Concrete building bricks prepared by using waste slag of magnesium-smelting and preparation method thereof

A technology for concrete blocks and magnesium smelting waste residues, which is applied in the field of building materials, can solve the problems of increasing the manufacturing cost of concrete block bricks and the like, and achieves the effects of low manufacturing cost, simple manufacturing method and reduced emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

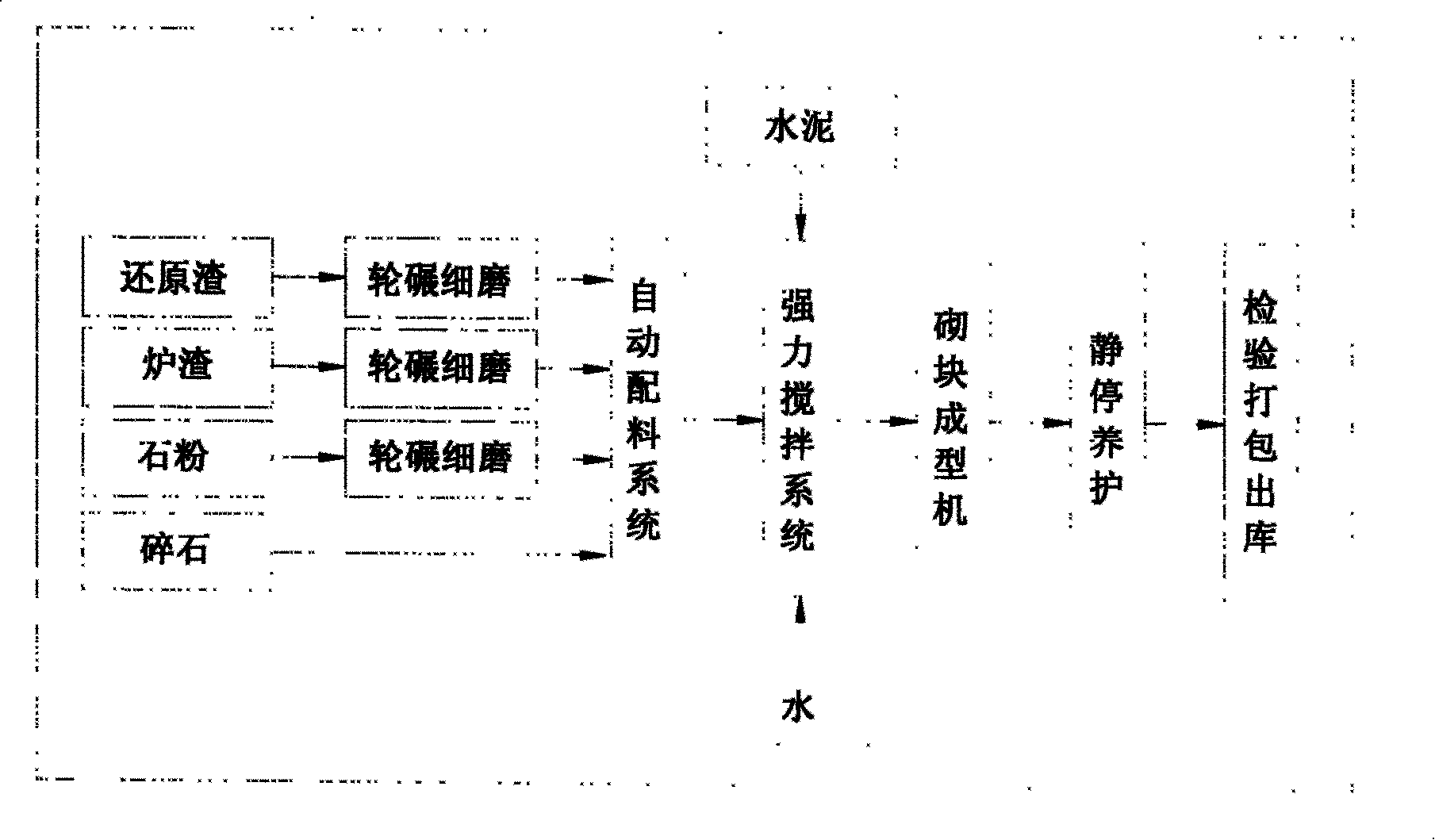

Method used

Image

Examples

Embodiment Construction

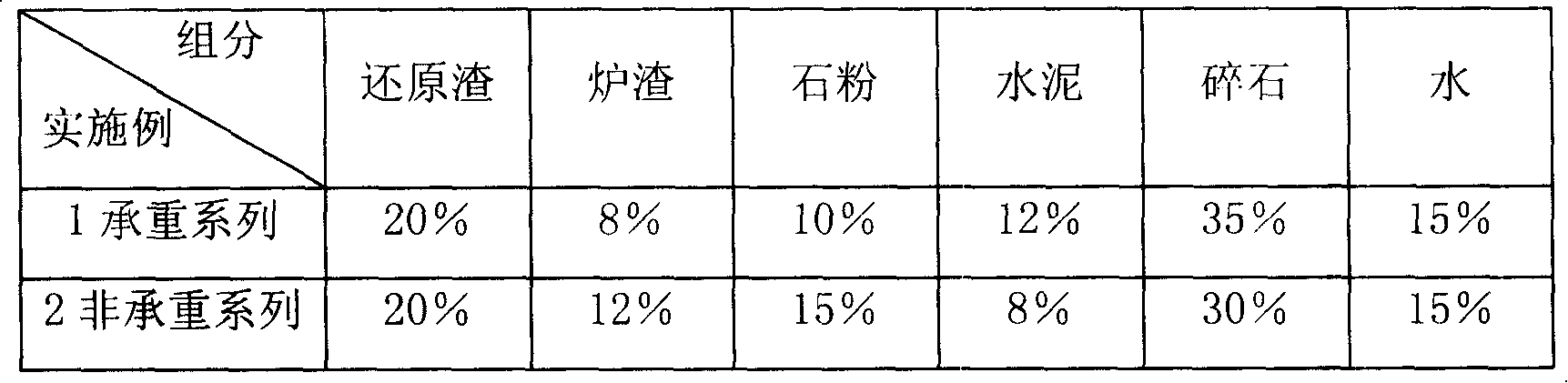

[0017] The industrial waste slag produced in the process of magnesium smelting mainly includes reducing slag, slag and stone powder, which contain relatively high silicon oxide, calcium oxide and aluminum oxide. These industrial wastes are the main raw materials for producing the concrete block bricks of the present invention. Reduction slag is the waste left after the metal magnesium is extracted in the reduction process, and it contains more calcium oxide, which combines with water to form calcium hydroxide, which is the reactant for the preparation of concrete block bricks. Slag is the ashes of raw coal combustion, which mainly plays the role of providing silica in the reaction process of preparing concrete block bricks. Stone powder is sand and stone discarded after screening dolomite. It is a kind of fine aggregate, which mainly plays the role of increasing the strength of block bricks. In addition, the present invention utilizes magnesium smelting waste slag to prepare ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com