Heat insulation structure used for high-mach-number air vehicle

An aircraft and support structure technology, applied in the direction of fuselage insulation, etc., can solve the problems of low connection strength, complex assembly process, increase the weight of the aircraft, etc., to achieve the effect of improving the structural strength and simplifying the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

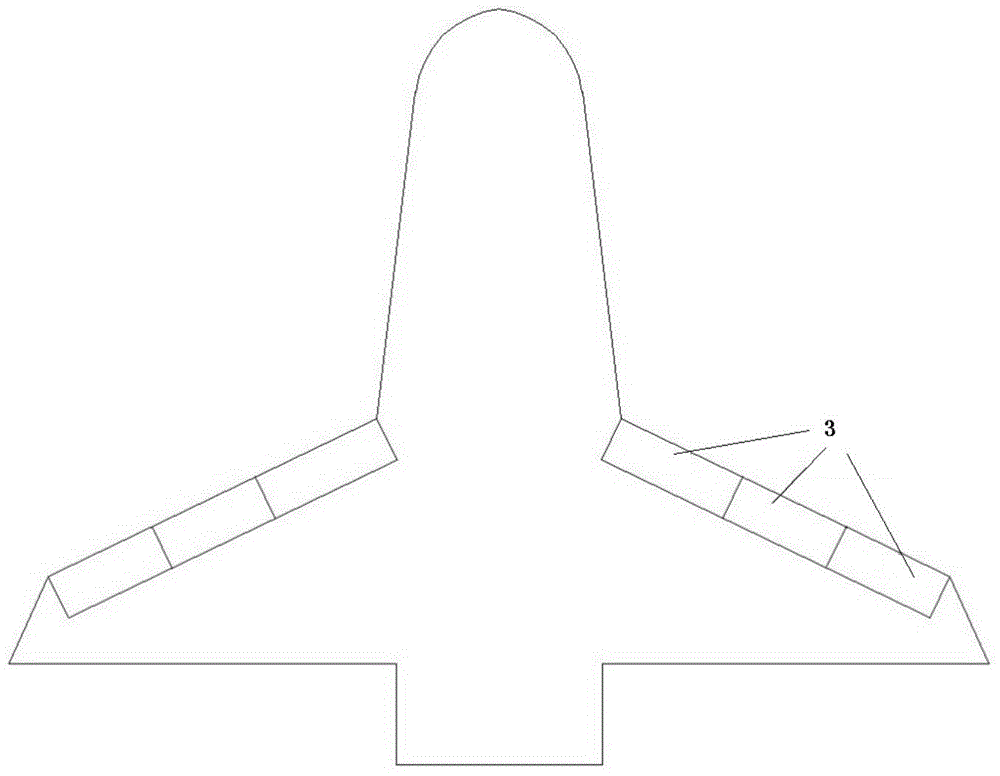

[0015] The specific implementation method is: design the heat insulation structure according to the temperature distribution and aerodynamic shape of the aircraft, and design different forms of hollow sandwich structure modules 3 with gas cooling channels for different parts, and several modules can be connected in series Or in parallel, cold air is introduced from the engine or the atmosphere to cool the insulation structure, and finally discharged into the atmosphere.

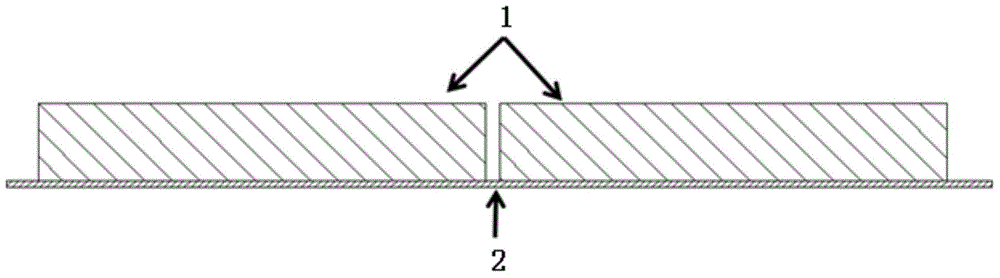

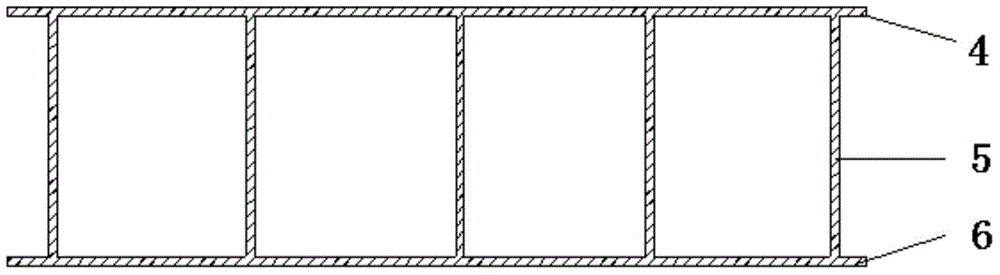

[0016] The concrete heat insulation structure is: described heat insulation structure comprises skin 4, the fuselage 5 of aircraft and support structure 6, and described support structure is supported between skin and the fuselage of aircraft, by skin, the fuselage of aircraft And the support structure forms a cooling channel, the cooling channel communicates with the cold air source, and the heat of the skin is taken away by the cold air to dissipate heat from the high Mach aircraft.

[0017] Further, the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com