Integrated packaging antenna and packaging method thereof

An integrated packaging and antenna technology, applied in the antenna grounding device, antenna, antenna support/installation device, etc., can solve the problem of poor heat dissipation of the adapter board and cannot be used as a mechanical support.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

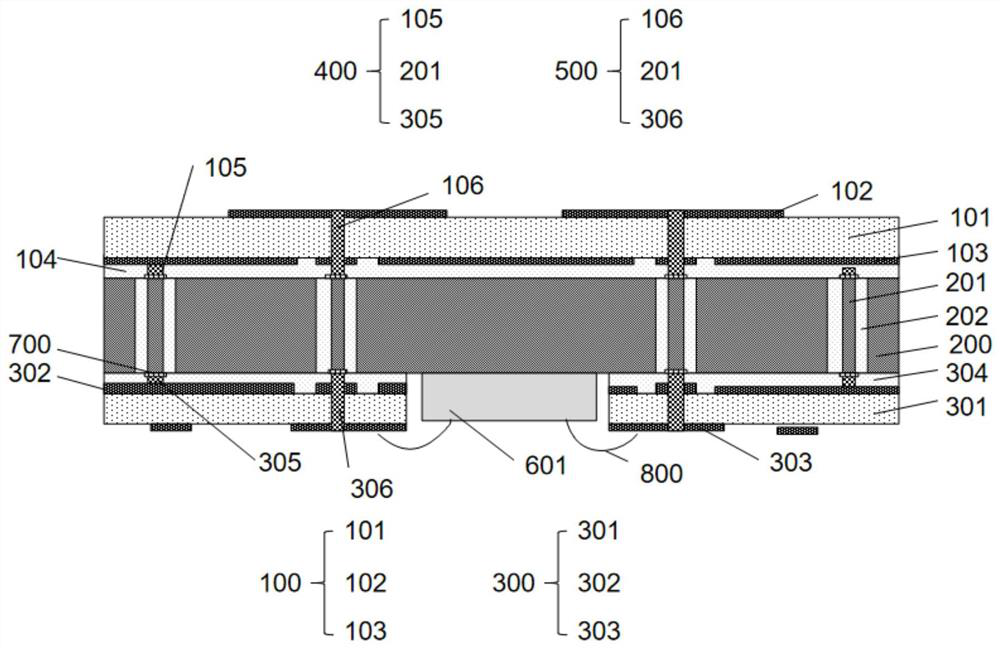

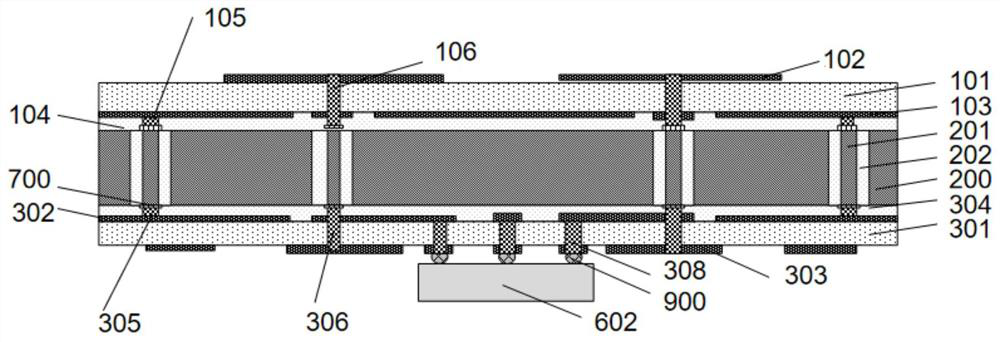

[0074] see Figure 1 to Figure 2 As shown, this embodiment provides an integrated package antenna, including at least one semiconductor chip and an antenna module substrate 100, an aluminum-silicon adapter plate 200, and a radio frequency module substrate 300 laminated sequentially from top to bottom:

[0075] The material of the aluminum-silicon adapter plate 200 is selected as Al30Si70, and the aluminum-silicon adapter plate 200 is placed between the antenna module substrate 100 and the radio frequency module substrate 300 to provide mechanical support and electrical interconnection. The aluminum-silicon adapter plate has high heat dissipation, The advantages of low thermal expansion coefficient and high strength can reduce costs and improve heat dissipation compared with traditional silicon interposers or LTCC substrates.

[0076] The antenna module substrate 100 includes an antenna layer LCP substrate 101 and an antenna pattern layer 102 and an antenna ground layer 103 res...

Embodiment 2

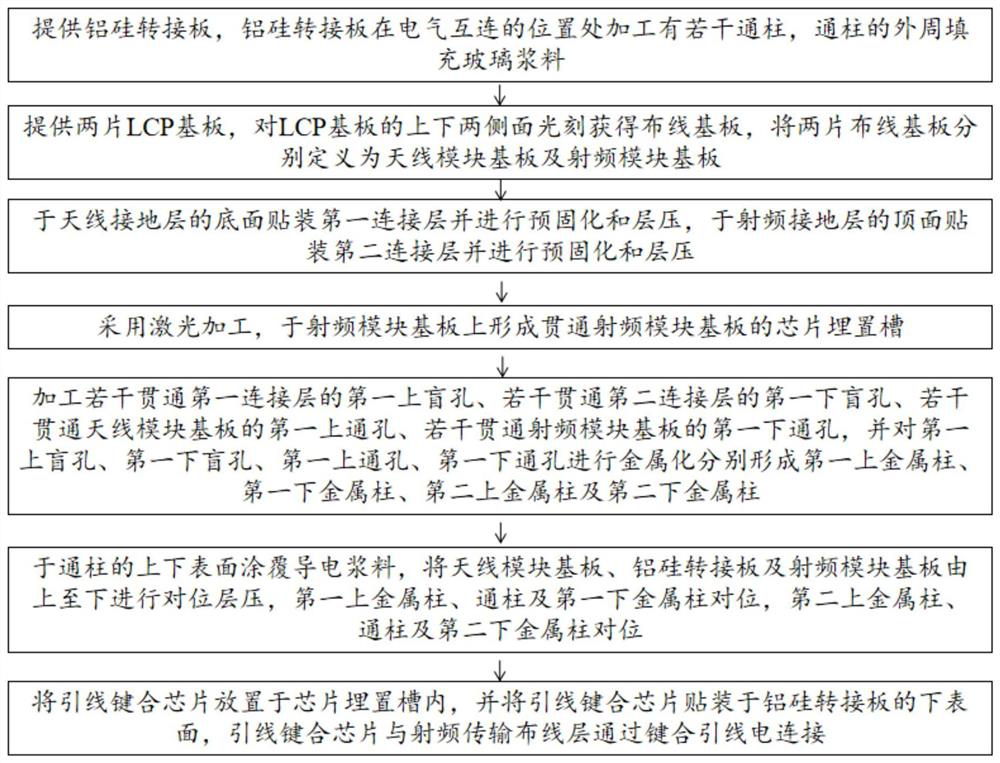

[0087] see Figure 3 to Figure 11 , based on the same inventive concept, this embodiment provides a packaging method for an integrated packaged antenna, including the following steps:

[0088] S1: see Figure 4 As shown, an Al-Si adapter plate 200 is provided, and the Al-Si adapter plate 200 is processed with a number of via posts 201 at the position of electrical interconnection, and the outer circumference of the via posts 201 is filled with glass paste 202. In this embodiment, Al-Si The material of the adapter plate 200 is Al30Si70, and the thickness of the Al-Si adapter plate 200 is 0.1-1 mm;

[0089] In this embodiment, the step S1 specifically includes the following:

[0090] S11: Provide aluminum-silicon substrate;

[0091] S12: Use a laser to ablate the outer peripheral area of the electrical interconnection of the aluminum-silicon substrate to obtain through-pillars for electrical interconnection and grooves surrounding the through-pillars. The depth of the groov...

Embodiment 3

[0102] see Figure 12 to Figure 18 As shown, based on the same inventive concept, this embodiment also provides a packaging method for an integrated packaged antenna, including the following steps:

[0103] A1: Provide an aluminum-silicon adapter board 200. The aluminum-silicon adapter board 200 is processed with a number of through posts 201 at the position of electrical interconnection, and the outer circumference of the through posts 201 is filled with glass paste 202. The material of the connecting plate 200 is Al30Si70, and the thickness of the aluminum-silicon connecting plate 200 is 0.1-1 mm;

[0104] In this embodiment, the step A1 specifically includes the following:

[0105] A11: Provide aluminum silicon substrate;

[0106] A12: Use a laser to ablate the outer peripheral area of the electrical interconnection of the aluminum-silicon substrate to obtain through-pillars for electrical interconnection and grooves surrounding the through-pillars. The depth of the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com