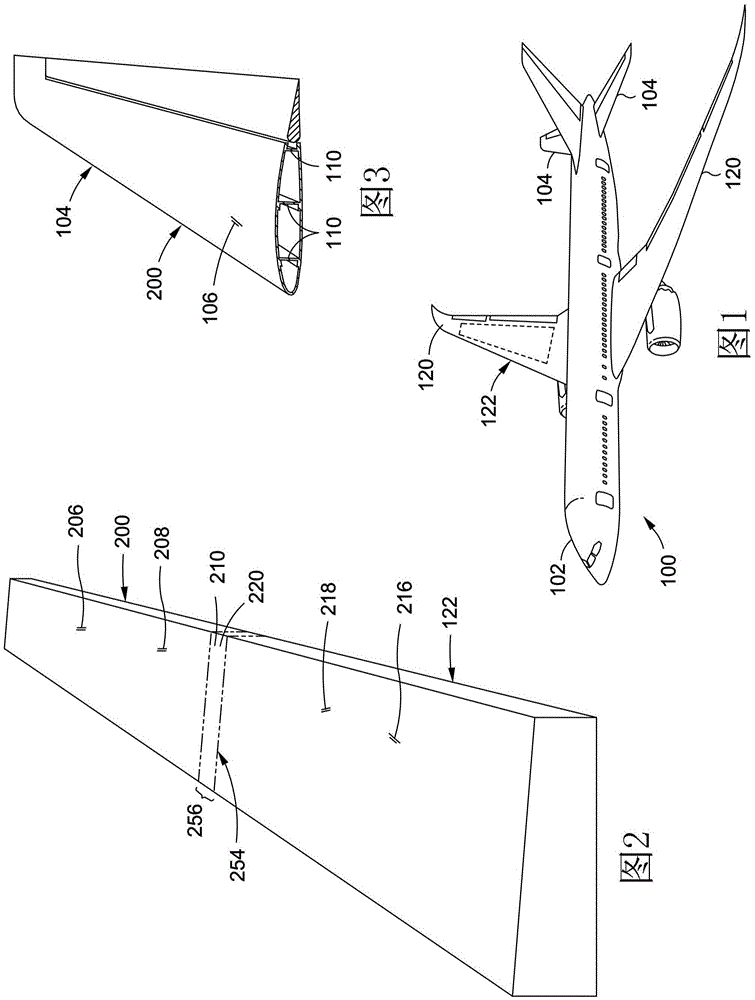

Co-curing process for the joining of composite structures

A composite material, composite material layer technology, applied in the field of assembled composite material structure, can solve the problems of composite material part limitation, high operation and maintenance cost, high initial construction cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

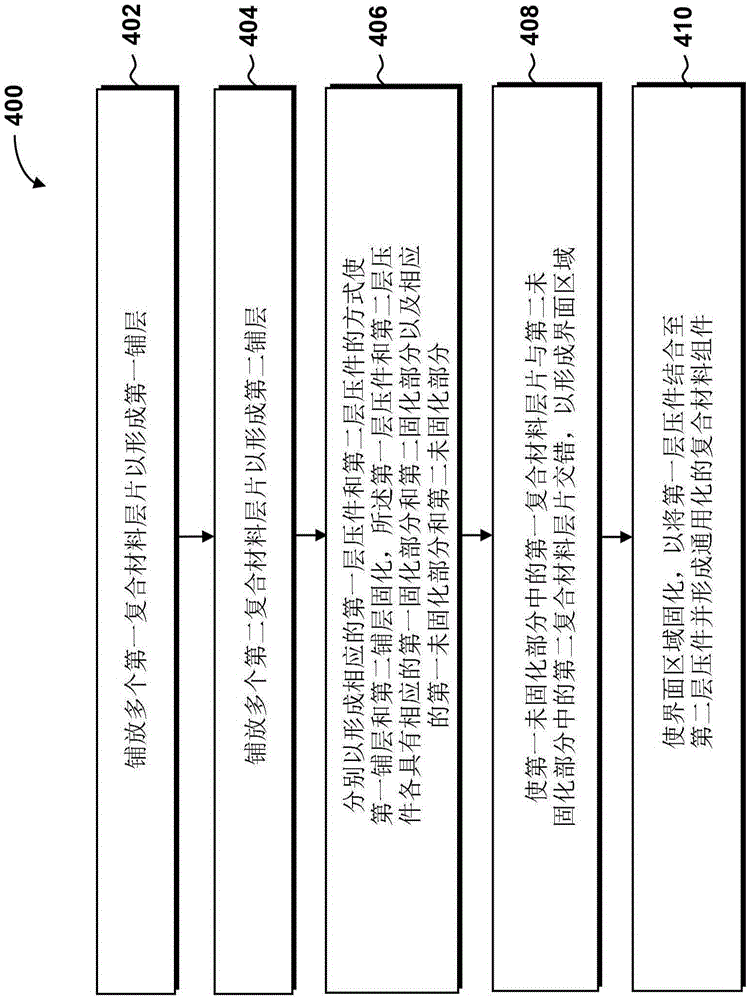

[0105] Clause 1. A method of manufacturing a composite component, said method comprising the steps of:

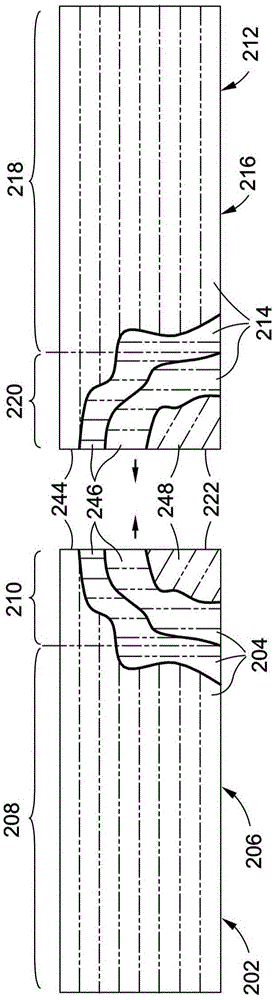

[0106] providing a first laminate and a second laminate formed from a first ply of composite material and a second ply of composite material, respectively, and having a corresponding first cured part and second cured part and corresponding first uncured part and second uncured part;

[0107] interleaving at least one of said first plies of composite material in said first uncured portion with said second plies of composite material in said second uncured portion to form an interfacial region; and

[0108] The interface region is cured to bond the first laminate to the second laminate and form a generalized composite component.

[0109] Clause 2. The method of clause 1, wherein the interleaving steps comprise:

[0110] At least one of the first plies of composite material in the first uncured portion is inserted between a pair of immediately adjacent second plies of compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com