A kind of preparation method of graphene damping composite material

A technology of damping composite materials and composite materials, which is applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of low strength and poor mechanical properties, and achieve excellent damping characteristics and good bending resistance , good vibration damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

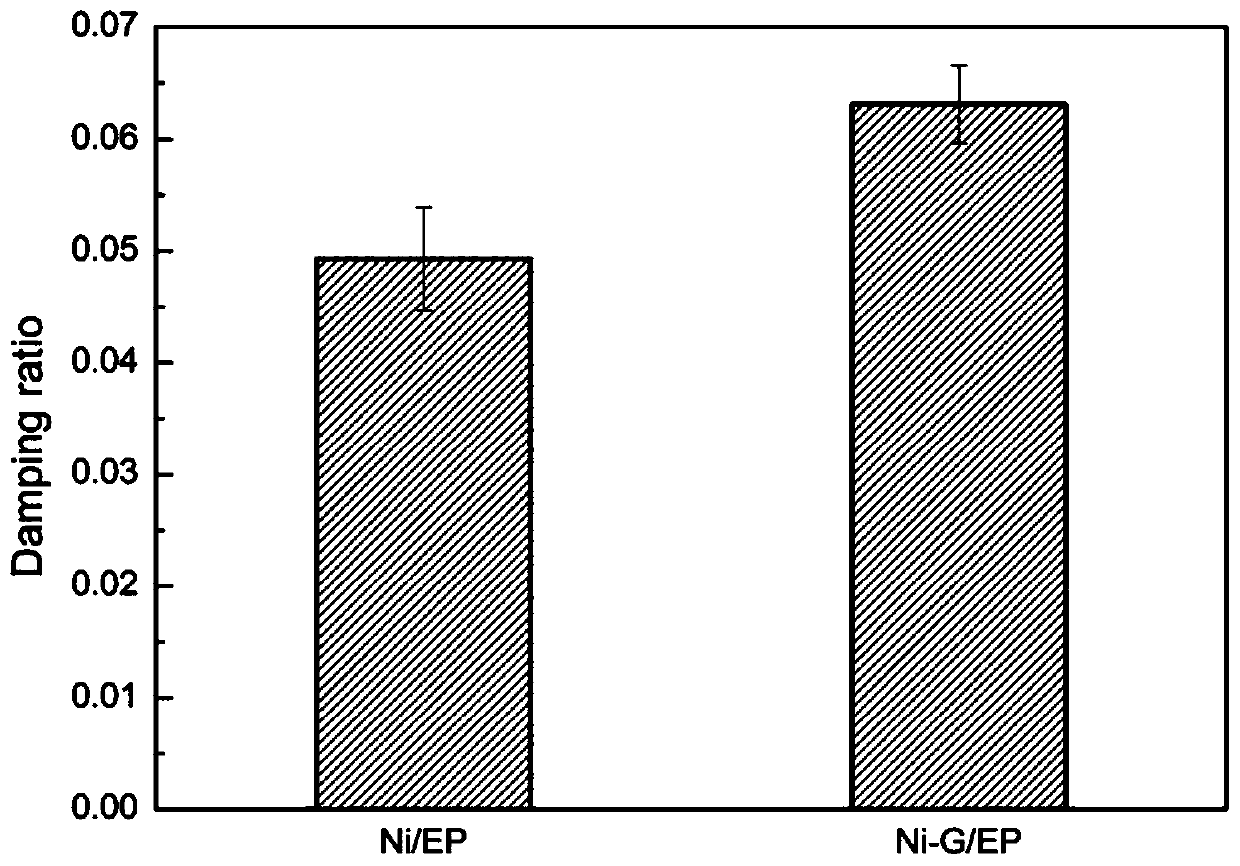

[0028] In the specific implementation process, the preparation method of the graphene damping composite material of the present invention can significantly improve the damping performance of the foam metal by coating the graphene on the foam metal skeleton, and after compounding with the resin, the mechanical properties can be significantly improved And a graphene / foam metal / polymer composite material with good damping and vibration reduction properties, specifically comprising the following steps:

[0029] (1) Obtain graphene / foam metal composite material by coating graphene on the metal foam skeleton, the preparation method can be by chemical vapor deposition method (CVD method) and the method of chemical bonding;

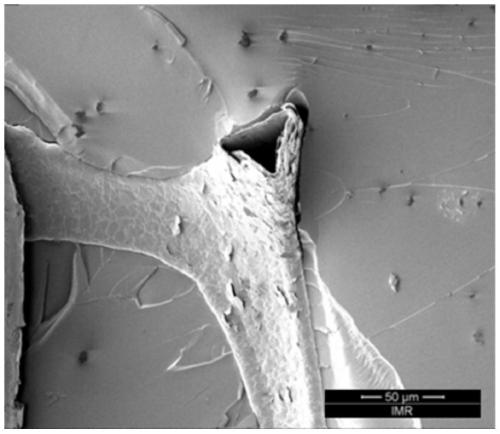

[0030] (2) preparing the graphene / foam metal / polymer composite material, the preparation method may be one of the methods of vacuum-assisted resin transfer molding, high-temperature injection molding or resin impregnation.

Embodiment 1

[0033] In this embodiment, the specific process and process parameters for the preparation of the graphene damping composite material are:

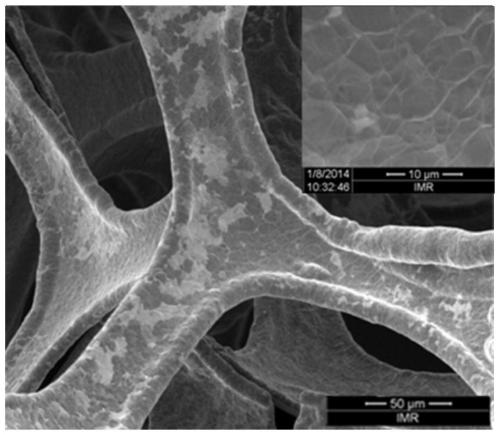

[0034] (1) CVD growth of graphene on nickel foam substrate. The surface density of foamed nickel is 380g / m 2 , with a thickness of 1.9 mm, an open-pore structure, a pore diameter of 100-400 μm, a porosity of 95%, and a graphene layer of 3-5 layers. Put the cleaned nickel foam into the center of a horizontal tube reactor (Lindberg Blue M, HTF55347C, outer diameter 75mm, inner diameter 72mm), and 2 heated to 1000°C in an atmosphere and treated for 15 minutes, H 2 The flow rate is 500 sccm. After the heat treatment is completed, CH is introduced 4 and Ar under normal pressure to start CVD growth, CH in the atmosphere 4 , Ar and H 2 The flow rates are respectively 100sccm, 200sccm and 50sccm, CH 4 The volume ratio in the total gas flow is 28%. CH 4 Close, push the sample out of the high temperature zone of the furnace for rapid cooli...

Embodiment 2

[0038] The difference from Example 1 is that in this example, the specific process and process parameters for the preparation of the graphene damping composite material are:

[0039] (1) Graphene is coated on the foamed aluminum metal, and the foamed aluminum is an open-pore structure with a porosity of 98%. The foamed aluminum is cleaned with 5 wt% acetic acid, dried, and then washed and soaked with an industrial alkali solution with a concentration of 50 mg / ml for 1 hour, washed with water repeatedly, and then dried.

[0040] (2) Carry out silanization treatment to foamed aluminum metal, use gamma-aminopropyltriethoxysilane (adopting the aqueous solution that concentration is 10wt%) silane coupling agent to soak foamed aluminum for 2 hours and take out, in the baking oven of 120 ℃ Dry for 1 hour to obtain silanized aluminum foam.

[0041] (3) Select graphene oxide as raw material, use sodium hydroxide and monochloroacetic acid to carry out carboxylation treatment on graphen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com