Volute structure for range hood with inclined side wall and circular arc inlet cone

An air intake cone and range hood technology is applied in the components of pumping devices for elastic fluid, household appliances, and oil fume removal. Achieve the effect of improving oil fume performance, reducing sound source pulsating pressure, and improving aerodynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

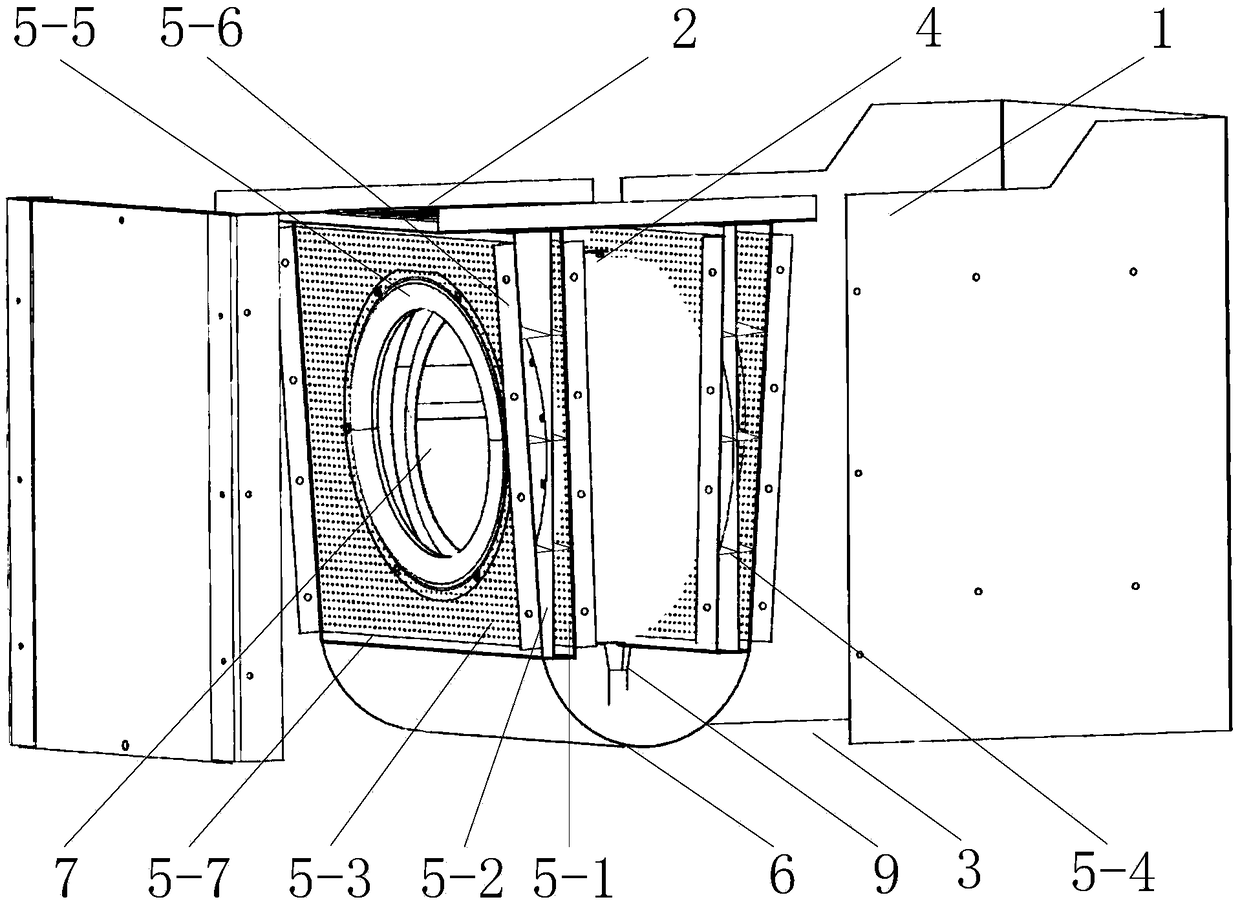

[0027] refer to figure 1 , a range hood volute structure with an arc inlet cone side wall inclined in this embodiment includes a volute case, a volute air outlet and a volute air inlet 7; the volute air outlet and the casing air outlet 2 opposite; the volute case includes a spiral volute profile 4 and two oppositely arranged volute sides, the volute side is provided with a volute air inlet 7, and the volute air outlet is located in the spiral case of the volute Tail end; also includes an arc inlet cone 6 arranged at the lower part of the volute; the side of the volute is a volute inclined side wall structure 5;

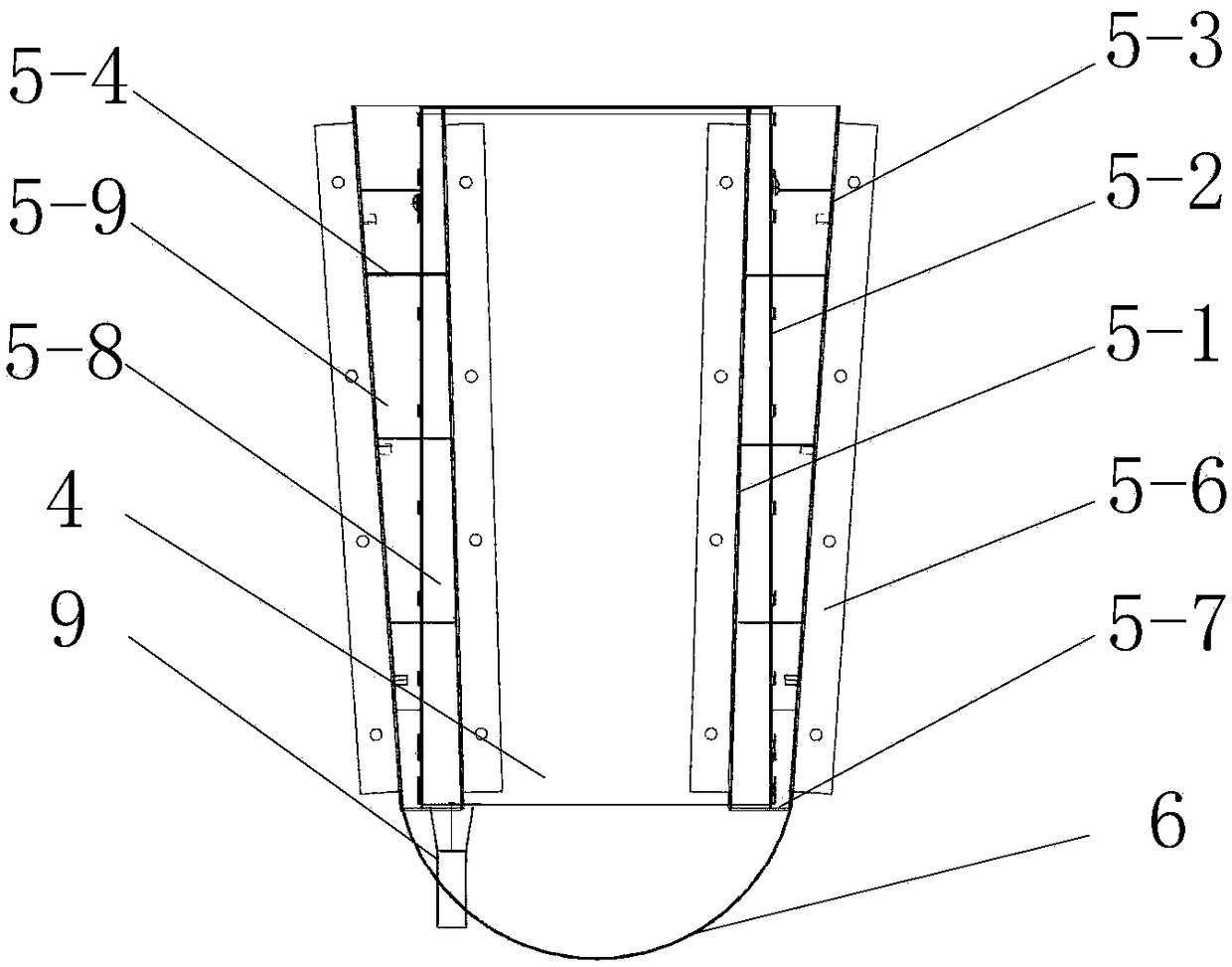

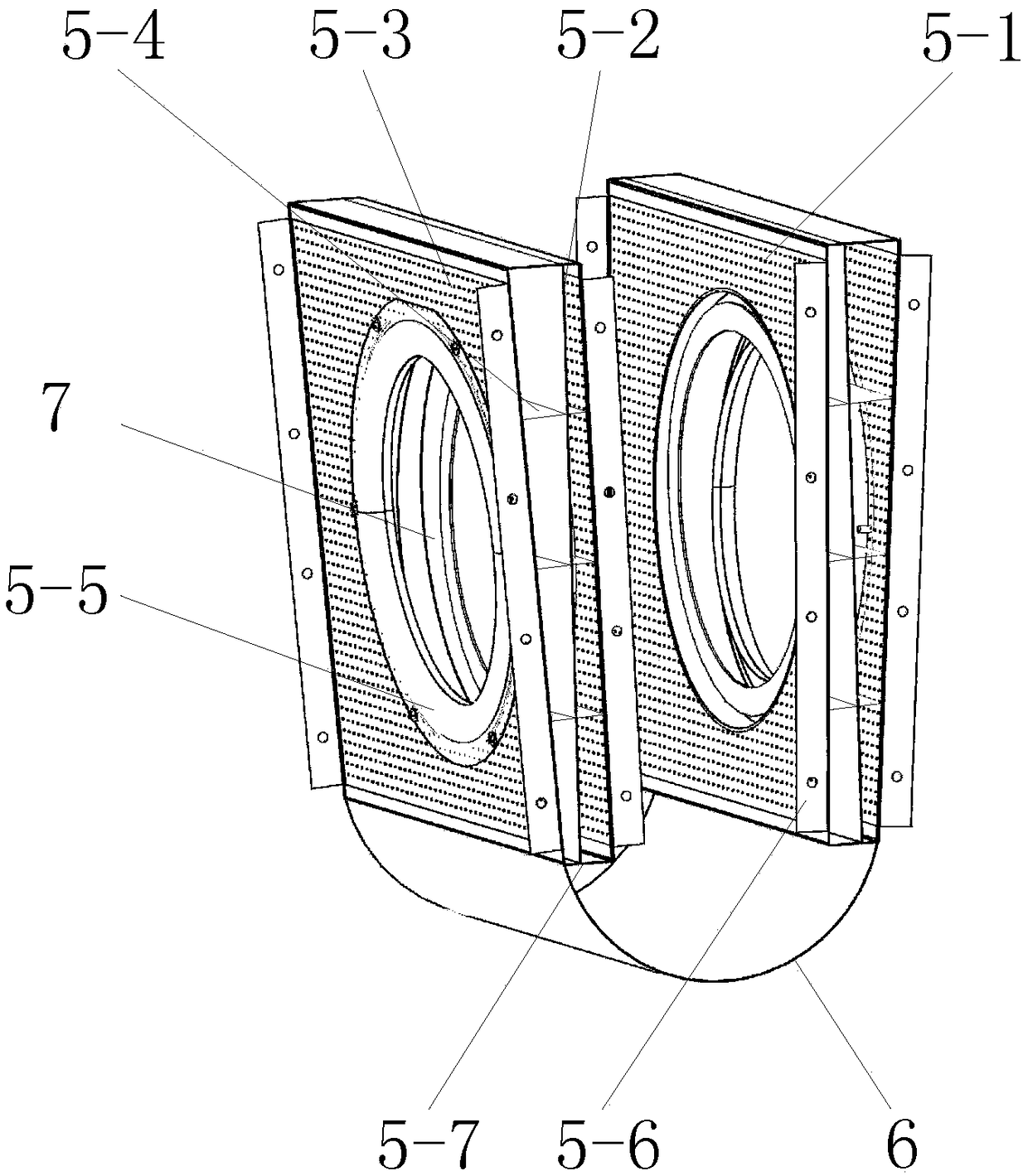

[0028] refer to figure 2 and image 3 , the volute includes a volute surface 4, an inclined side wall structure 5 of the volute, and an arc inlet cone 6; the inclined sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com