Horizontal tail front edge for bird strike-resisting airplane

A technology for the leading edge and leading edge of a wing, applied in aircraft parts, wings, multi-layer structures, etc., can solve the problems of high cost, breakdown, deformation, etc., and achieve the effect of simple production and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The present embodiment is used for the leading edge of the horizontal tail of an anti-bird strike aircraft of a certain type.

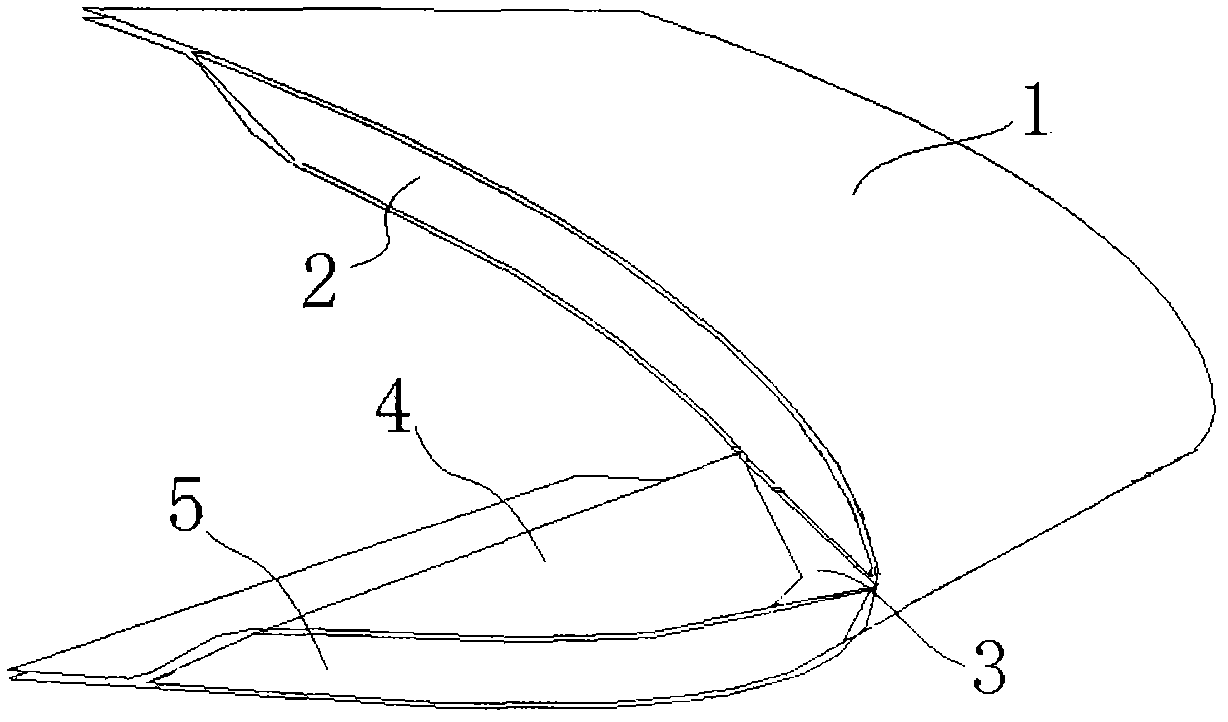

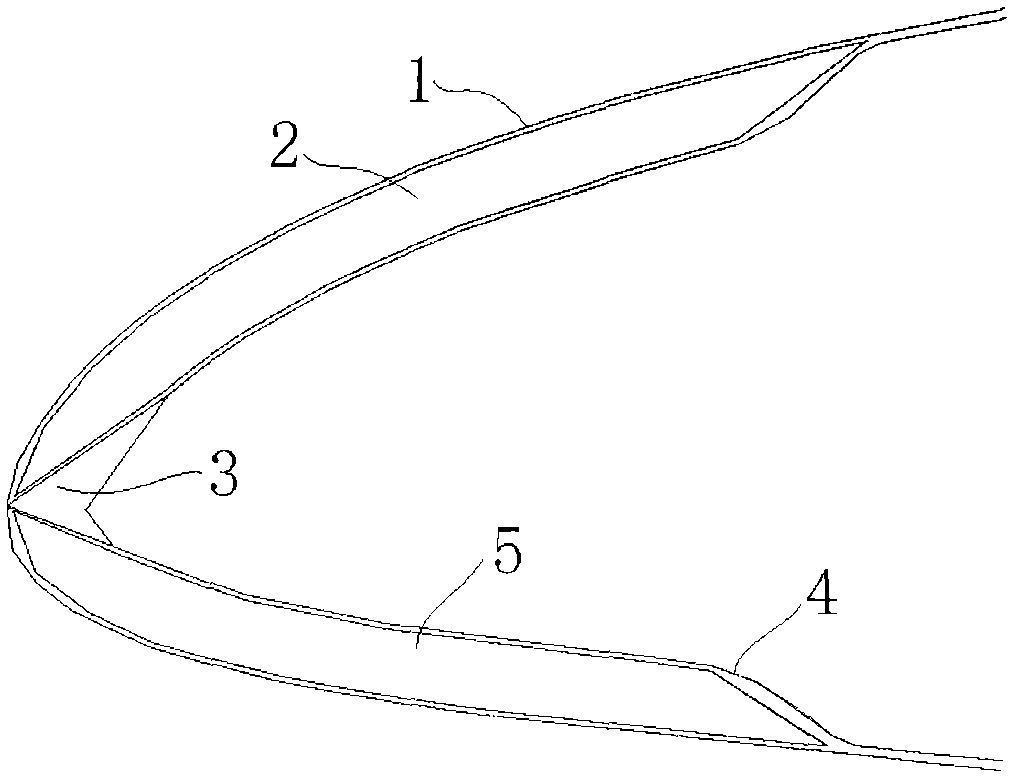

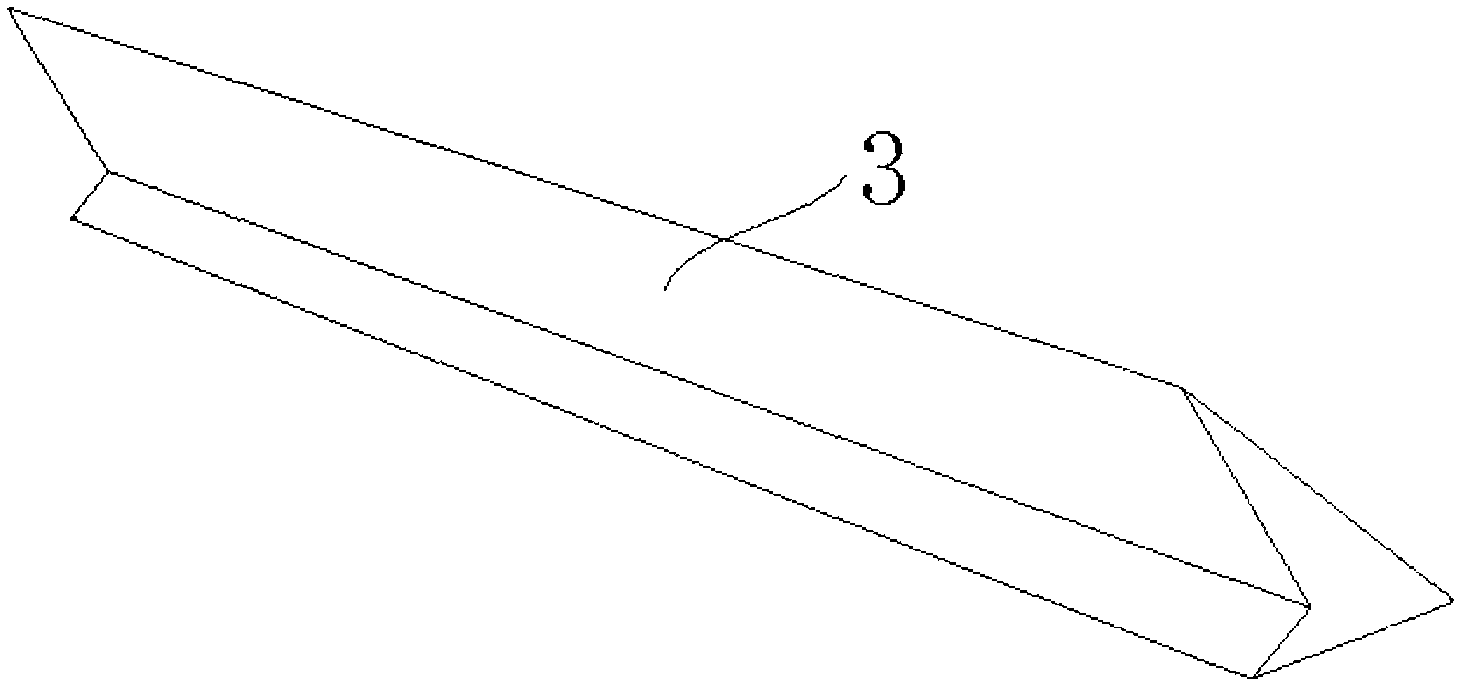

[0028] Such as figure 1 As shown, this embodiment includes a leading edge skin 1, an upper honeycomb core layer 2 and a lower honeycomb core layer 5, a leading edge reinforcement 3 and a wing liner 4, an upper honeycomb core layer 2 and a lower honeycomb core layer 5, a front The edge reinforcement 3 and the wing liner 4 are all arranged between the spans in the leading edge of the wing along the horizontal tail span; wherein the leading edge reinforcement 3 is a triangular prism, and one corner of the leading edge reinforcement is located At the front end of the leading edge of the wing; the upper honeycomb core layer 2 and the lower honeycomb core layer 5 that are parallelograms are respectively fixed on the upper and lower inner surfaces of the leading edge skin 1, and one of the upper honeycomb core layer 2 and the lower honeycomb core lay...

Embodiment 2

[0035] The present embodiment is used for the leading edge of the horizontal tail of an anti-bird strike aircraft of a certain type.

[0036] Such as figure 1As shown, the present embodiment comprises flat tail skin 1, upper honeycomb core layer 2 and lower honeycomb core layer 5, leading edge stiffener 3 and wing liner 4, upper honeycomb core layer 2 and lower honeycomb core layer 5, leading edge The reinforcement 3 and the wing liner 4 are all arranged between the spans in the leading edge of the wing along the span direction of the horizontal tail of the aircraft; At the front end of the leading edge of the wing; the upper honeycomb core layer 2 and the lower honeycomb core layer 5 that are parallelograms are respectively fixed on the upper and lower inner surfaces of the leading edge skin 1, and an oblique of the upper honeycomb core layer 2 and the lower honeycomb core layer 5 The edges are all matched with one side surface of the leading edge reinforcement 3; the wing ...

Embodiment 3

[0043] The present embodiment is used for the leading edge of the horizontal tail of an anti-bird strike aircraft of a certain type.

[0044] Such as figure 1 As shown, the present embodiment comprises flat tail skin 1, upper honeycomb core layer 2 and lower honeycomb core layer 5, leading edge stiffener 3 and wing liner 4, upper honeycomb core layer 2 and lower honeycomb core layer 5, leading edge The reinforcement 3 and the wing liner 4 are all arranged between the spans in the leading edge of the wing along the span direction of the horizontal tail of the aircraft; At the front end of the leading edge of the wing; the upper honeycomb core layer 2 and the lower honeycomb core layer 5 that are parallelograms are respectively fixed on the upper and lower inner surfaces of the leading edge skin 1, and an oblique of the upper honeycomb core layer 2 and the lower honeycomb core layer 5 The edges are all matched with one side surface of the leading edge reinforcement 3; the wing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com