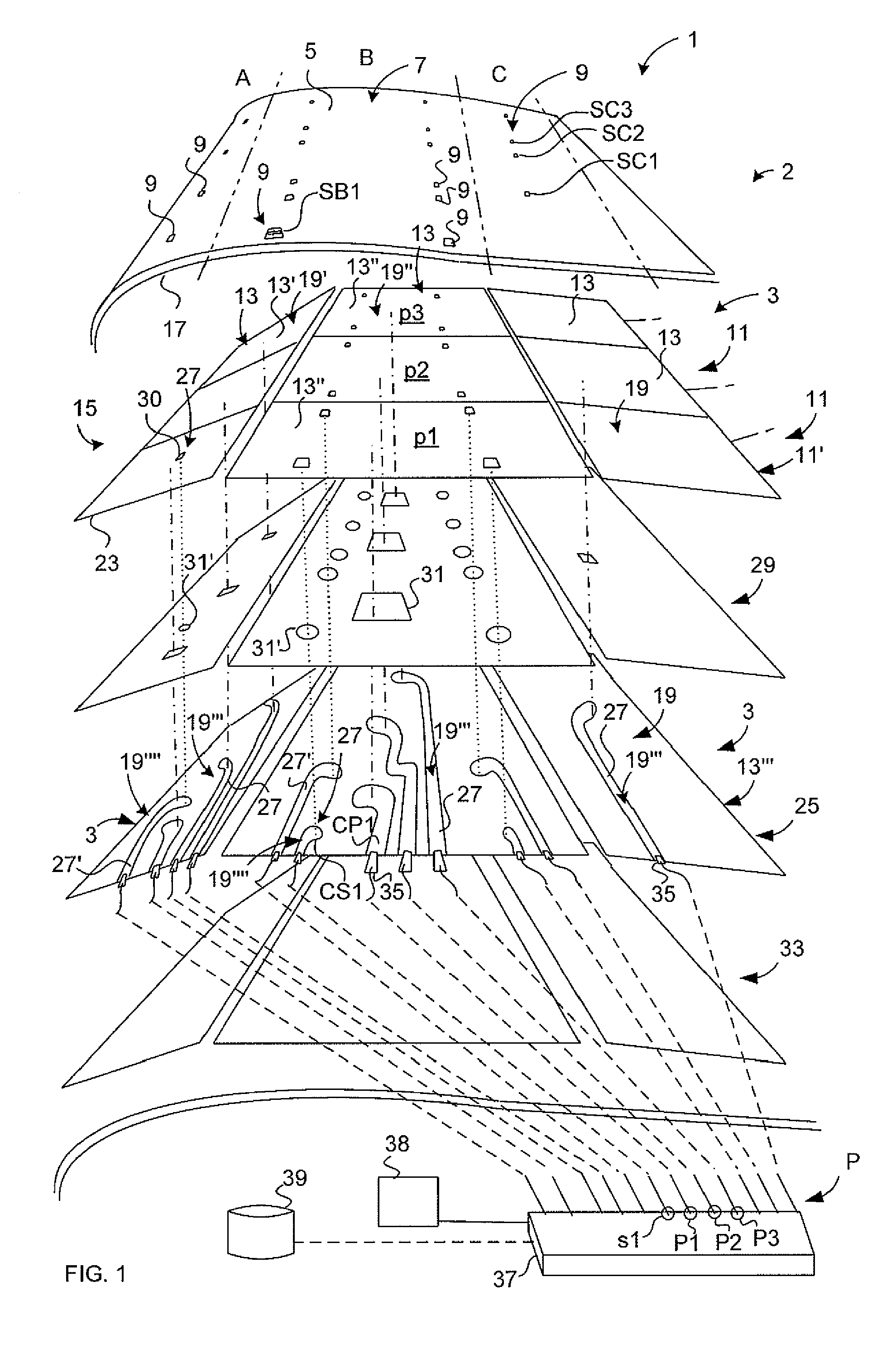

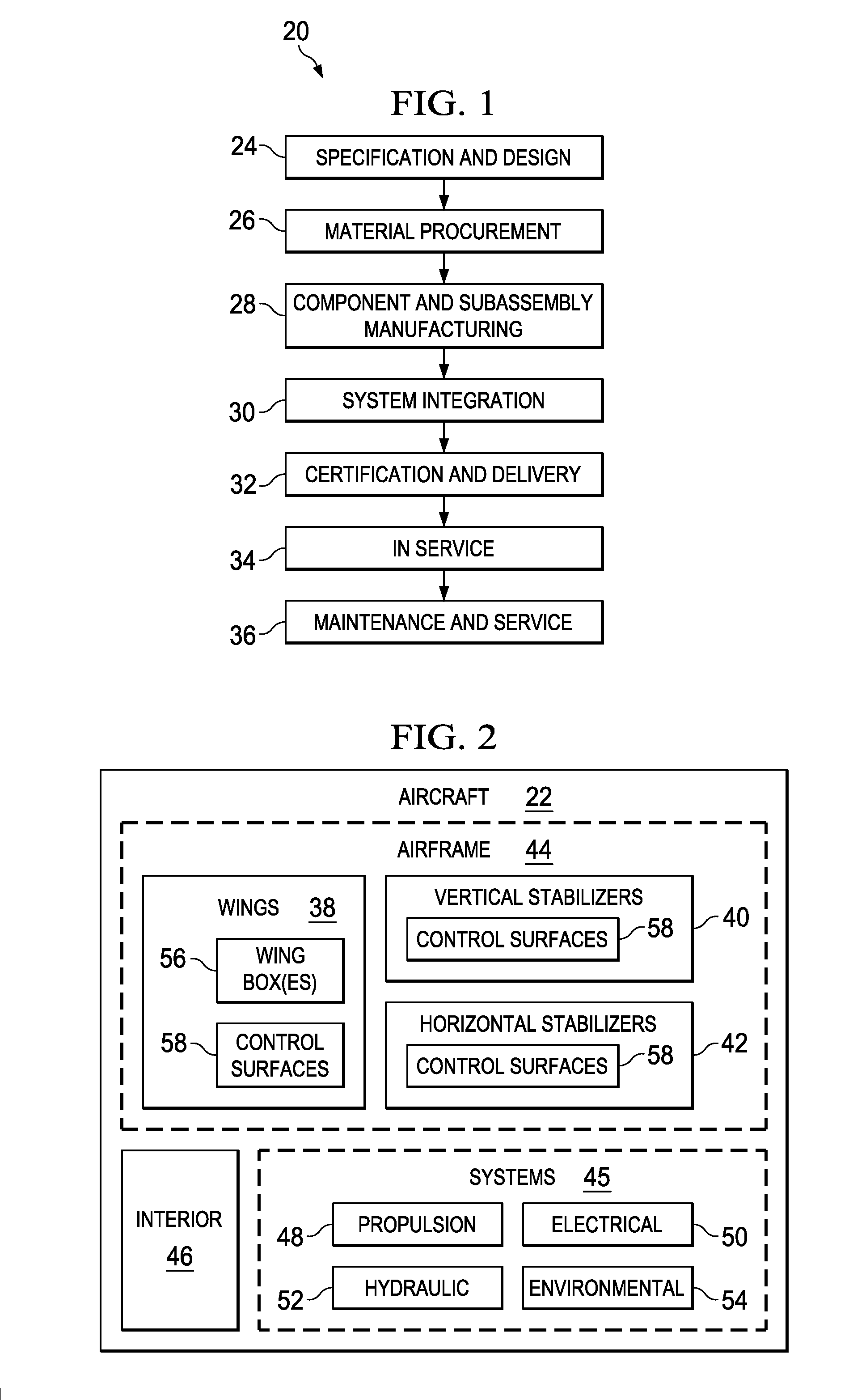

Monolithic composite wing manufacturing process

InactiveUS6190484B1Aircraft stabilisationPaper/cardboard wound articlesLeading edgeIncreased torsion

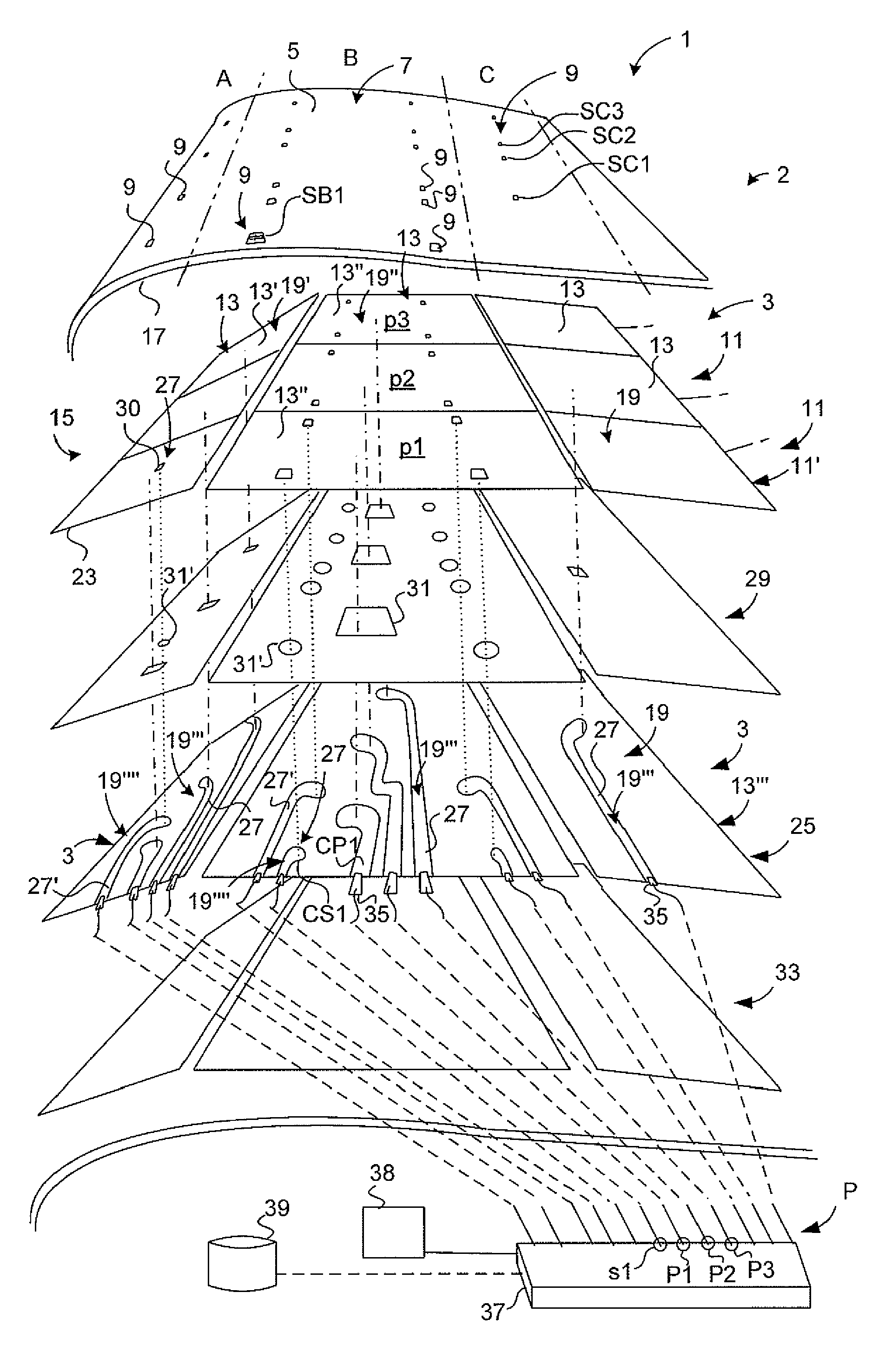

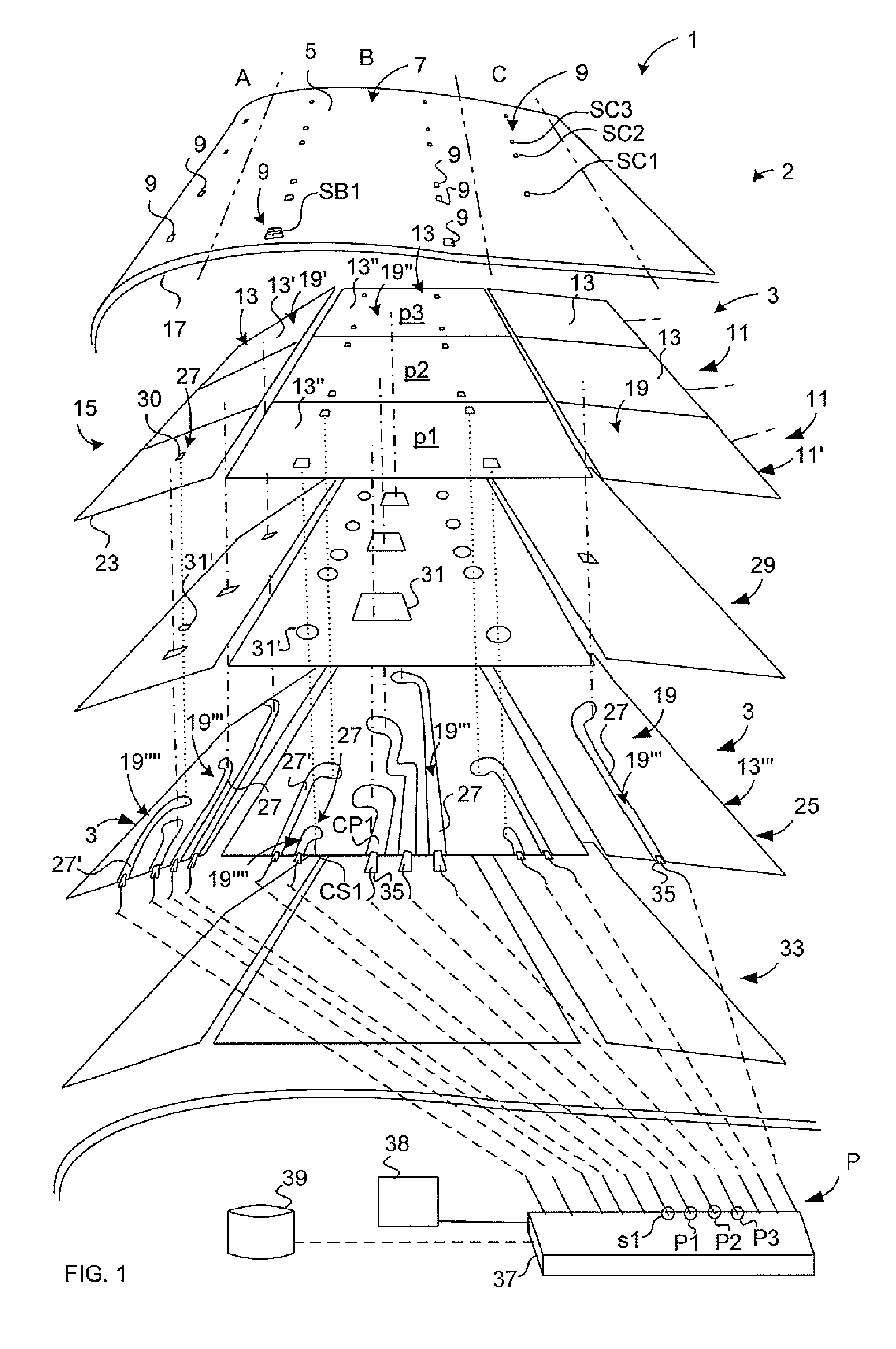

A method of manufacturing a monolithic composite wing without using mechanical fasteners is described. The process begins with the formation of a center wing box in combination with a pair of spars, riblets and a pair of skin-molds including the wrapping and binding of the box by means of resin impregnated composite tapes. Next, additional cells are adjoined contiguously on either side of the current framework and an overlap wrapping and bonding process is continued around the current framework. The overlap wrapping and binding procedure provides increased torsion stiffness and reduced structural weight. All cells up to the leading and trailing edges will be included in the assembly process. Conduits to convey fuel, hydraulic fluid and electrical wiring will also be installed in designated cells. Finally, the completed wing will be cured in an autoclave under uniform pressure and temperature.

Owner:APPA KARI

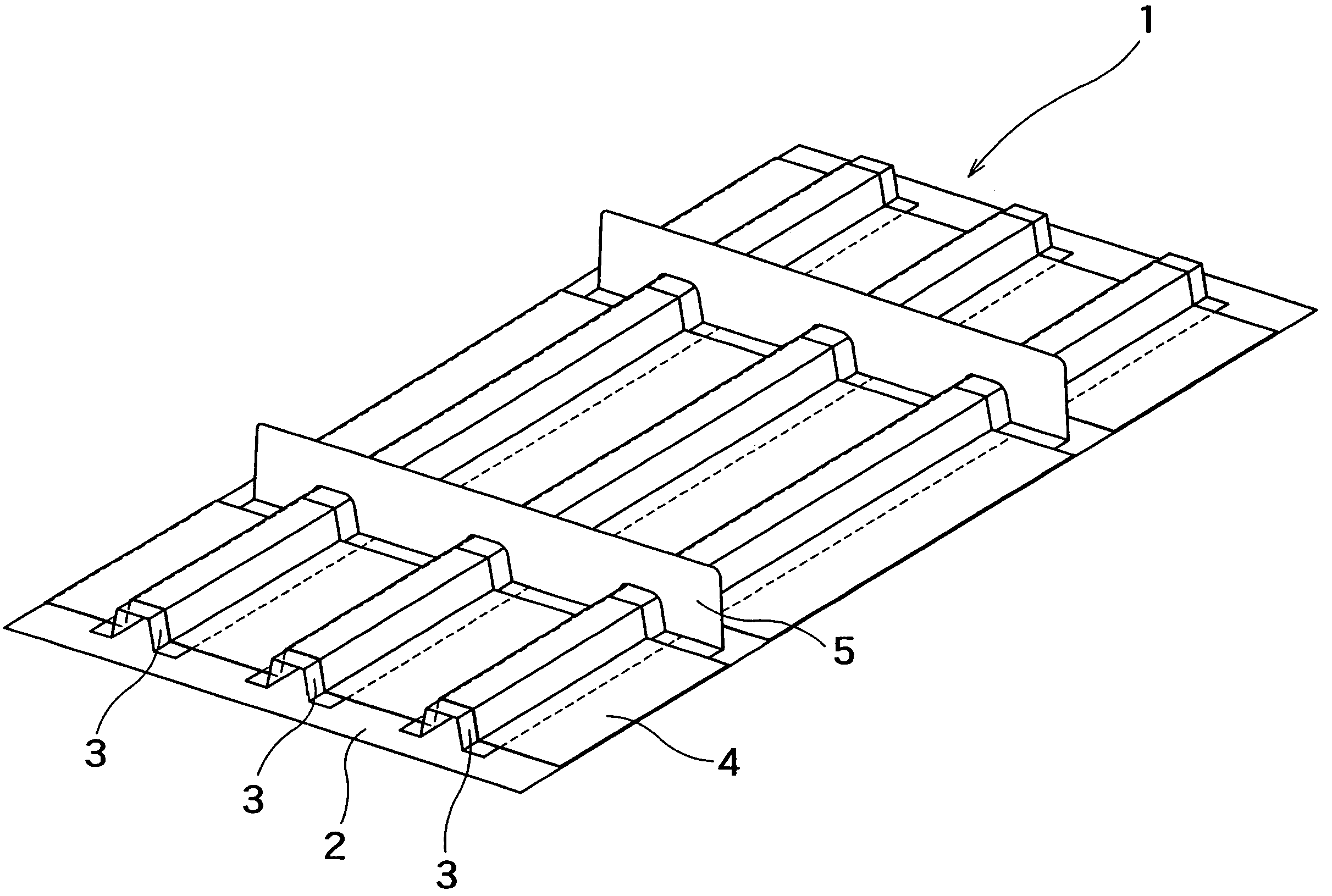

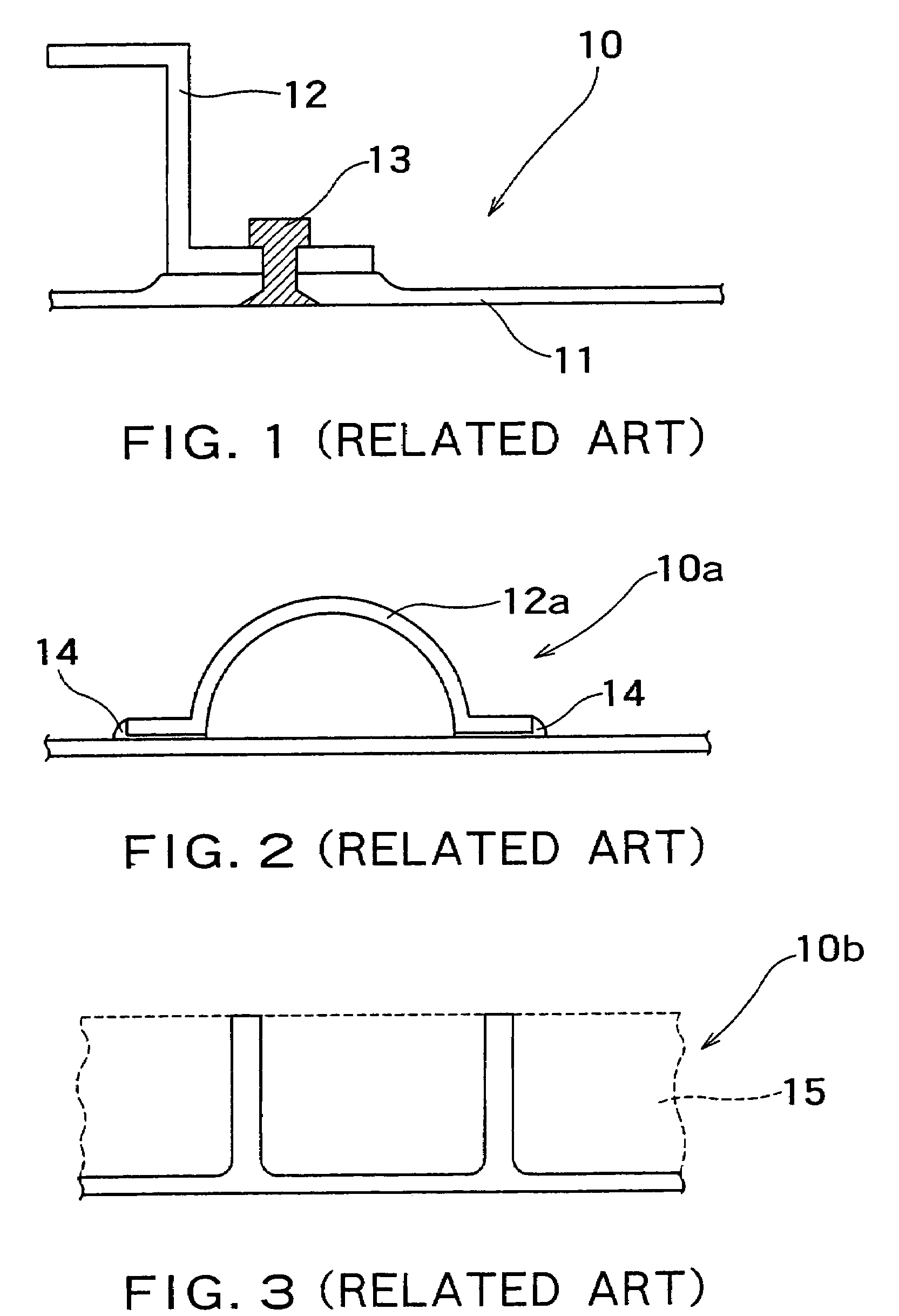

Composite material-stiffened panel and manufacturing method thereof

A composite material-stiffened panel has a skin obtained by molding a fiber-reinforced resin composite material into a flat skin, stiffeners arranged in rows on one surface of the skin, and a fiber-reinforced resin-composite material stitched on the skin covering the stiffeners. The composite material-stiffened panel can be manufactured as follows: A first fabric material is placed on a tool having a panel-shaped surface. Stiffeners are placed on the first fabric materials. A second fabric material is placed on the stiffeners to cover at least some of the stiffeners. The second fabric materials are reformed to match the shape of the stiffeners. The reformed second fabric material is stitched on the first fabric material along edges of the stiffeners. All the materials are covered with a bagging film for vacuum. Resin is infiltrated into the fabric materials by a RTM or a RFI method. The infiltrated resin is heated to be hardened.

Owner:SUBARU CORP

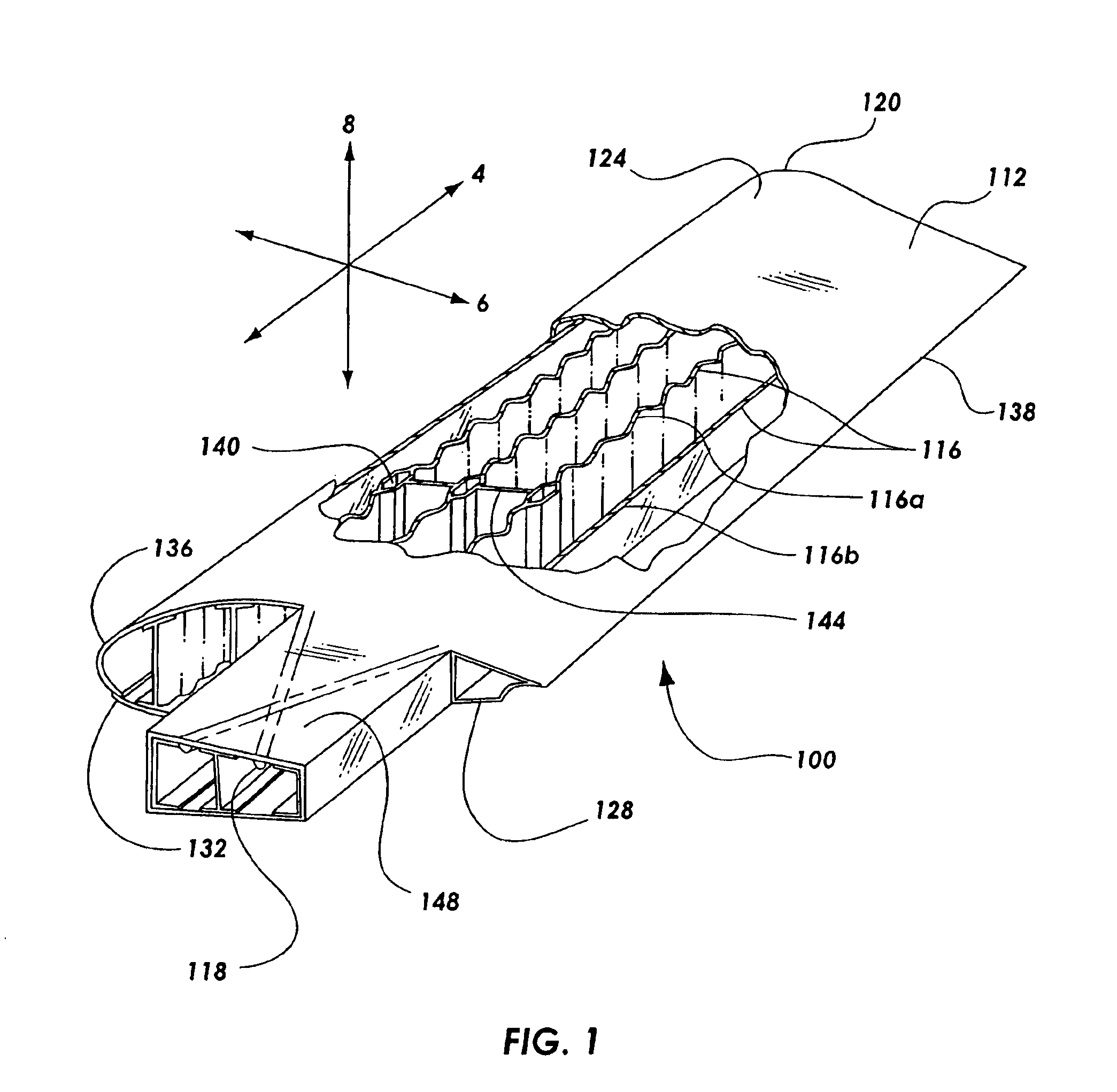

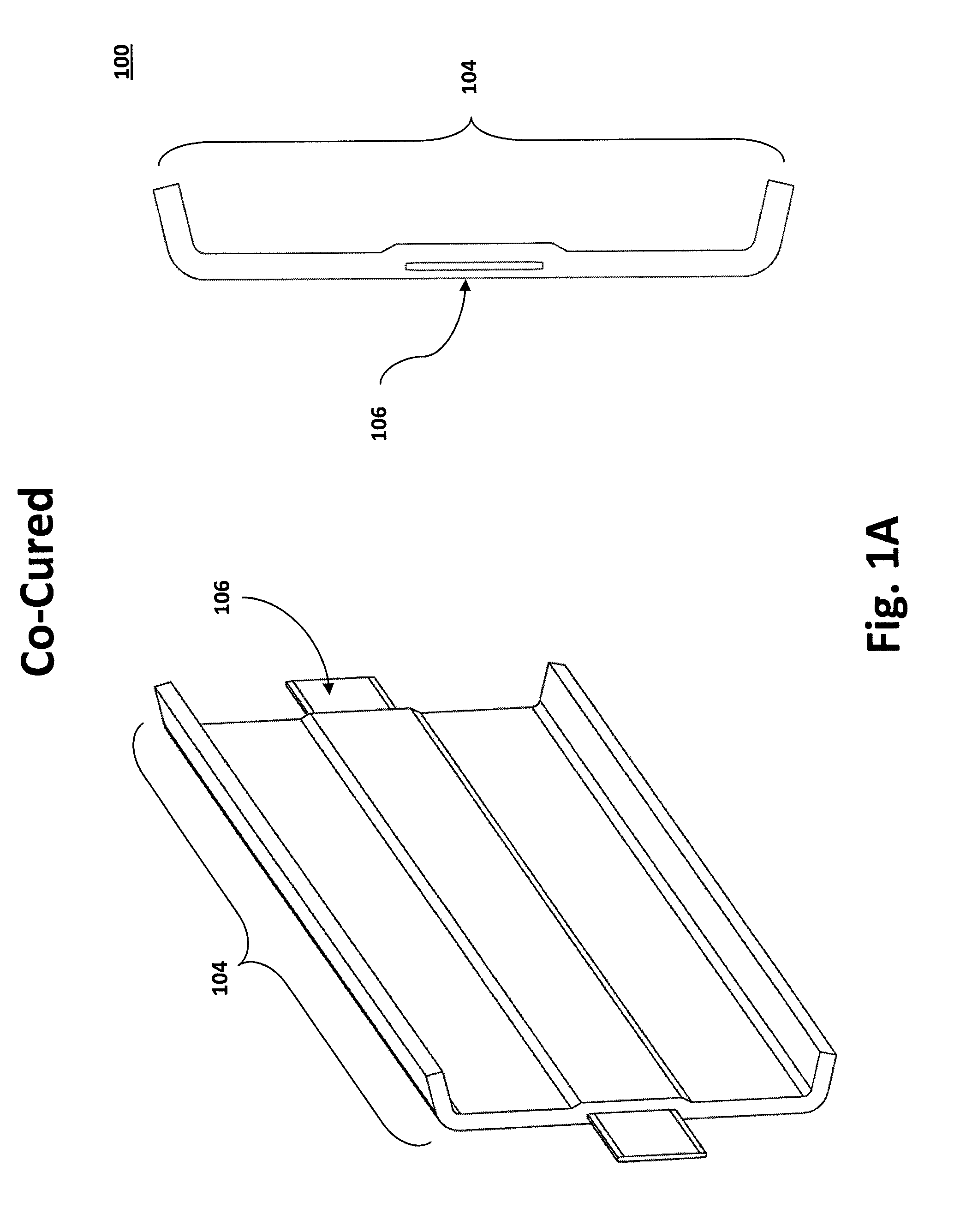

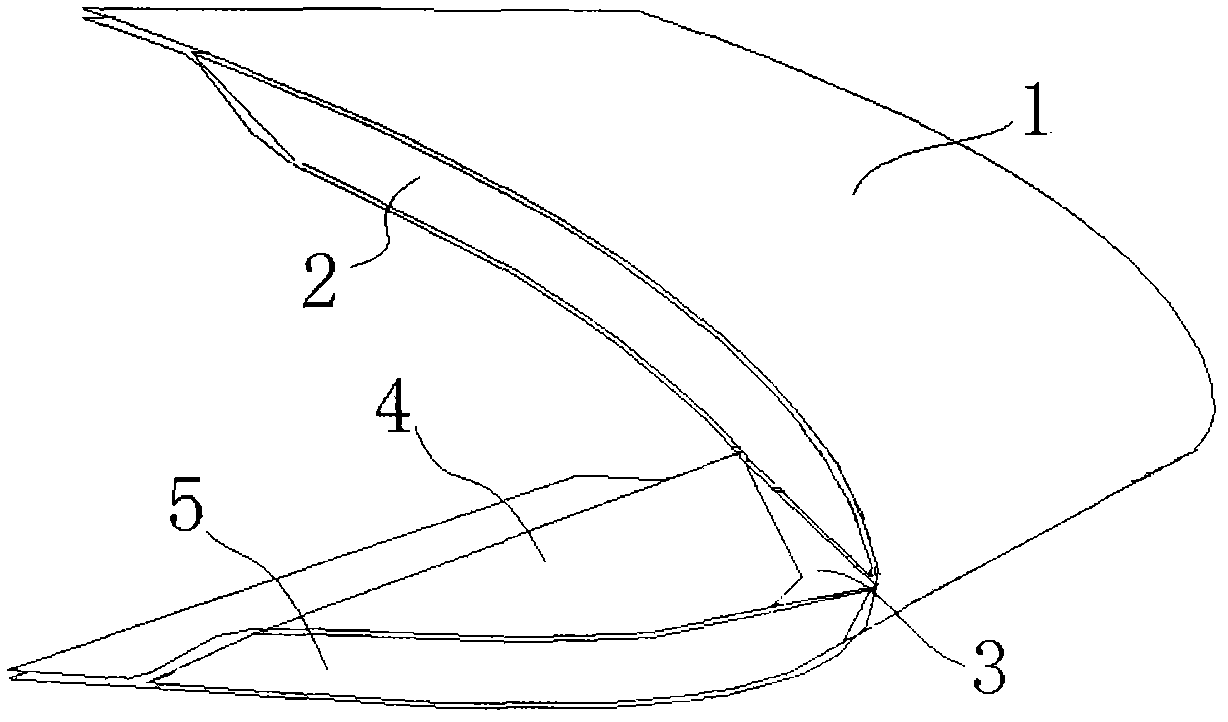

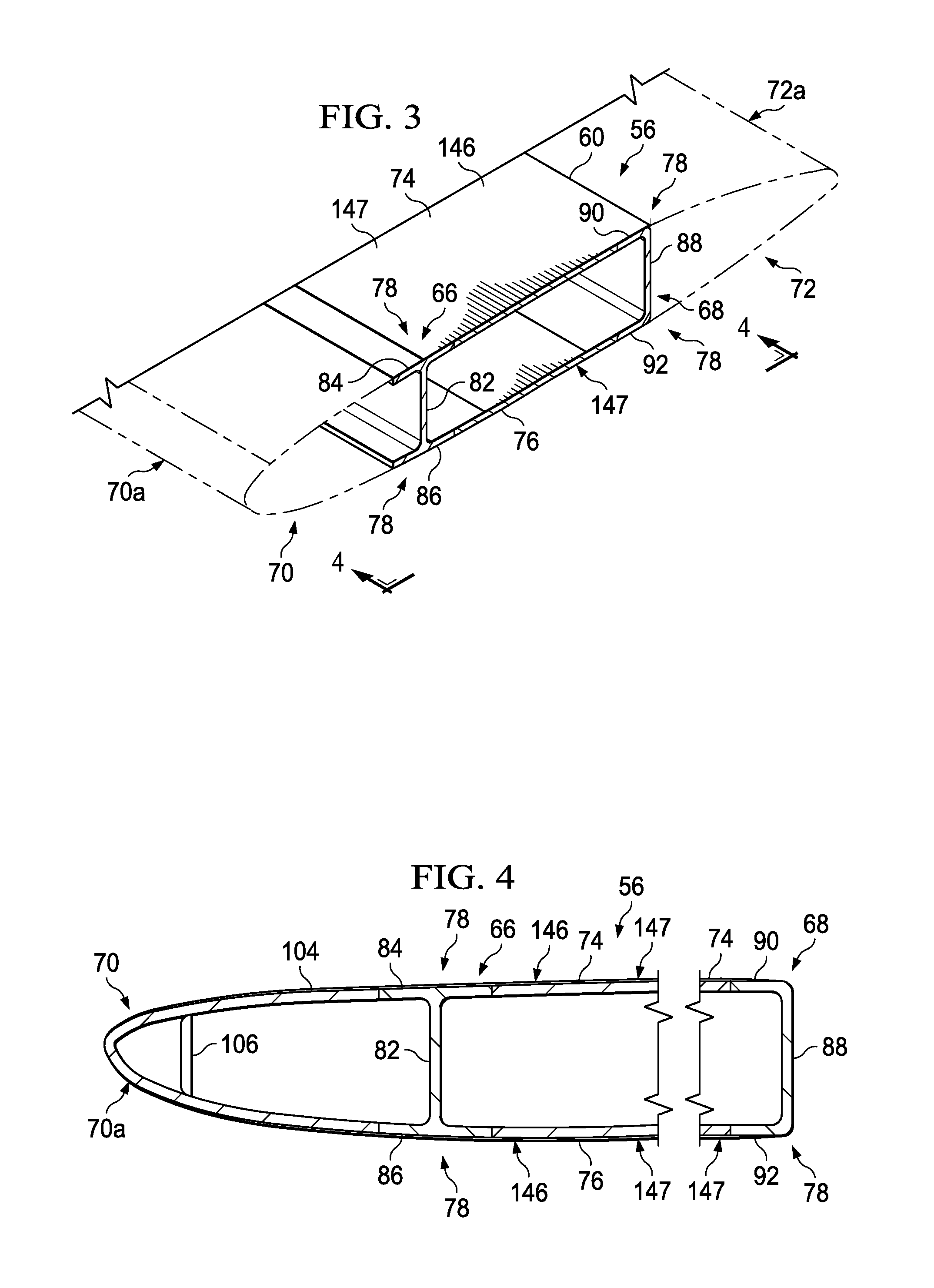

Single piece co-cure composite wing

InactiveUS20060249626A1Improve performanceImprove protectionAircraft stabilisationLayered productsWave shapeComposite wing

Owner:SPECTRUM AERONAUTICAL

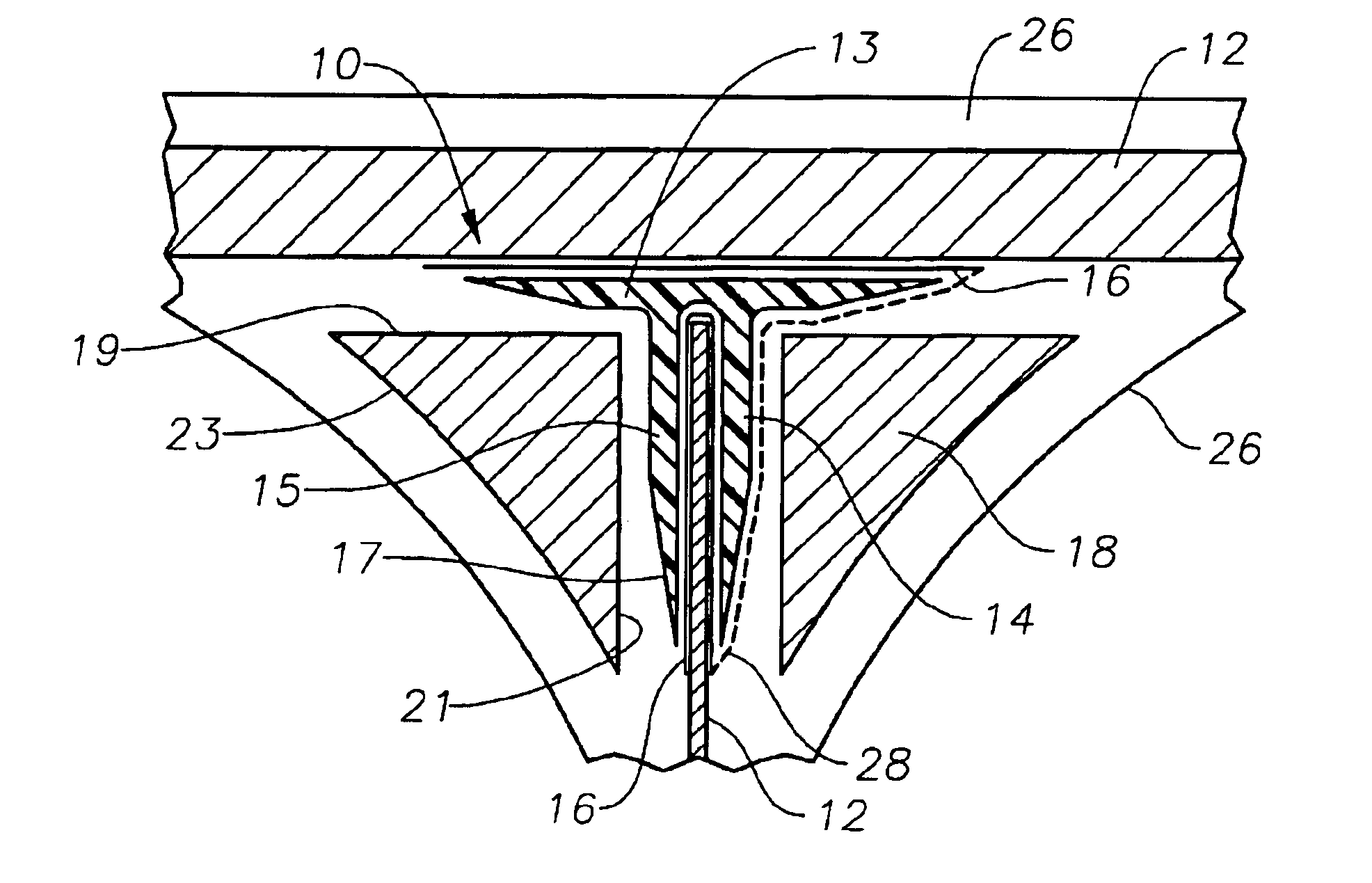

System and method of forming structural assemblies with 3-D woven joint pre-forms

InactiveUS6849150B1Improve structural strengthEliminate needFuselage framesCylinder headsAdhesiveEngineering

A system and method for forming structural assemblies with 3-D woven joint pre-forms. The method of the present invention forms complex structural assemblies with pre-formed structures. Adhesive is applied between the preformed structures and uncured 3-D woven textile pre-forms. Then together the preformed structures and uncured resin impregnated 3-D woven textile are cured with heat and / or pressure to form the larger complex structural assemblies.

Owner:LOCKHEED MARTIN CORP

Integral structural shell component for an aircraft and method of manufacturing the same

A structural panel component, such as an aircraft fuselage shell component, includes a single integral part having longitudinal and crosswise stiffening elements integrally arranged on a skin sheet. This integral component has been formed by a high speed milling chip removal process applied to a solid plate-shaped semi-finished starting material. The skin sheet has areas of differing thicknesses, and the height, thickness, and spacing of the stiffening elements varies as needed, depending on the local loading conditions that will prevail on the finished structural component. The configuration of the component can be optimized to minimize the weight while satisfying all load strength requirements. The manufacturing method is very simple and economical.

Owner:AIRBUS OPERATIONS GMBH

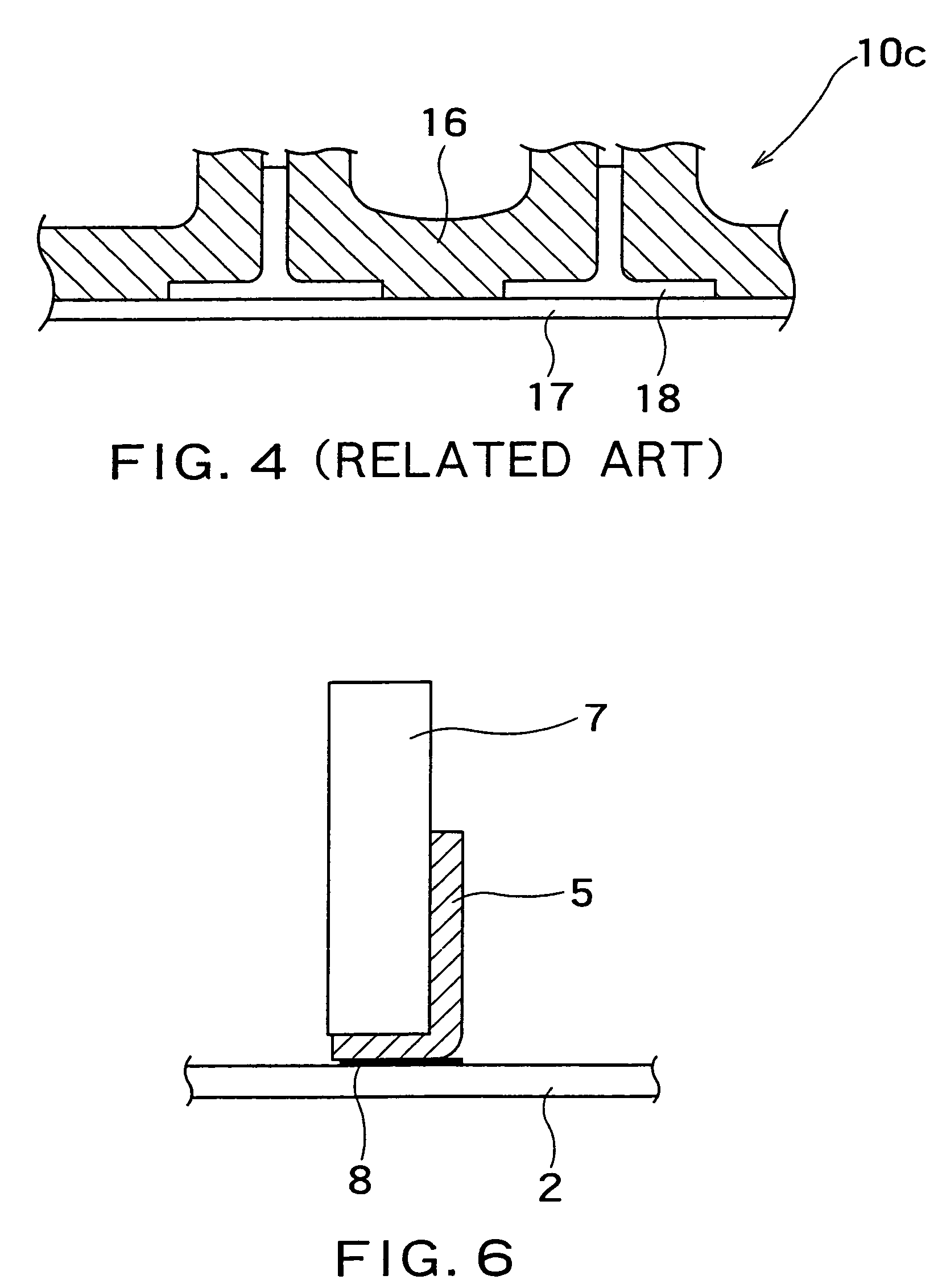

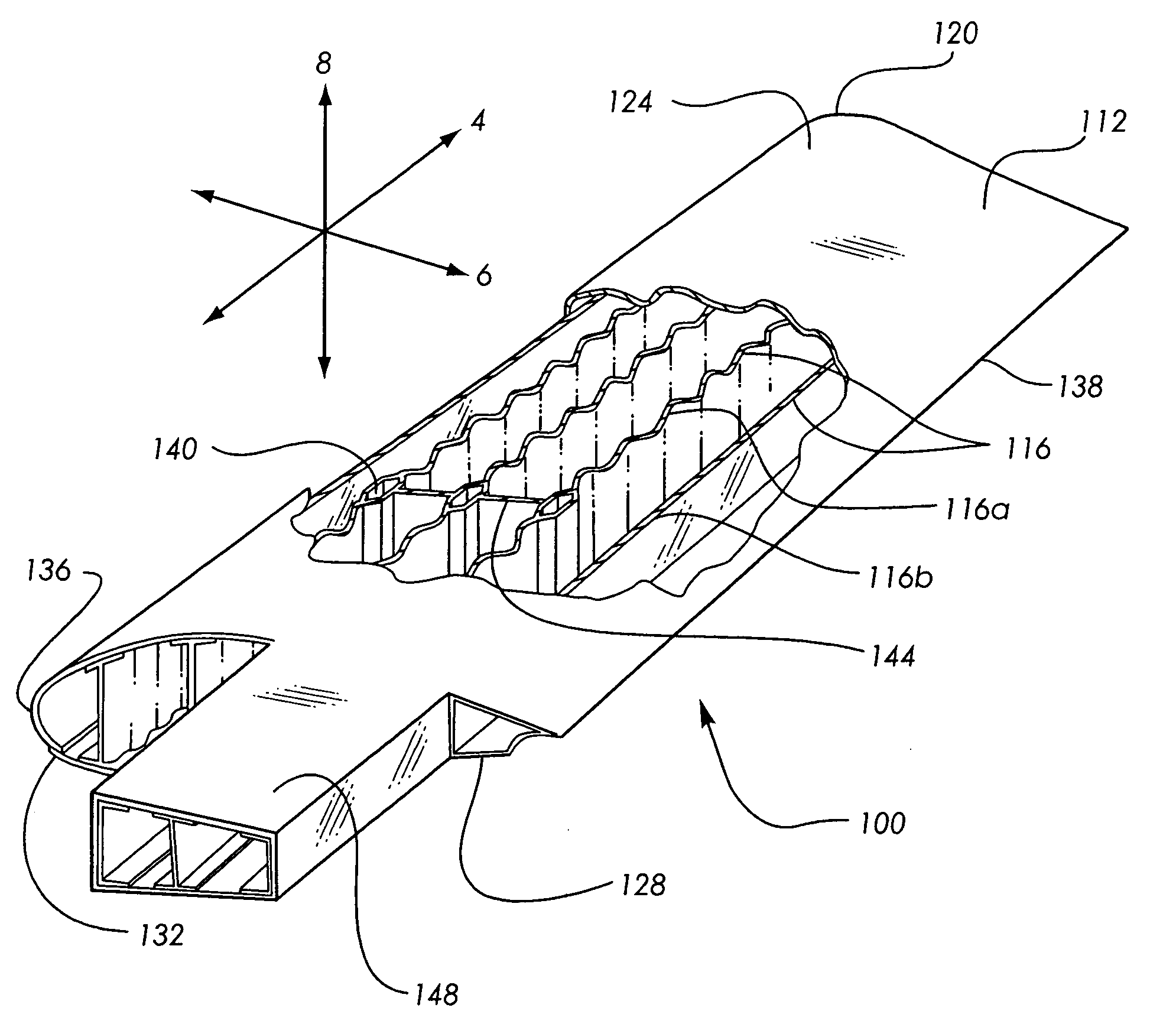

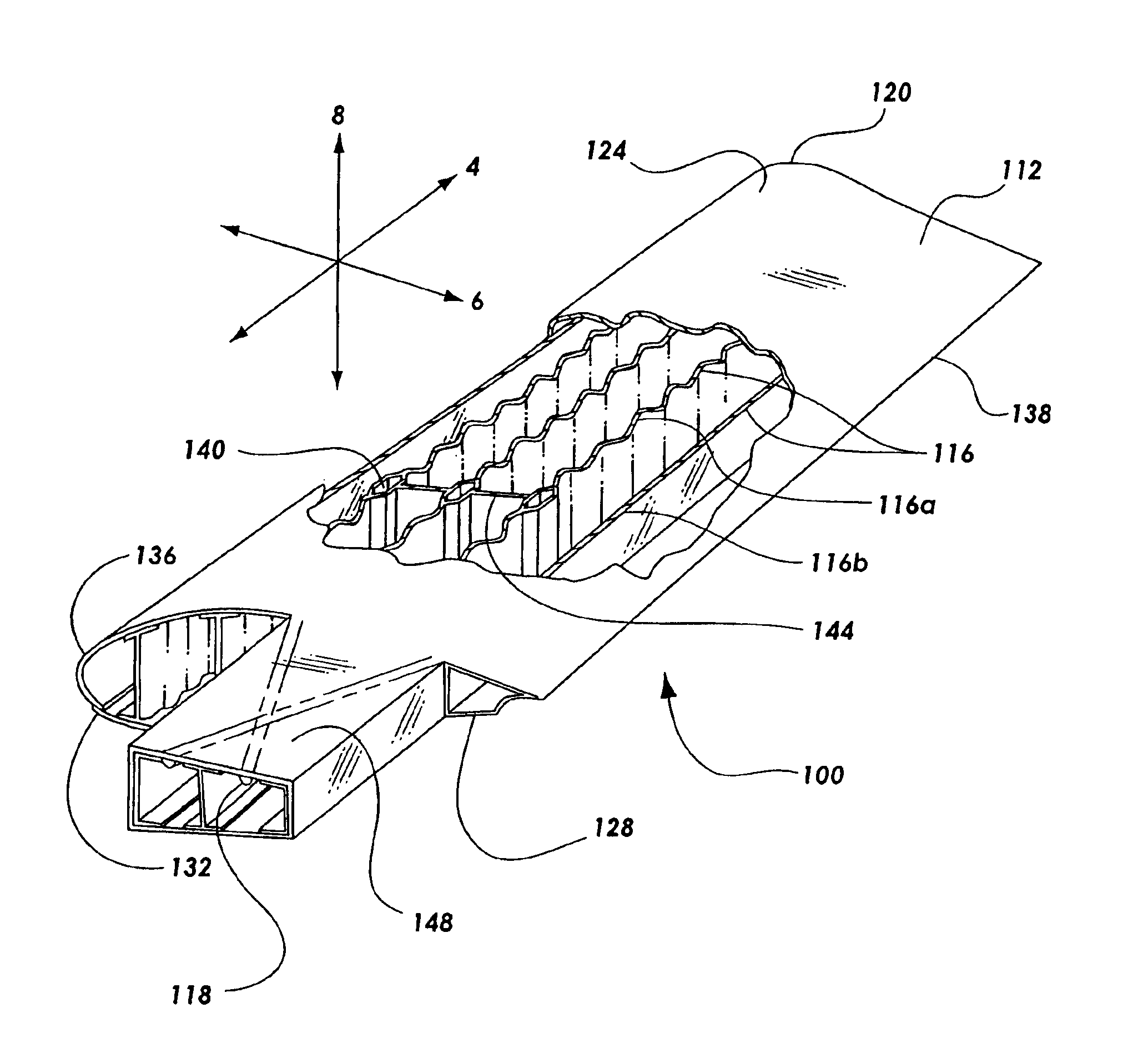

Single piece co-cure composite wing

InactiveUS6889937B2Easy to disassembleAircraft stabilisationOther chemical processesWave shapeComposite wing

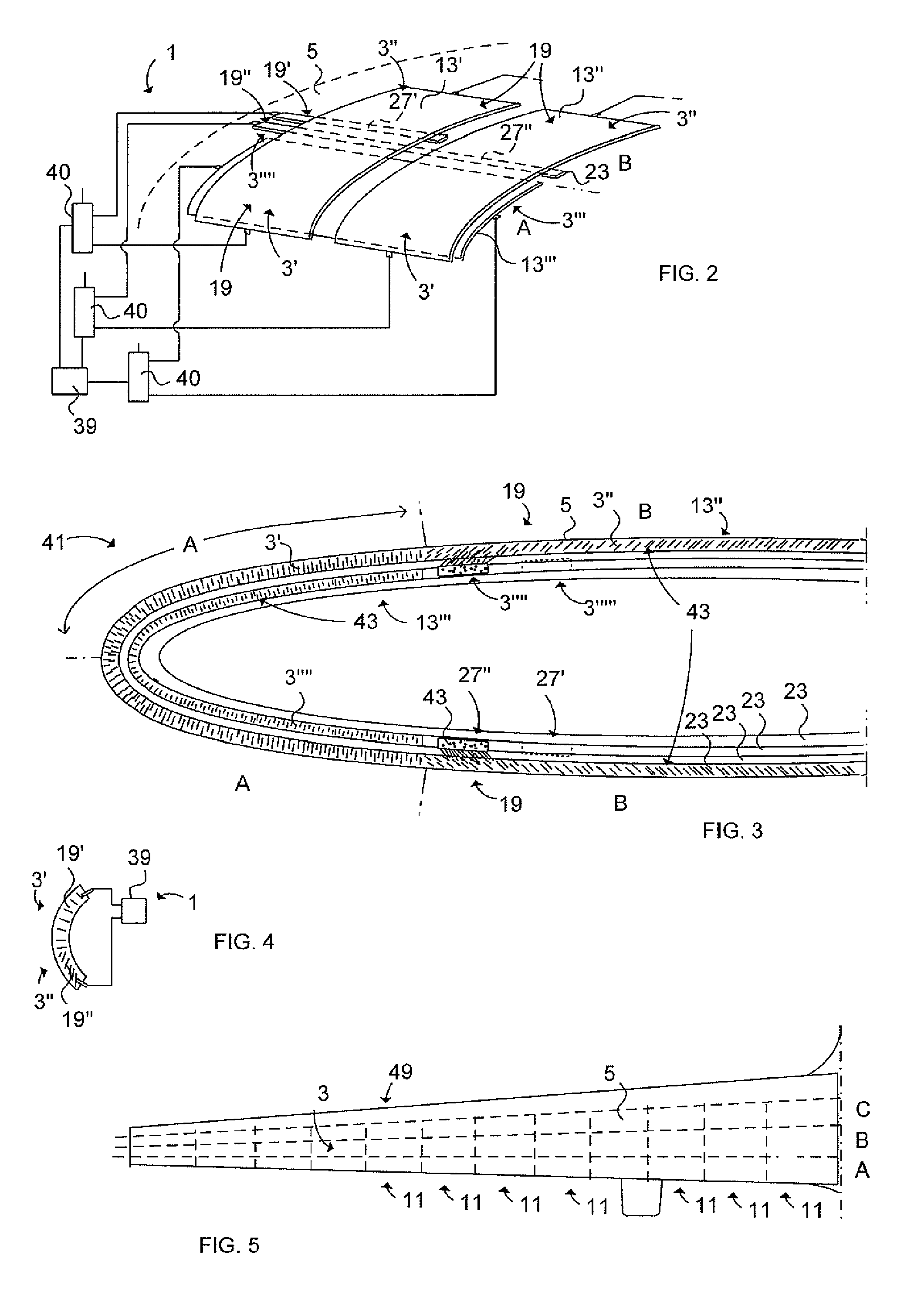

A single piece co-cured composite wing is disclosed. The wing has a flying surface and structural members. In one embodiment the structural members may be a plurality of spars. The spars may have various shapes to increase the buckling strength. The spars may be wave shaped, such as a sinusoidal shape. The flying surface and the structural members are co-cured in order to form a single piece, integral wing structure. A process for manufacturing a single piece co-cured wing is also disclosed. The process may include laying out composite sheets for the flying surface of the wing. Then, the composite material of the spars is arranged around a plurality of pressurizable forms. Finally, the composite material is cured in a clamshell frame.

Owner:SPECTRUM AERONAUTICAL

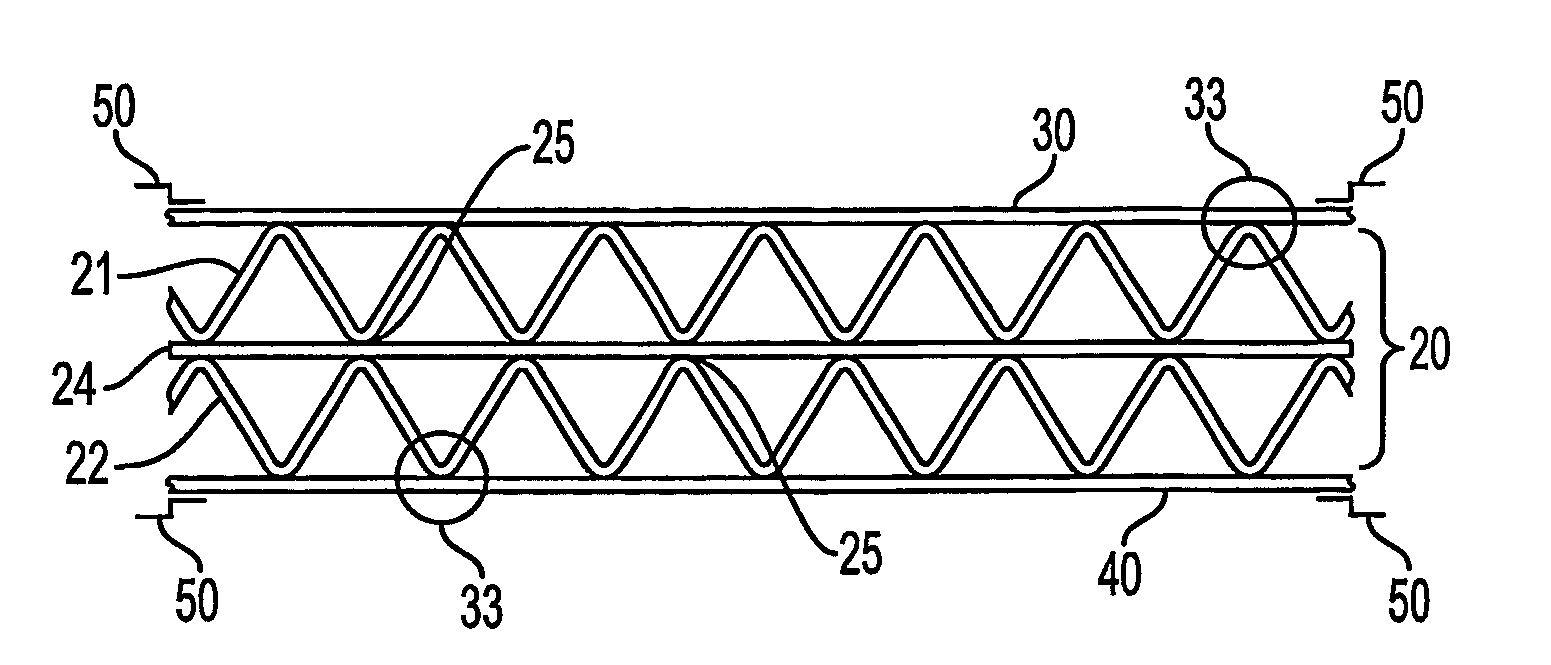

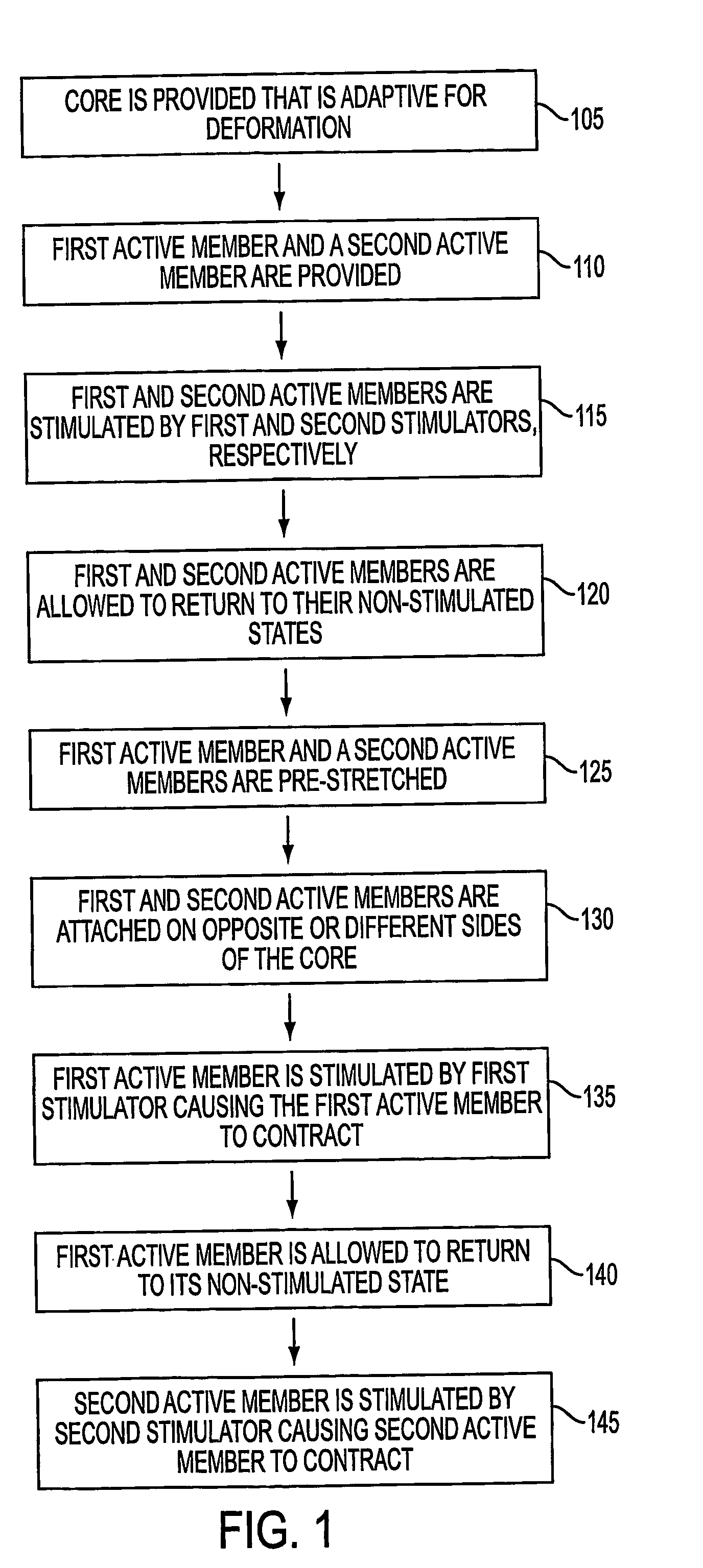

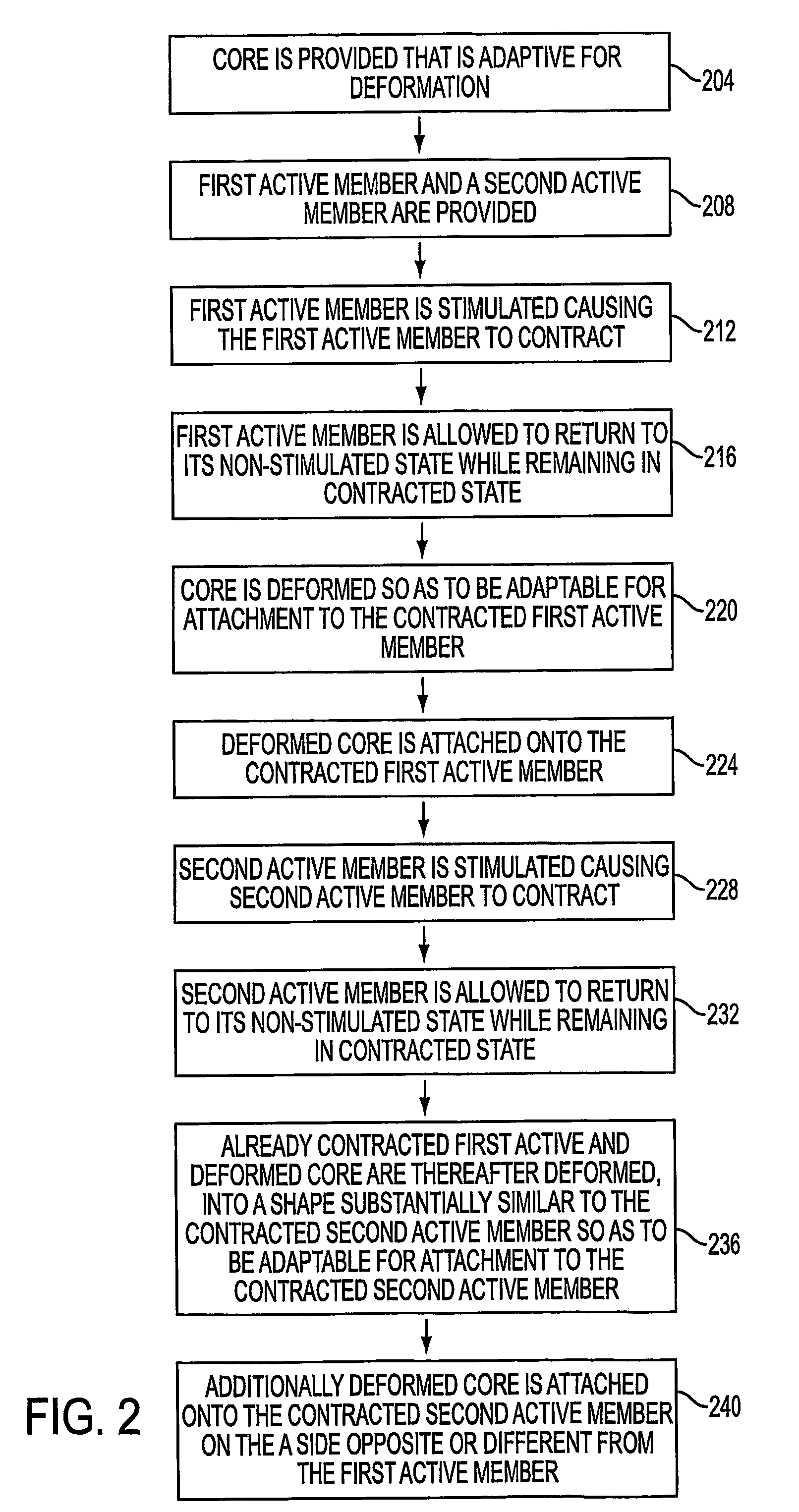

Reversible shape memory multifunctional structural designs and method of using and making the same

InactiveUS7669799B2Simple designChange shapeAircraft stabilisationSoldering apparatusEngineeringMulti-function structure

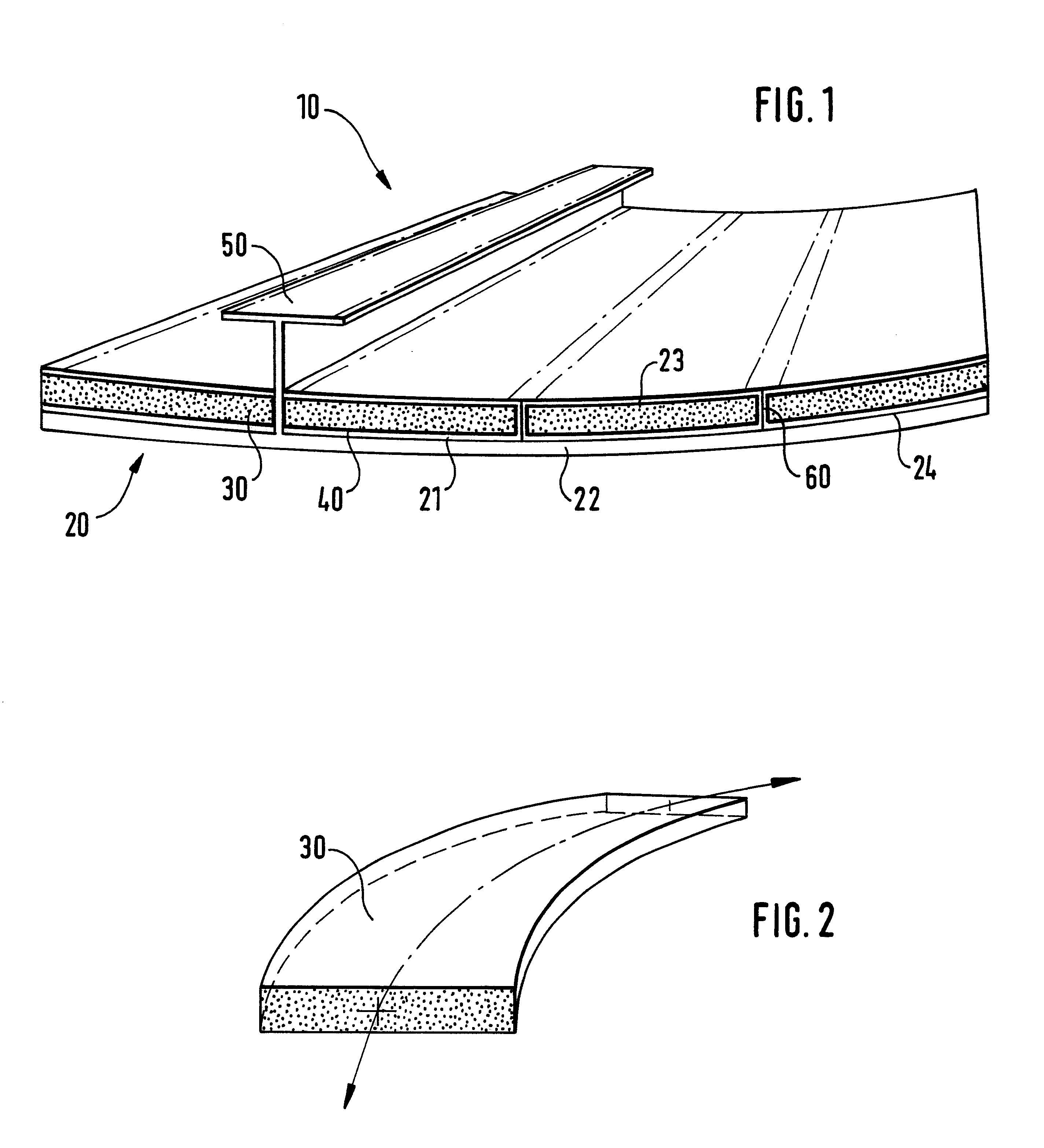

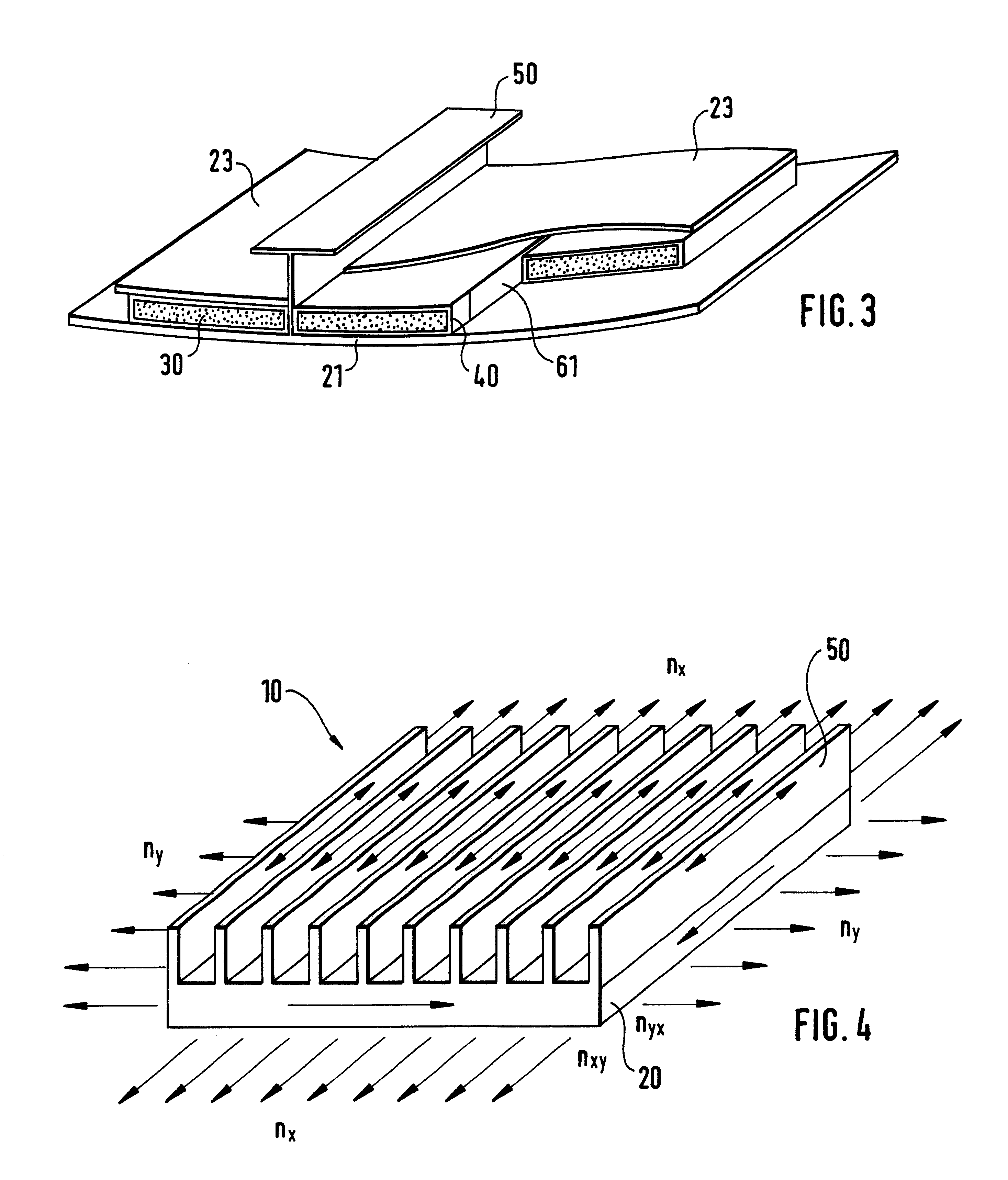

A multifunctional member with a first active member (30), which is adapted to contract if exposed to a temperature above a first transition temperature range. A second active member (40), which is adapted to contract if exposed to a temperature above a second transition temperature range. A core member (20), which is adaptive for deformation. The first and second active members (30, 40) are attached on opposite or different sides of the core member (20). A heat source operatively connected to the first and second active members (30, 40) to expose them to transition temperatures. The first active member (30) contracts while above the first transition temperature range causing the second active member (40) to expand, wherein the second active member (40) is below the second transition temperature range. The second active member (40) contracts while above the second transition temperature range causing the first active member (30) to expand, wherein the first active member (30) is below the first transition temperature range.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

Nanoreinforced films and laminates for aerospace structures

ActiveUS20140011414A1Improved ultraviolet resistance and resistance to microcrackingMaterial nanotechnologyWarp knittingPolymer resinNanofiber

A composite laminate for use on an external part of an aerospace vehicle has improved ultraviolet resistance and resistance to microcracking from thermal cycling. The laminate comprises a nanoreinforcement film, a support veil, and a composite layer. The laminate also can have a lightning strike protection layer and an external paint and primer. The nanoreinforcement film can comprise carbon nanomaterial and a polymer resin, and the composite layer has one or more layers of a reinforcement and a polymer resin. The carbon nanomaterial can be carbon nanofibers, and the nanoreinforcement film can have an areal weight of less than about 100 g / m2. The carbon nanomaterial can also comprise carbon nanofibers and carbon nanotubes.

Owner:ROHR INC +1

Integral structural shell component for an aircraft and method of manufacturing the same

A structural panel component, such as an aircraft fuselage shell component, includes a single integral part having longitudinal and crosswise stiffening elements integrally arranged on a skin sheet. This integral component has been formed by a high speed milling chip removal process applied to a solid plate-shaped semi-finished starting material. The skin sheet has areas of differing thicknesses, and the height, thickness, and spacing of the stiffening elements varies as needed, depending on the local loading conditions that will prevail on the finished structural component. The configuration of the component can be optimized to minimize the weight while satisfying all load strength requirements. The manufacturing method is very simple and economical.

Owner:AIRBUS OPERATIONS GMBH

Structural element of high unidirectional rigidity

In a structural element of high unidirectional rigidity, in which unidirectional fiber strands are completely embedded in sheaths and said sheaths are connected to a shell skin and wherein part of the shell skin is in the form of stringers, there is provided an inner division of the cross-section of the shell skin thereby providing the strength of the fibers and the stiffness of the fibers in a direction perpendicular to the skin plane for every direction of loading.

Owner:DEUTSCHES ZENTRUM FUER LUFT & RAUMFAHRT EV

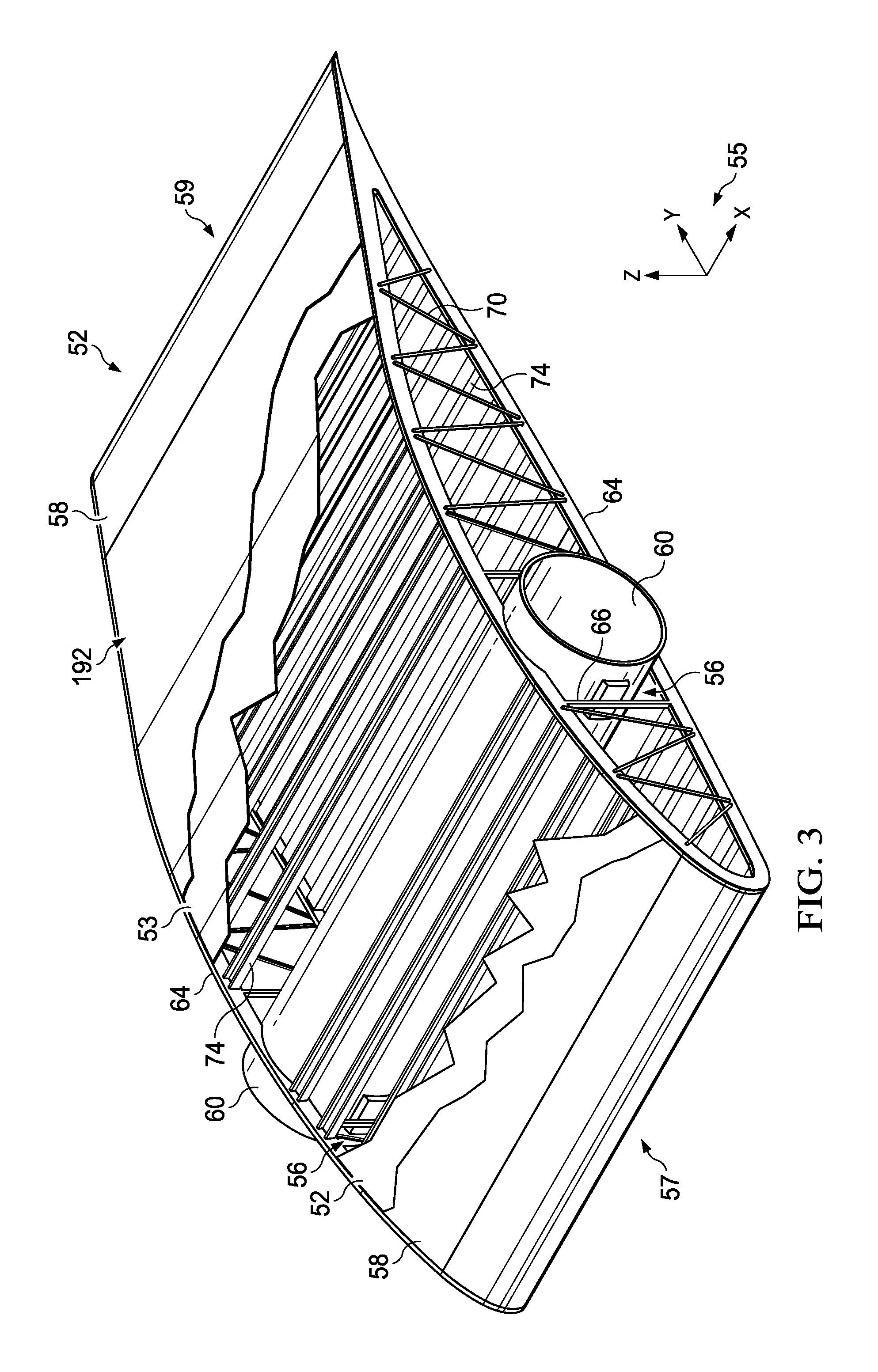

Single piece co-cure composite wing

InactiveUS7681835B2Light weightSuperior strength and durabilityAircraft stabilisationLayered productsWave shapeComposite wing

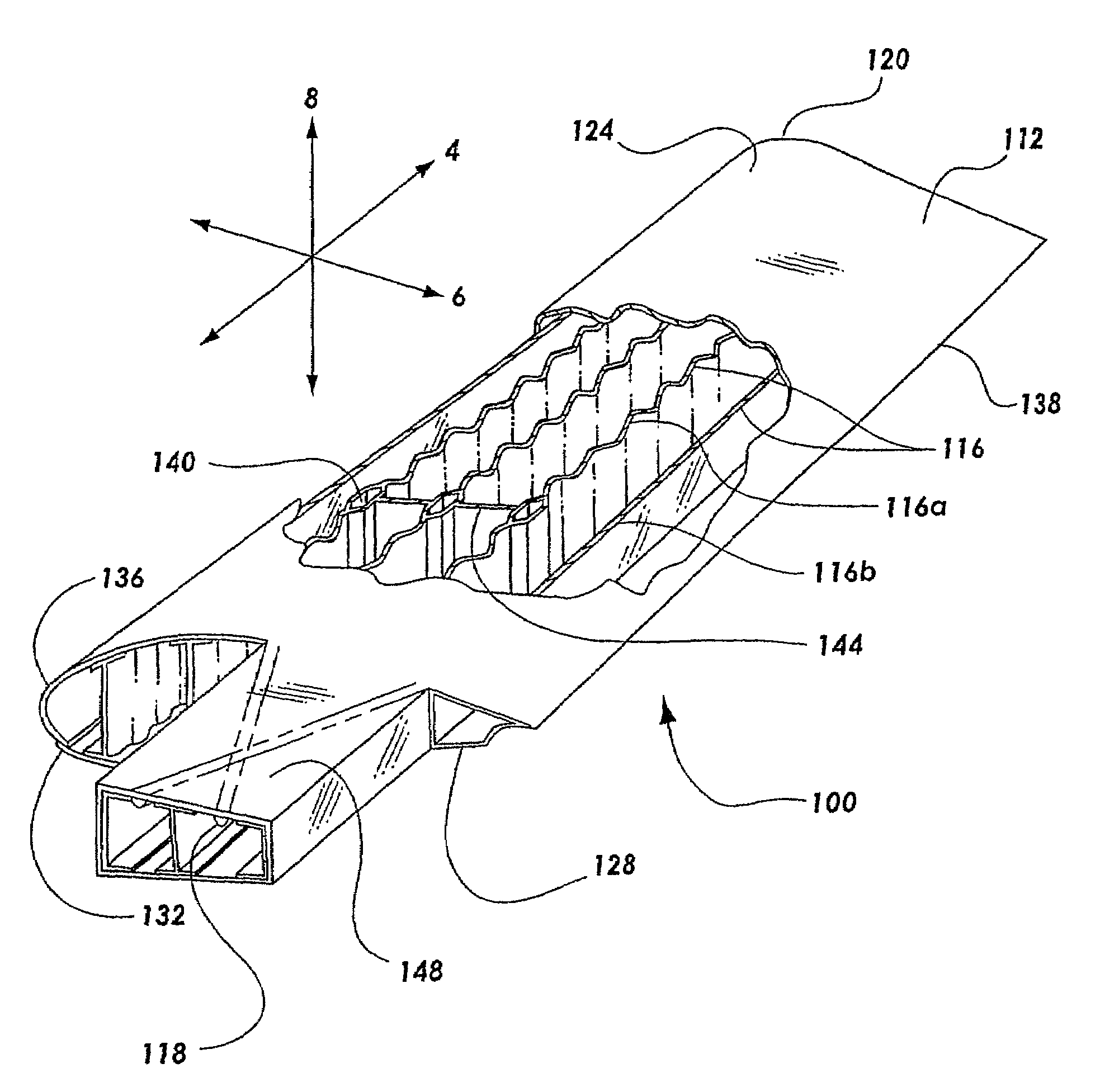

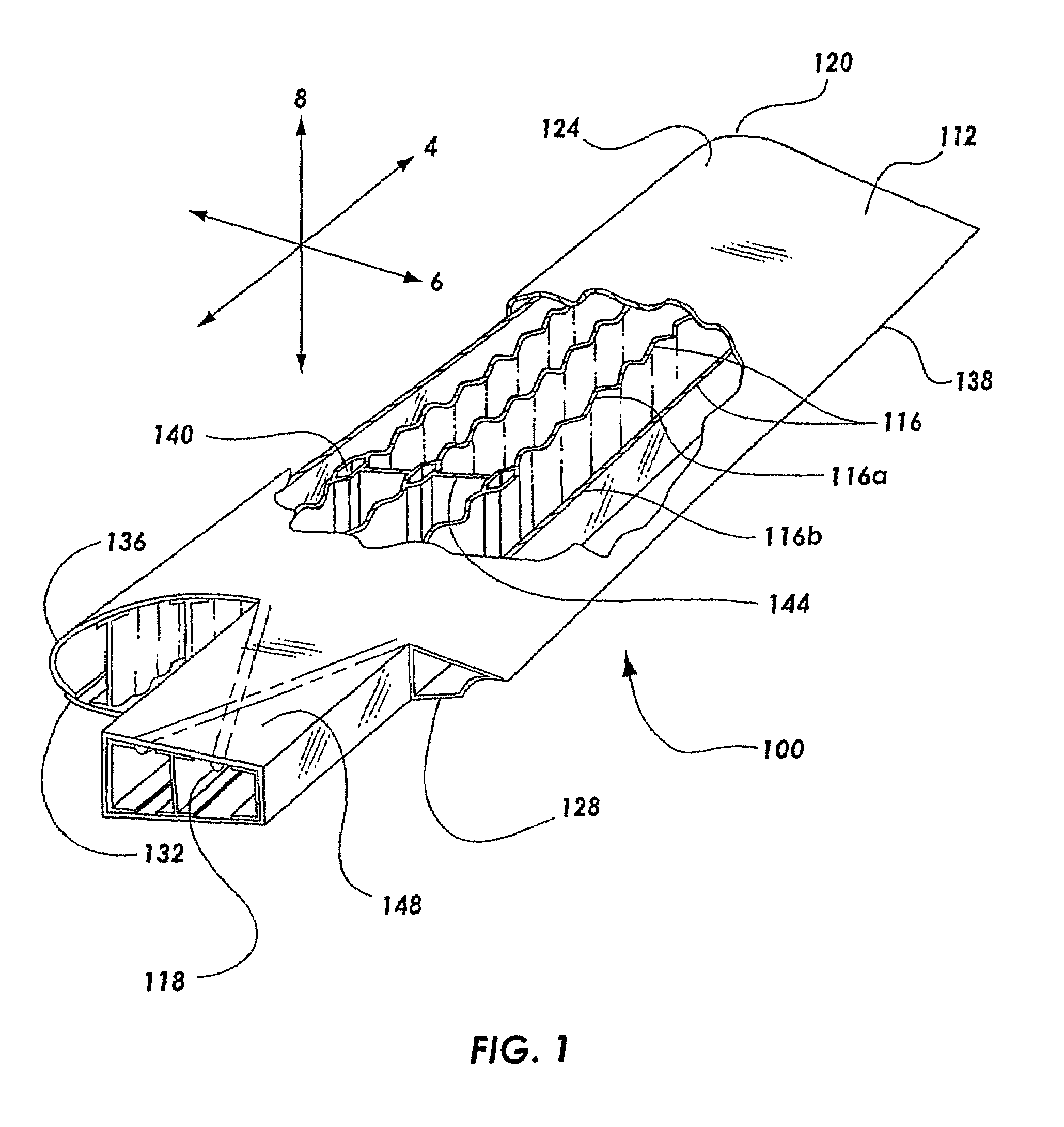

A single piece co-cured composite wing is disclosed. The wing has a flying surface and structural members. In one embodiment the structural members may be a plurality of spars. The spars may have various shapes to increase the buckling strength. The spars may be wave shaped, such as a sinusoidal shape. The flying surface and the structural members are co-cured in order to form a single piece, integral wing structure. A process for manufacturing a single piece co-cured wing is also disclosed. The process may include laying out composite sheets for the flying surface of the wing. Then, the composite material of the spars is arranged around a plurality of pressurizable forms. Finally, the composite material is cured in a clamshell frame. A single piece co-cured composite structure is also disclosed that includes an outer skin, and inner skin, a frame, and a stringer.

Owner:SPECTRUM AERONAUTICAL

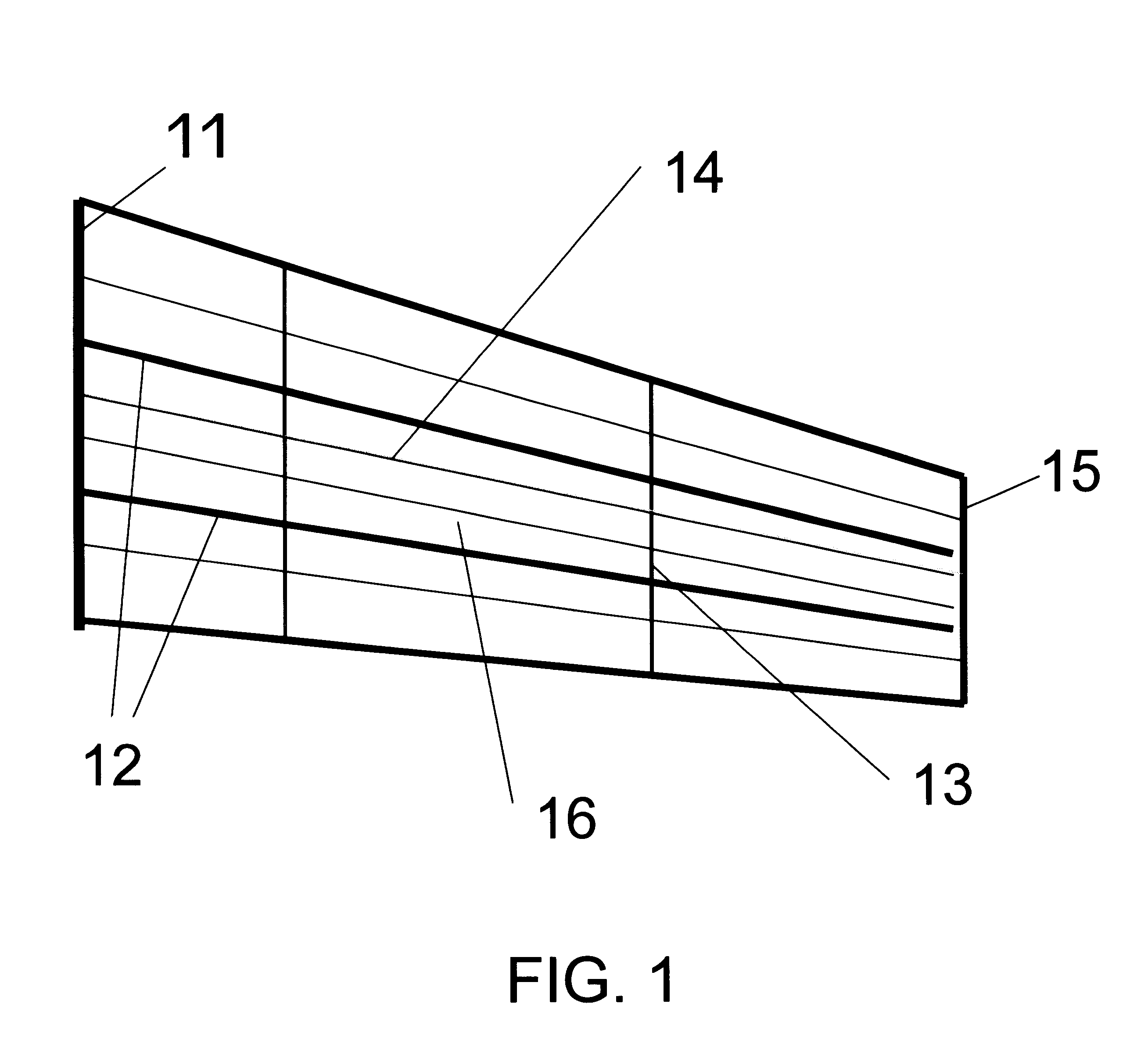

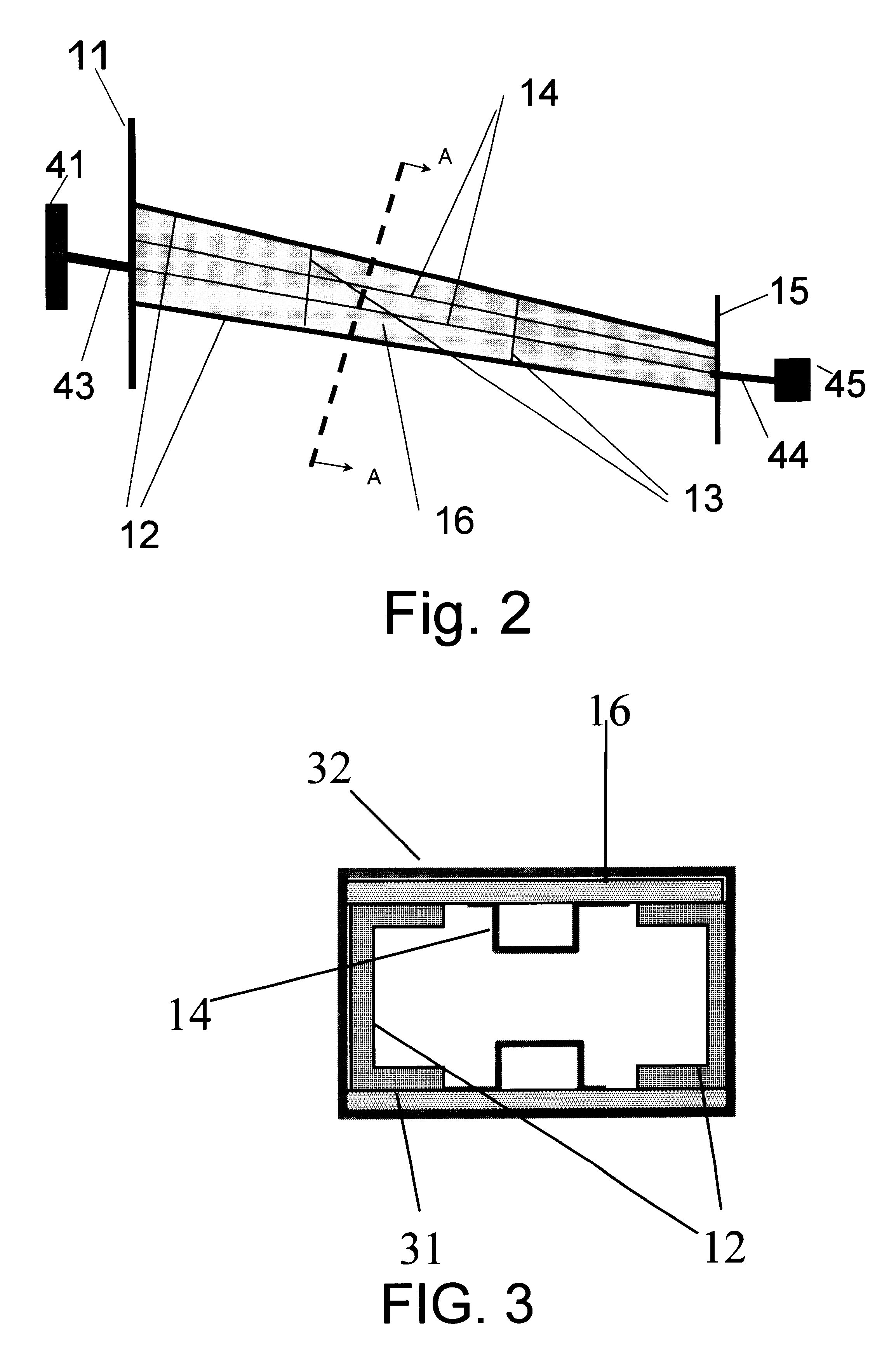

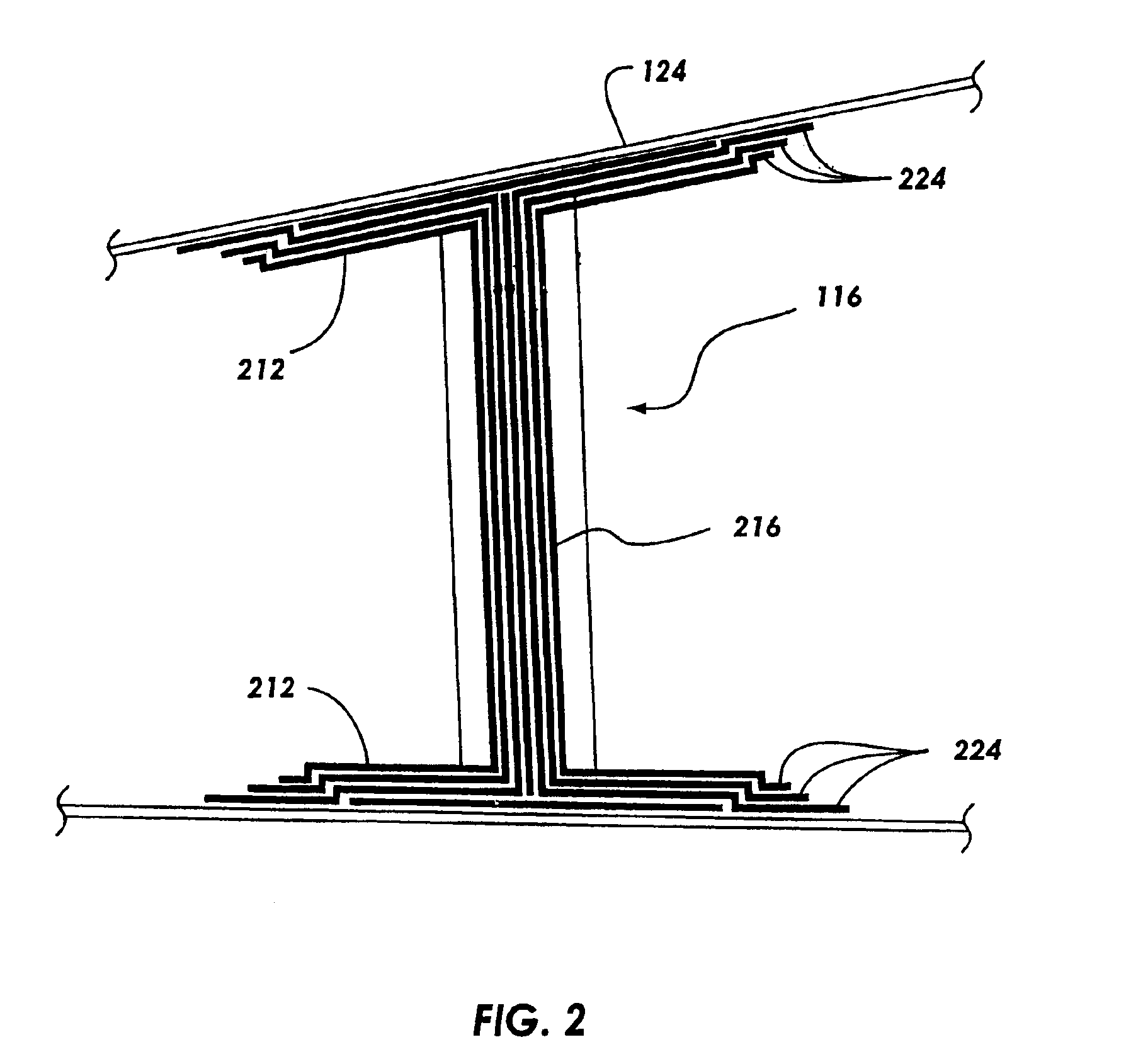

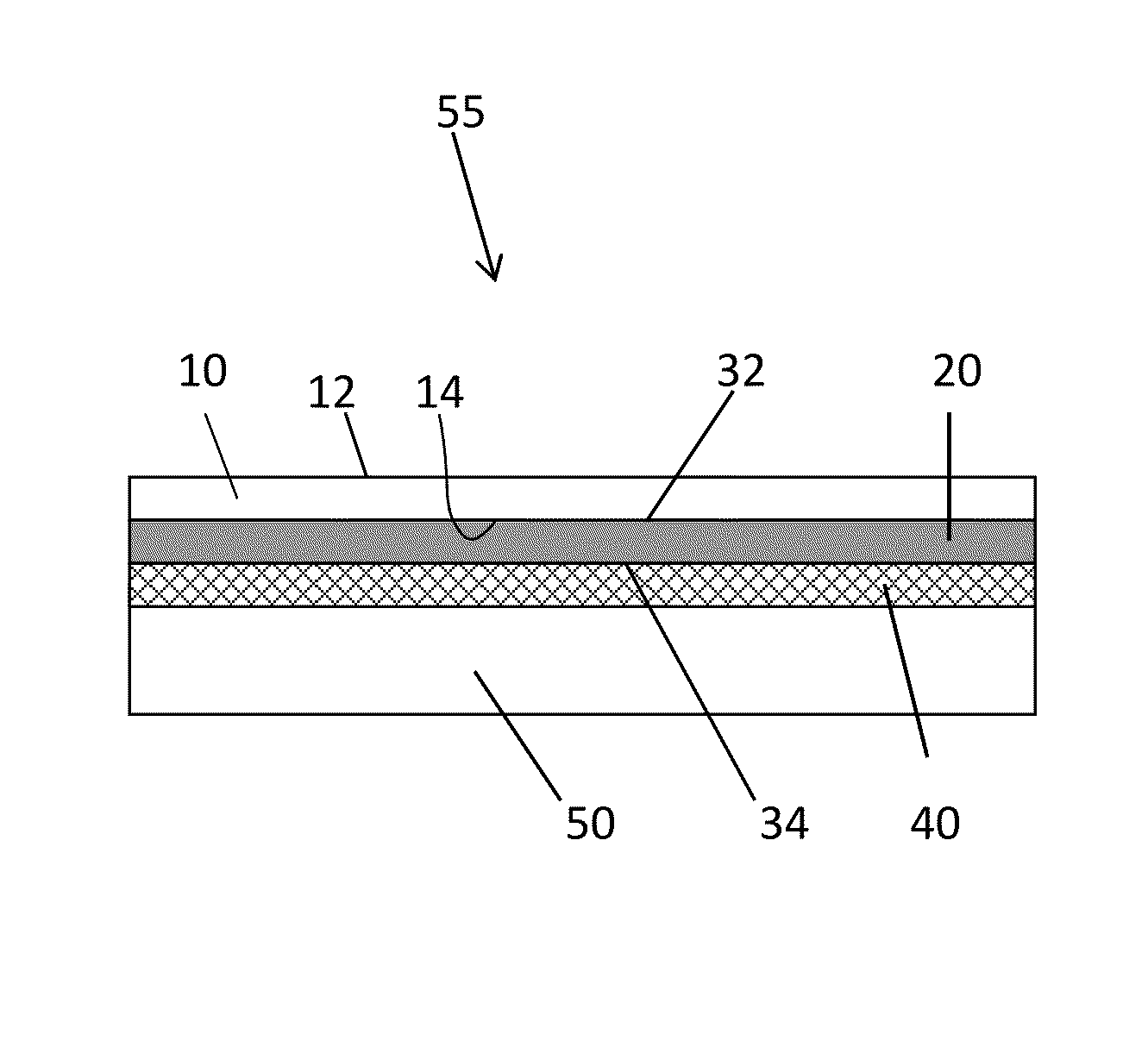

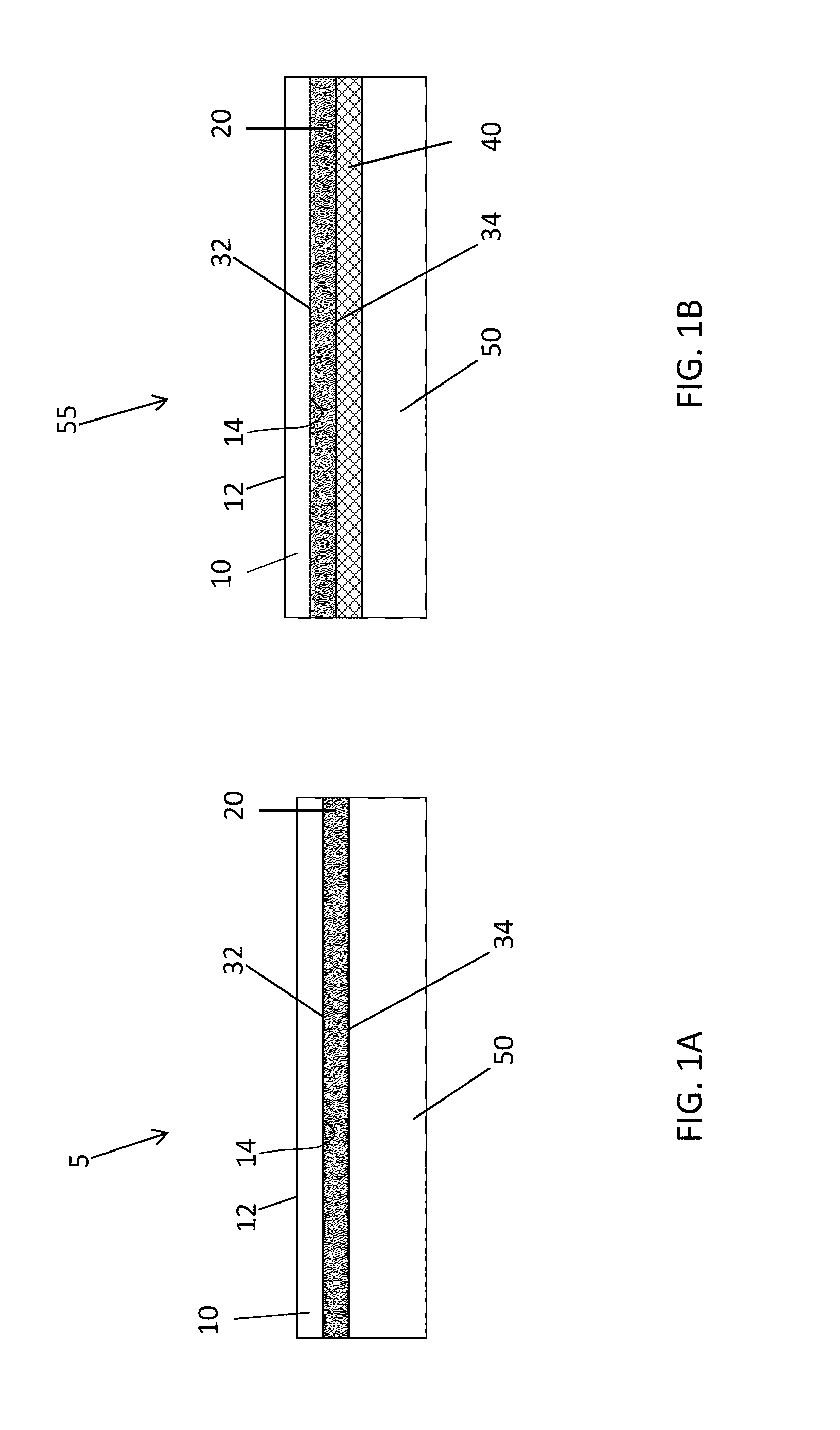

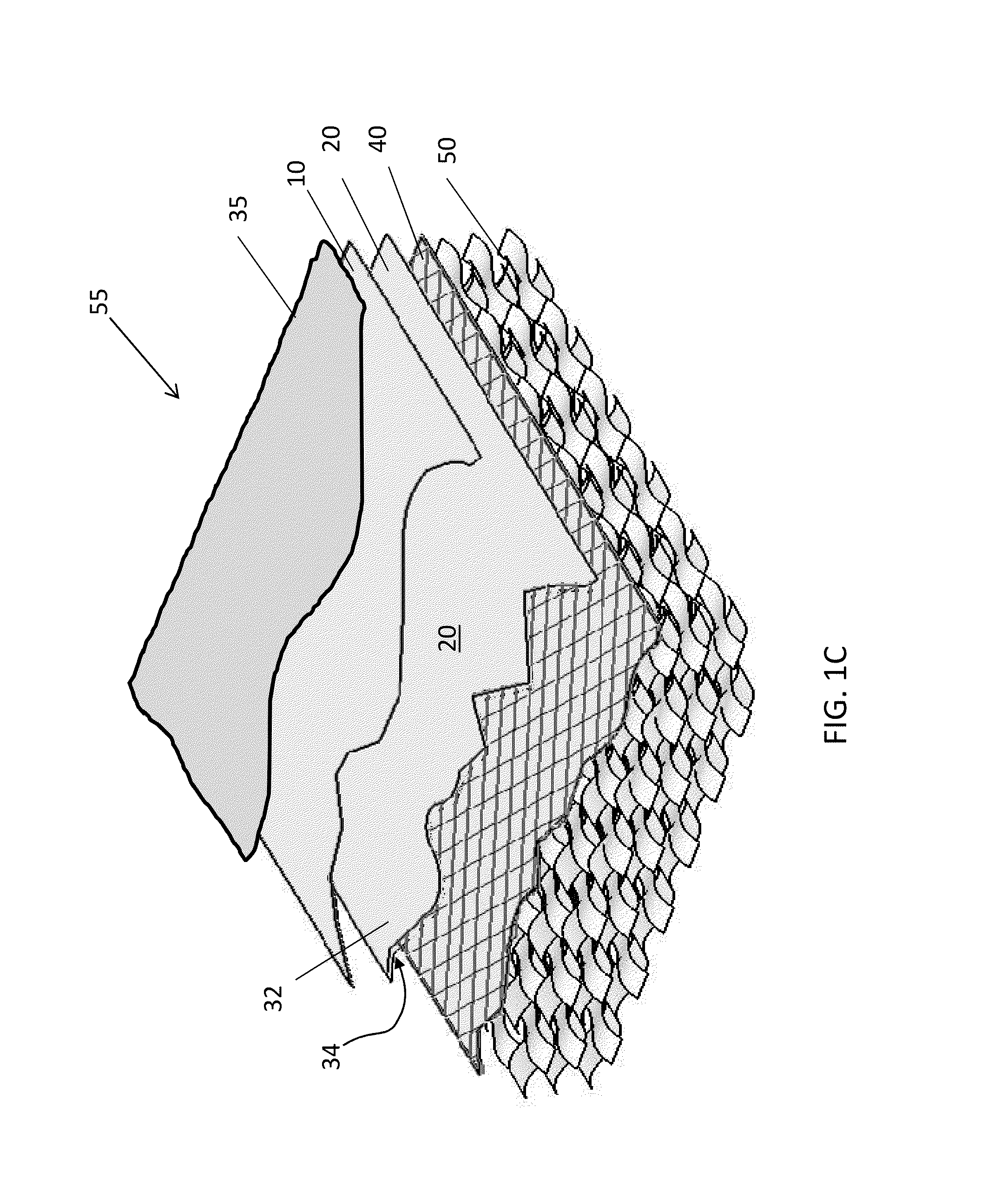

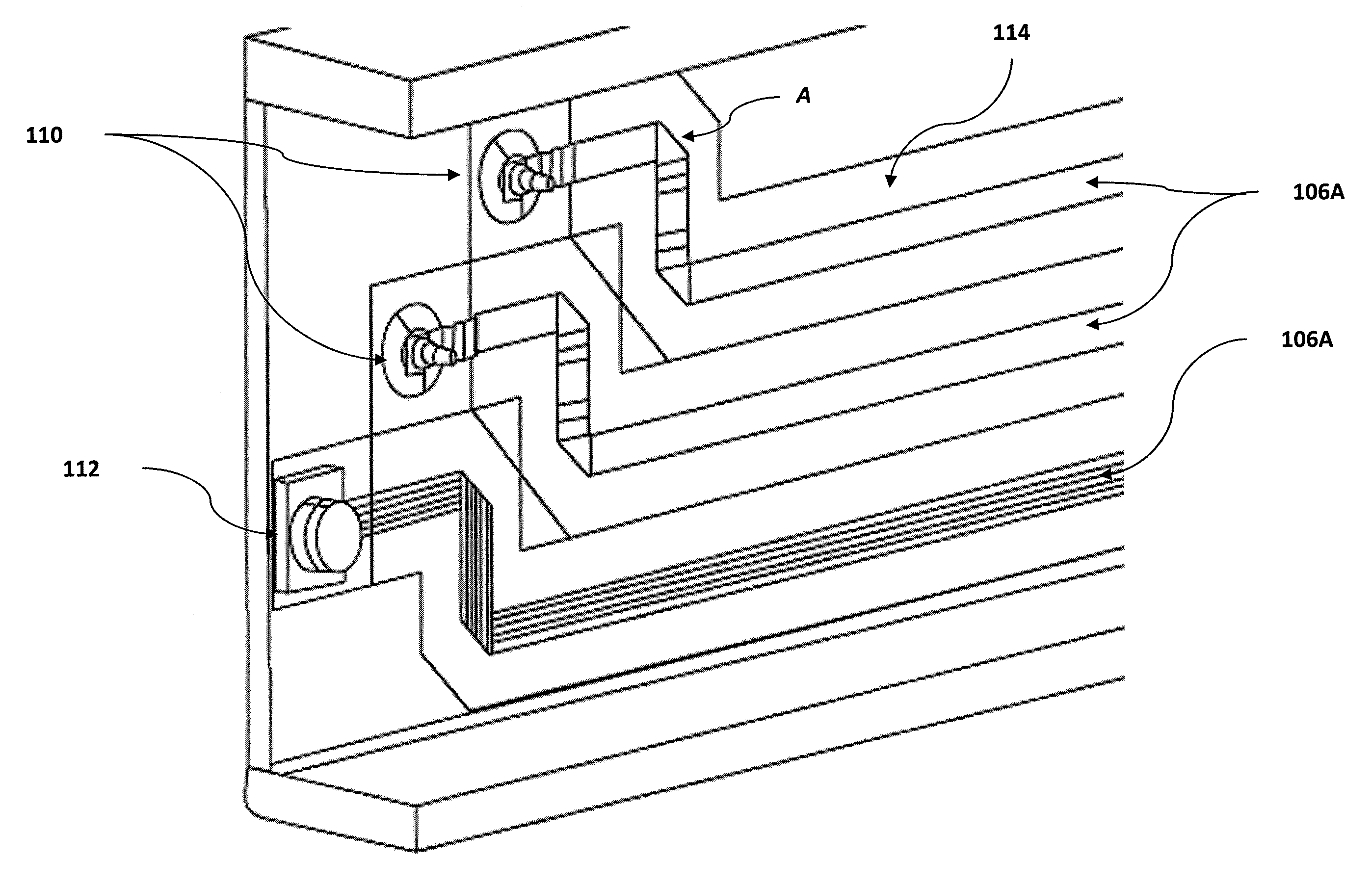

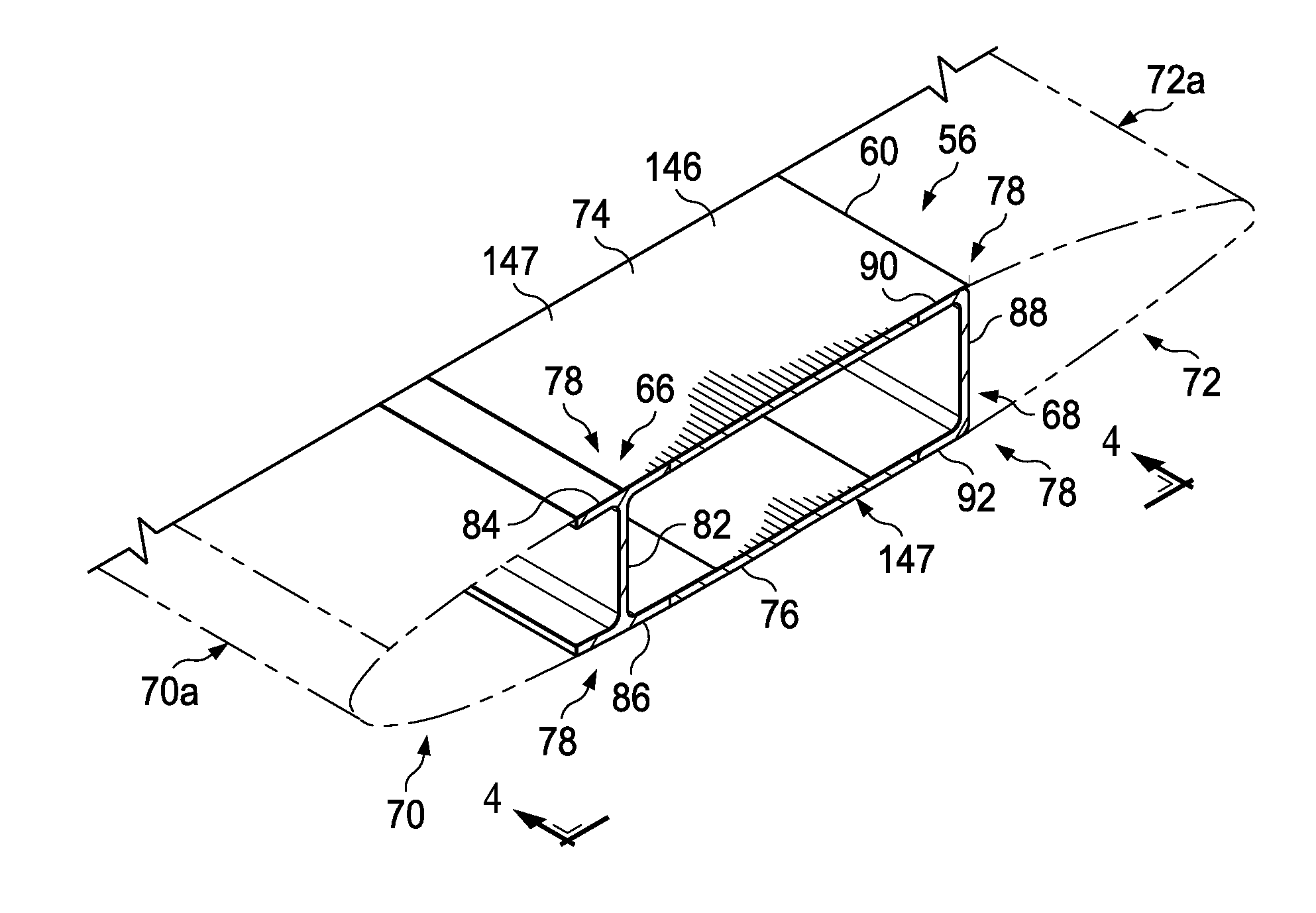

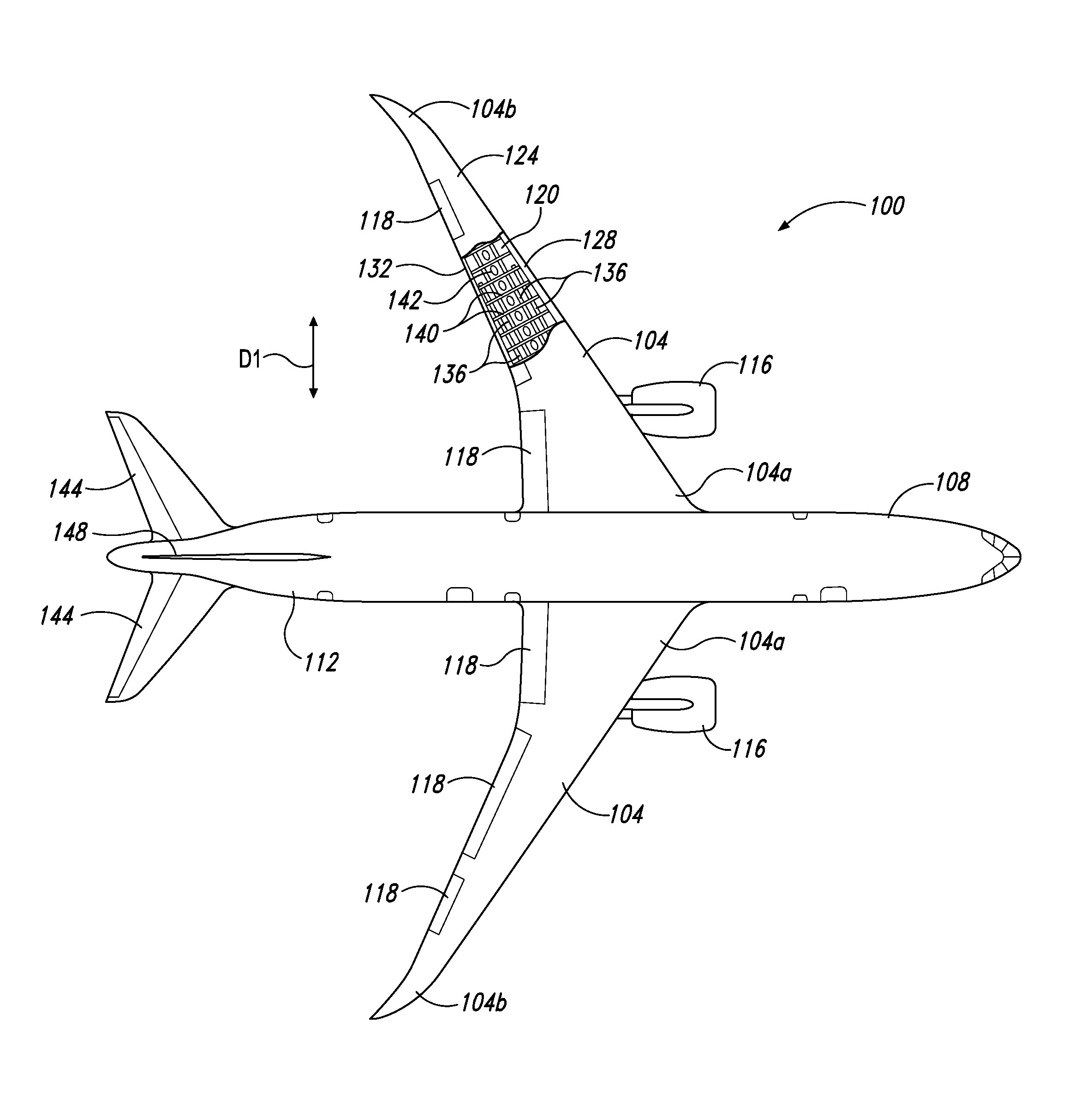

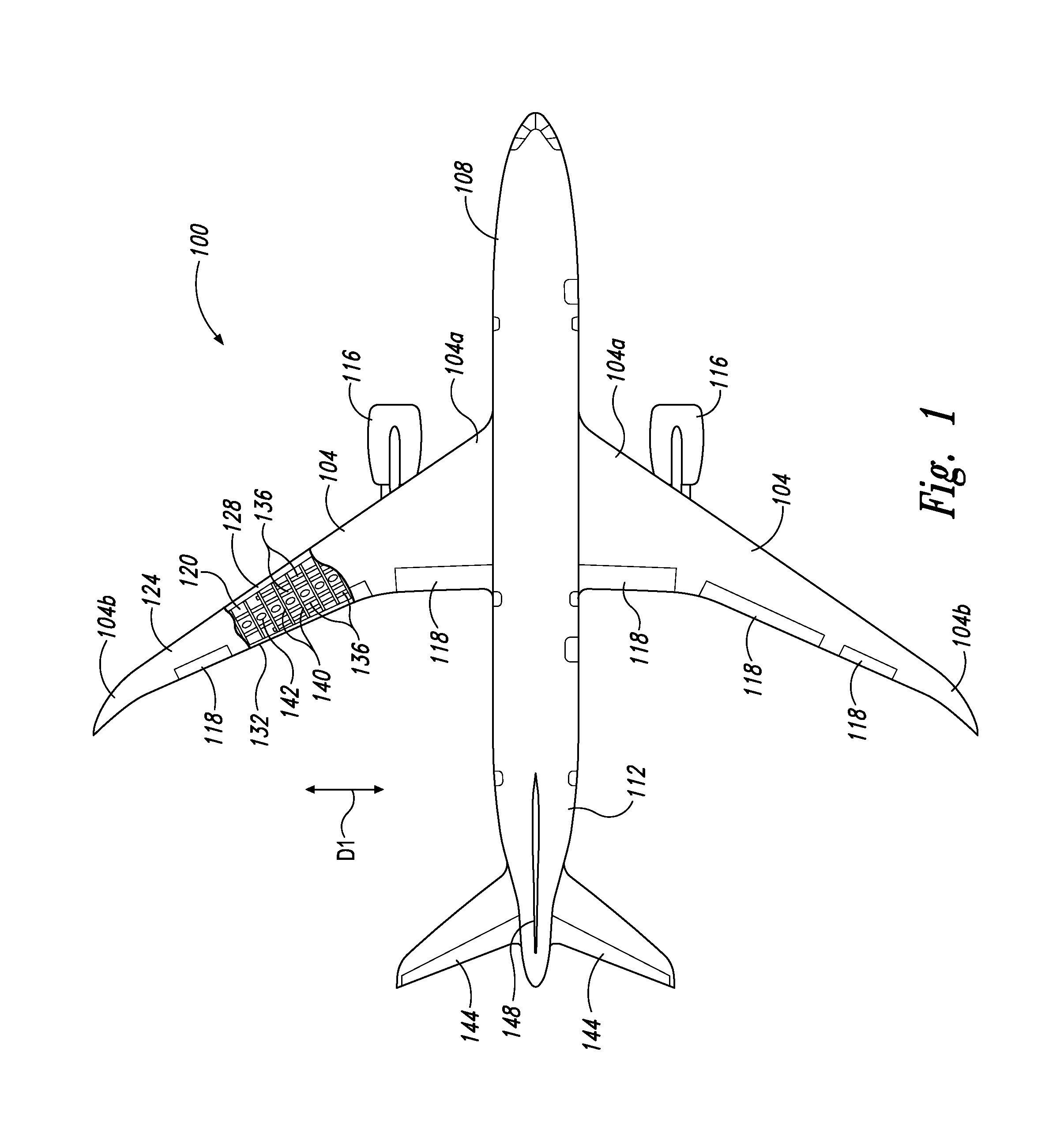

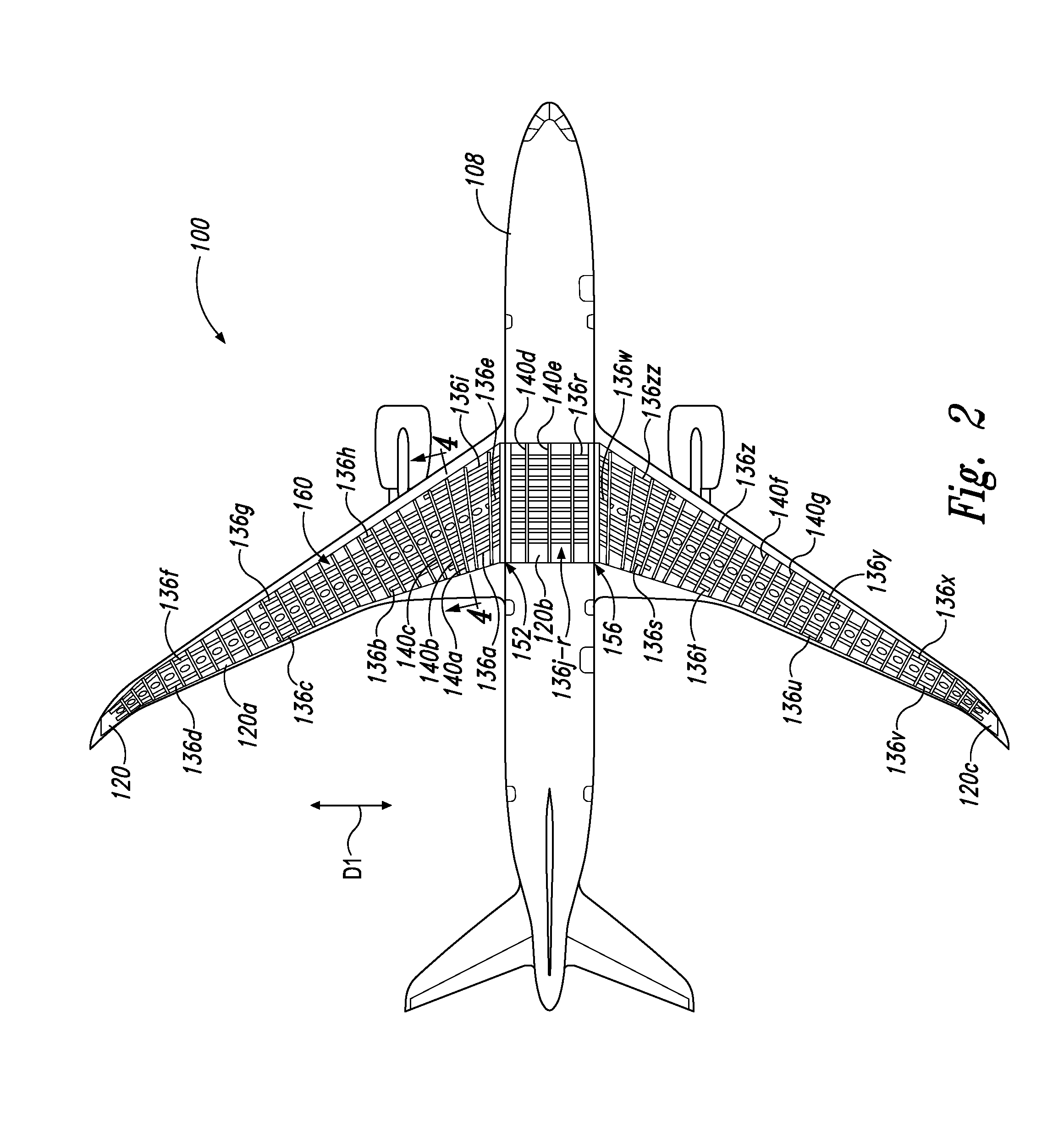

Apparatus and method for an aircraft conductor sandwich assembly embedded to an aircraft structure

ActiveUS8937254B2Reduce eliminateReduce weightElectric power distributionLaminationElectrical conductorStructural engineering

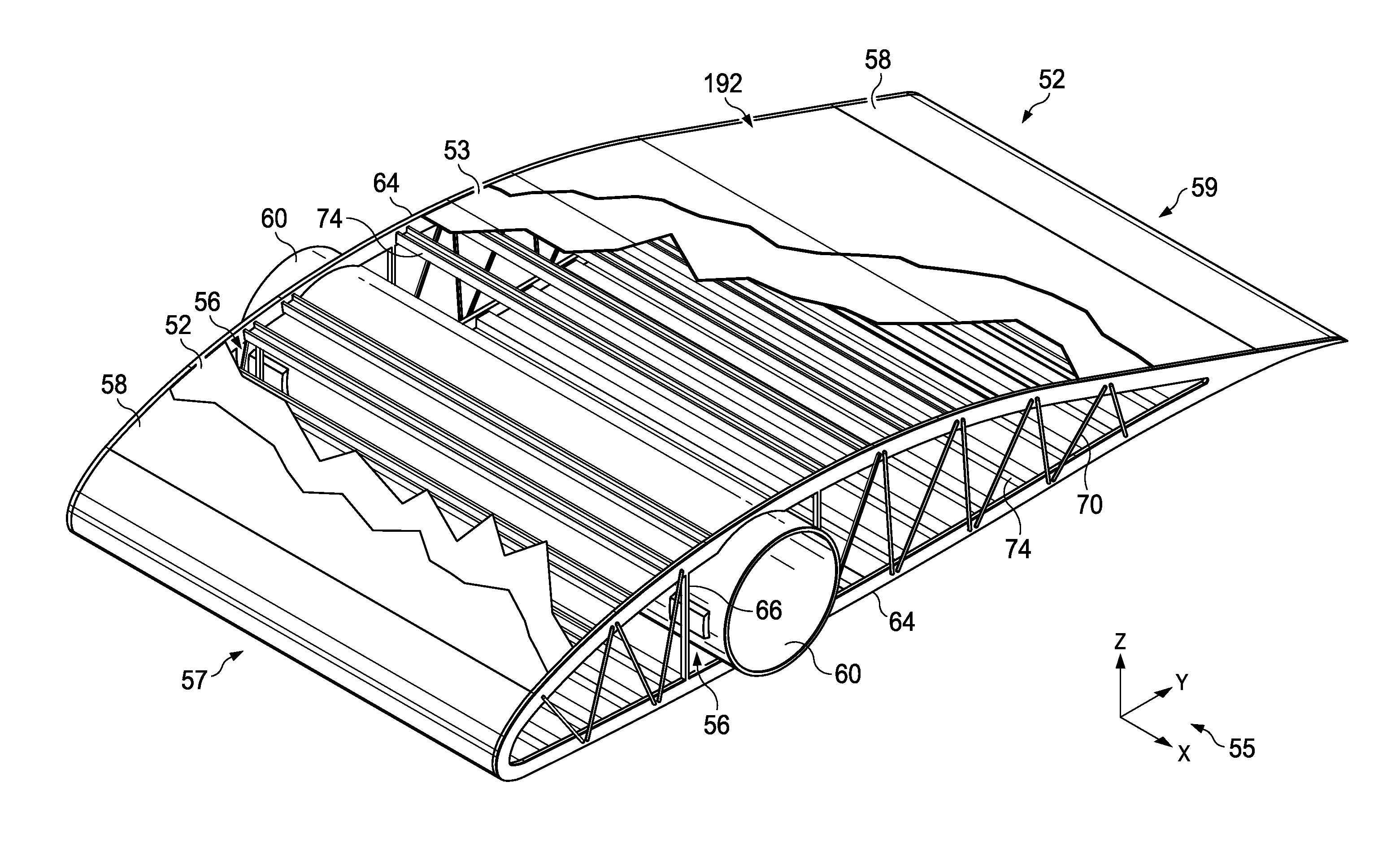

An aircraft conductor sandwich assembly configured to be embedded in a composite aircraft structure. The conductor sandwich assembly comprises a plurality of carbon conductors disposed between two sheets of insulating layers and an adhesive resin bonding the plurality of carbon conductors and the two sheets of insulating layers into a carbon sandwich assembly such that (i) the conductors are electrically isolated and (ii) structural loads can be passed through said conductor sandwich assembly.

Owner:AURORA FLIGHT SCI CORP

Multifunctional de-icing/Anti-icing system

ActiveUS20130043342A1Cost-effective and flexibleIncrease temperatureAircraft lighting protectorsDe-icing equipmentsNano structuringElectrical conductor

A de-icing / anti-icing system including at least two conductive structures embedded in an article that includes an outer surface designed as an aerodynamic surface. At least one of the conductive structures is arranged adjacent the outer surface. A control unit adapted to control the energy supply to the conductive structures for generating heat to the outer surface. A first of the conductive structures includes a first conductive nano structure and a second of the conductive structures includes a second conductive nano structure. A conductive property of the first of the conductive structures differs from a conductive property of the second of the conductive structures. The first conductive nano structure serves as a heating conductor and the second conductive nano structure serves as a heating element. The first and second conductive nano structures are embedded in a common plane of a resin layer forming the outer surface.

Owner:SAAB AB

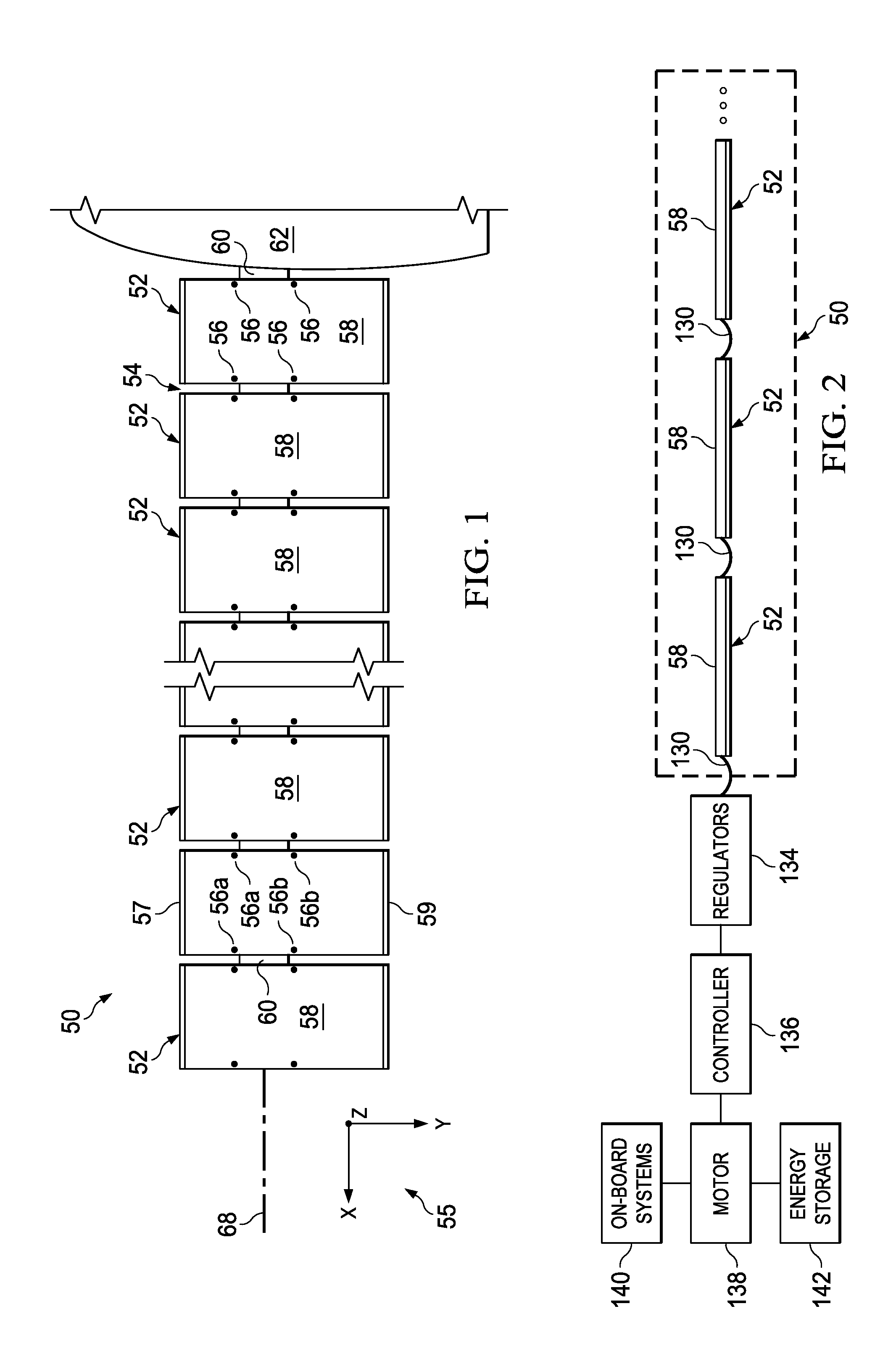

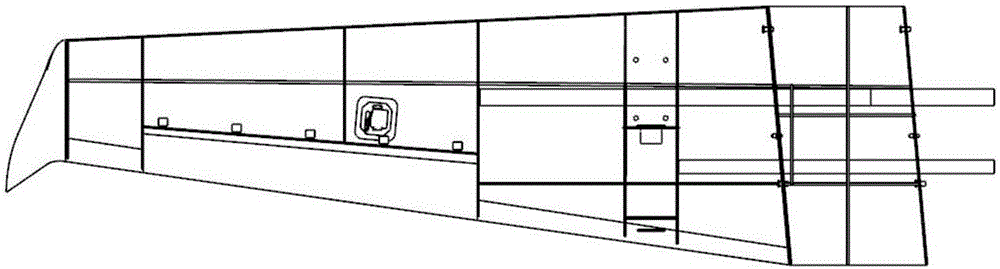

Segmented Aircraft Wing Having Solar Arrays

ActiveUS20130099063A1Long wingspanLow strain levelSpars/stringersSolar panel attachmentsThermal expansionInduced stress

An aircraft wing has a plurality of wing segments mounted on a wing spar by joints that allow relative movement between the spar and the wing segments. Tuning of coefficients of thermal expansion is employed to reduce induced stresses from changes in temperature.

Owner:THE BOEING CO

Box Structures for Carrying Loads and Methods of Making the Same

Owner:THE BOEING CO

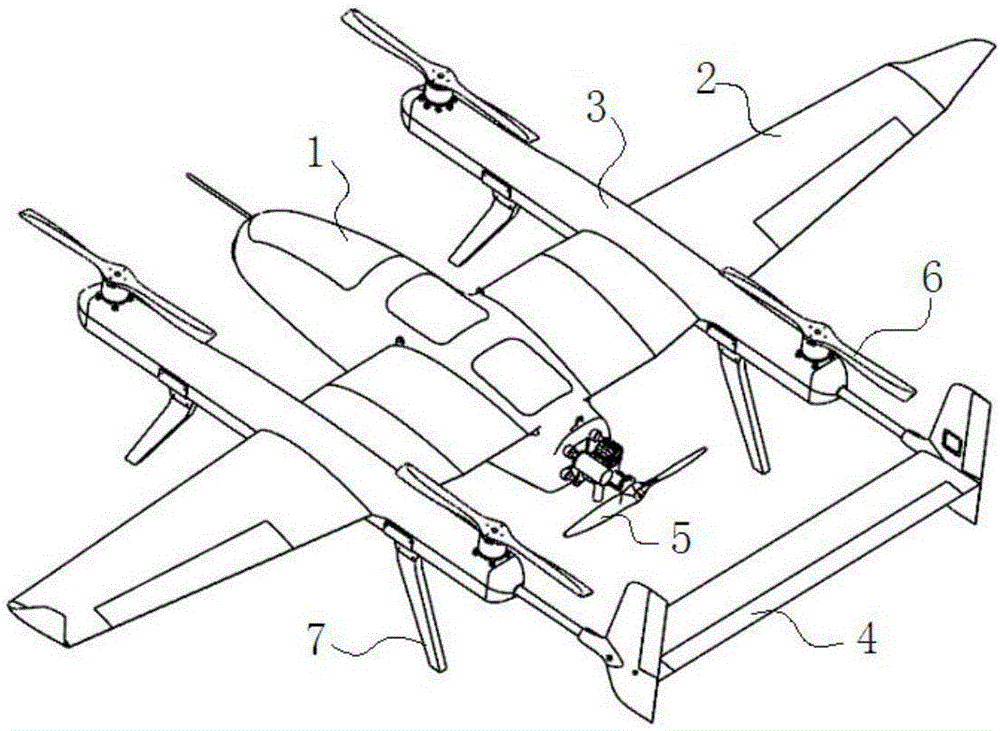

Vertical take-off and landing fixed-wing unmanned aerial vehicle

InactiveCN106741820ASmall landing spaceIncrease cruising speedWing shapesSandwich constructionsFlight vehicleRotary wing

The invention provides a vertical take-off and landing fixed-wing unmanned aerial vehicle, which belongs to the technical field of aircrafts. The purpose is to solving problems that the take-off and landing condition of a fixed-wing aircraft is harsh, the loitering speed of a rotor craft is low and the endurance of the rotor craft is short in the prior art are solved. The vertical take-off and landing fixed-wing unmanned aerial vehicle comprises a fixed-wing structure system, a fixed-wing power system, a rotor structure and power system, a rotor structure supporting piece as well as a flight control system and an avionic system, wherein the fixed-wing power system comprises a single cylinder two-stroke engine and a propeller A, which are fixed at the tail end of an aerial vehicle body; a power output end of the engine is connected with the propeller A; the rotor structure and power system is arranged on the fixed-wing structure system; the rotor structure and power system comprises a motor, an electronic speed controller and propellers B; the motor is electrically connected with the electronic speed controller; an output end of the motor is connected with the propellers B; four propellers B are respectively arranged on the upper end surfaces of two supporting rods of the fixed-wing structure system; the propeller A is perpendicular to the propellers B; the rotor structure supporting piece is fixed at the upper end of a wing of the fixed-wing structure system and used for mounting a rotor power system; and the flight control system and the avionic system are used for controlling the flight path and posture of the unmanned aerial vehicle.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Horizontal tail front edge for bird strike-resisting airplane

The invention relates to a horizontal tail front edge for a bird strike-resisting airplane. An upper honeycomb sandwich layer, a lower honeycomb sandwich layer, a front edge reinforcing member and an aerofoil lining layer are arranged among spans on the horizontal tail front edge in a spanwise mode along a horizontal tail of the airplane; one angle of the front edge reinforcing member is positioned at the front end of the horizontal tail front edge; the upper honeycomb sandwich layer and the lower honeycomb sandwich layer which are in a shape of a parallelogram are fixed on upper and lower internal surfaces of a horizontal tail skin respectively, the edge of one vertex angle of each honeycomb sandwich layer is fixed with surfaces of the front edge reinforcing member and the horizontal tail skin respectively, and the edge of the other vertex angle is fixed with the surfaces of the horizontal tail skin and the aerofoil lining layer; and the honeycomb sandwich layers and the front edge reinforcing member are coated between the aerofoil lining layer and the internal surfaces of the horizontal tail skin by the aerofoil lining layer. In the horizontal tail front edge, birds are cut by the front edge reinforcing member, the impact force of the birds is absorbed by the honeycomb sandwich layers, and an internal structure of the horizontal tail front edge is protected against damage bythe aerofoil lining layer. The horizontal tail front edge is also suitable for vertical tails, aerofoil front edges and all beam edges which are likely to be subjected to bird strike on the airplane.

Owner:西测翱翔(太仓)航空科技有限公司

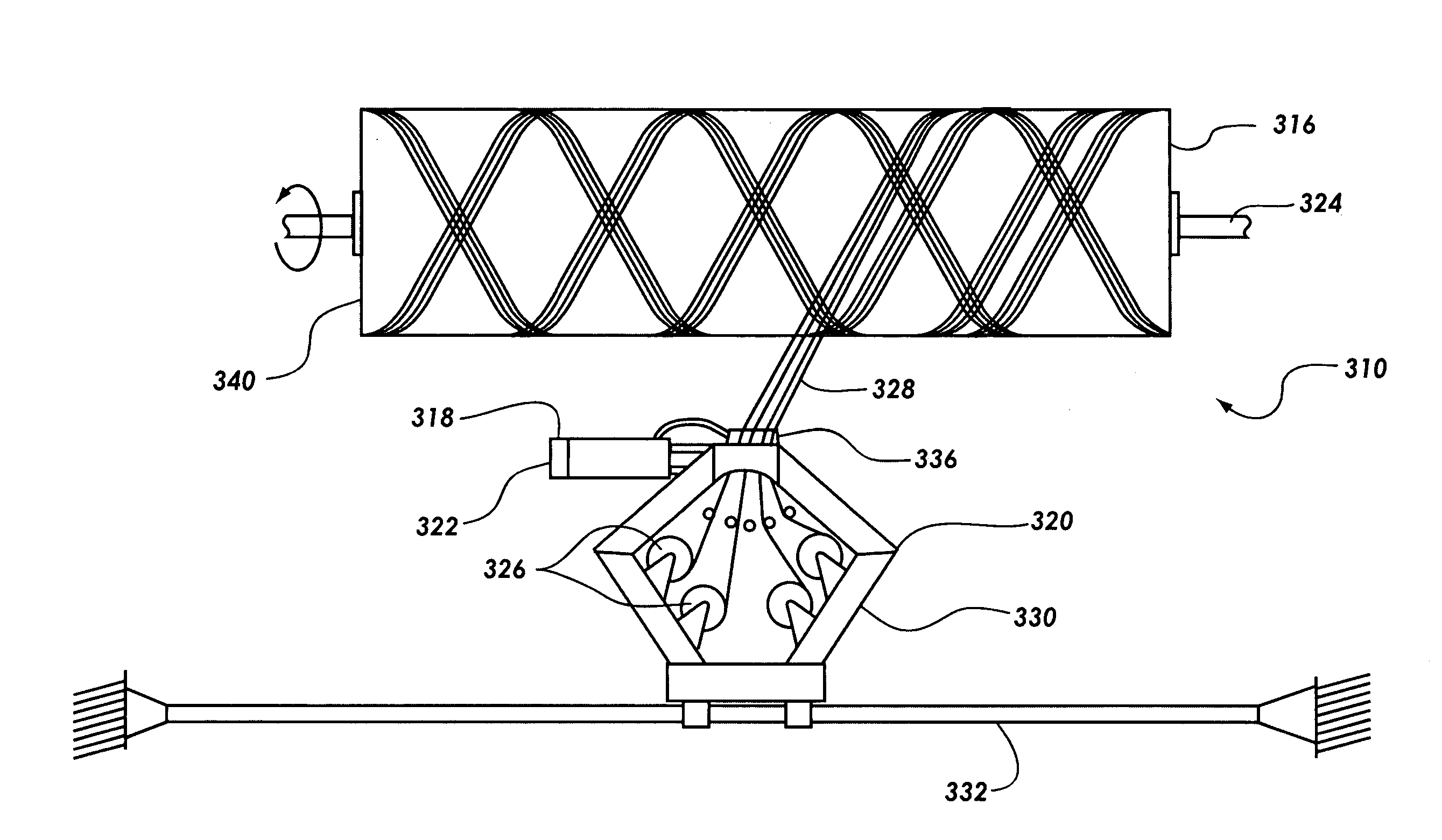

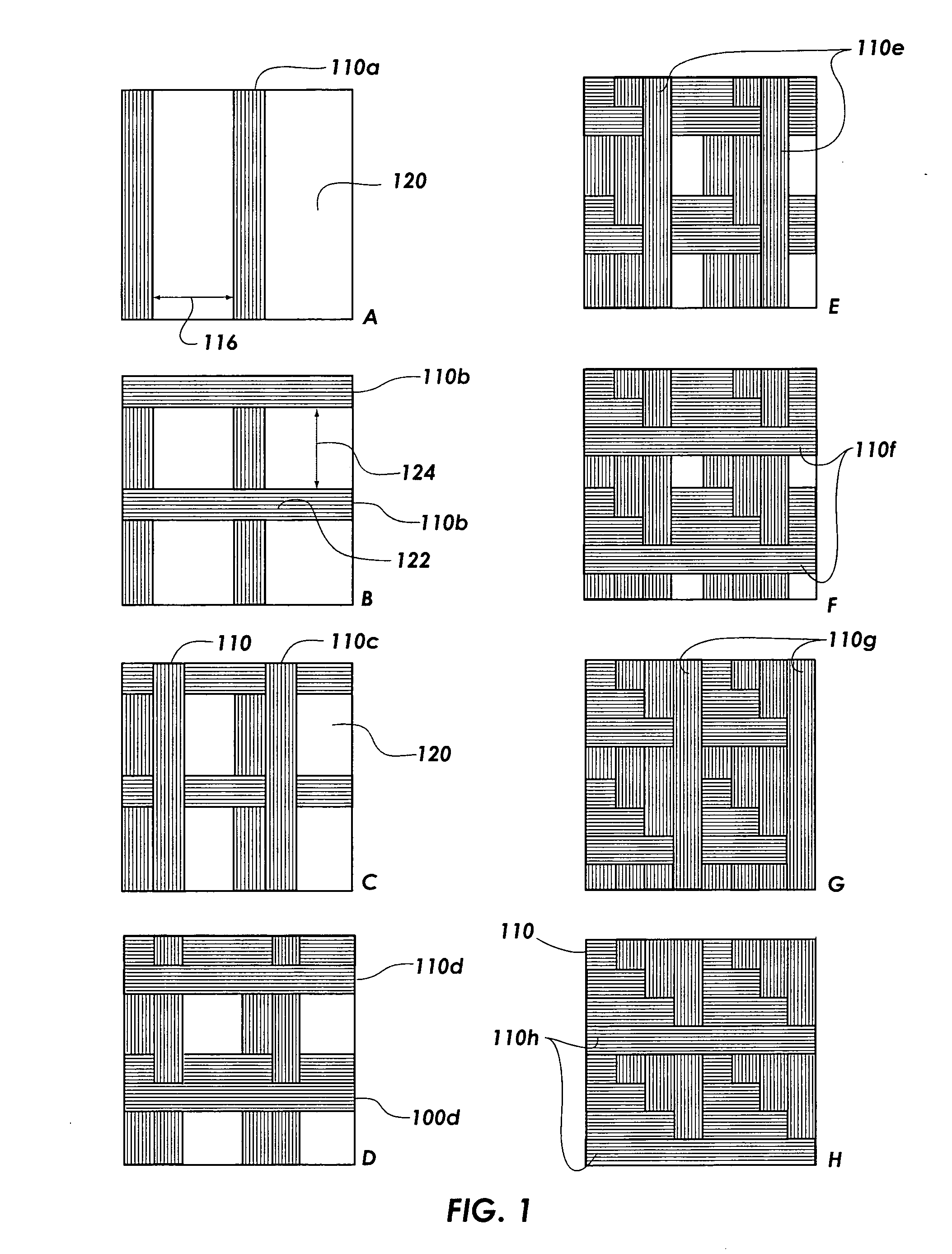

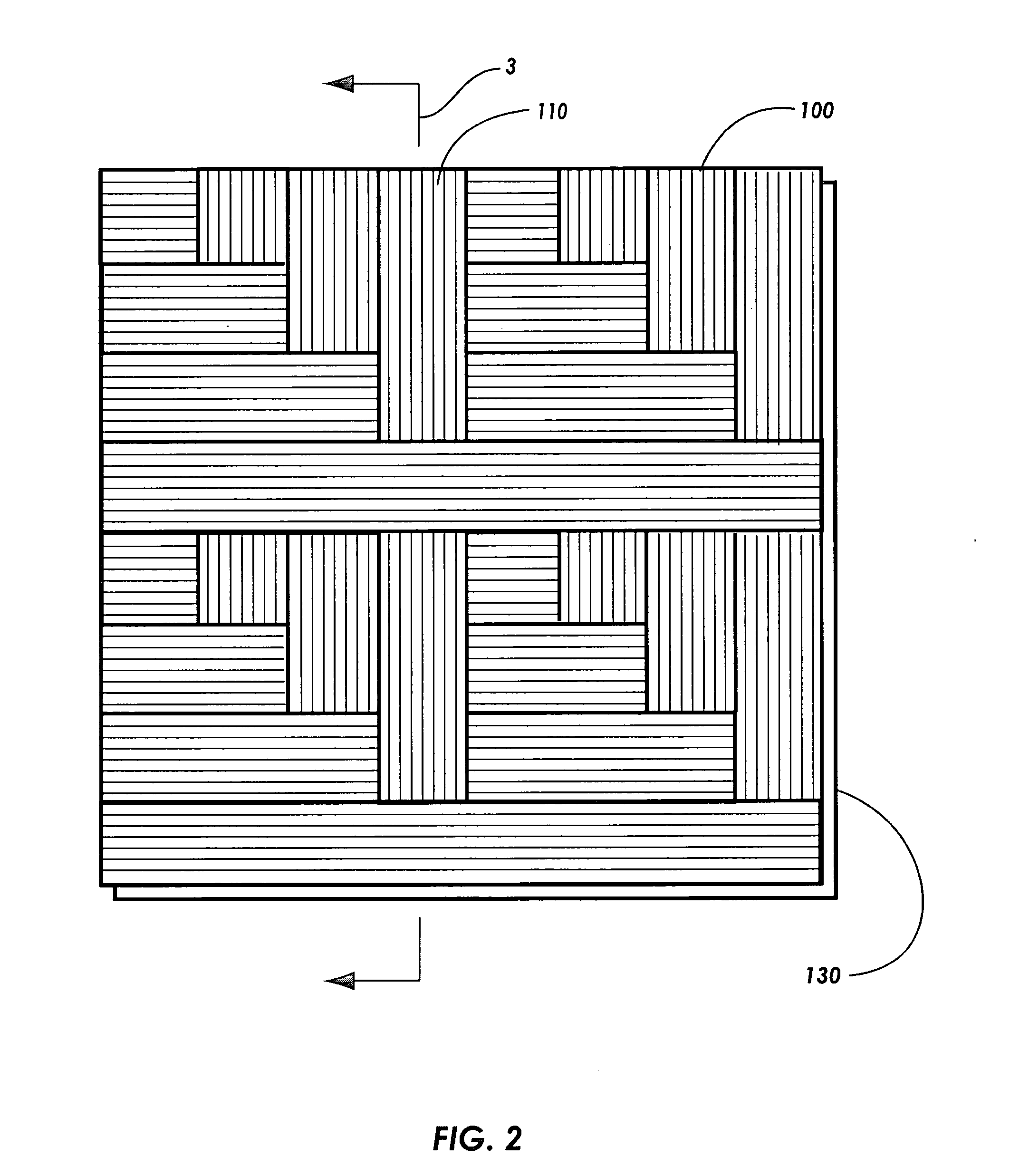

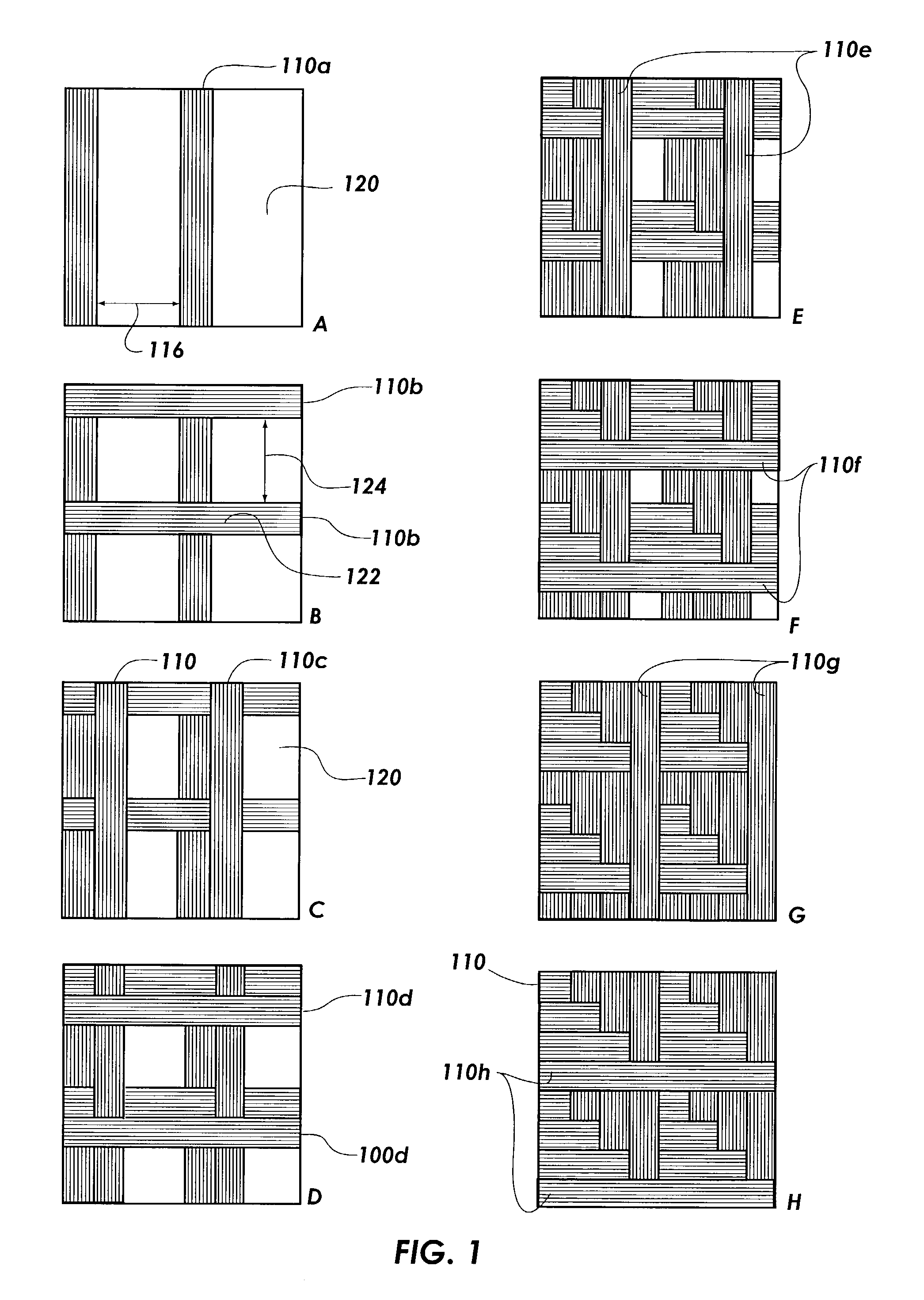

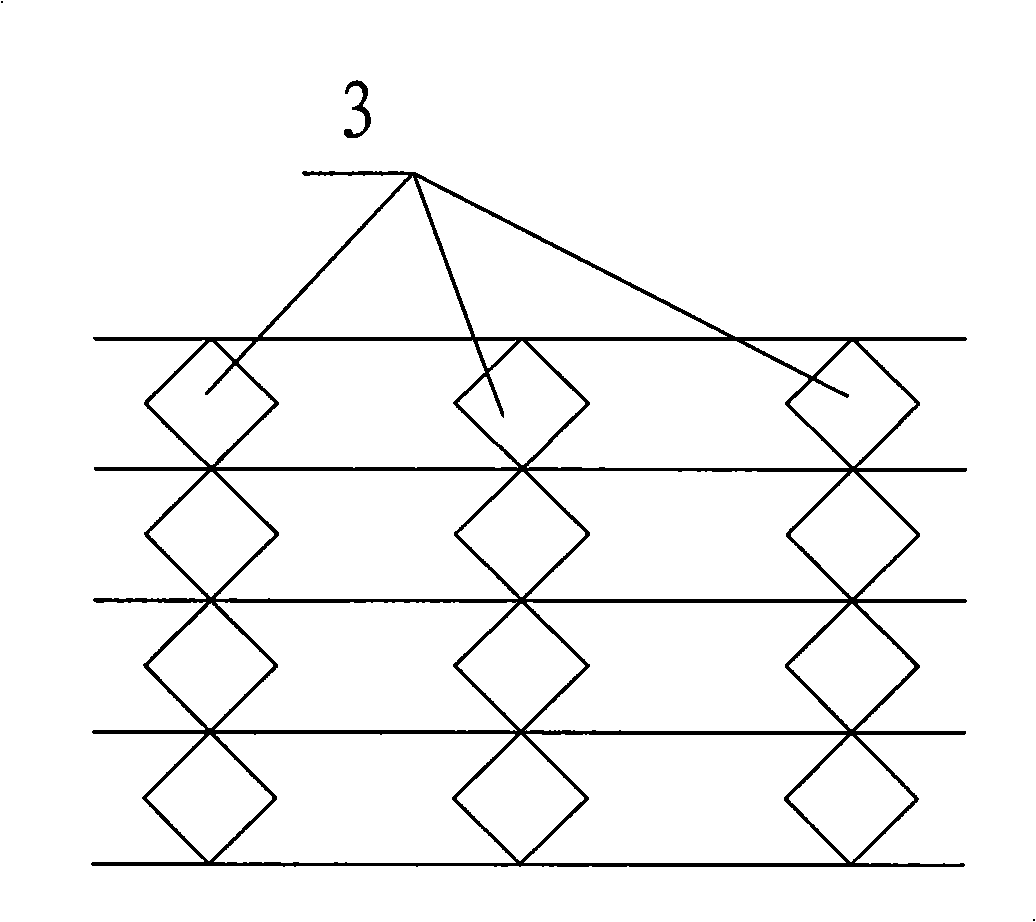

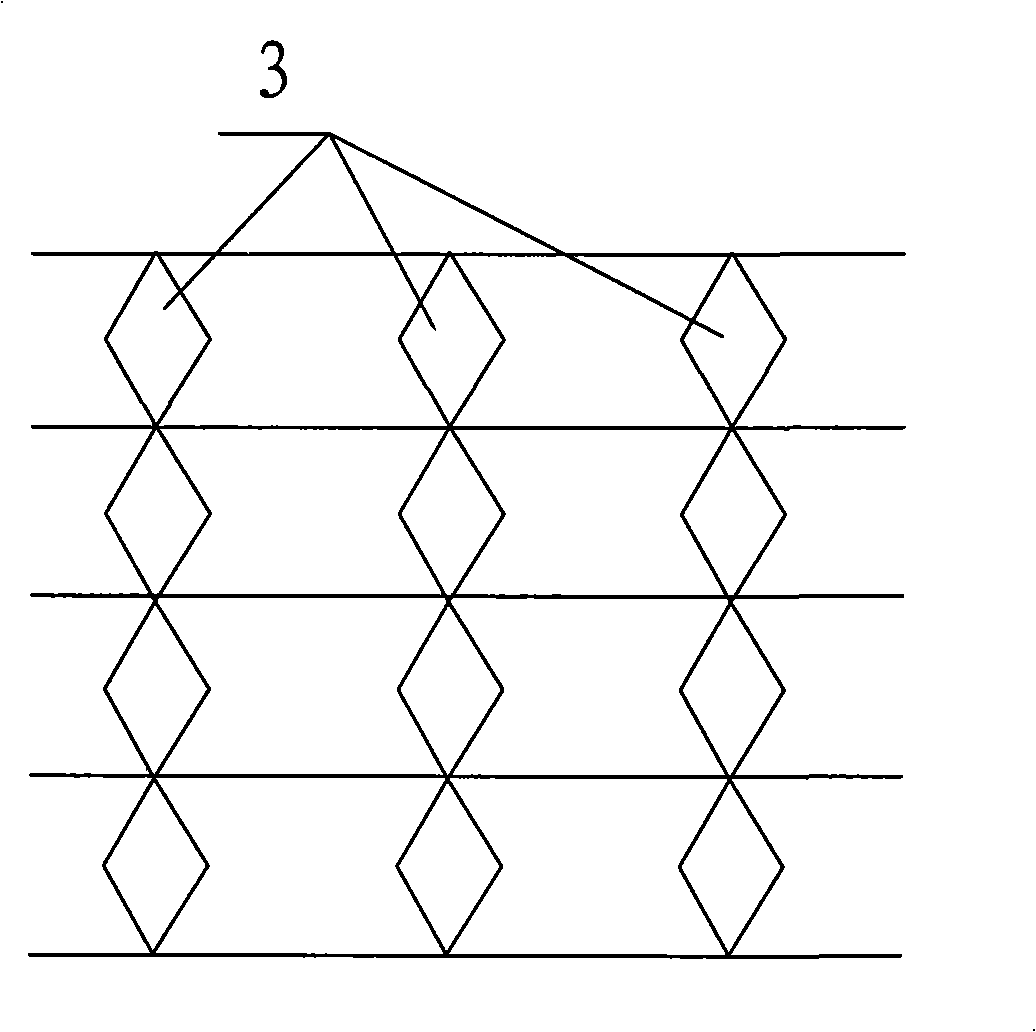

Resin impregnated multi orientation composite material

A composite material made of multiple filament bands is disclosed. The filament bands are wound to create a composite material. The filament bands may be impregnated with a solid or semi-solid resin. The filament bands are wound in multiple orientations to form a sheet of composite material. Additionally, the composite material may be made to have a varying number of layer and fiber orientations throughout the sheet of composite material. In another embodiment, a composite component requiring multiple layers and fiber orientations may be substantially manufactured during a filament winding process.

Owner:ASHTON LARRY J +4

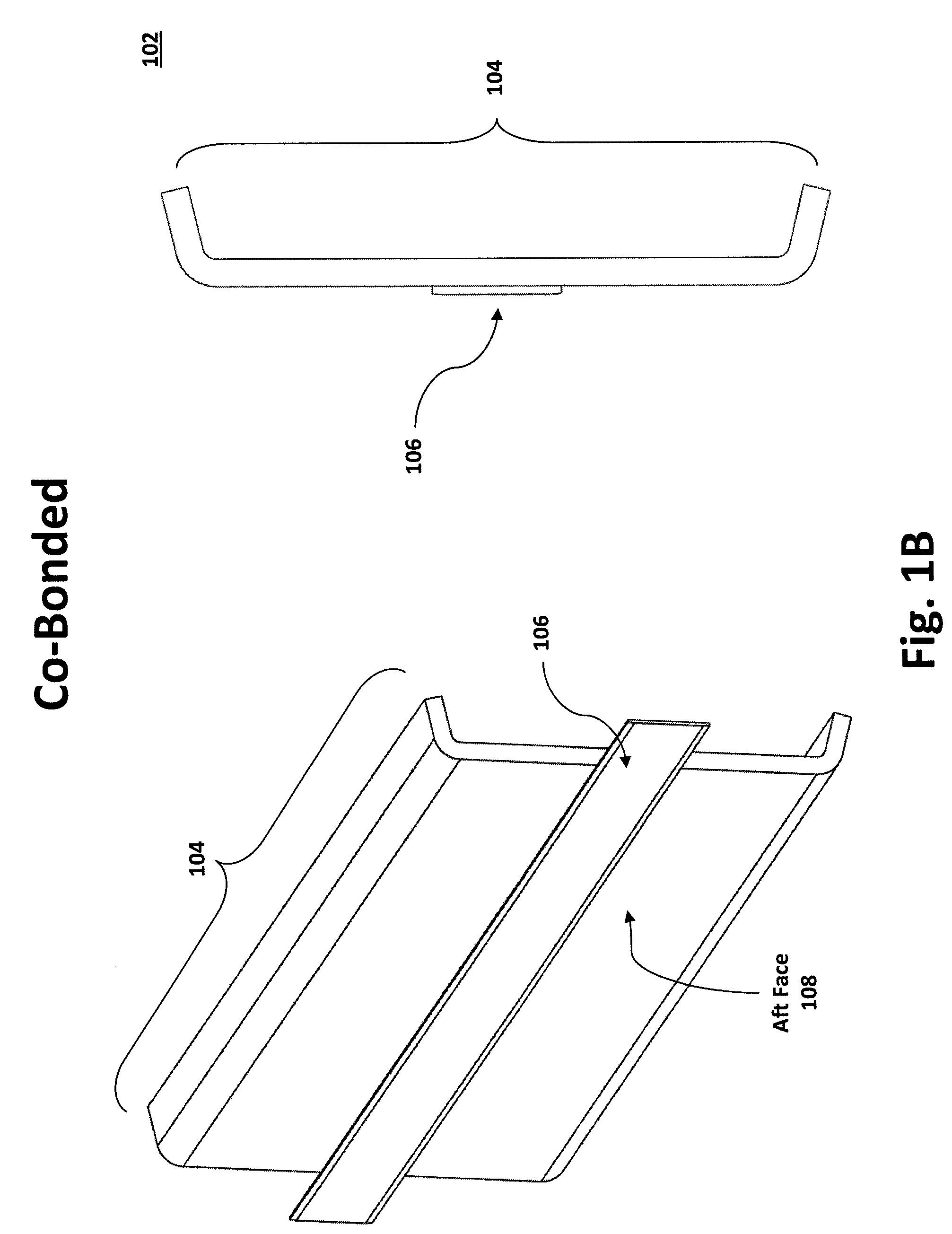

Bonded Composite Airfoil and Fabrication Method

ActiveUS20130320142A1Quality improvementEasy to produceAircraft stabilisationLaminationEngineeringComposite skin

An airfoil includes at least one precured composite spar having a web and at least one flange integrated with an end of the web. A precured composite skin is attached to the spar by adhesive bonding the skin to the flange.

Owner:THE BOEING CO

Multi orientation composite material impregnated with non-liquid resin

A composite material made of multiple filament bands is disclosed. The filament bands are wound to create a composite material. The filament bands may be impregnated with a solid or semi-solid resin. The filament bands are wound in multiple orientations to form a sheet of composite material. Additionally, the composite material may be made to have a varying number of layer and fiber orientations throughout the sheet of composite material. In another embodiment, a composite component requiring multiple layers and fiber orientations may be substantially manufactured during a filament winding process.

Owner:ROCKY MOUNTAIN COMPOSITES +1

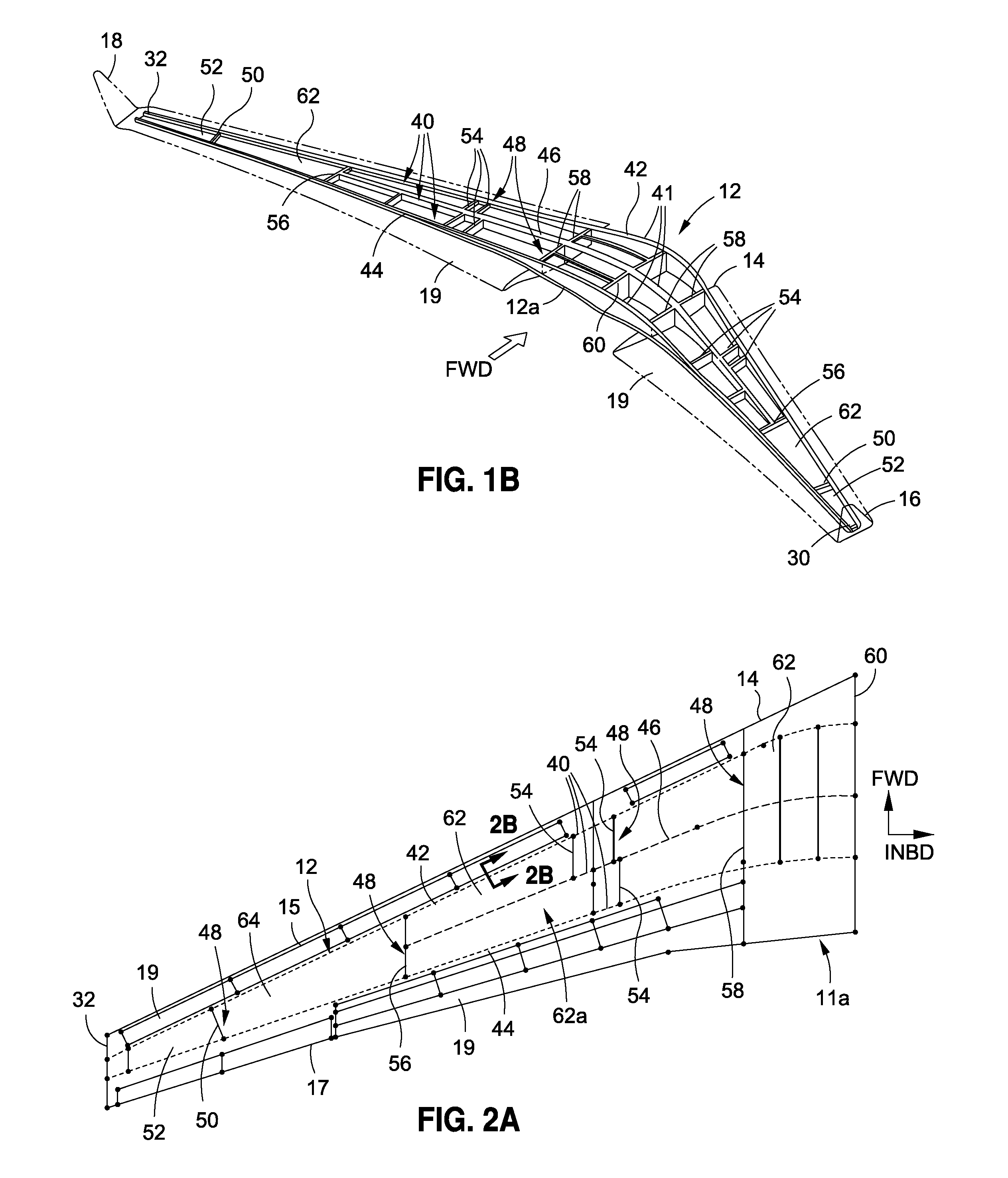

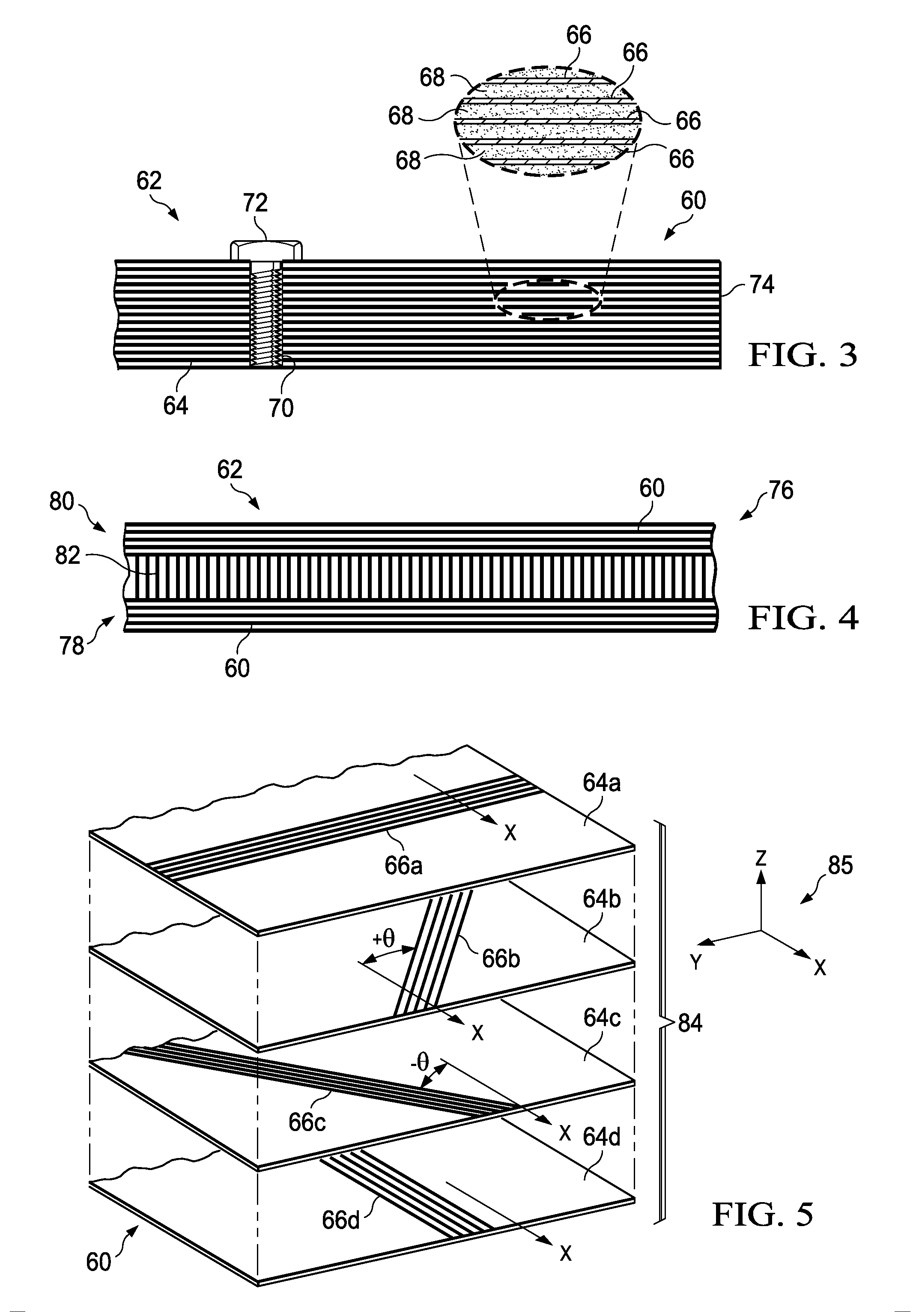

Laminate composite wing structures

ActiveUS20160207607A1Stiffening wingAircraft stabilisationMetal-working apparatusLaminated compositesFlange

A wing may include a wing skin, a laminate composite first stringer, a rib, and at least one fastener. A majority of the first stringer may be characterized by a stacked plurality of generally planar plies of reinforcement material structurally joined as a stack to an interior surface of the wing skin and extending generally parallel to the interior surface and a span-wise direction of the wing along a substantial portion of the interior surface. The first stringer may have a generally solid trapezoidal cross section when viewed in a plane that is generally perpendicular to the span-wise direction. The rib may be positioned adjacent the interior surface, and may extend generally perpendicular to the span-wise direction. The trapezoidal cross section may be interfaced with the rib flange. The fastener may extend through the wing skin, the trapezoidal cross section, and the rib flange.

Owner:THE BOEING CO

Multifunctional de-icing/anti-icing system

ActiveUS8931740B2Increase temperatureHigh component strengthDe-icing equipmentsSandwich constructionsIce protection systemElectrical conductor

A de-icing / anti-icing system including at least two conductive structures embedded in an article that includes an outer surface designed as an aerodynamic surface. At least one of the conductive structures is arranged adjacent the outer surface. A control unit adapted to control the energy supply to the conductive structures for generating heat to the outer surface. A first of the conductive structures includes a first conductive nano structure and a second of the conductive structures includes a second conductive nano structure. A conductive property of the first of the conductive structures differs from a conductive property of the second of the conductive structures. The first conductive nano structure serves as a heating conductor and the second conductive nano structure serves as a heating element. The first and second conductive nano structures are embedded in a common plane of a resin layer forming the outer surface.

Owner:SAAB AB

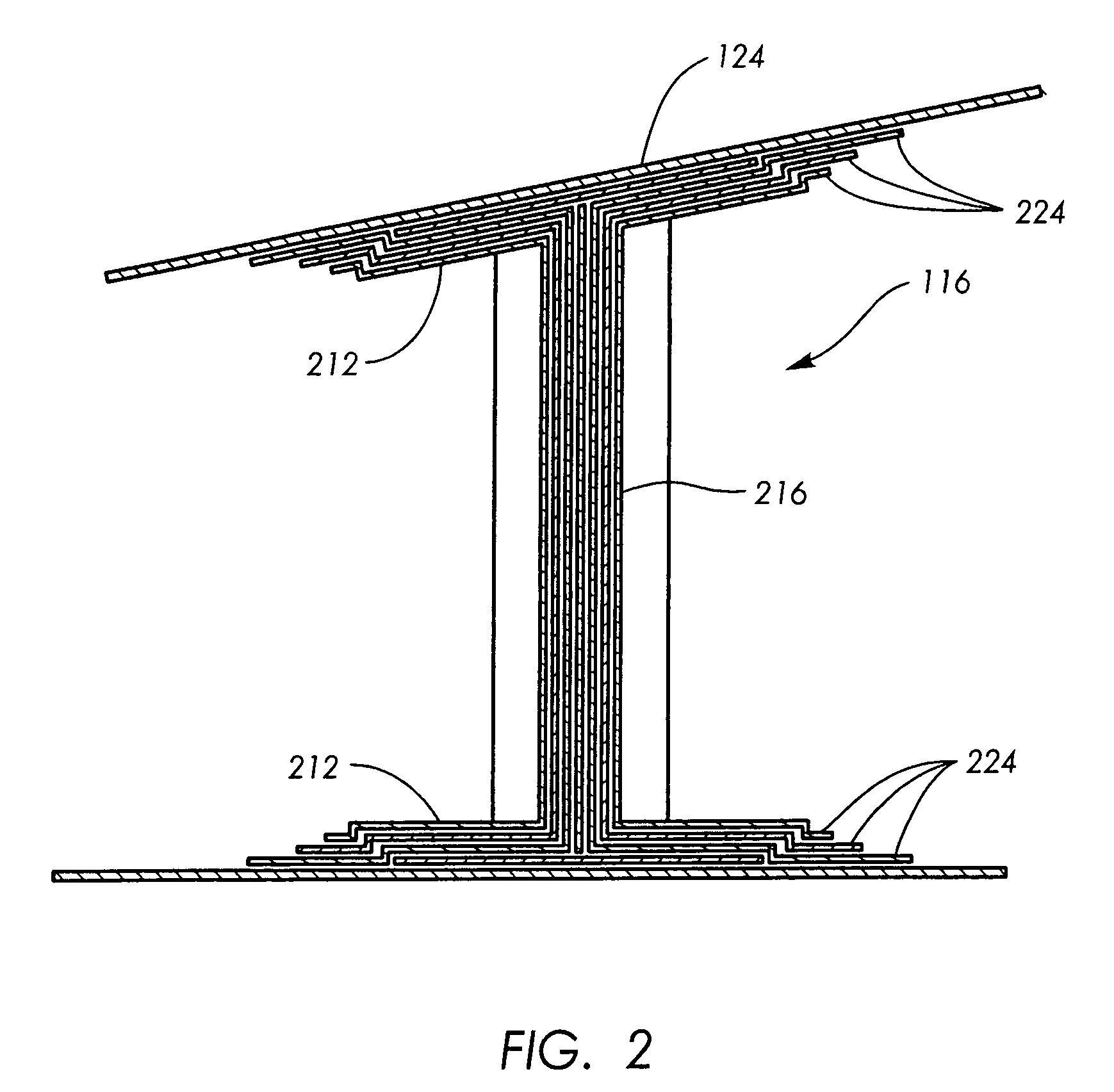

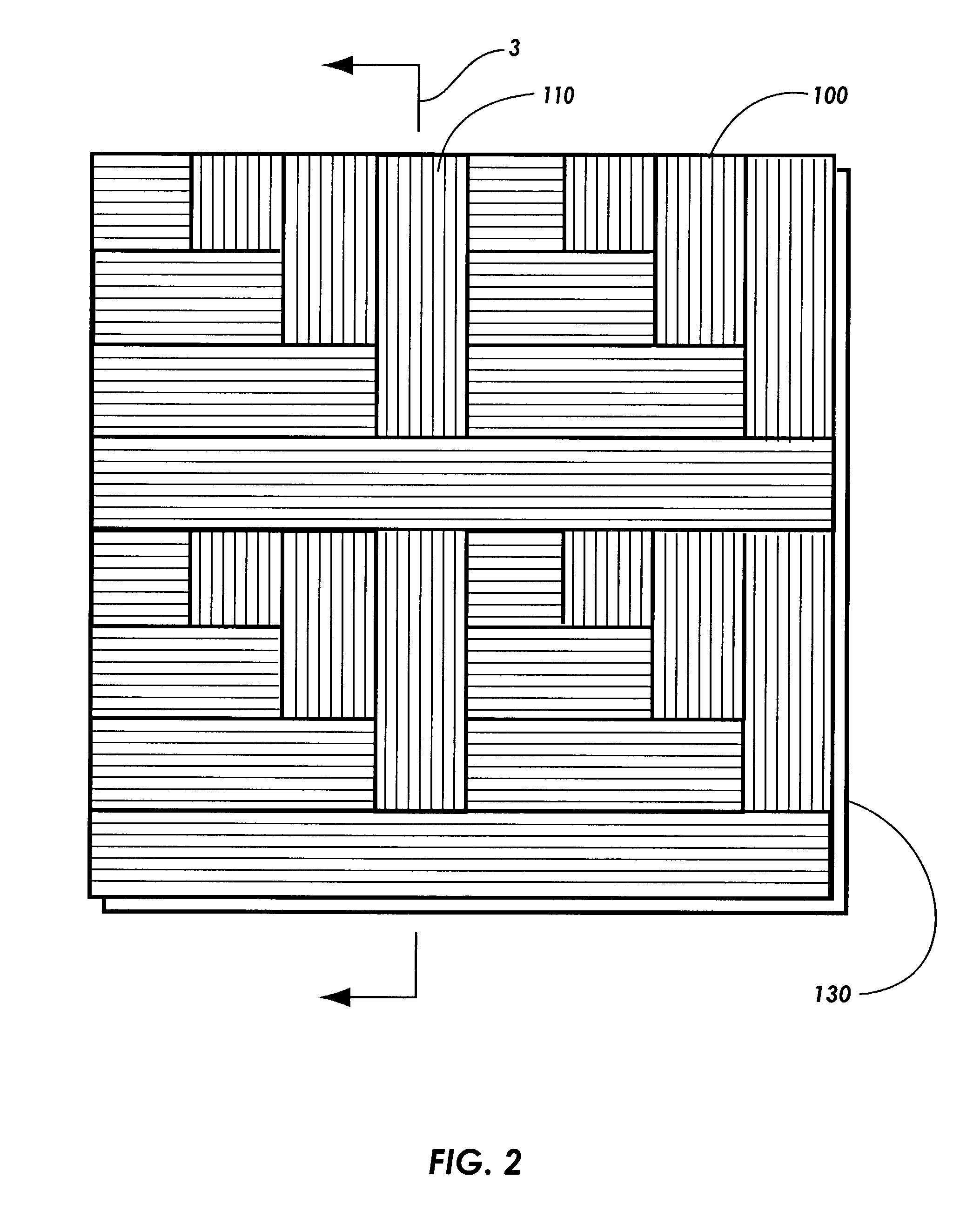

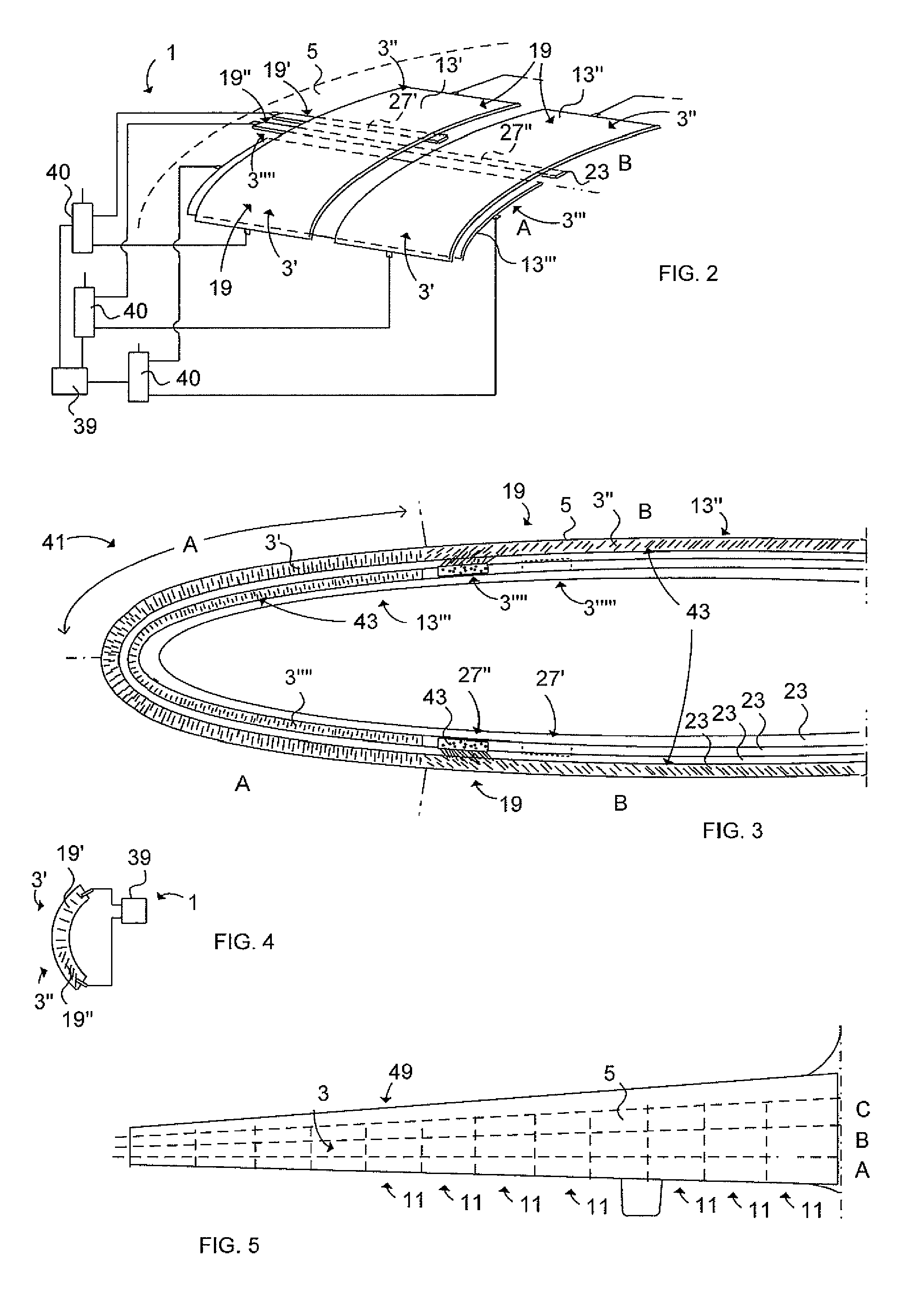

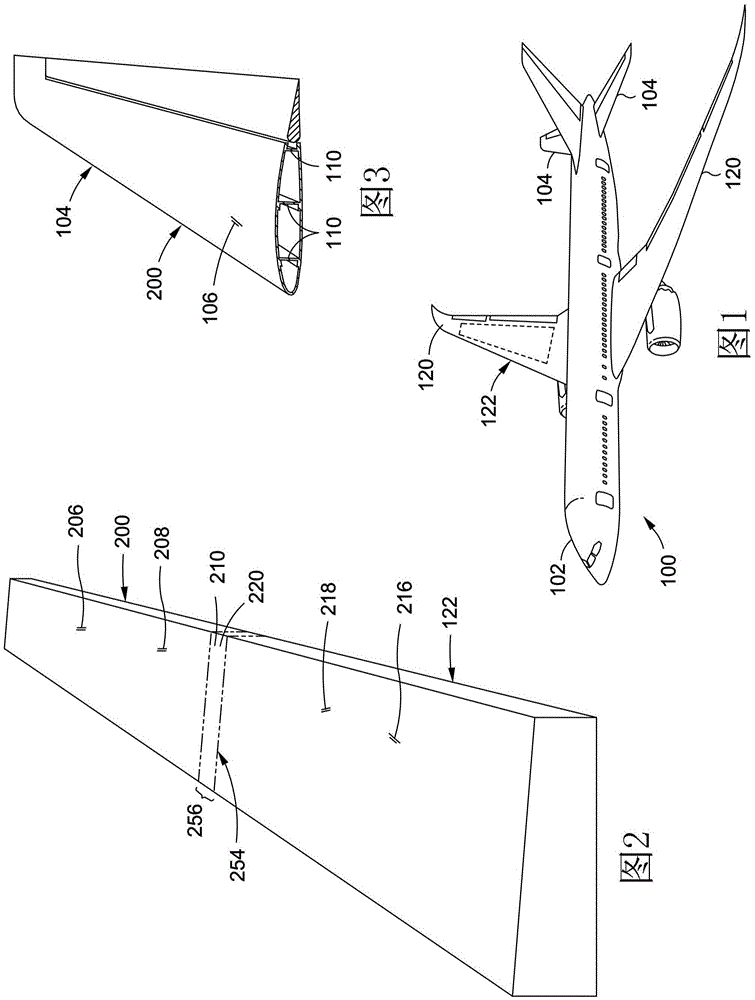

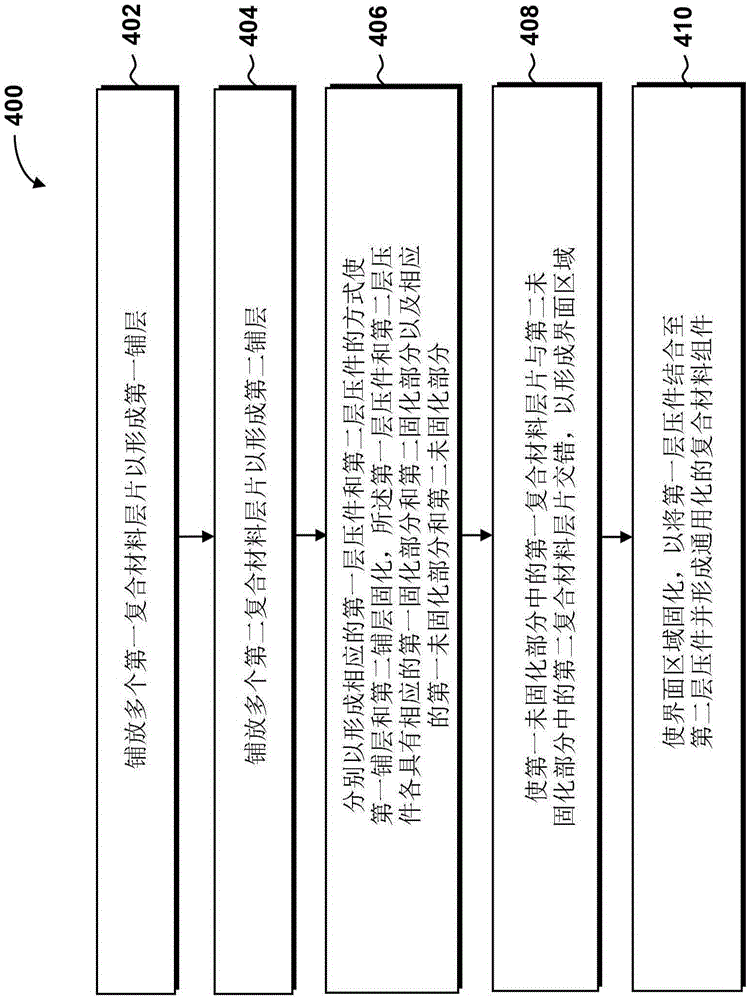

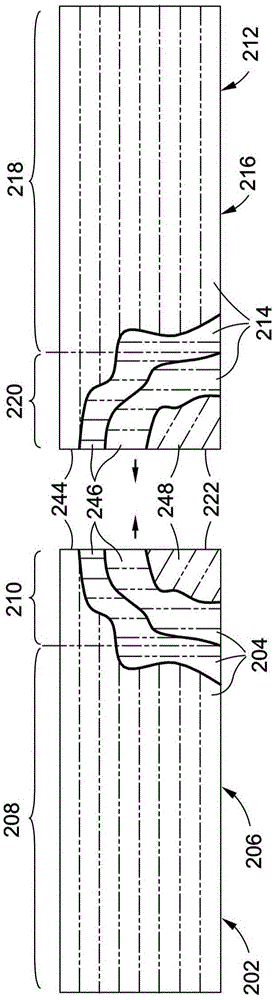

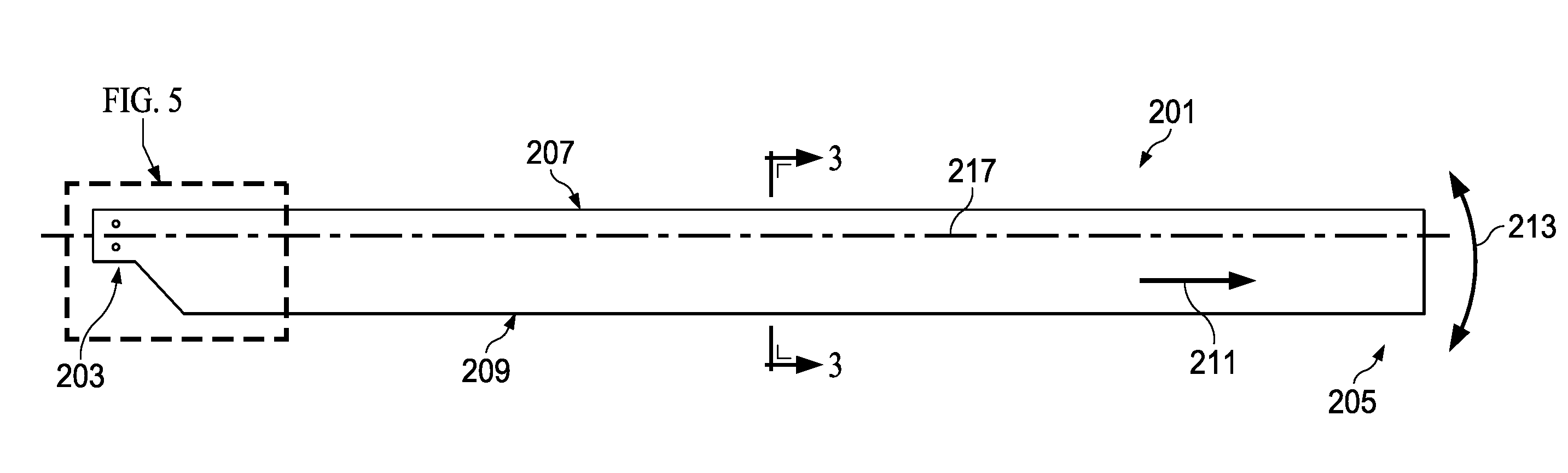

Co-curing process for the joining of composite structures

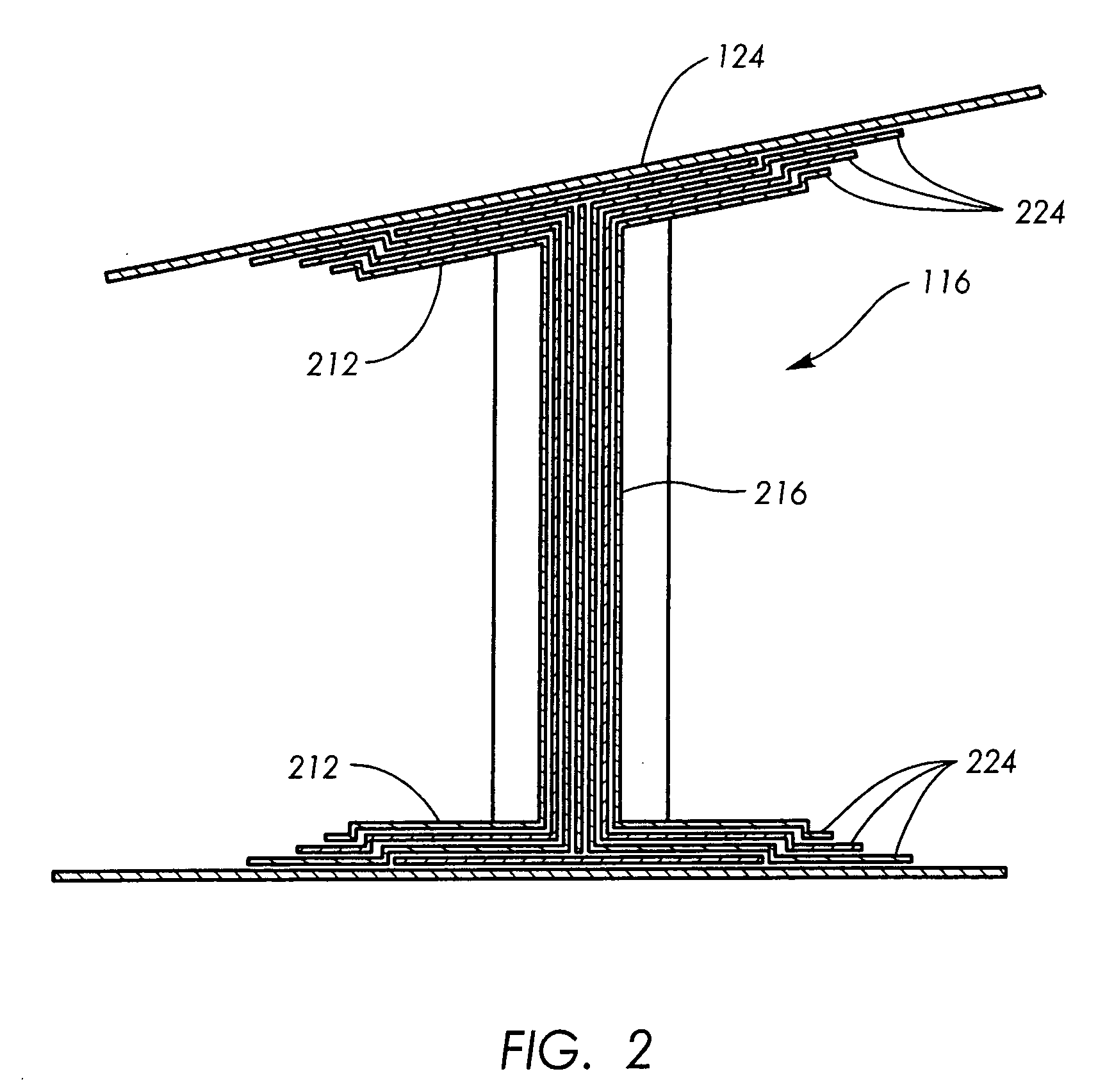

The invention relates to a co-curing process for the joining of composite structures. A method of fabricating a composite assembly (200) may include providing a first laminate (206) and a second laminate (216) respectively formed of first and second composite plies (204, 214), and having a respective first and second cured section (208, 218) and a respective first and second uncured section (210, 220). The method (200) may further include interleaving the first composite plies (204) in the first uncured section (210) with the second composite plies (214) in the second uncured section (220) to form an interfacial region (256). The method may additionally include curing the interfacial region (256) to join the first laminate (206) to the second laminate (216) and form a unitized composite assembly (200).

Owner:THE BOEING CO

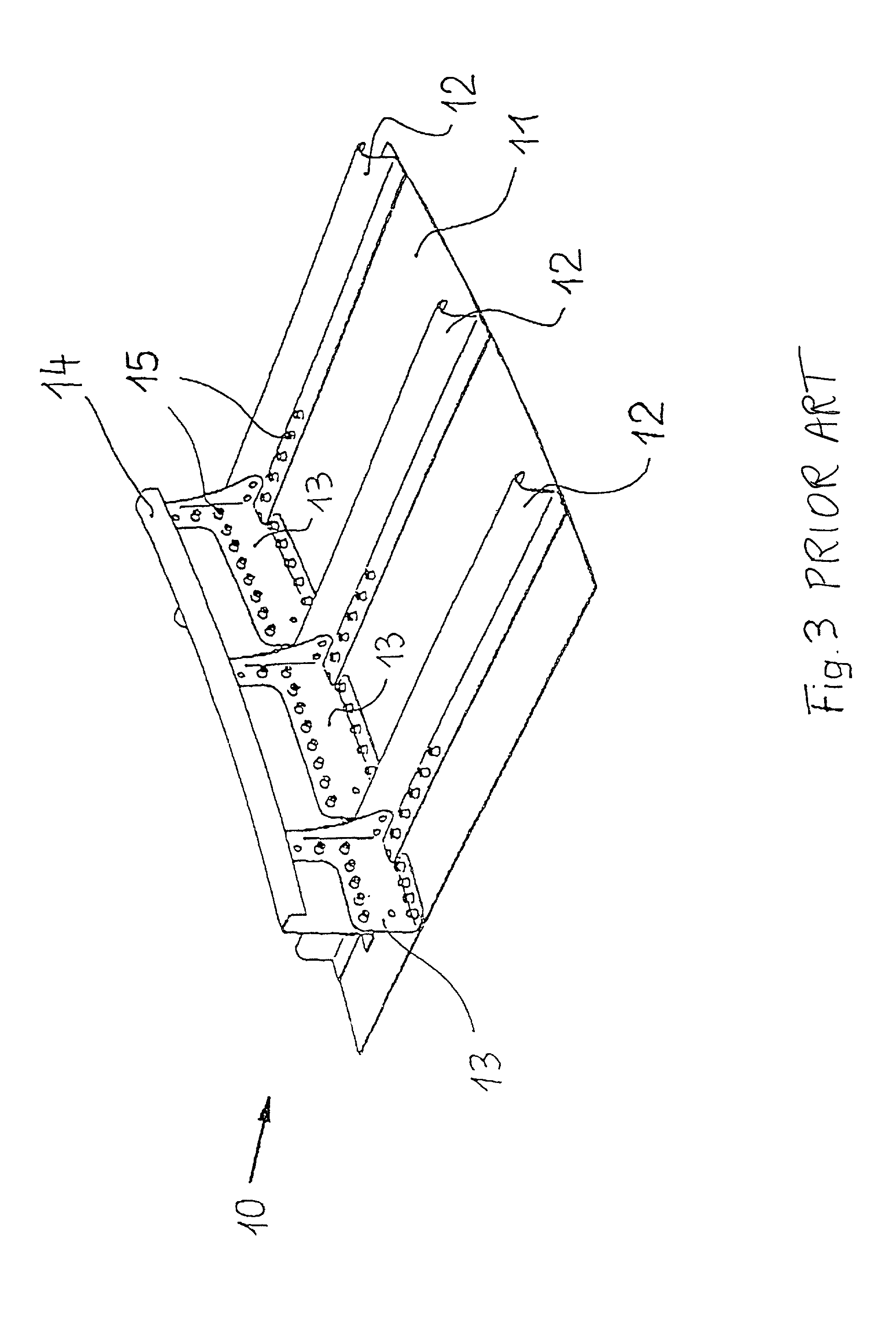

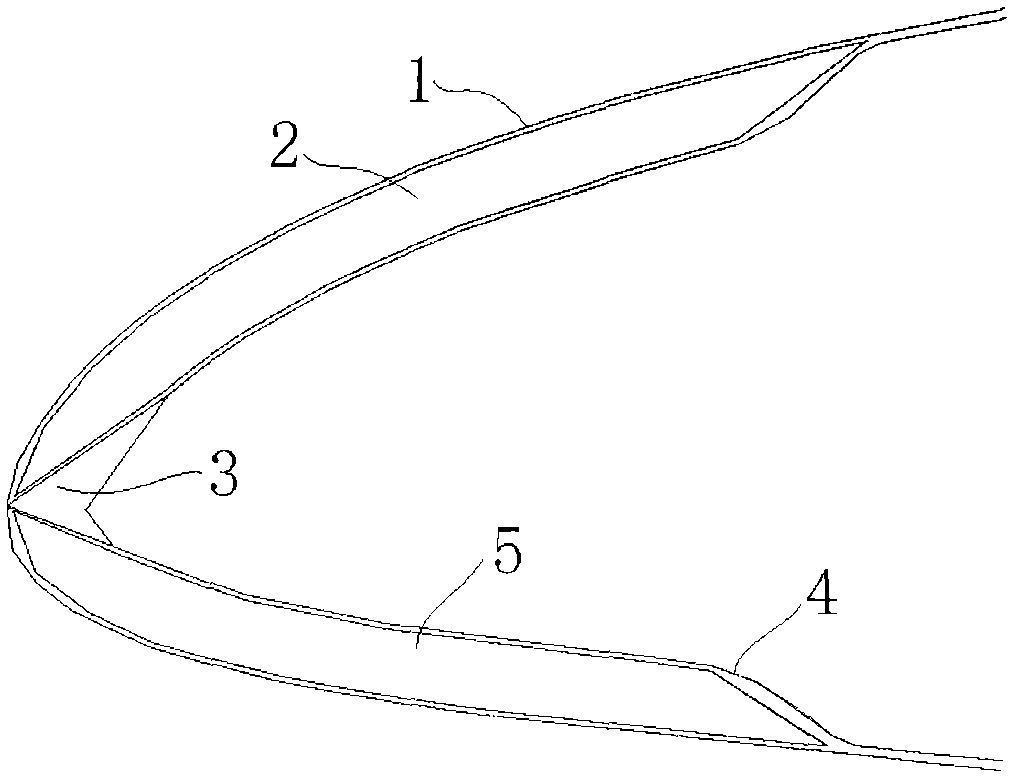

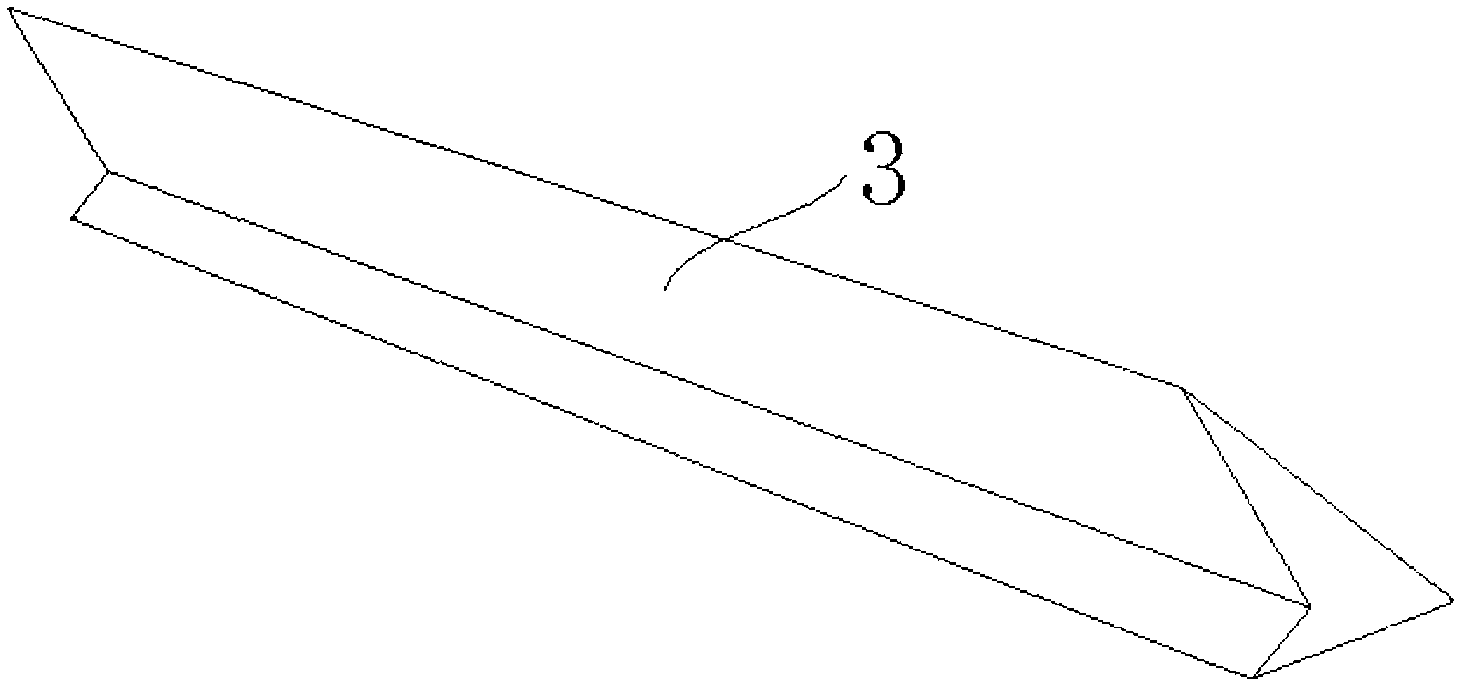

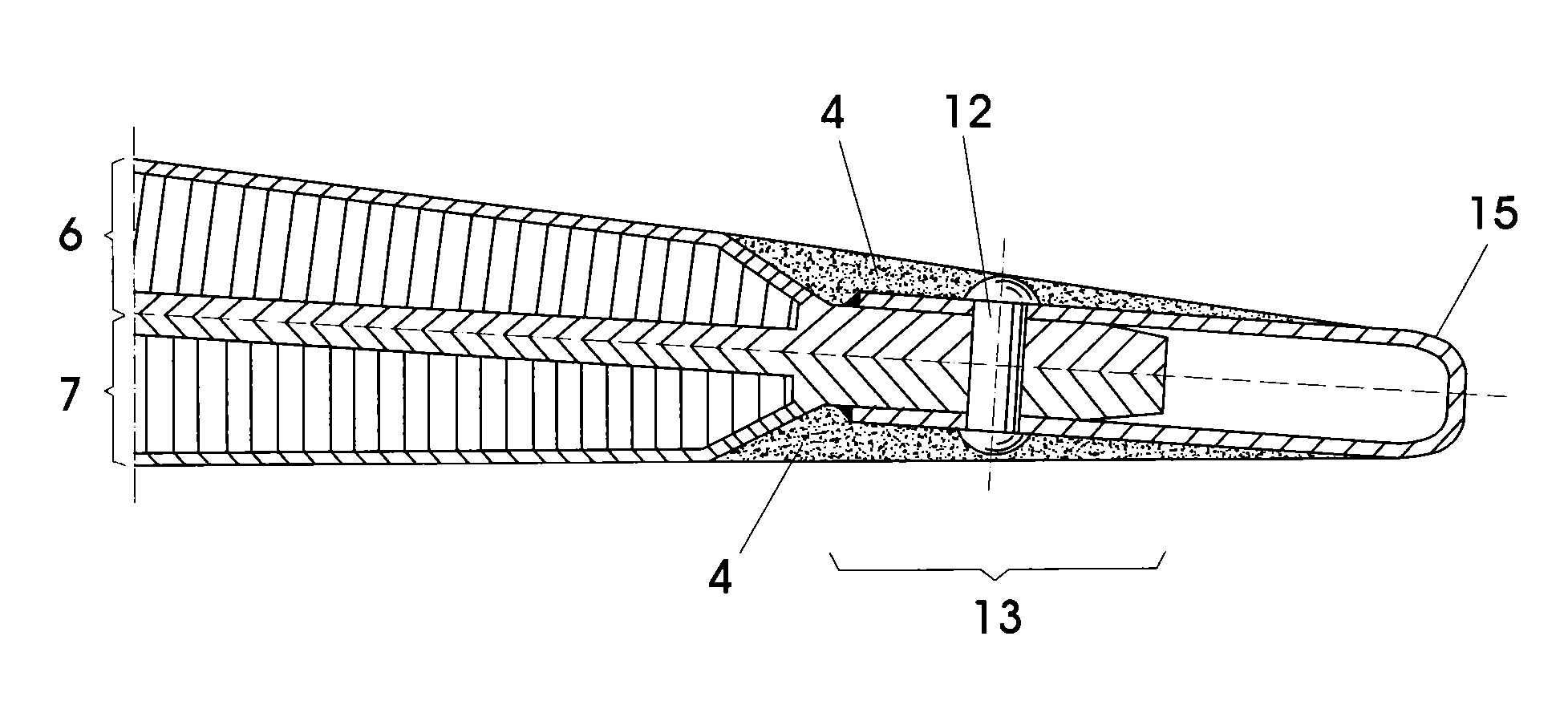

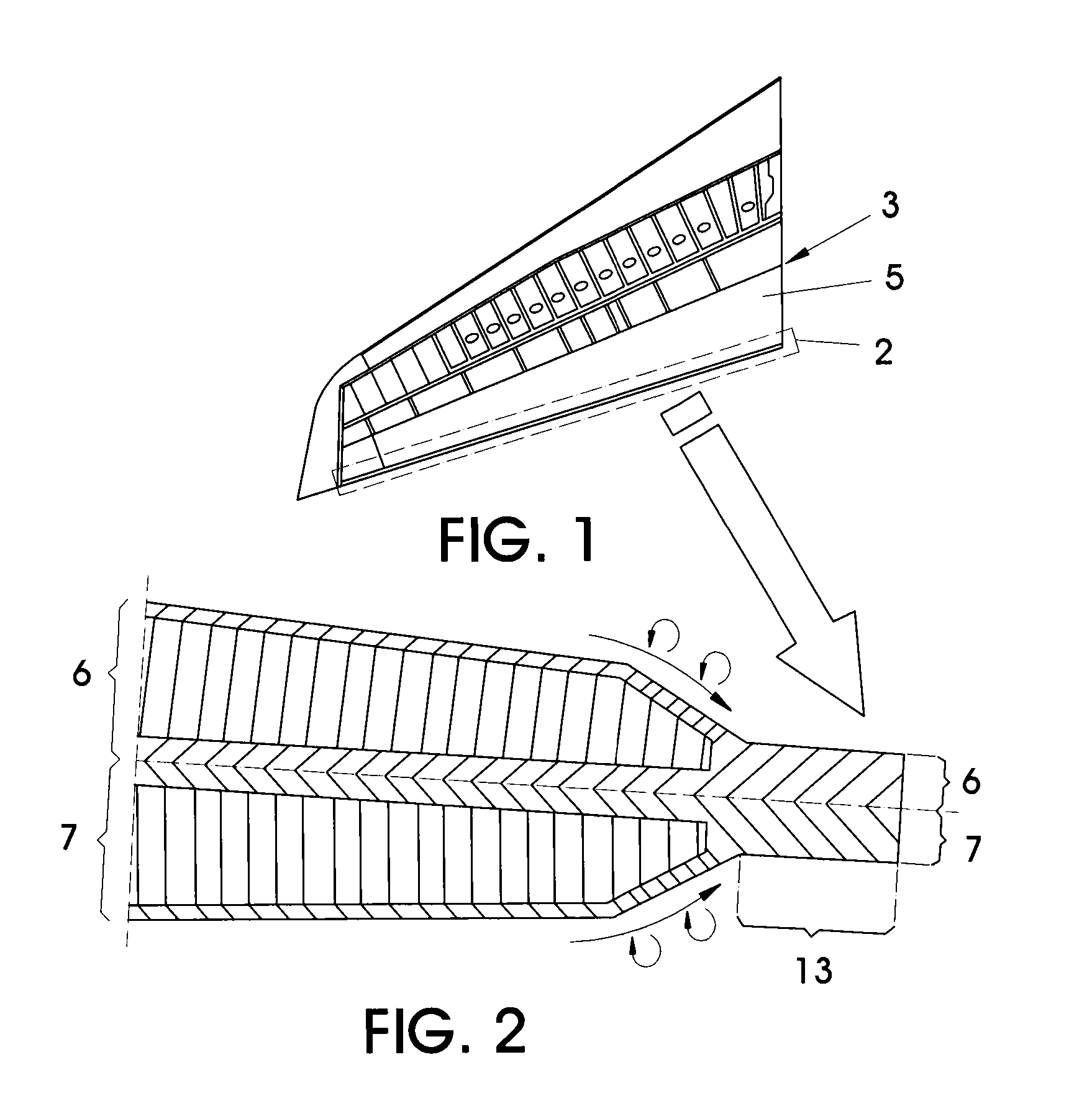

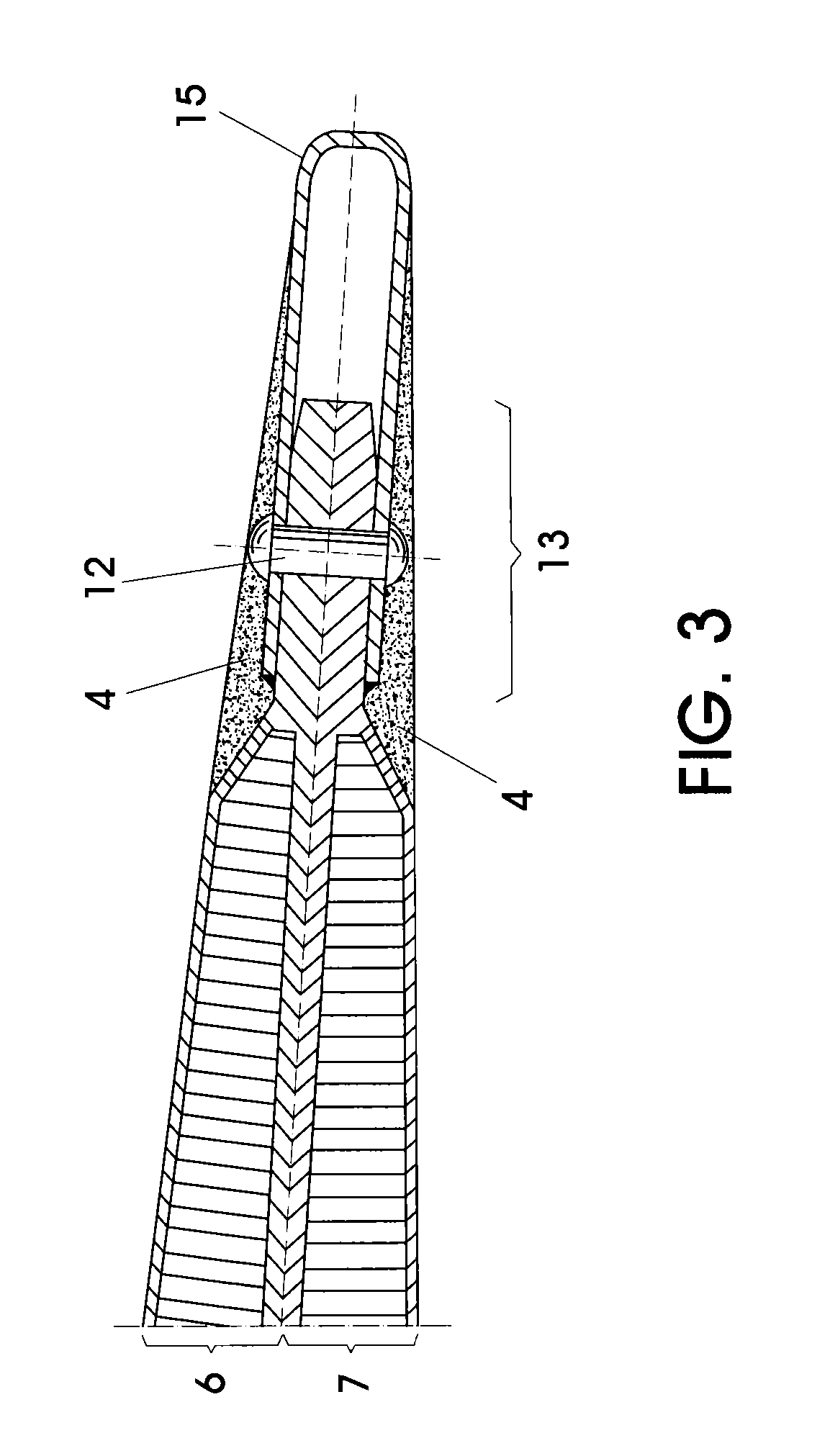

Trailing edge of an aircraft aerodynamic surface

The invention discloses a trailing edge (2) of an aircraft aerodynamic surface, which comprises an upper skin (6) and a lower skin (7), being the upper and lower skins (6, 7) made of composite material. In the trailing edge (2) a lightweight part (1) is assembled at an end section (13) of the upper and lower skins (6, 7). The lightweight part (1) is covered by a metallic sheet (8), and has a “V”-shaped cross section with arms and peak, where the peak of the “V”-shaped cross section has a rounded shape and is located opposite the end section (13) of the upper and lower skins (6, 7).

Owner:AIRBUS OPERATIONS SL

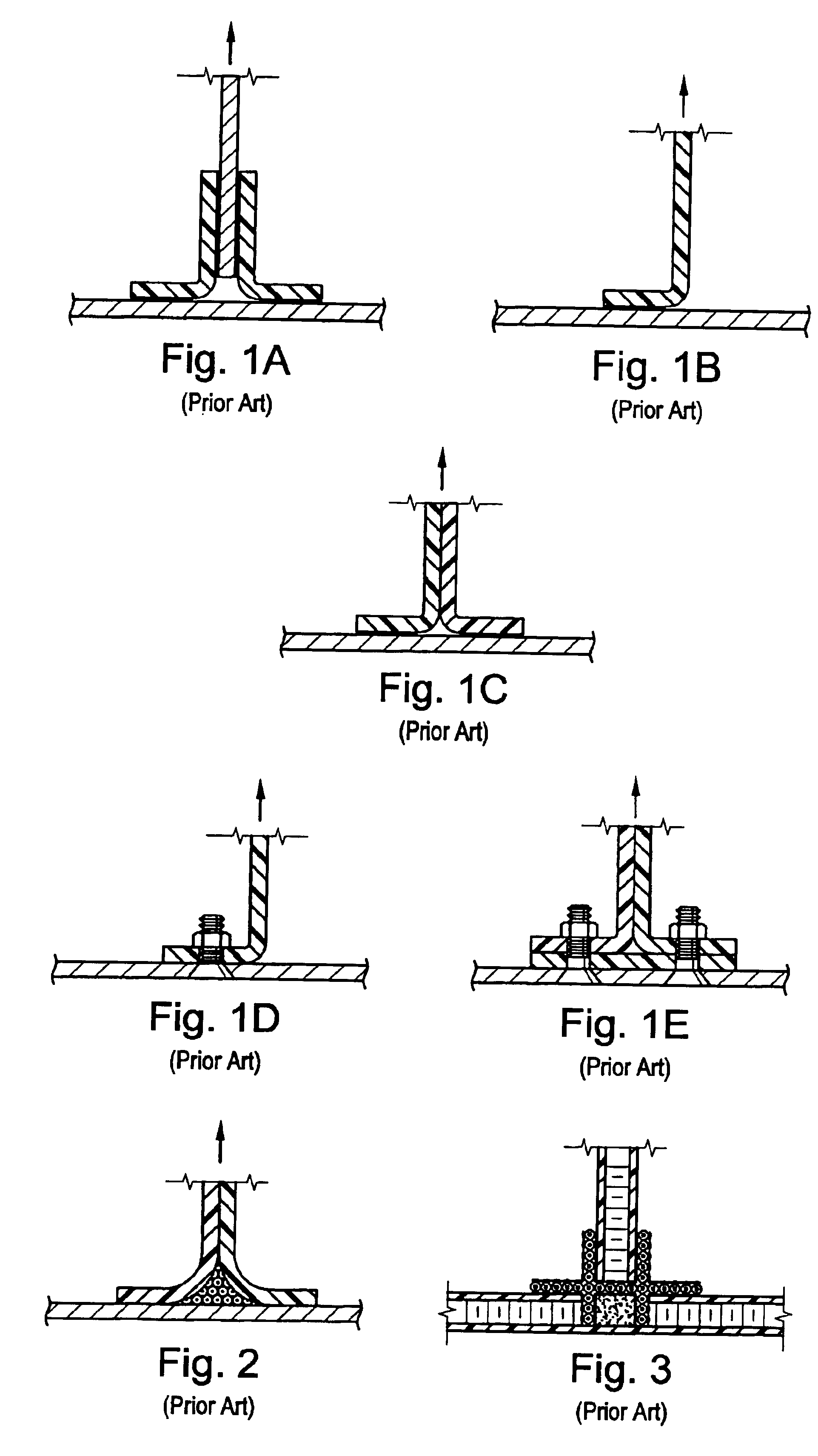

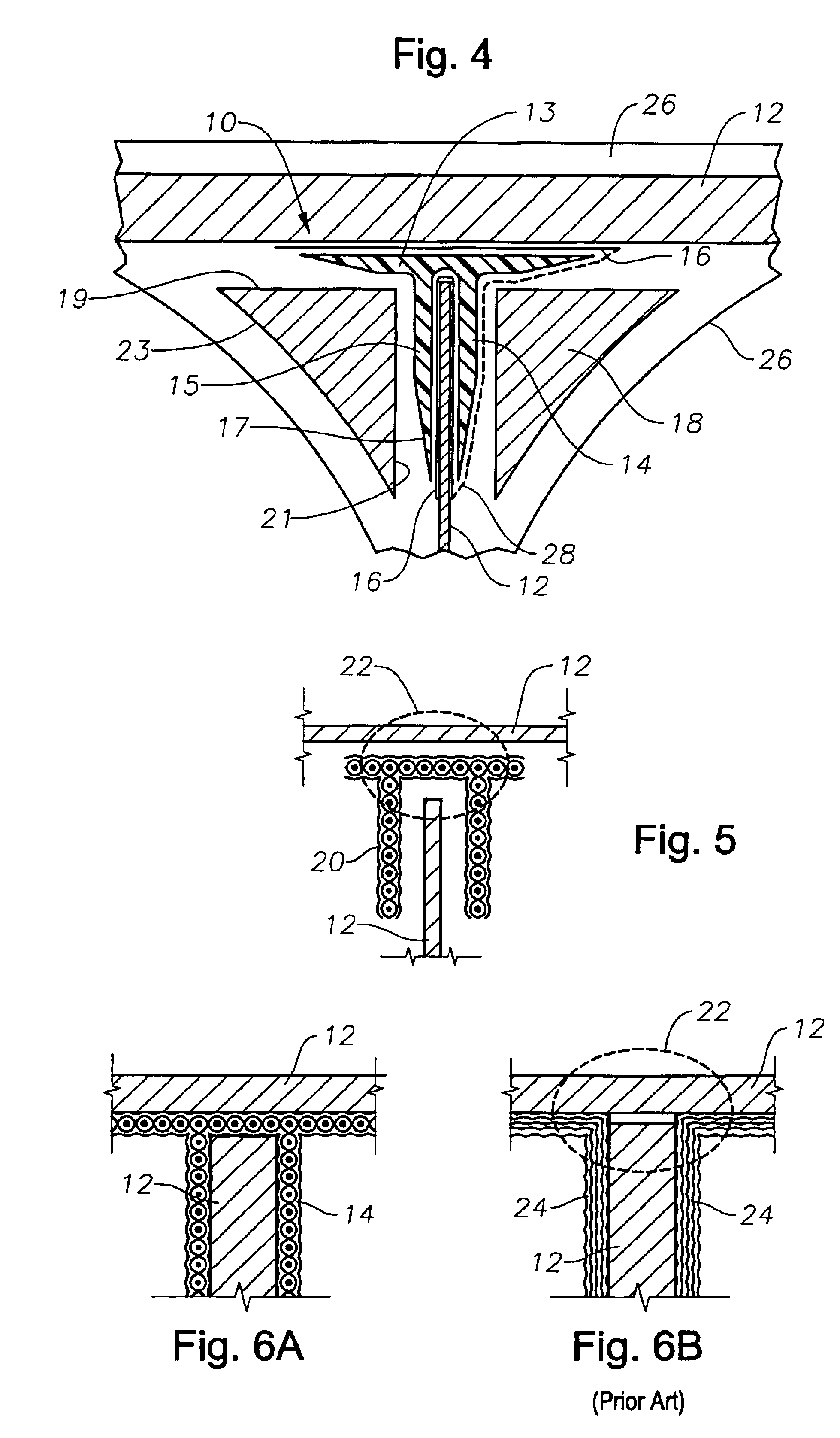

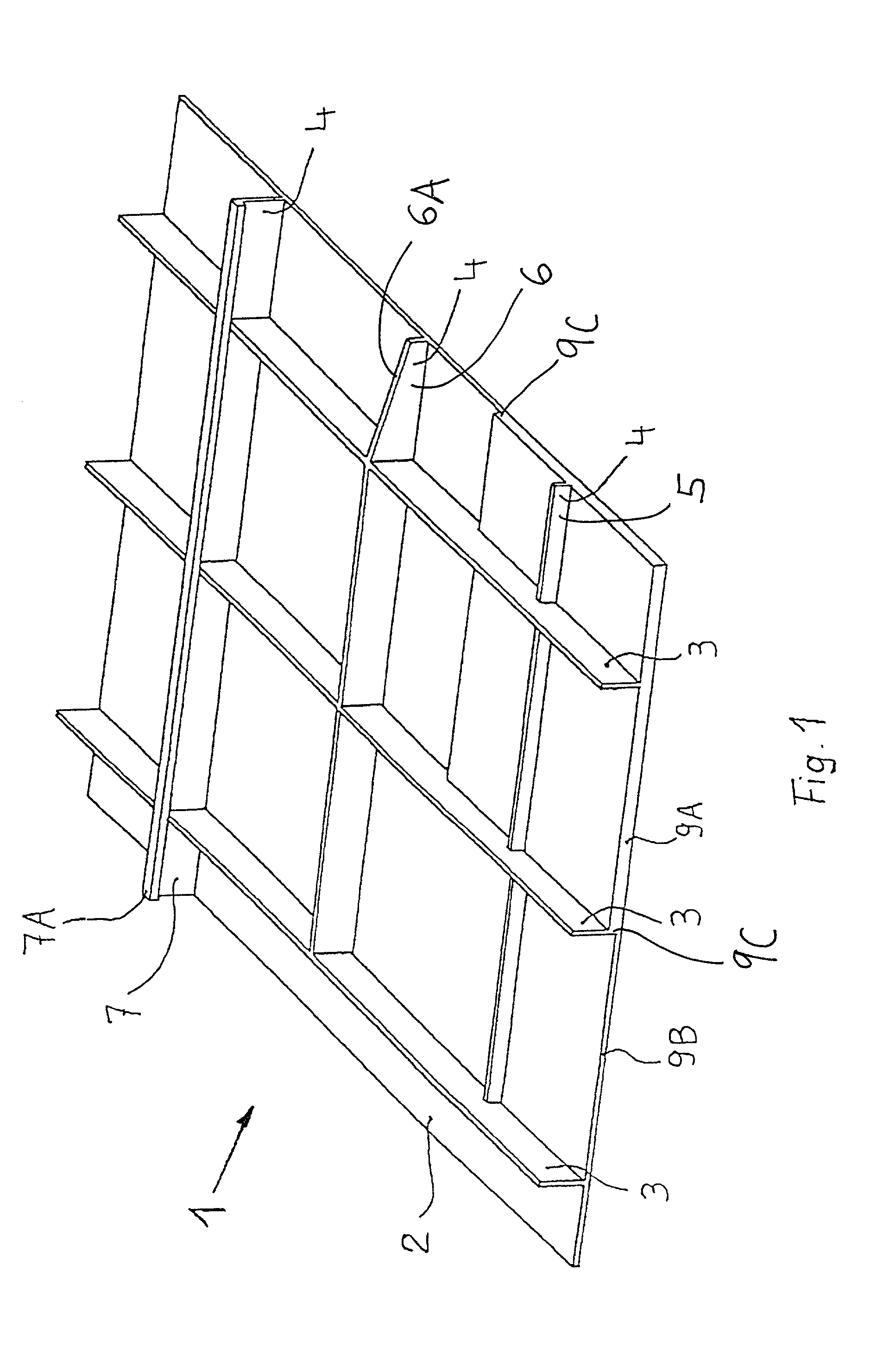

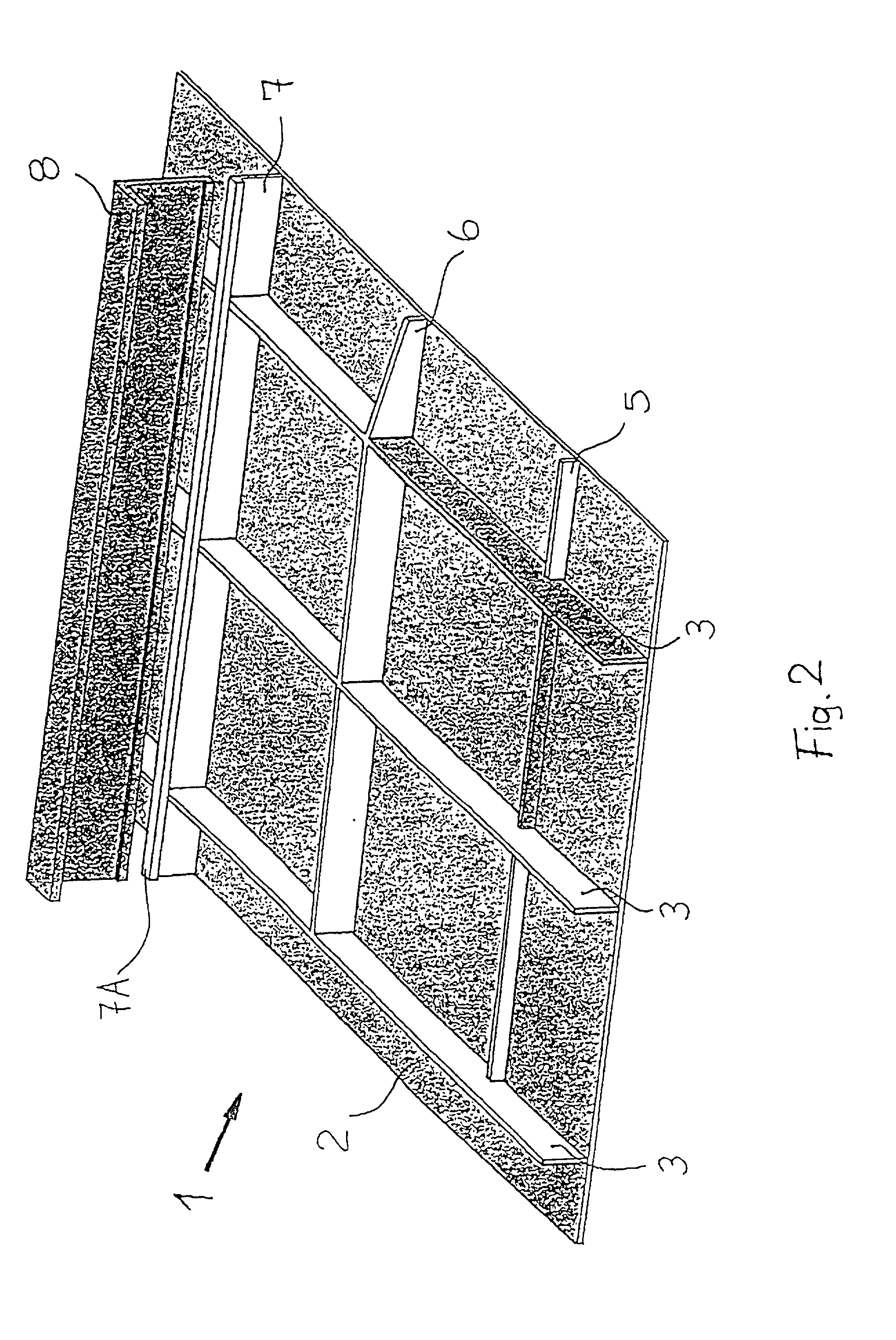

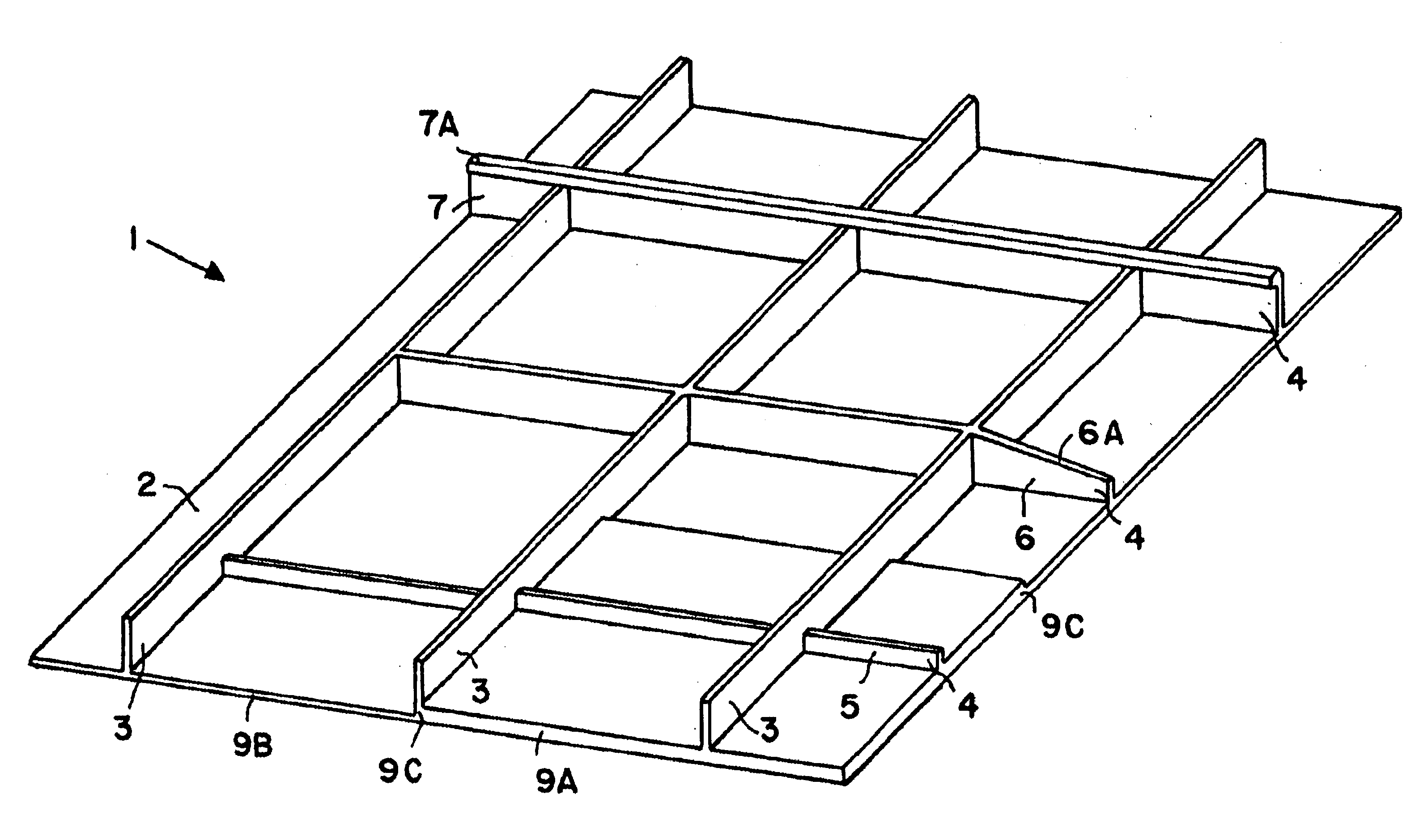

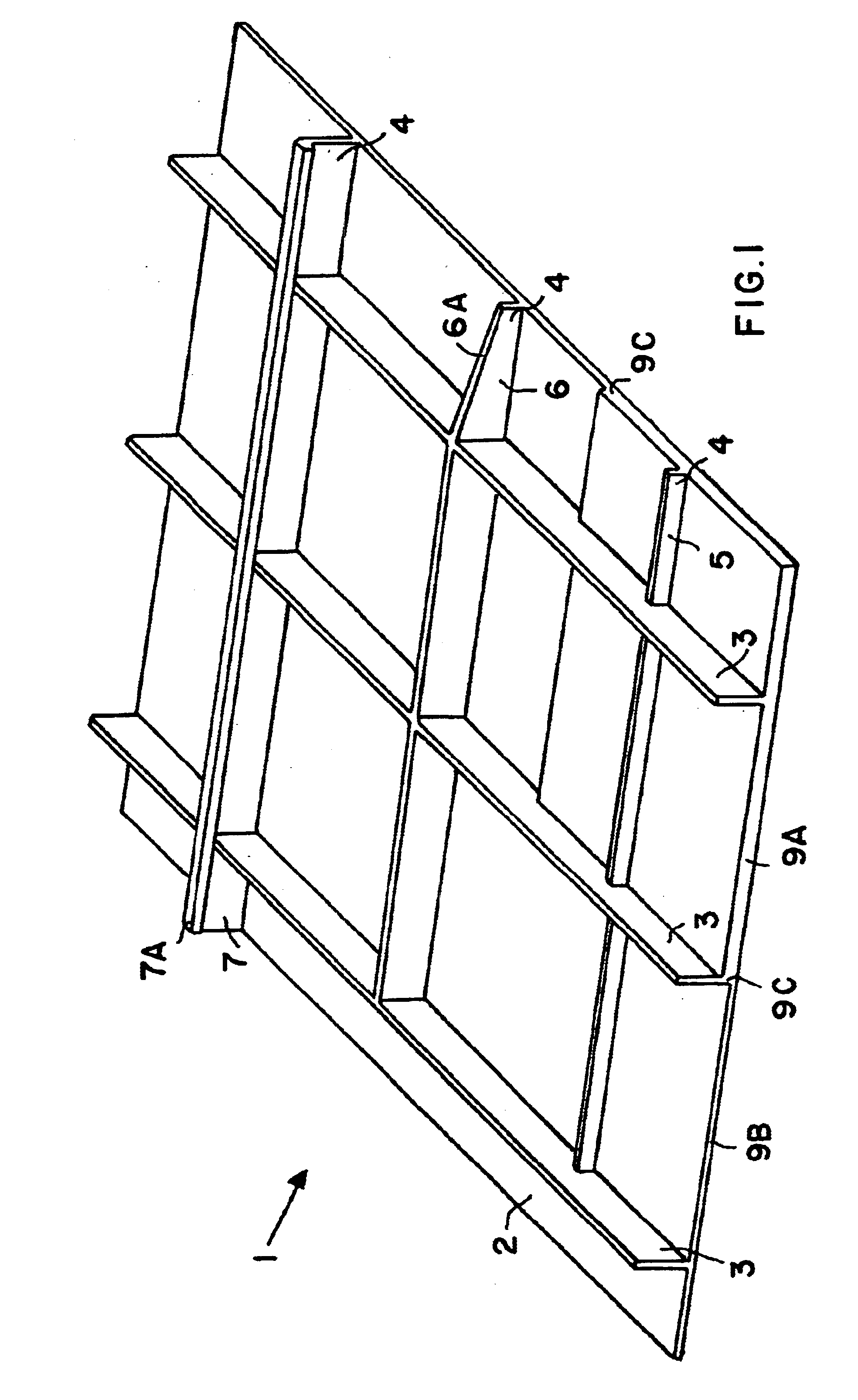

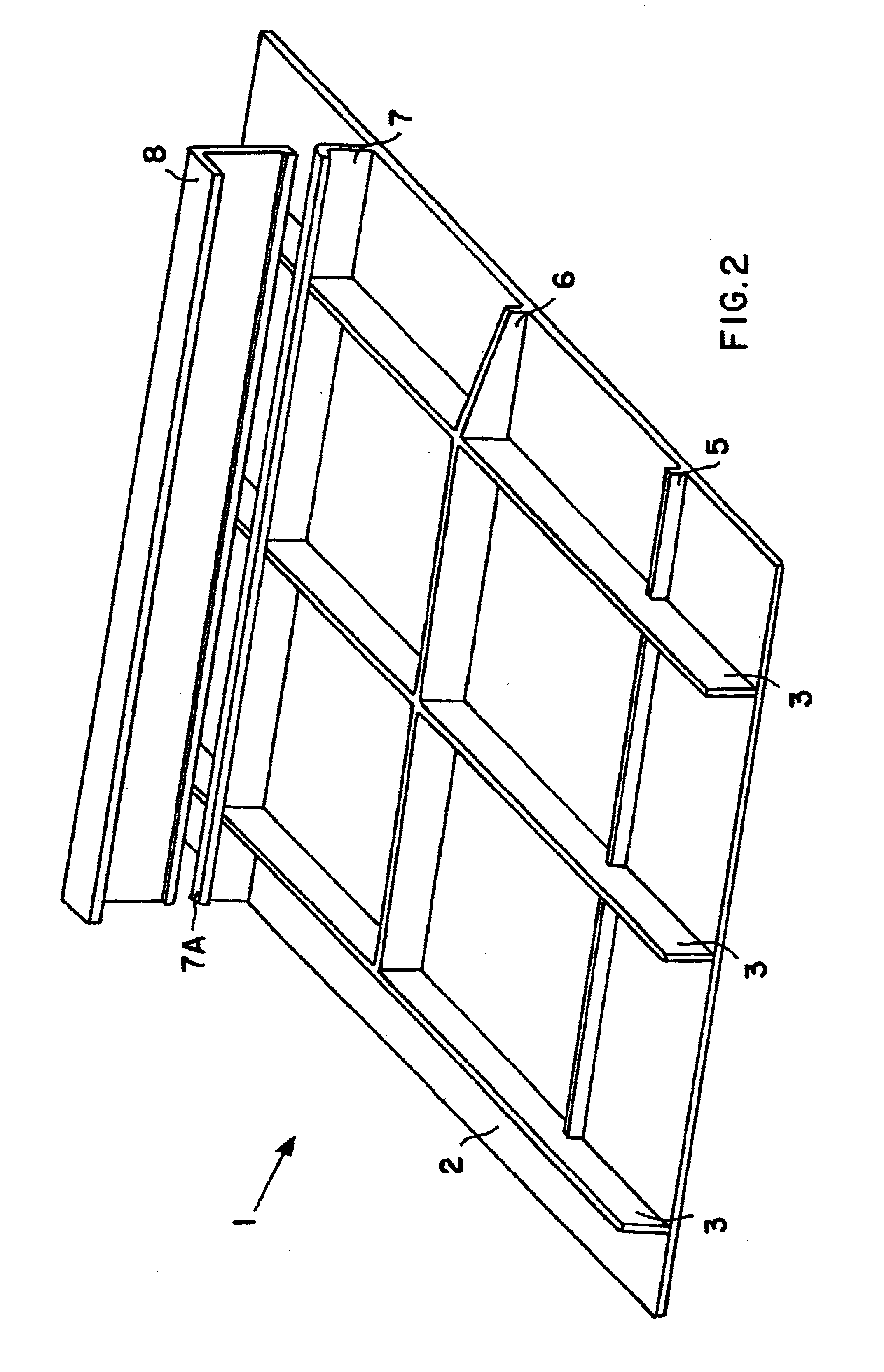

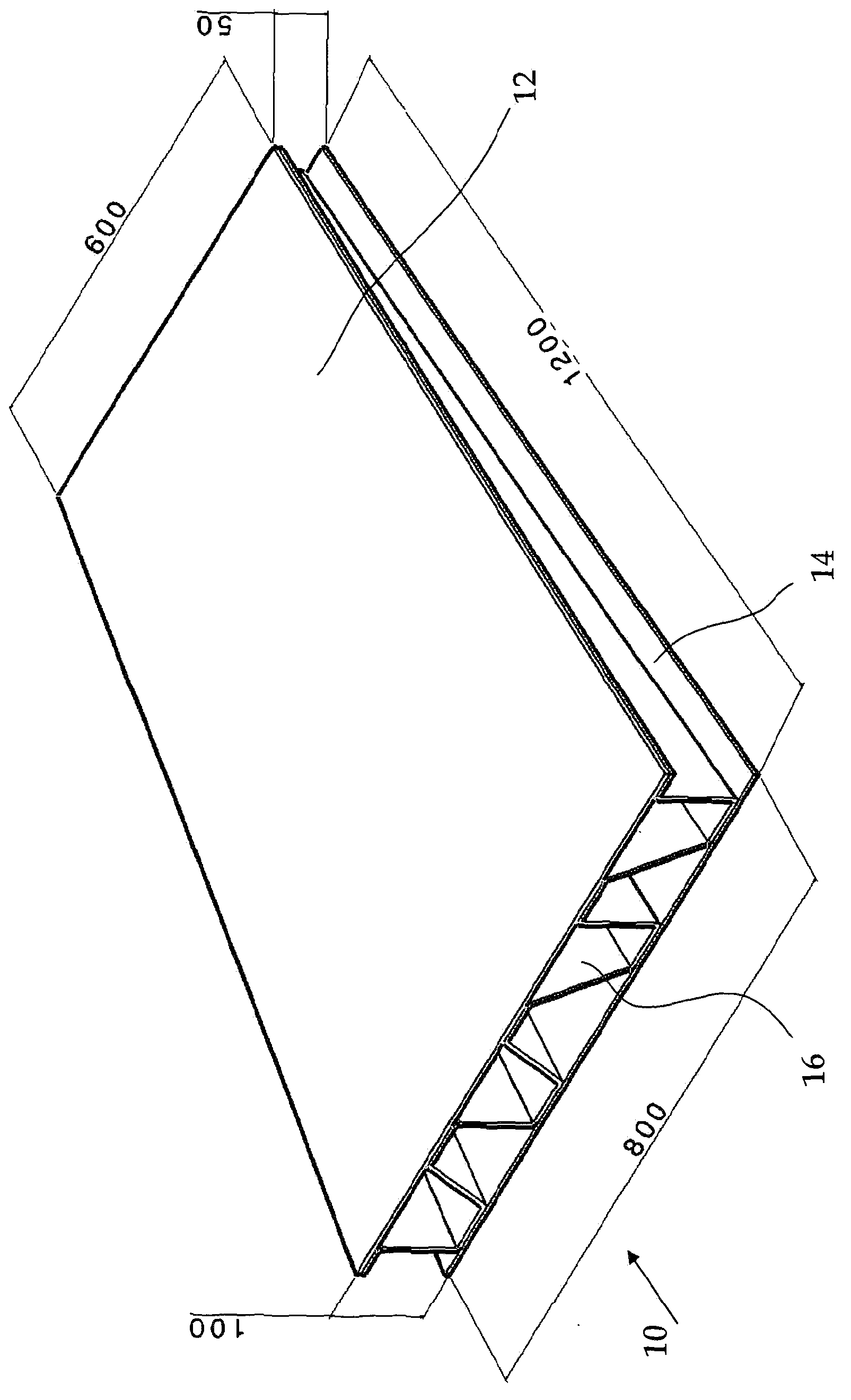

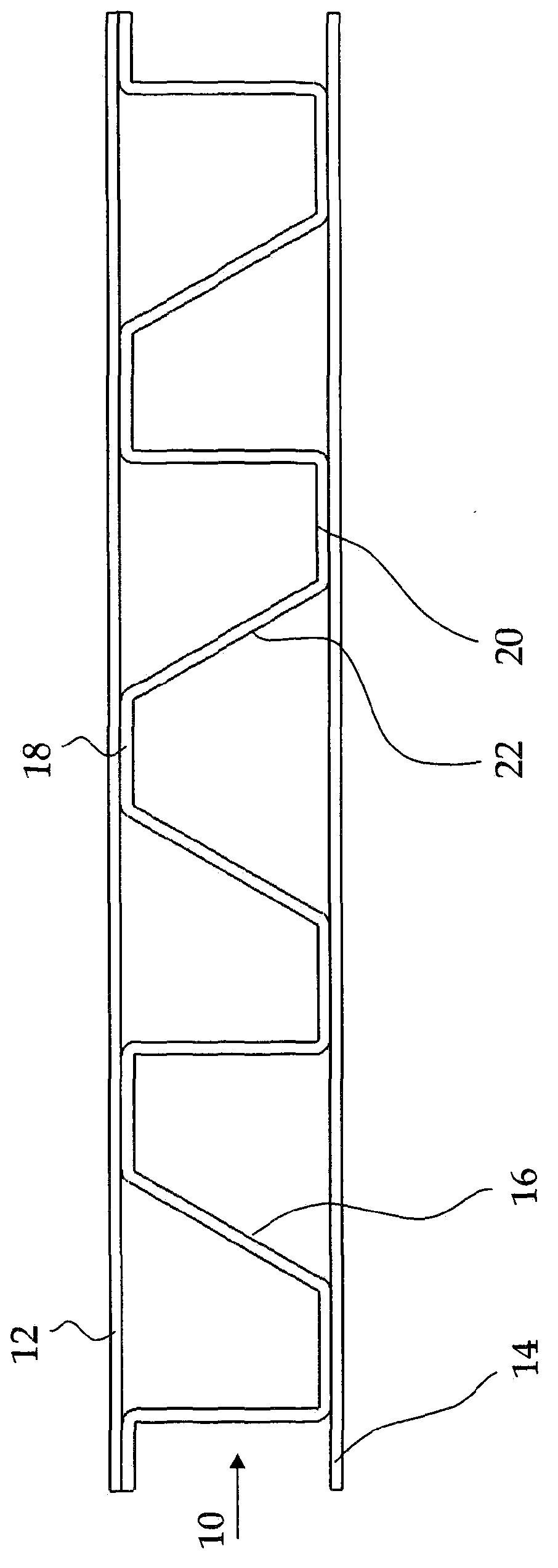

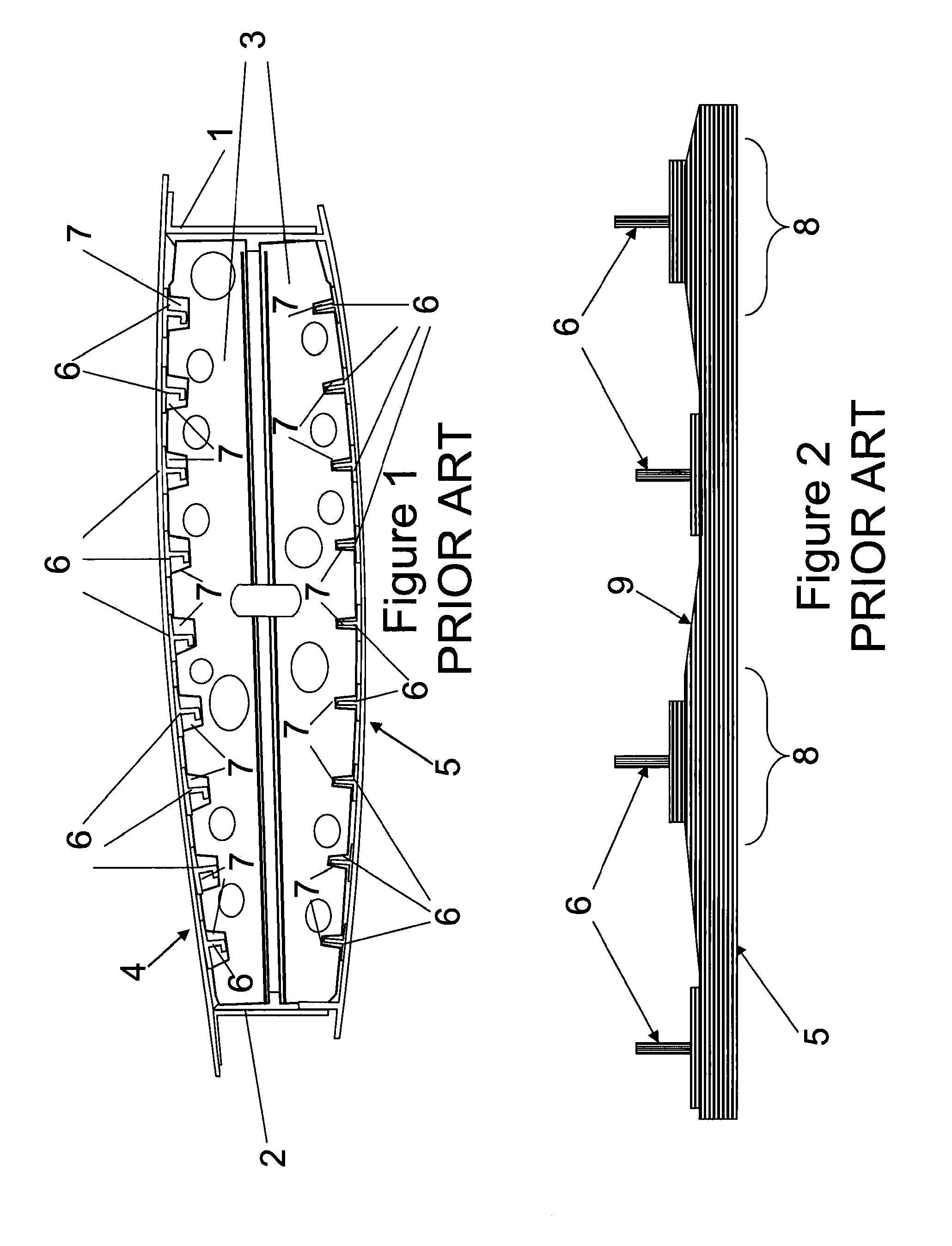

Dual-skin structures

A dual-skin structure comprises a first skin, a second skin and an intermediate structure. The intermediate structure comprises a plurality of first contact portions connected to an interior surface of the first skin, a plurality of second contact portions connected to an interior surface of the second skin and a plurality of interconnecting web portions integral to the first and second contact portions and extending between ones of the first and second contact portions to form an internal supporting structure alternating between the interior surfaces of the first and second skins.

Owner:GKN AEROSPACE SERVICES LTD

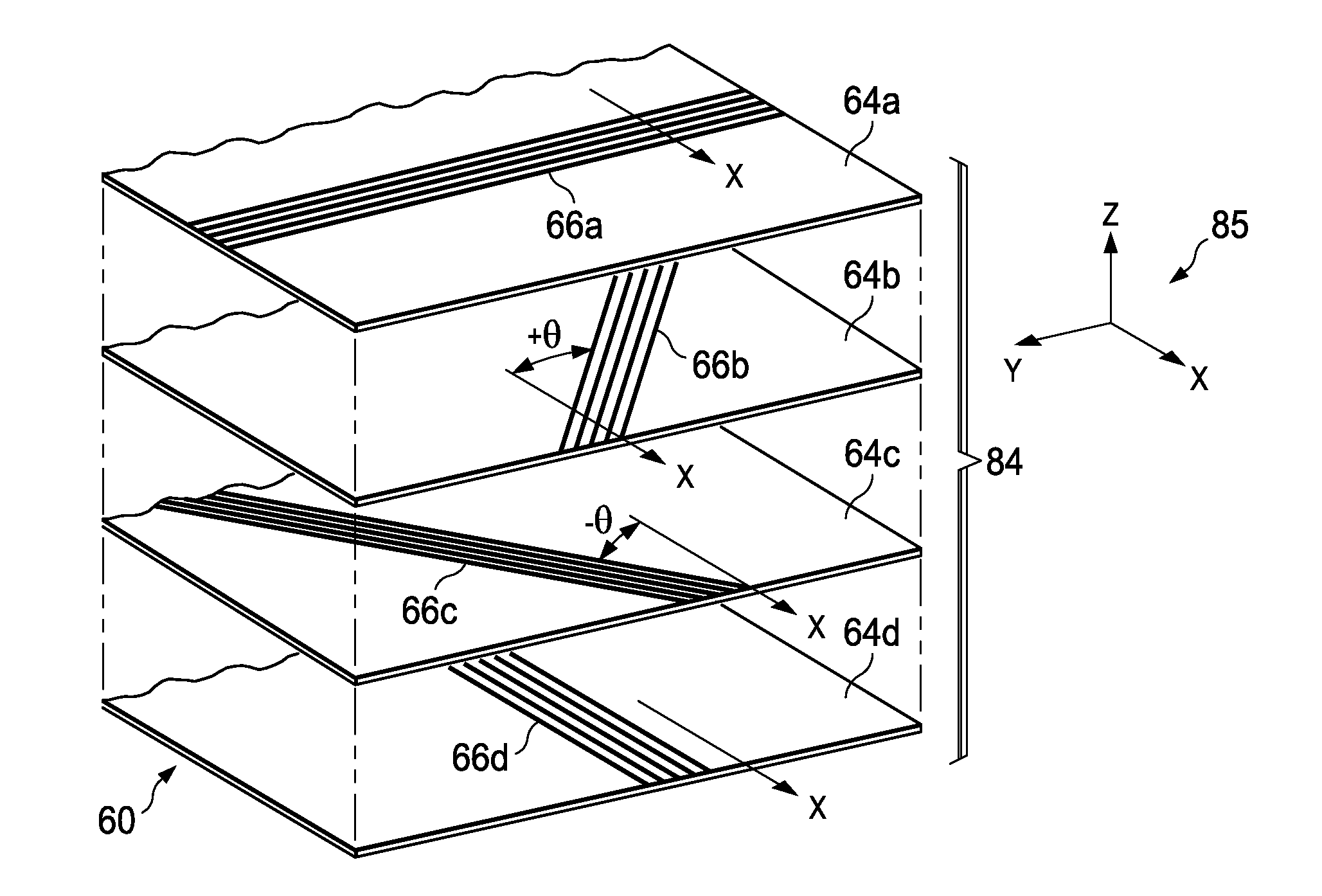

Optimized Cross-Ply Orientation in Composite Laminates

ActiveUS20130330503A1Reduce weightImprove suppression propertiesSynthetic resin layered productsLaminationComposite laminatesEngineering

Owner:THE BOEING CO

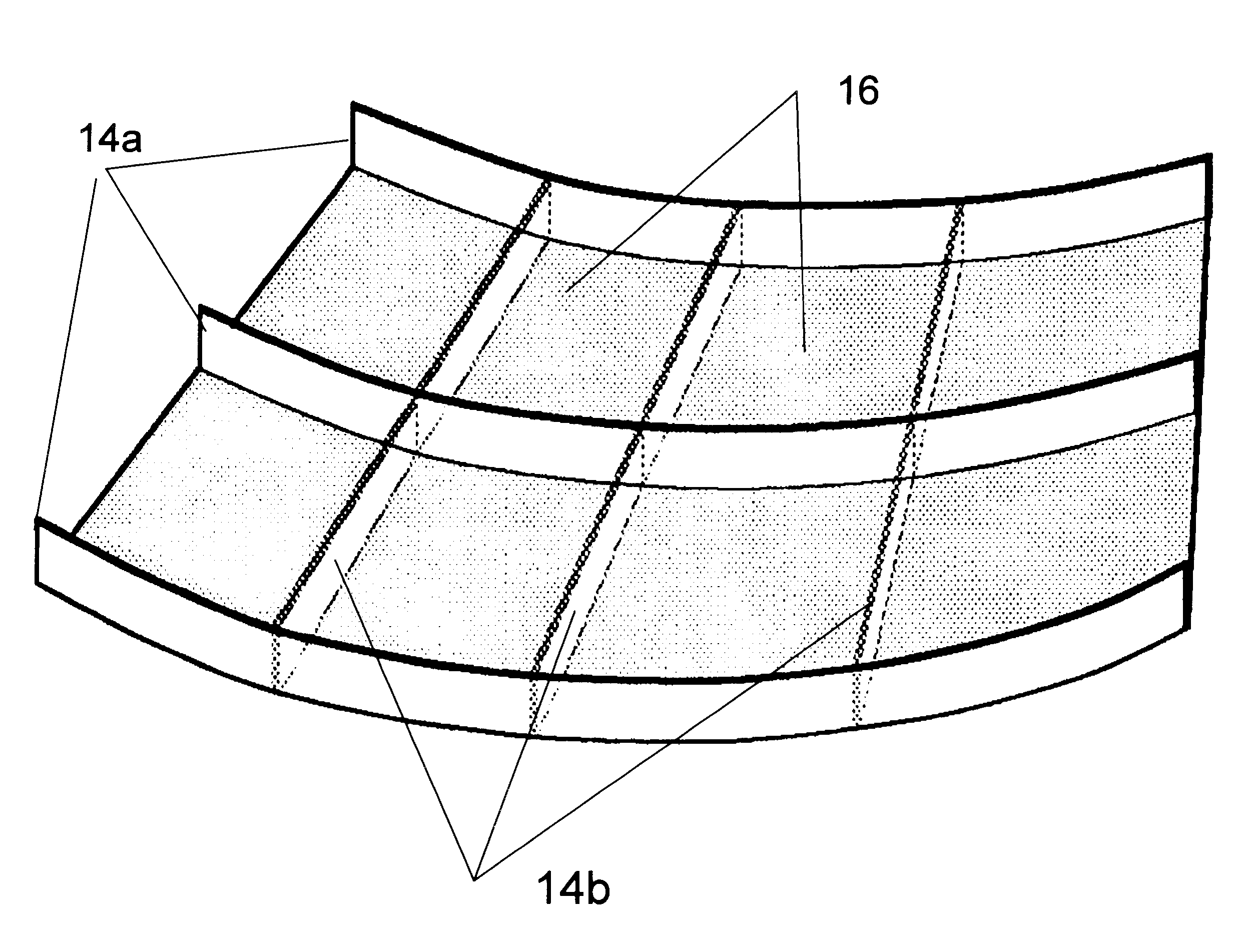

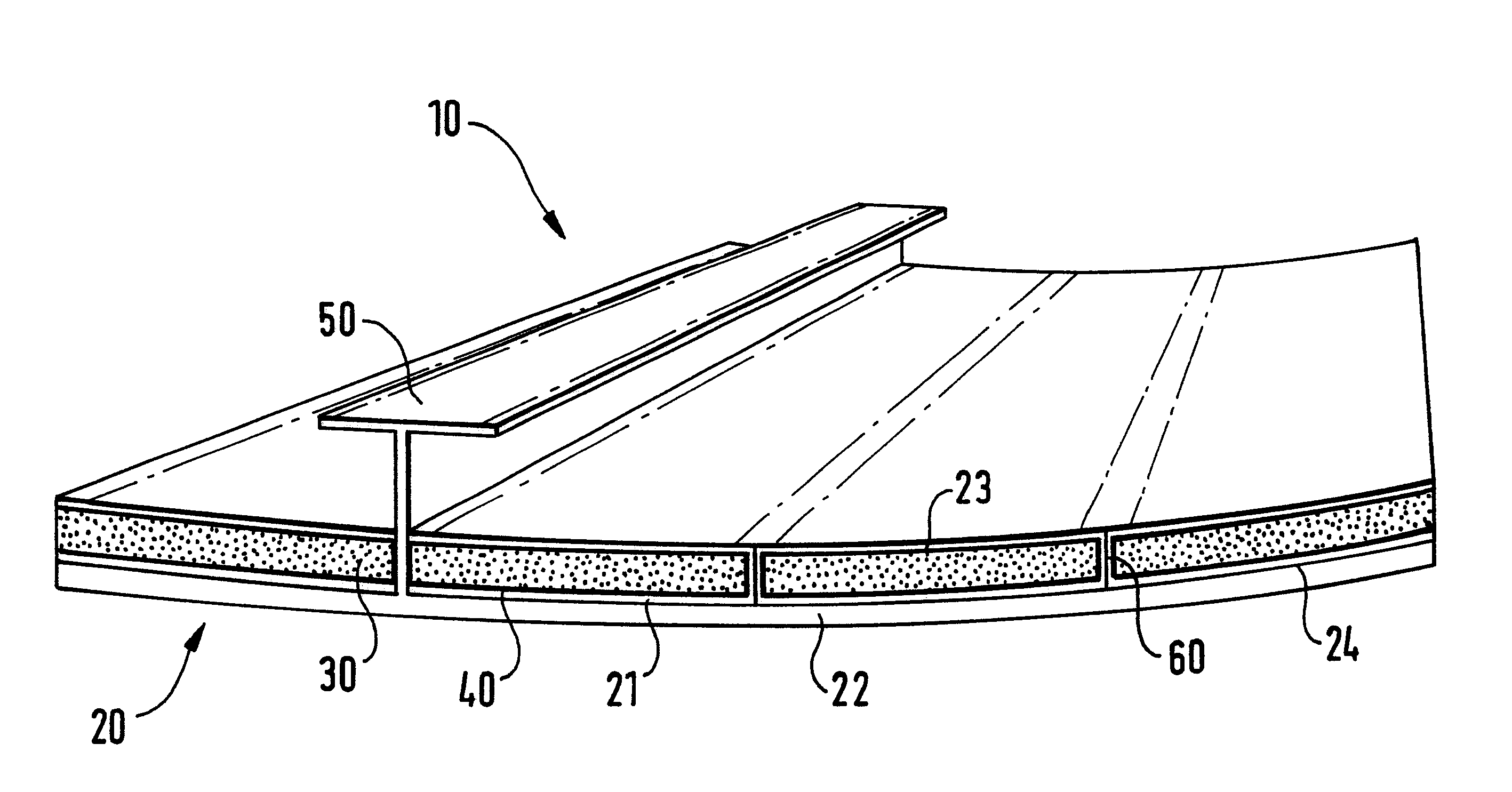

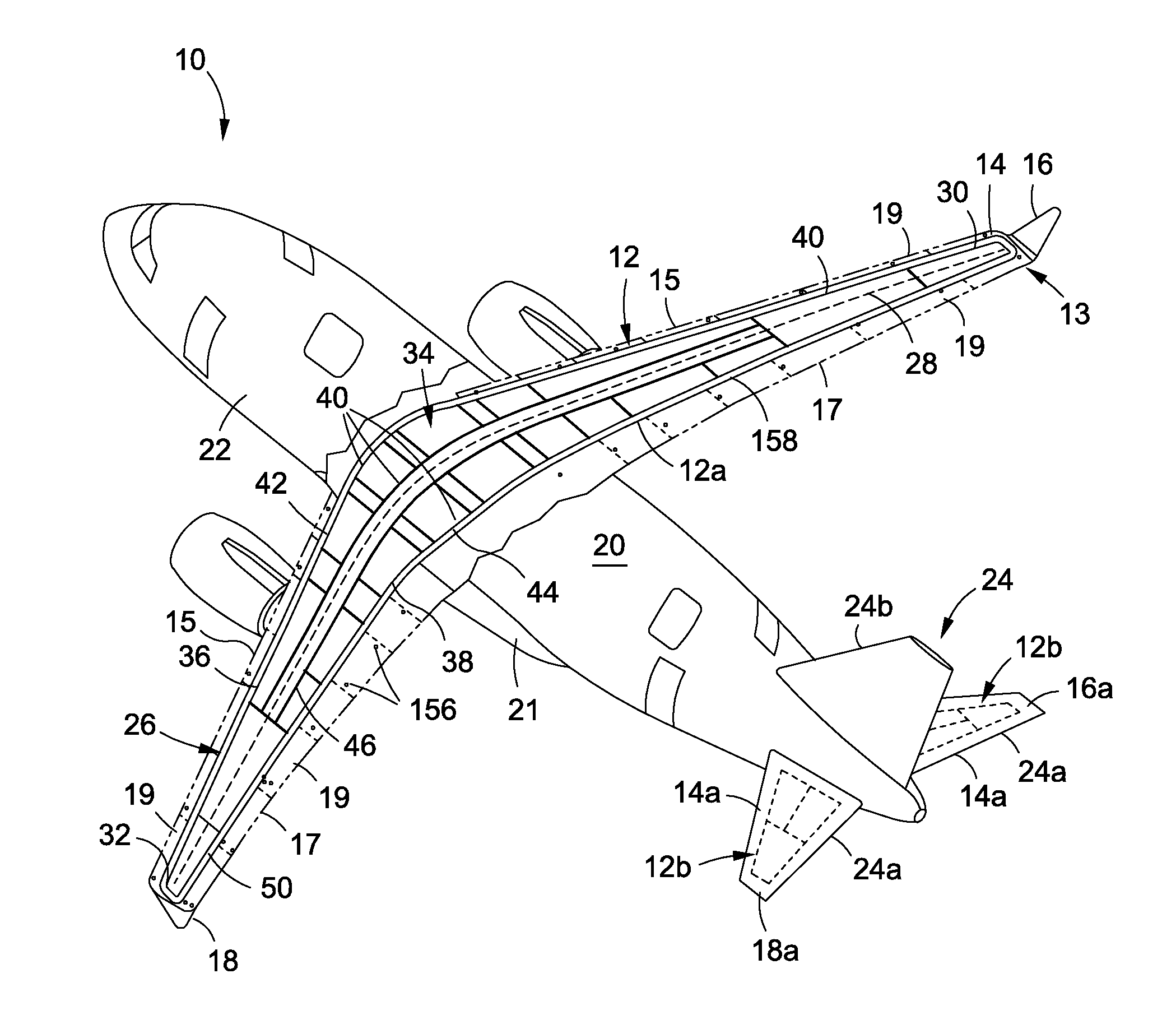

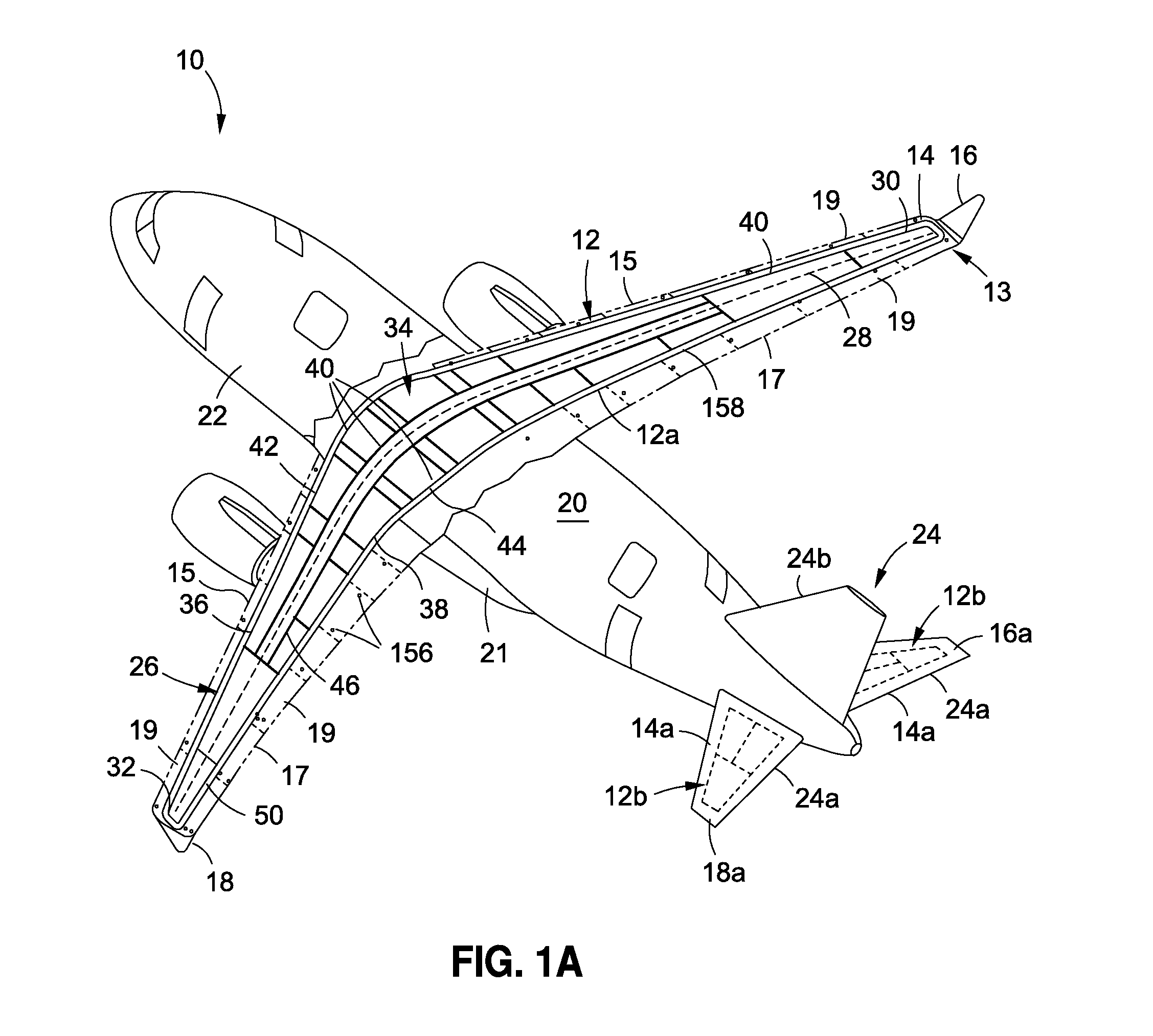

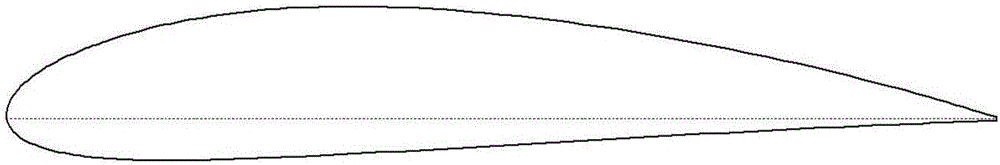

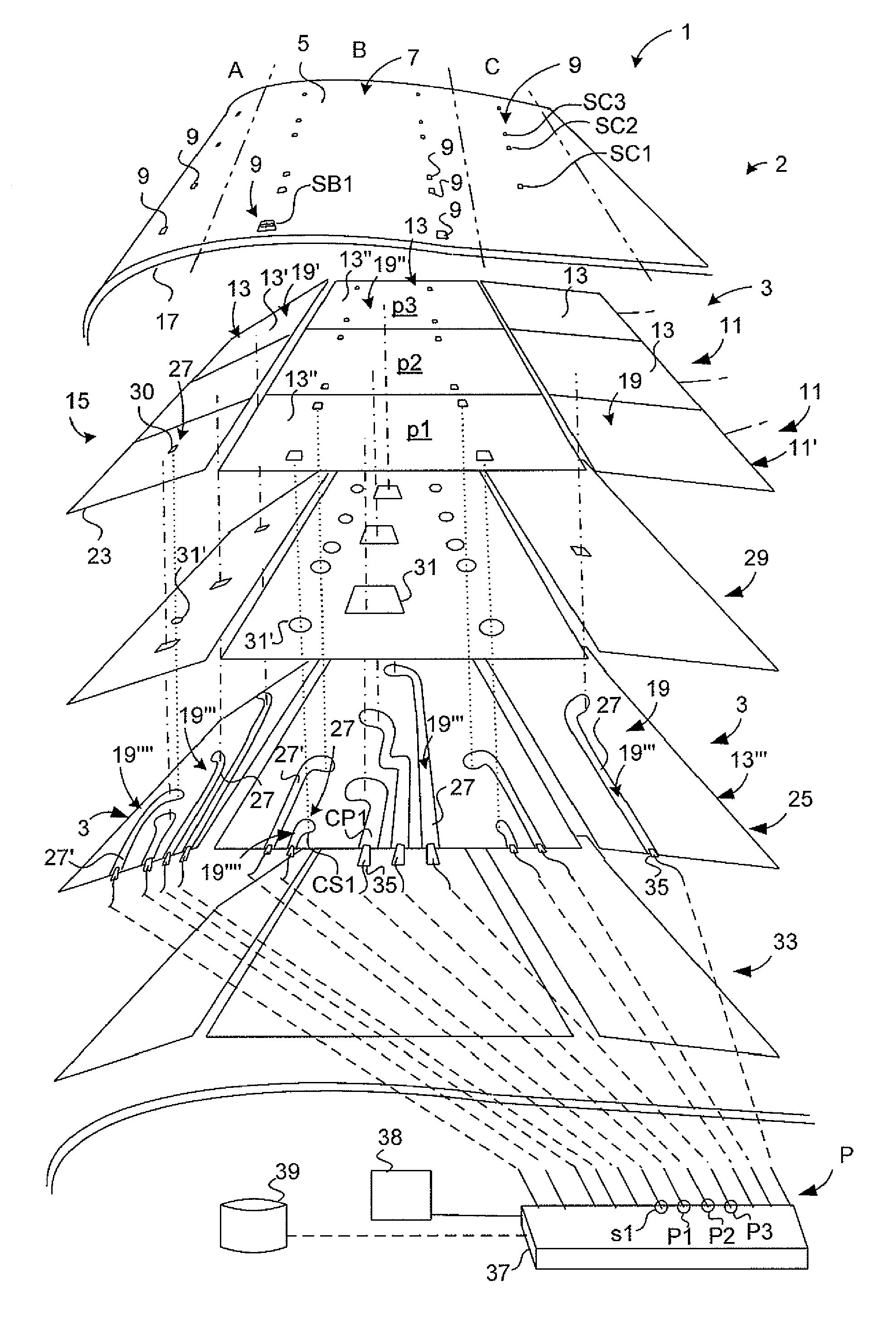

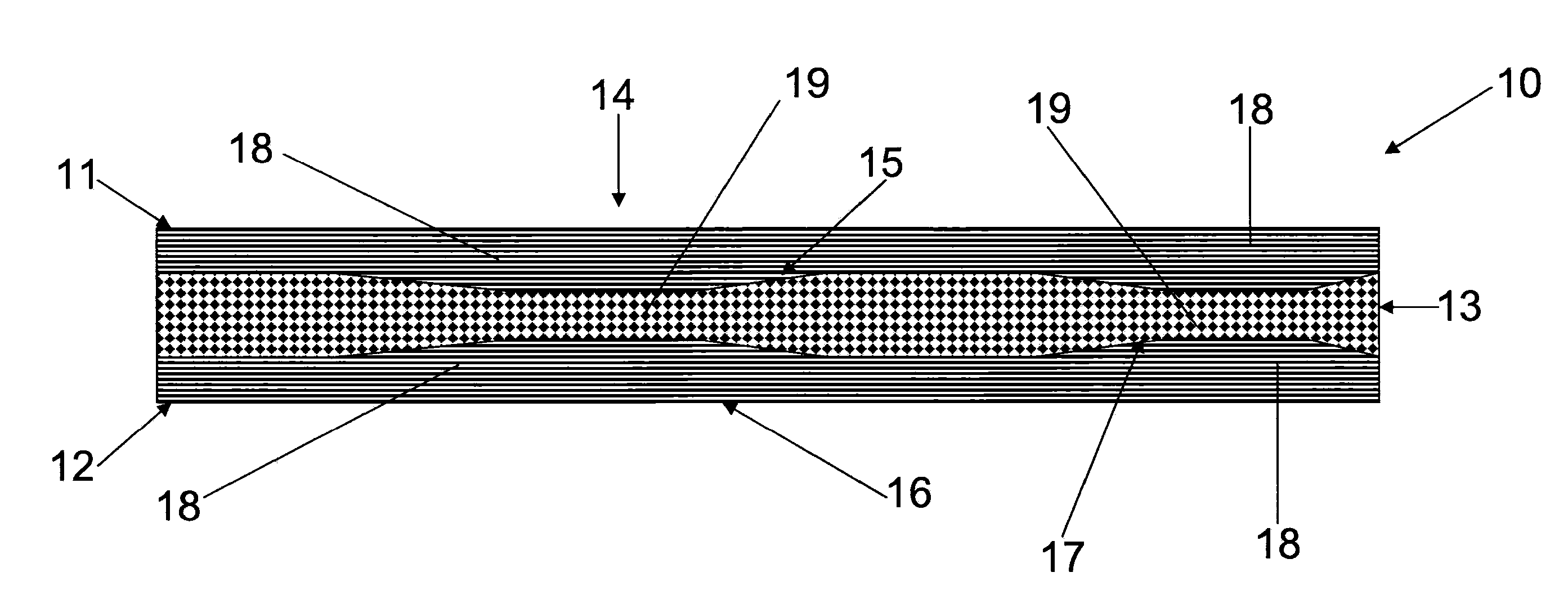

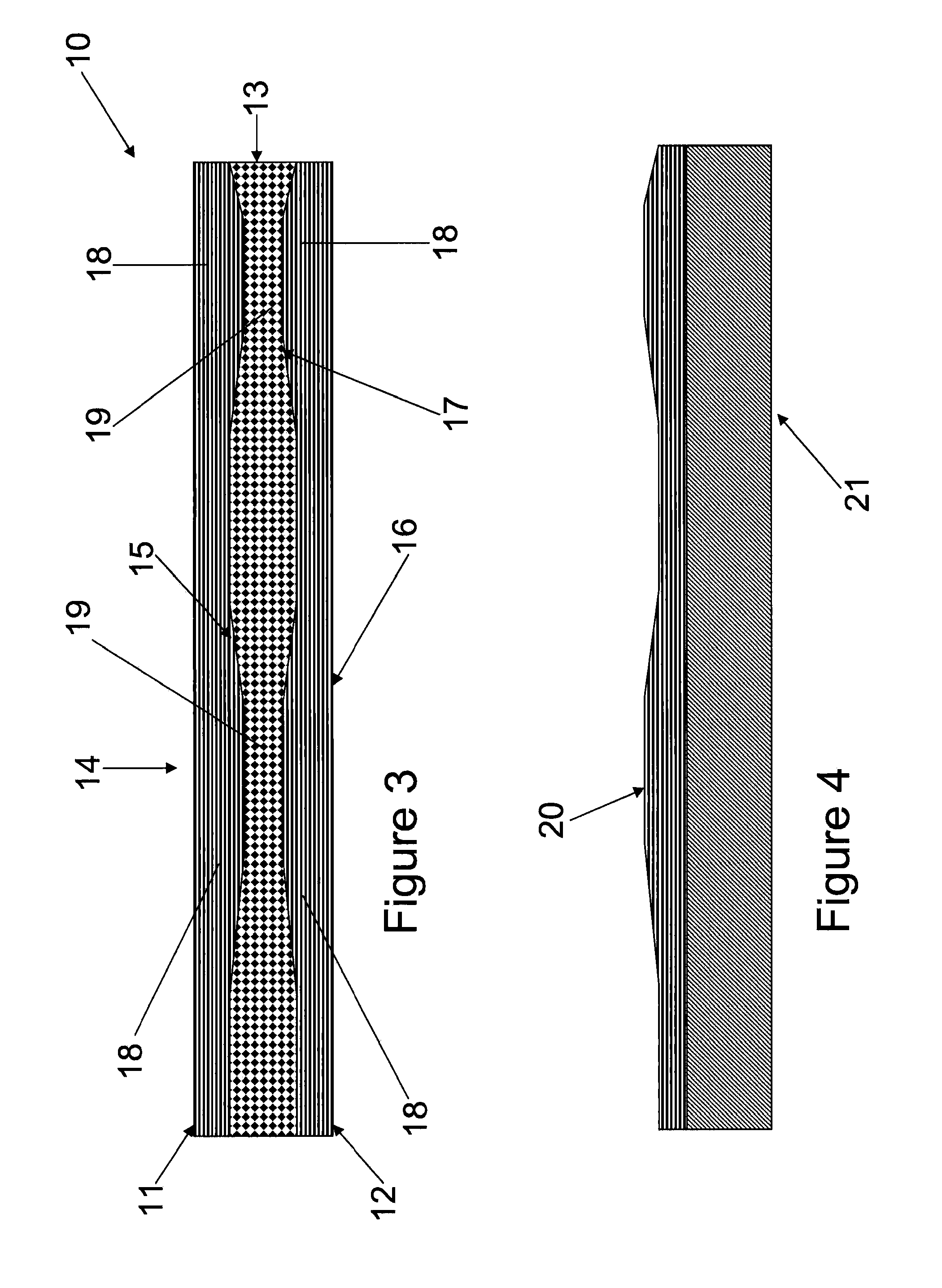

Aircraft wing cover comprising a sandwich panel and methods to manufacture and design the said wing cover

ActiveUS20130099058A1Increasing the thicknessReduce thicknessLamination ancillary operationsAircraft stabilisationSandwich panelDecreased thickness

An aircraft wing cover (10) comprising an integrally stiffened sandwich panel including first and second skins (11, 12) sandwiching a core layer (13), wherein at least one of the skins has a plurality of spanwise extending integral regions of increased thickness (18) accommodated by corresponding regions (19) of decreased thickness in the core. Also, a method of fabricating an aircraft wing cover, and a method of designing an aircraft wing.

Owner:AIRBUS OPERATIONS LTD

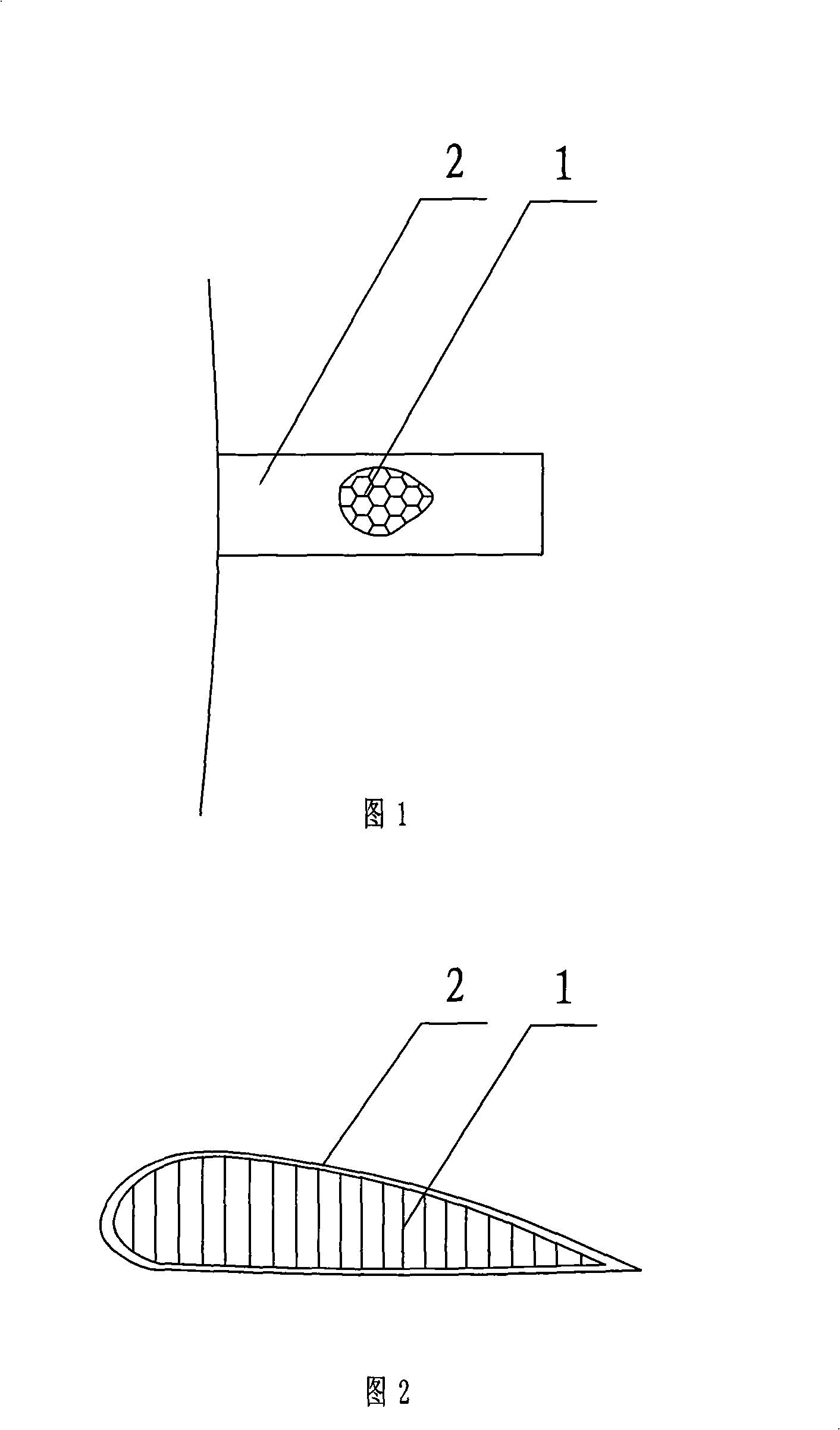

Deformable aerofoil

ActiveCN101513931AReduce quality problemsImprove air tightnessSandwich constructionsShape changeElectromagnetic wave transmission

The invention relates to a deformable aerofoil, which solves the problems of complex structure, and large mass of the aerofoil of the existing deformable aircraft and the problems of low flying efficiency and poor air-tightness of the aircraft. The invention consists of a honeycomb sandwich matrix (1) and a cover (2); the honeycomb sandwich matrix (1) is an integral honeycomb structure of a prefabricated aerofoil shape; the cover (2) is coated on the outer surface of the honeycomb sandwich matrix (1). The aerofoil of the invention employs the honeycomb sandwich structure which has higher specific strength and specific rigidity, corrosion and fatigue resistance, excellent electric insulating performance and electromagnetic wave transmission characteristic. The honeycomb sandwich structure greatly reduces the mass of the aerofoil, and improves the flying efficiency of the aircraft. The integral honeycomb structure of a prefabricated aerofoil shape of the honeycomb sandwich matrix leads the aircraft to have better air-tightness and is a simple. The design of the honeycomb sandwich structure leads the aerofoil to be suitable for various shape changes.

Owner:HARBIN INST OF TECH

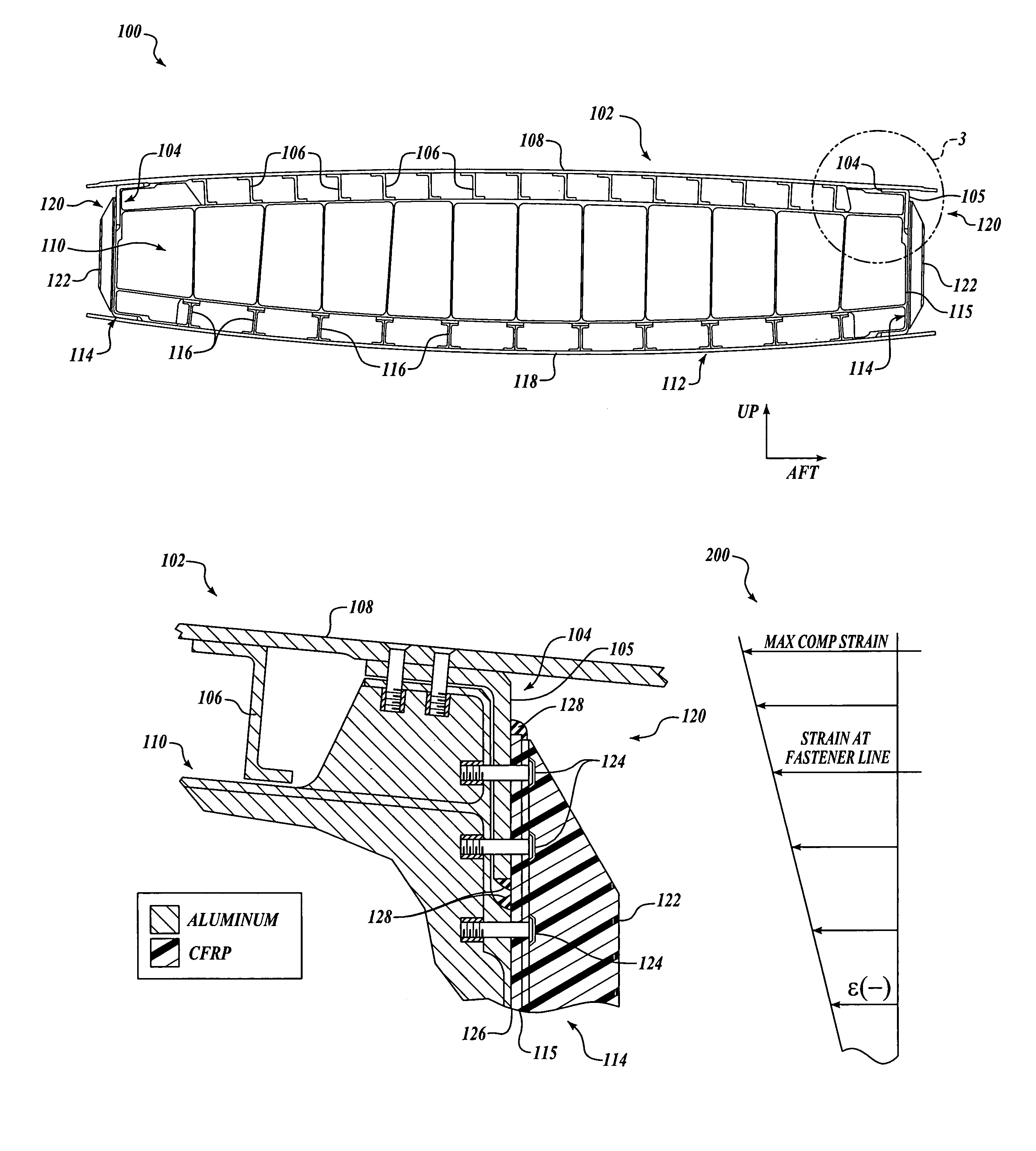

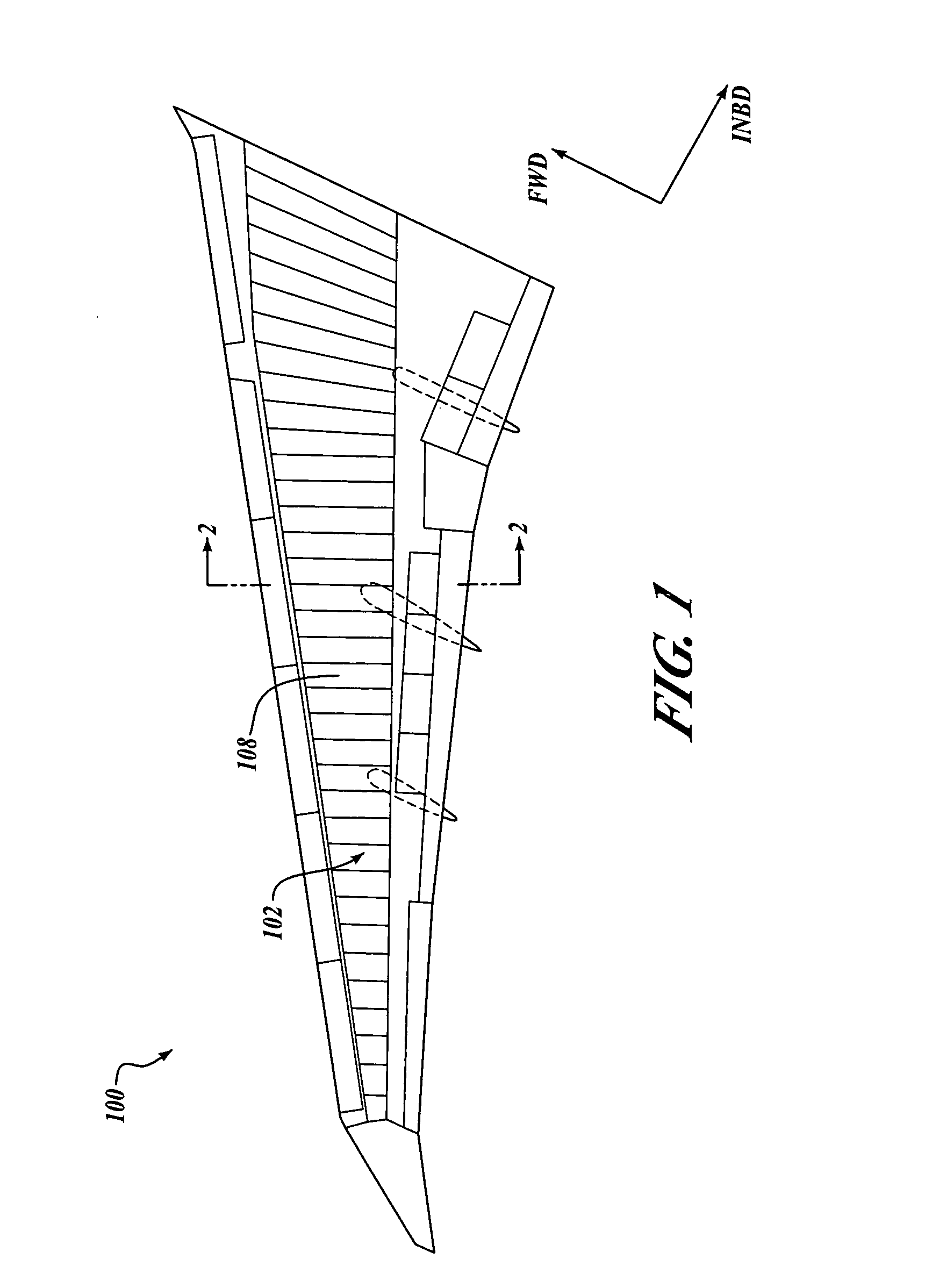

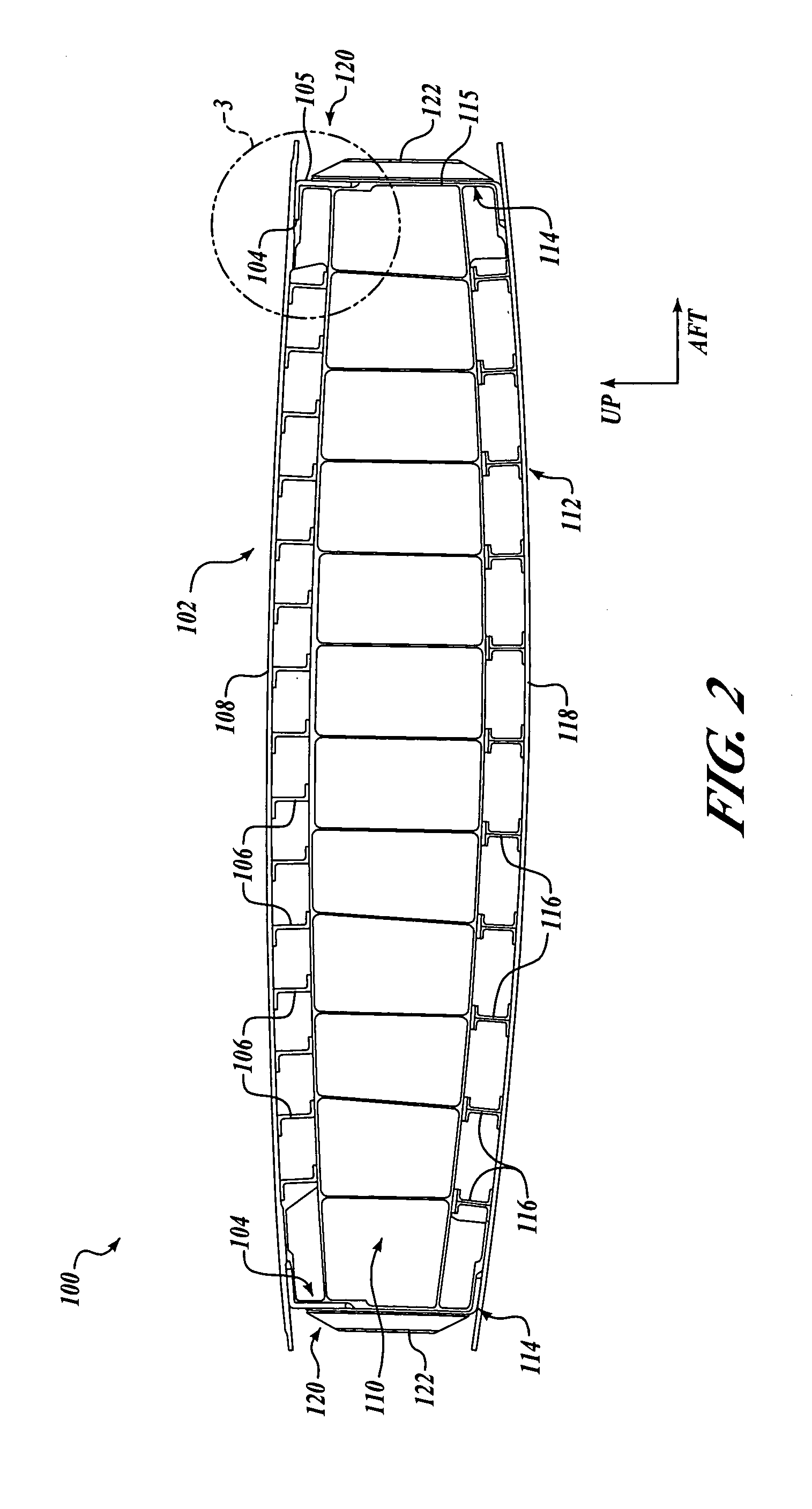

Aircraft wing composed of composite and metal panels

ActiveUS7387277B2Large weightMore robust lightning/EME protection characteristicsAircraft stabilisationSandwich constructionsFiberCarbon fibers

Aircraft wing assemblies having both composite and metal panels are disclosed. In one embodiment, a wing assembly includes a support structure, an upper panel assembly formed from a metal material and coupled to the support structure, and a lower panel assembly formed from a composite material and coupled to the support structure. The metal material may be aluminum, titanium, or any other suitable metal, and the composite material may be a carbon fiber reinforced plastic (CFRP) material or other suitable composite material. In another embodiment, the upper panel assembly includes a downwardly depending first web portion, and the lower panel assembly includes an upwardly depending second web portion, the second web portion being proximate the first web portion, and an interface member of an isolating material is disposed between the first and second web portions.

Owner:THE BOEING CO

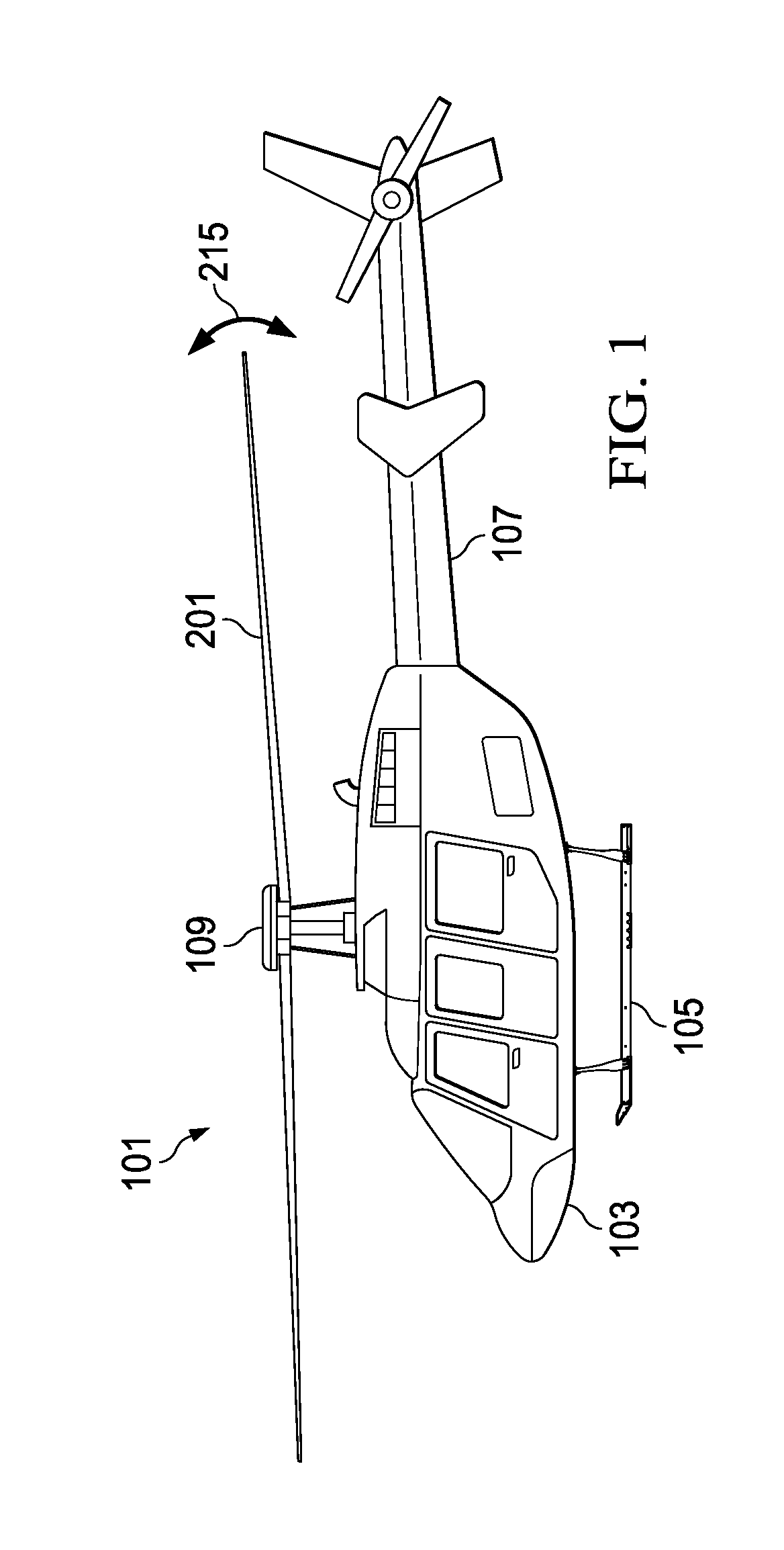

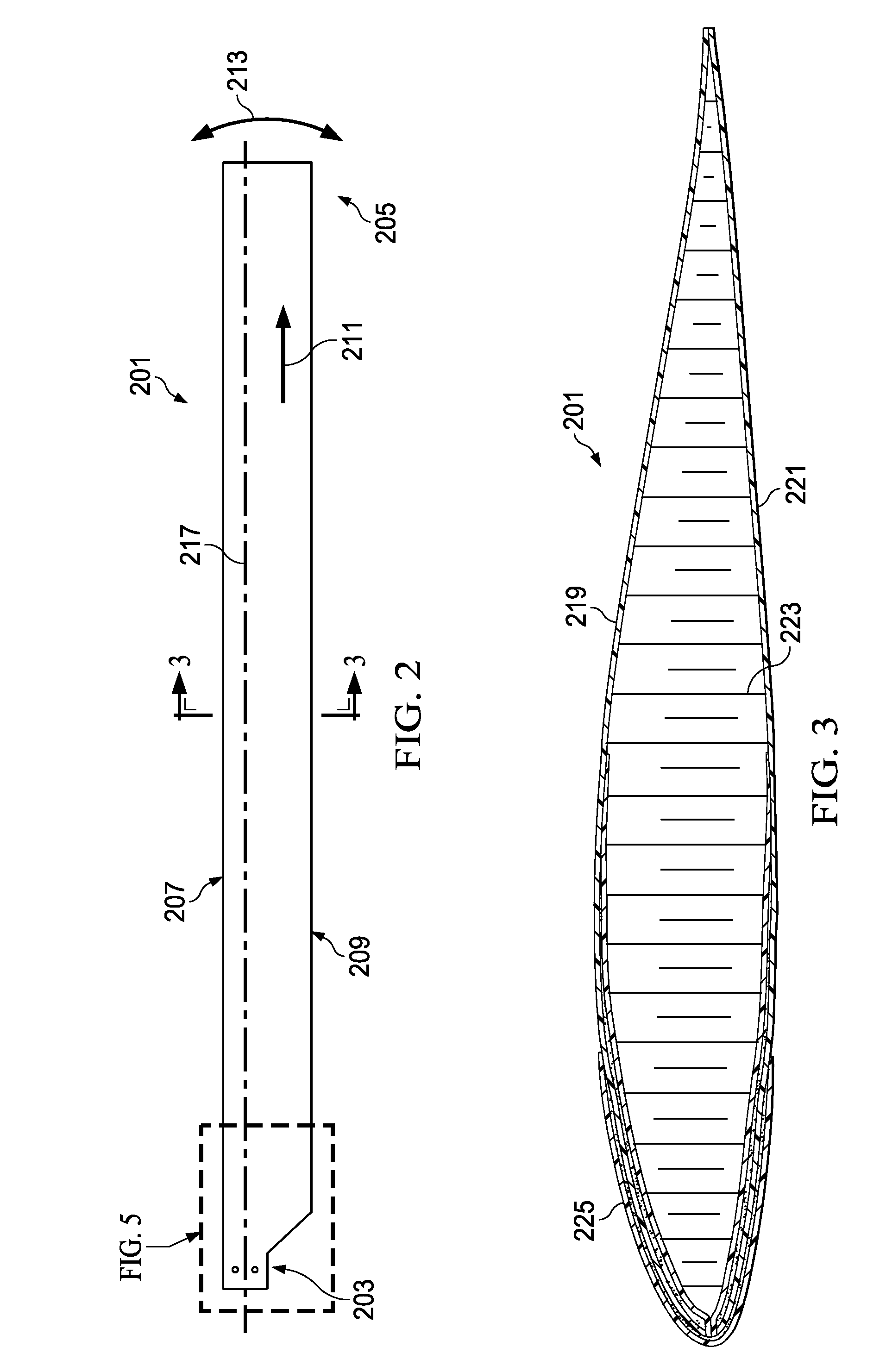

Method of optimizing and customizing rotor blade structural properties by tailoring large cell composite core and a rotor blade incorporating the same

An airfoil member can have a root end, a tip end, a leading edge, and a trailing edge. The airfoil member can include an upper skin, a lower skin, and a composite core member having a plurality of cells, an upper surface network of the cells can be bonded to the upper skin, a lower surface network of the cells can be bonded to the lower skin. The composite core can have a septum layer embedded in the cells that form the composite core, the septum layer being configured to provide tailored characteristics of the airfoil member.

Owner:BELL HELICOPTER TEXTRON INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com