Double-layer roller-way kiln provided with lifting device

A technology of lifting device and roller kiln, which is applied in the direction of lighting and heating equipment, furnace type, furnace, etc., can solve the problems of lack of description of the working principle of the elevator structure characteristics, inconvenient maintenance and management of roller table, and large floor area, etc., to achieve heat The effect of small loss, easy maintenance and management, and shortened floor space

Inactive Publication Date: 2015-09-02

绥阳县华夏陶瓷有限责任公司

View PDF7 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The purpose of the present invention is to provide a double-layer roller kiln with a lifting device, which solves the problem of using a single-layer roller kiln in the prior art, which requires a large area, a long construction period, and high cost, and it is also inconvenient for workers to align the rollers. Road maintenance and management, while the use of the above-mentioned double-layer roller kiln, but the lack of description of the structural characteristics and specific working principles of the elevator

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0018] The specific implementation manner of the present invention will be described in further detail below in conjunction with the accompanying drawings.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

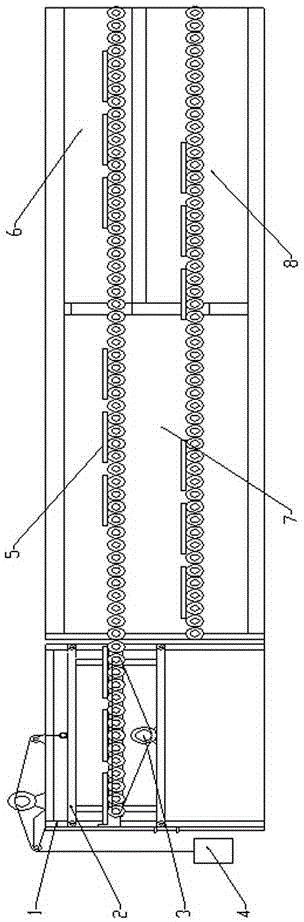

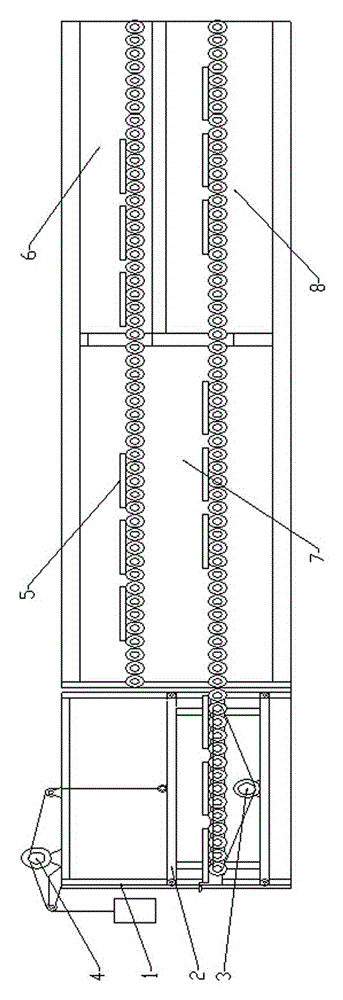

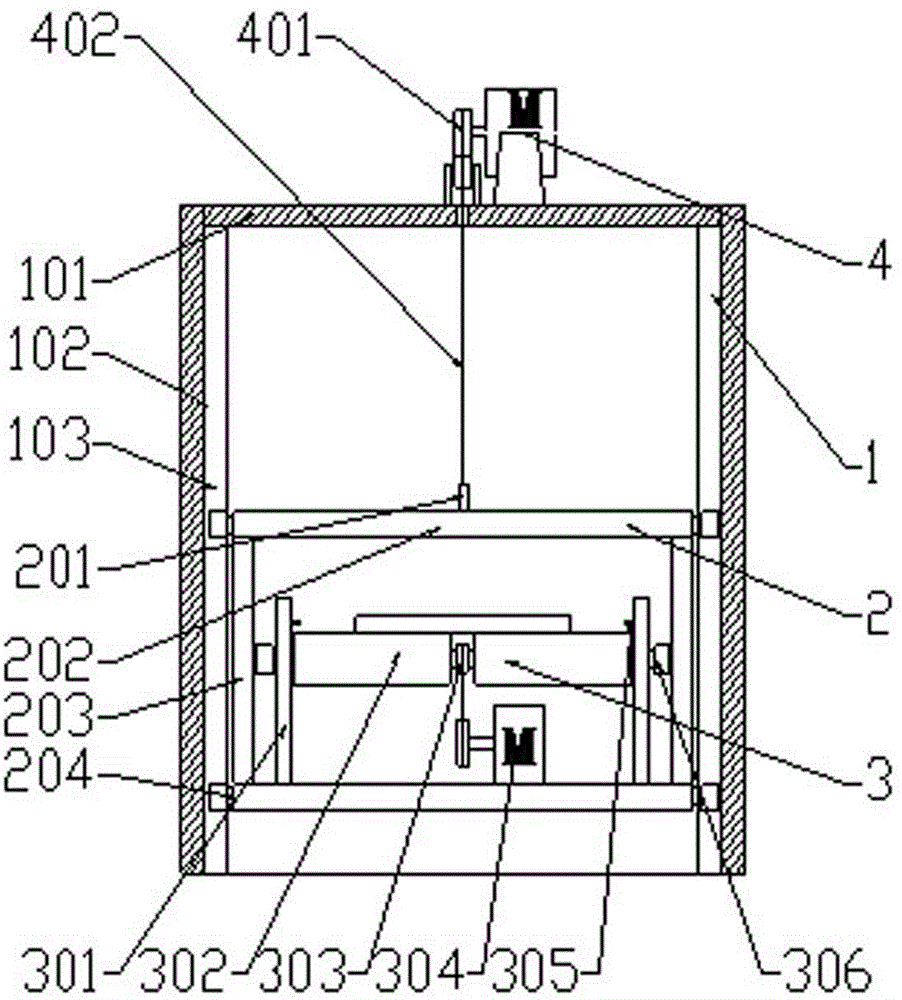

The invention discloses a double-layer roller-way kiln provided with a lifting device. The double-layer roller kiln comprises a double-layer roller-way device and the lifting device, the double-layer roller-way device comprises an upper layer kiln way and a lower layer kiln way, the upper layer kiln way is provided with a preheating chamber and a firing chamber, the lower layer kiln way is provided with a firing chamber and a cooling chamber, and the lifting device is arranged beside the firing chambers; the lifting platform comprises a fixing frame, a lifting platform, a roller platform located in the lifting platform and a lifting mechanism which drives the lifting platform to ascend and descend; the lifting platform comprises a lifting plate, a load-bearing plate and support plates which are located between the lifting plate and the load-bearing plate, and the roller platform comprises a rack, a chain wheel transmission device and roller rods; the lifting mechanism comprises a motor, a hauling cable and a balance weight. According to the double-layer roller-way kiln, the structure is simple, the operation is convenient, the manufacture and use can be conducted, the occupied area is small, and the management and maintenance are facilitated; meanwhile, the energy utilization ratio is high, the cost is saved, and the kiln is suitable for being used and popularized.

Description

technical field [0001] The invention relates to the field of equipment for silicate products, in particular to a double-layer roller kiln provided with a lifting device. Background technique [0002] Ceramic tiles are refractory metal oxides and semi-metal oxides, which are formed through the process of grinding, mixing, pressing, glazing and sintering, and are an acid and alkali resistant porcelain or stone construction or decoration material. It is always called tiles. Its raw materials are mostly mixed with clay, quartz sand, etc. [0003] The production process of tiles includes: material selection—powder preparation—compression molding—drying and printing / inkjet—firing—edging and polishing—grading, packaging and storage. Generally, roller kilns and roller kilns are used in the firing process. Also known as roller hearth kiln, it is a continuous firing kiln, a tunnel kiln that uses rotating rollers as the carrier of the green body. Ceramic products are placed on many ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F27B9/02F27B9/30F27B9/40

Inventor 王麟华赵红兵

Owner 绥阳县华夏陶瓷有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com